Universal long burning unit

Water circuits can not be connected to gas generating units, they will heat the room well without them. The only condition is that you need to correctly calculate the power.

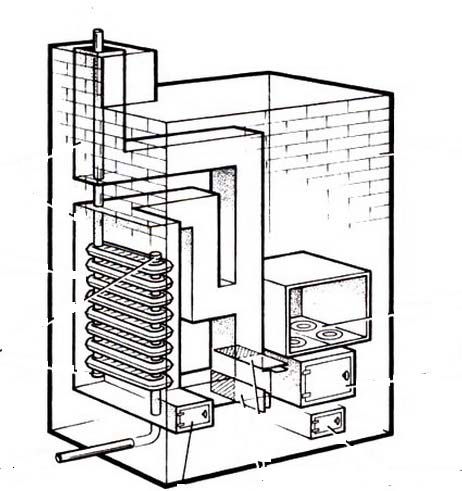

Some models are additionally equipped with a hob and oven.

Long-burning heating furnaces with a water circuit are considered the most efficient, since heat comes from two systems at once - the furnace itself and from radiators.

Connecting the water circuit to the gas generating furnace is not difficult.

It is much easier to do this than to a brick oven, which is far from always suitable for such a purpose. A heat exchanger is built above the furnace. The water in the jacket around the furnace is warmed up, then the coolant goes through pipes to the radiators. Additional space heating is obtained without increasing energy resources.

The advantages of such a system are obvious.

Device design

Having decided to equip an economy water oven with their own hands, many are faced with the problem of where to get the drawings of a device of this design. In this age of technology, obtaining such information is a mere trifle. Moreover, having understood the principle of operation of such a furnace, many try to create their own version, and sometimes such attempts lead to the appearance of very effective samples.

Details may vary, but the main components of such a device are unchanged.

Here is a list of those parts:

- Steam generator. A device that supplies water and converts it into steam. The principle of operation is well known to those who are familiar with moonshine.

- Superheater. This device is used to superheat steam above 500°C.

- Auxiliary nodes. They may be different depending on the design, but connecting hoses and tubes are indispensable elements of any such device.

- Expansion tank or other container for storing water.

- Bake. The shape and materials from which such furnaces are made are so diverse that it makes no sense to list them. In fact, any wood, peat, or coal-fired stove can be converted into a steam oven.

Operating principle

No wonder they say that everything new is a well-forgotten old. The ancient Bible echoes this proverb: “What was, is what will be; and what has been done is what will be done, and there is nothing new under the sun” (Ecclesiastes 1:9). Indeed, all physical and chemical laws were invented and put into practice long before our birth, so a person can only use them for his own purposes.

So, few people know that to enhance combustion in steam locomotives and other similar units that were actively used in past centuries, water was used as a combustion catalyst. Remembering this feature of a public liquid, some modern Kulibins came up with a simple design for a furnace, where water as a fuel helps to increase the heat transfer efficiency by tens of percent.

The fact is that when water vapor is heated to a temperature above 600 degrees, a combustible mixture of hydrogen and carbon monoxide is formed. In combination with oxygen, it burns remarkably and contributes to an even greater rise in temperature. That is why strong fires and fires with high temperatures cannot be extinguished with water or snow. On the contrary, this method contributes to an even greater flare-up.

However, if you take control of this feature of the most common liquid, you can achieve an amazing effect that improves the combustion process.

Here are the main advantages of this method:

- More complete combustion of fuel and less combustion waste.

- The absence of black smoke, respectively, less soot - a cleaner chimney.

- Higher combustion temperature, greater heat transfer.

- Excellent burning of raw firewood, no smoke at the same time.

- The combustion time for the same amount of fuel increases almost twice.

In this video, more about the stove on the water:

fireplace stove

Fireplaces have always served not only as a source of heat, but also as a favorite place for households, friends and lovers. The fire in the fireplace fascinates, soothes and sets up romance.

