Rehau pipe features

The manufacture of pipes using a new technology determines the fundamental features of products, which are in the following aspects:

- increased sound insulation. Cross-linked polyethylene is able to absorb the sounds produced by the flow of water;

- installation of Rehau pipes is made by a unique method that allows you to create the most durable connection;

- the material from which the pipes are made is universal. It is possible to create systems of hot and cold water supply, heating from pipes, to apply for arranging a warm floor. The maximum liquid temperature in the pipe is 95ºС;

- pipes are practically not subject to the formation of cracks and deformation during mechanical damage, so they can be laid under plaster or covered with other structures;

- high degree of thermal insulation, which helps to save natural resources;

- any pipe is able to withstand fluctuations in the temperature regime of the liquid and internal pressure;

- complete safety for humans. The company's products are certified;

- a special coating of the inner walls of the pipes prevents the formation of plaque and a reduction in throughput.

Materials that give Rehau pipes their unique qualities

Pipelines of any complexity and purpose can be constructed from Rehau pipes and various fittings.

The only drawback of Rehau pipes is the high cost of products and fittings.

Pipe installation

To install Rehau pipes with your own hands, you need:

- purchase the necessary tool;

- read the assembly instructions for the pipeline in advance.

Tool required mounting

Before proceeding with the installation of pipes, it is necessary:

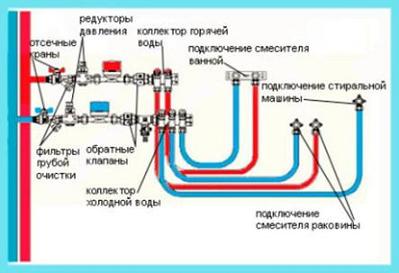

- purchase the required number of pipes, connecting fittings and adapters. To calculate the necessary materials, a water supply scheme is drawn up;

Approximate layout of pipes for hot and cold water in a city apartment

- prepare a tool for installing Rehau pipes:

Expander for pipe installation

press clamp with additional nozzles of different diameters. Since the installation of the type of pipes in question is somewhat different from conventional welding, the procedure requires such a specific tool for installing Rehau pipes;

Hand press used to connect pipes, REHAU RAUTOOL

pipe cutting tool. Standard pipe cutter, used for all types of plastic pipes;

Tool for cutting plastic pipes

tape measure, marker for marking pipes.

Standard measuring tool used in construction

All tools can be purchased individually or as a set. The average cost of a set is 2,500 rubles.

Pipeline assembly process

The installation of Rehau XLPE pipes begins with the preparation of the pipes. Preparation consists of two steps:

- according to the previously prepared drawing, pipes of various sizes are cut;

The process of cutting the pipe to the desired size

- the fittings necessary for the assembly of a specific section of the pipeline are being prepared.

If heating is being installed with Rehau pipes, then it is more expedient to immediately prepare all sections of the system, and then first check the correctness of the segments according to the scheme.

To check, all pipes and fittings are placed on the floor in a certain order. This is especially true for heating in city apartments, since it is necessary to turn off the heating throughout the house.

When cutting pipes, one should be guided by an old Russian proverb - "measure seven times, cut once." Mistakes in cutting pipes can make it impossible to install the piping system in the room.

