Lift

Modern lifts by type are divided into:

- Foot. They are capable of lifting heavy loads weighing up to 2 tons to a height of 8 meters.

- Telescopic. Their advantages include: low weight and compactness. These devices are capable of lifting loads to a working height of up to 150 kg.

They, in turn, are divided into:

- self-propelled;

- non-self-propelled.

When choosing a lift, it is worth considering several factors: their dimensions, load capacity, scope.

To make a lift on your own, prepare the materials and a preliminary drawing. For its construction we need:

- winch, which can be made from a drum and a cable;

- pipes;

- electric drive.

The advantages of construction hoists include:

- maneuverability;

- high load capacity;

- safety;

- convenience in operation.

Best Answers

Kainov Evgeny:

It has a self-elevation mechanism. Parts of the crane are only substituted, and it pushes itself up.

I am:

I can tell you a joke that happened in Ukraine, in which city I don’t know exactly. In general, they installed a crane and began building a house, what does the house have to be, how to say .... well, along the perimeter, and in the center it turns out such a closed children's playground, which can only be accessed directly from the house or from a helicopter))). So, what did these Ukrainians stir up. They built a house to build, but this same crane was just placed in the middle of this house.

PS: I don’t know what they, fools, did next, but I would like to.

mouse Tanya:

Come, we are building a new microdistrict, you can take a look...although lately I'm more interested in why they fall on neighboring houses

BorodaQ:

The crane is located in accordance with the established plan, which determines the areas of the crane. First, the site is leveled, the rails are installed with the help of a truck crane, the construction crane is delivered to the site using an autotractor on pneumatic wheels. The first (lowest) section is somewhat wider than all the others. With the help of its own winch, the second section inside the first rises almost to the top of the last and is fixed there. The third section is placed in the resulting free space and fastened with bolts to the bottom of the second and rises to its place. In this sequence, the entire crane is assembled. I was struck by the pitching during the operation of the crane. It was necessary to install an additional floodlight during the installation of formwork weighing more than 10 tons, the amplitude of oscillations exceeded 1 meter. Although from the outside it is almost imperceptible.

Viktor Biturin:

I can say that the length of the crane boom is chosen depending on the load capacity! The greater the load capacity, the smaller the boom reach!

Andrey Lozovoy:

Expert answers

N@desh@:

Vitaly:

Vertical

Ivanov Ivan:

A tower crane, even disassembled into parts - oversized cargo, is transported with flashing lights and cops escorting, slowing down the general movement ...

AIDS:

Dismantled and transported.

M.G.T.:

Dismantled and transported piece by piece

Bell A Morr:

the little ones go. large ones are partially dismantled and transported. huge ones are disassembled into parts and also transported. it's troublesome.

Iron Balls:

They are not transported in their entirety, they are disassembled and assembled at construction sites, but the machine is disassembled and assembled by a crane) then, as usual, they were taken to a truck. And some are taken directly to the metal collection point)))

User deleted:

disassemble the arrow, drive it onto the conveyor and forward

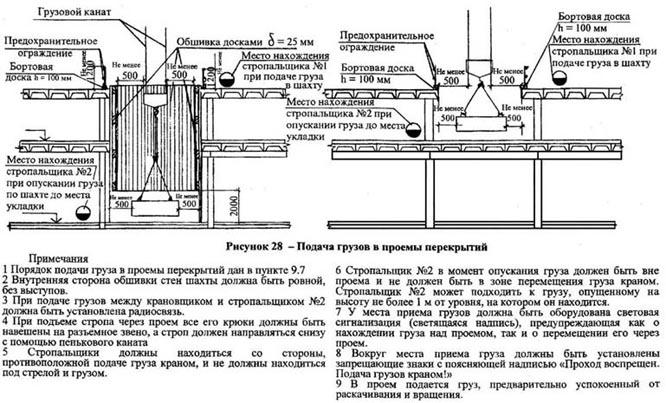

4. Construction and installation works Supply of goods to the openings of floors.

Directions.

Submission

cargo into openings (hatches) of floors and

coatings should be made according to

specially designed project. At

supply of cargo to the openings (hatches) of floors

and covers, it is necessary to lower the load and

raise the hook with slings at a minimum

speed without swinging.

Distance

between the edge of the opening (hatch) and the load (or

hook block if it is lowered

in the opening (hatch)) should provide

free movement of cargo (or hook

clips) through the opening and should not be

less

0.5 m

In exceptional

cases, it is allowed to reduce this

escort distance

through the opening (hatch) with the help of a guy line.

let down

to the opening (hatch) the load must be calmed

from rocking and only after that

lowered into the opening. When lifting the sling through

opening (hatch) all hooks must be hung

on the detachable link, and the sling should

be guided from below with a hemp

rope; hemp rope is unhooked from

sling after sling will

removed from the opening (hatch). Slinger

can approach the load (move away from the load),

when the load is lowered (raised) on

height no more

1 m from the level

surface (platform) where

slinger.

At

places of acceptance (or dispatch) of submitted

(or removed) through the opening (hatch) of goods,

as well as at the opening in the floor (covering)

should be equipped with lighting

alarm (luminous inscriptions),

warning about the presence of the cargo

above the opening (hatch), and about lowering

it through the opening (hatch), as well as inscriptions and

signs prohibiting the presence of people

under the transported load.

Light signaling

must be positioned so that

could be damaged by moving

load or lifting equipment.

Between the crane operator

and a slinger outside

visibility of the crane operator should be

radio connection established.

opening

(hatch) through which the supply is made

cargo, must be permanently guarded

height (distance from the level of the working

places to the lowest point

top

horizontal element) not less than

1200 mm with

with a solid board on the bottom on

height not less than

100 mm.

The fence must meet the requirements

GOST 12.4.059-89.

At

supply of cargo to the openings (hatches) through

inter-farm space or through

several overlaps when positioned

openings (hatches) directly to each other

above the other, a shaft with smooth

walls or lowering the load must

be made with the obligatory

escort. Examples of cargo delivery

through openings (hatches) are presented on

figure

28.