Modern designs are somewhat different from the old, familiar buildings. They are safer, the firebox is covered with fire-resistant glass. Through it you can watch how the firewood burns, but the sparks will not get into the room. Fireplaces are often installed in Moscow in private cottages.

In modern wood-burning stoves for steam heating, the efficiency reaches 80%. For the construction of the heating system, models with a water circuit are purchased. In this case, it will be warm not only near the fireplace, but also in all rooms of the cottage. They choose designs for power, but also for design performance. Some fireplaces have a heating surface. A kettle or coffee pot is placed on it so that drinks are always warm.

The heat exchanger is made of steel or copper. It is a serpentine; has a top exit for steam or water. The condensate line is located at the side wall. Furnaces are equipped with pyrolysis function. This increases the efficiency of the heating system.

A chimney must be provided for the fireplace. The structure is built near the wall, away from furniture and interior items. For the furnace, it is recommended to equip a platform of concrete. It is often decorated with decorative tiles. Manufacturers offer the following fireplaces with a water circuit:

- "Bavaria" - power 11 kW; the contour is made of steel; the firebox is lined with fireclay; the observation window is made of heat-resistant glass with a self-cleaning system; installation and operation is not difficult; all work can be done without the help of a specialist;

- "Pechora Aqua" - 13 kW; requires a heating system with forced circulation;

- "Angara Aqua" - 16 kW; viewing window panoramic; the heat exchanger is made of steel; there is a heating surface.

A stove with a water circuit for heating a house, how to choose and install it correctly

There are many ways to heat, but a water circuit stove for home heating is a frequent choice of the consumer. This method of heating combines the advantages of stove and water heating.

The mechanism heats the coolant, the water circuit itself, the smoke channels of the furnace and the walls. When using a simple stove, heat is distributed unevenly: the water circuit allows you to distribute heat throughout the house.

The decisive distinguishing feature of this heating system is the presence of a heat exchanger, or “coil”.

It is placed in the firebox, and all elements of water heating are connected to it. The heat exchanger has two branch pipes: the upper one, connected to the supply circuit, and the lower one, leading to the return circuit of the furnace heating.

How to convert a furnace into a boiler

Almost nothing. Such a heat generating unit will have to be built from scratch. After all, the integration of the heat exchanger into the furnace will end with a violation of air circulation in the chimney.

Simply put: you will lose draft and, as a result, you will begin to receive a stable "dose" of smoke and soot into the room during each kindling.

How to make a furnace-boiler?

Very simple - for this you need to lay out the first layers of brick, rising above the level of the blower, and lay the previously prepared heat exchanger on the support. After that, you just have to overlay the water jacket with bricks, forming a firebox, and go to the chimney zone. Borovok and the chimney are built according to the "classic" scheme.

Where can I get a heat exchanger?

A shirt for a boiler-furnace can be purchased from specialized companies that "rivet" such metal structures in small batches.In this case, a specific type of heat exchanger is chosen according to the displacement or the area of the outer surface of the metal structure. After all, the thermal power of the future "boiler" depends precisely on these parameters.

Jacket for boiler-furnace

In addition, you can “assemble” a water jacket for a furnace with your own hands using drawings downloaded from the network and a welding machine. The thermal power in this case can be "peeped" in the specification or comments on the drawings.

Choosing the Right Radiators

Heating radiators are important design elements of a water heating system. They differ in material, size, heat output, design. The main types of water heating radiators: sectional and panel designs. The material used is cast iron, steel, aluminum. Modern water heating radiators are bimetallic.

The most reliable are cast-iron sectional batteries, recruited from separate sections with a capacity of 1.4-1.6 liters. Standard batteries of this type are designed for a pressure of 6-9 atm at a coolant temperature of up to 140ºС. The system is tested at a pressure of about 15 atm. The main advantage of cast iron elements is thermal inertia, which allows the stored heat to be released into the surrounding air for a sufficiently long time. Modern sectional batteries are made of aluminum, which has an elegant appearance, quickly warms up, but also cools down quickly, which requires a constant supply of coolant.

Panel radiators are usually made of steel. They are made of stamped steel sheets that form vertical and horizontal channels for the coolant. For better heat transfer, ribs will be made on the batteries. Such radiators can be one-, two- or three-row. Recently, bimetallic radiators have gained popularity.

A stove with water heating and a wood-burning firebox does not lose its popularity today. In country houses, cottages, garages or outbuildings, wood-fired water heating reliably and effectively performs its task of providing warmth and comfort.

What materials and how to make ventilation in the cellar?

Hood: installation in the garage

If you do it all on your own

Furnace steam heating can be done by hand. Some knowledge and, most importantly, a tool are necessary, but acquiring them is not a big problem:

- The stove should be located in a place where it will not interfere with residents. And it's not that she will require free space for herself. Throwing firewood or filling coal - sometimes the smoke breaks out and then the risk of absorbing the “smoky aroma” is very high.

- If you have to choose between a steel pipe and a plastic one, then it is better to stop at the first option. A metal pipeline for stove heating is the most acceptable, since the economy in this case cannot be compared if gas or liquid fuel were used. Therefore, it is possible to increase the diameter of the pipeline, thereby increasing the volume of the coolant. But only the area of \u200b\u200bthe metal from which heat will emanate will also increase. So it makes sense to think about it.

-

The furnace is made of metal or refractory bricks. Both options have proven successful. But there are differences and for some they can be fundamental. For example, a metal stove cools down much faster after the last batch of firewood or coal has burned out. Brick retains heat for much longer: even if the oven goes out in the evening, in the morning you will feel a temperature of about 30-40 degrees on the surface of the brick. For steam heating, this will not play a special role, but if the stove heats a separate room, then it is better to look towards the brick.

- Installing a circulation pump will help solve two problems at once.Firstly, when designing steam heating, the layout of radiators, their height, the slope of the supply and return pipes - all this becomes secondary and such that it has no fundamental influence. Secondly, the pump will allow the coolant to be transferred faster, which means that the time it takes to fully heat it up is saved.

- Do not neglect the expansion tank - it is necessary for the integrity of the entire steam system, including the house. Heating with wood can be more efficient than other types of fuel. The coolant increases in volume and the "excess" needs to be redirected somewhere. Such a place will be an expansion tank, which in a private house can easily be placed in the attic. Only in this case it needs to be insulated.

- Firewood is the cheapest type of fuel. But for greater efficiency of steam heating, it is better to use solid rocks. In this case, the firewood will burn for a long time, and with the mentioned feature - the lack of automation - it will be very useful for residents. Acacia belongs to such breeds, which are also very easy to get. It is not only a hard rock, but also one that can burn almost immediately after cutting. The lack of an abundance of juice in this type of wood leads to the fact that it is not necessary to look for dry acacia.

Steam heating through a stove is a cheap option, albeit with specific features. However, this option has been tested by time and proved to be extremely successful. So it's not worth throwing it away.

How is the distribution of steam heating from the furnace

In this case, most experts recommend a single-circuit wiring option.

Such a scheme of steam heating from the furnace is equipped as follows:

- A vertical branch of the pipeline rises from the pressure pipe of the heat exchanger, turning into a horizontal one at the very ceiling.

- At the junction of the vertical and horizontal branches of the pressure pipe, a tee cuts in, which is used to connect an open expansion tank. This drive is located behind the ceiling - in the attic.

- The horizontal branch of the pressure pipe stretches to the first battery, at a slope of 2 centimeters per 1 meter of pipeline. Moreover, above the radiator, the horizontal again turns into a vertical, which ends at the upper battery fitting.

- From the upper fitting of the first battery to the corresponding "connector" of the next radiator, a connecting pipe is thrown, the diameter of which matches the dimensions of the pressure branch of the wiring.

- The lower "connectors" of the first and second radiators are "connected" with the same pipe. At the same time, a plug is screwed into the free branch pipe (under the pressure pipe inlet).

- The second battery is connected to the third according to the same principle, stretching a double line from radiator to radiator to the extreme position.

- The last (before the furnace) radiator "accepts" the upper and lower pipes from the penultimate one from one edge. On the other hand, a tube is screwed into the lower branch pipe of the last battery, connecting it to the return pipe of the heat exchanger in the furnace. A Mayevsky tap is screwed into the free upper pipe of the extreme battery - with its help, air is bled from the wiring.

- Pressure equipment is mounted between the furnace and the extreme battery - in the return line of the wiring, using a standard bypass for pumps.

The wiring arranged in this way supports both forced and natural circulation of the coolant. Simply put: your stove will heat your house with radiators even if there is no electricity in the outlet. That is, by acting in this way, you will achieve complete energy autonomy of the home heating system.

https://youtube.com/watch?v=fm_dud7HRyQ

We also recommend seeing:

- Glass doors for stoves and fireplaces

- Fireproof Heat Resistant Glass for Fireplace

- What is the optimal pressure in the heating system of a multi-storey building?

- Stainless steel chimney pipe insulation

Do-it-yourself steam heating in a private house from a wood-burning stove

When starting the installation of steam heating, it is important to consider the size of the house and the heating scheme. So if a 2-circuit heating system is used with the ability to receive hot water for household needs, then it is better to purchase a more powerful boiler

During the operation of the entire system, a sufficiently large amount of heat is produced by the furnace. This does not allow the use of synthetic pipes that are not designed to work at high temperatures. Masters recommend using the following types of pipes for installation:

- Steel.

- Copper.

- Stainless.

The installation of steel pipes is traditional for our country, but their installation is associated with difficulties. For installation, you can not do without welding equipment and most often you will need to hire a good craftsman so that the installation of the system is done correctly and the owners are not threatened with leakage. Steel pipes have high strength under mechanical stress, but their disadvantage is that they are susceptible to corrosion.

Copper pipes are characterized by high cost and complexity of installation, which uses soldering joints. The advantage of copper is that it quickly gives off heat, as it has a high thermal conductivity and the room heats up much faster. Copper pipes easily tolerate exposure to high temperatures, are not subject to corrosion.

Galvanized and stainless pipes are strong enough, they are not destroyed by rust, they give off heat well in the room. Installation of a system of galvanized pipes is simple, since docking is carried out using a thread. Such pipes are guaranteed to last for decades, but are more expensive than steel pipes.

Steam heating in a private house: installation work, scheme

First of all, it is necessary to make calculations, purchase all the necessary materials and equipment, draw up a project. If the owner of a private house is engaged in such work for the first time, you should seek the help of a professional. When everything is ready, proceed to the installation according to the planned scheme.

Installation of a single-pipe steam heating system is simple, but has significant drawbacks. The system consists of series-connected radiators. The disadvantage of the single-pipe version is that a high temperature is maintained in the radiators, to which the coolant is delivered in the first place. However, the cooled coolant is delivered to the far points of the house and the efficiency of heating the room is significantly reduced.

The two-pipe option implies a parallel installation of the supply pipe and the return pipe, through which the coolant enters the central line, and then into the wood-burning stove. The advantage of this system is that all radiators simultaneously receive a coolant of the same high temperature, and the whole house, even distant points, warms up well.

A 2-pipe heating system is more complex, but much more reliable, more functional and more efficient. Owners have the opportunity, with the help of separately installed valves, to regulate the supply of hot water to each radiator. This allows you to save. If the room is not used for a long time, it can be set to a slightly lower temperature than the room where people live. Thanks to this adjustment, heat is used rationally.

Steam heating in a private house from a wood-burning stove, video

Steam heating in a private house from a wood-burning stove is a hot topic for owners of mansions, and especially with the advent of cold weather. They strive not only to save money, but to enjoy the warmth in the cold winters.We recommend that you look at the photos, study the diagrams, and choose the appropriate heating options in the house directly from the stove.