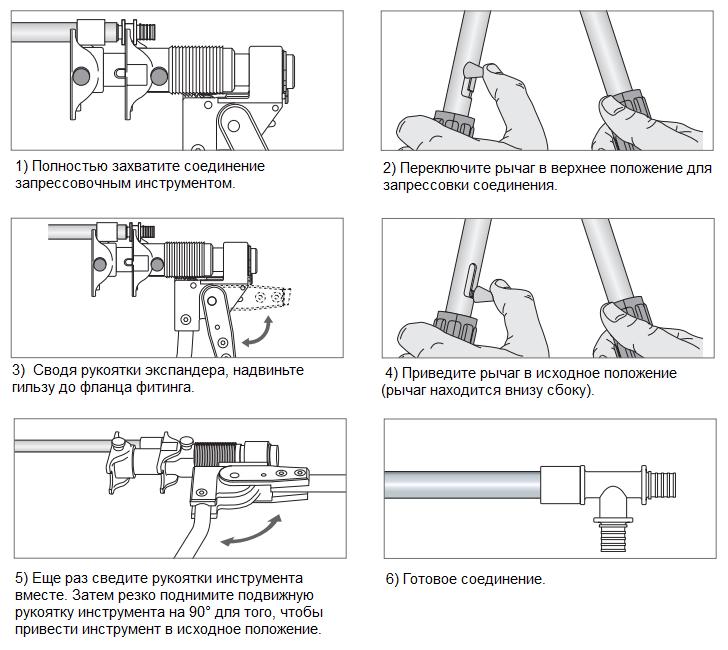

Docking of pipes and fittings with each other is carried out using sleeves, which are fixed as follows:

- a nozzle is selected on the expander, the diameter of which fully corresponds to the diameter of the pipe used. In this case, the handle of the tool must be completely divorced (the ends of the handle are at right angles to each other);

- the nozzle on the expander should hold firmly and sit on the pin until it stops;

- a sleeve is put on the pipe section that needs to be connected to the fitting. The diameter of the sleeve used must also match the diameter of the pipe;

Each sleeve has a chamfer. When installing, it should be directed towards the future connecting seam.

- a pipe is put on the other end of the nozzle installed on the expander. When reducing the handle of the expander, the pipe expands;

The process of expanding the pipe for further installation

- the expanded end of the pipe is connected to the fitting that must be installed in this place;

Inserting a fitting into a prepared pipe end

- a previously installed sleeve is brought to the fitting;

- using a press clamp, the sleeve is pushed into the fitting as far as it will go. A strong and reliable connection is ready.

Fixing the fitting with a press clamp

When arranging the connection of pipes and fittings, even the slightest distortions should not be allowed. All connecting parts must be located strictly horizontally to each other. Otherwise, the connection will be unreliable.

Step-by-step diagram of working with a press clamp

Installation of Rehau pipes for heating, gas or water supply must be carried out in compliance with all safety standards. First of all, you need to take care of protecting your eyes (using a mask) and hands, which are not recommended to be inserted into moving elements.

The Rehau pipe installation video below will allow you to observe the process from the side in order to more accurately find out all the most important aspects.

Everyone can install pipes from the German manufacturer Rehau. The main thing is to have the necessary tool and clearly follow the above instructions.

Preparation for installation work

The outlets of the collector should be the first elements that require increased attention. Only their correct processing will ensure complete tightness in the system.

Before installation, the workplace must be completely free of dust and debris, as well as the equipment. Welding, threading and gluing are the methods that are most widely used during installation. It is only necessary to purchase the appropriate type of fitting, depending on the method of installation work you have chosen.

Watch video: Beer Pex systems

Absolutely all parts that are used during installation must be solid and clean. A visual inspection is required before purchase. This will ensure the quality of the finished product. Their transportation deserves special attention.

What is the danger of unprofessional installation

Installation of Rehau pipes in an apartment, which was made by non-specialists and without the use of professional equipment, can lead to the most disastrous consequences. In the event of a pipe rupture, the residential premises and all areas adjacent to it are flooded.

If the gust passed on the heating system, then in winter you are threatened with a complete defrosting of the system and the difficulty of restoring it. If you order the Rehau pipeline installation service from the Plumber Service company, then you will not encounter any of the unpleasant consequences.

The work performed by professionals has several distinctive characteristics:

- the pipeline laying scheme is the most optimal, does not interfere with other systems and the conduct of normal life processes for the owners of the dwelling;

- each piping connection is of high quality and has even seams;

- for installation, the correct type of pipes is selected, which is compatible in terms of parameters with the installed system;

What are the main advantages and features

- The presence of reverse shrinkage.Products are able to resist high pressures, and after prolonged exposure, they return to their original shape. Other materials with similar parameters simply stretch after a while and become unusable completely.

- Increased heat resistance. Such pipes normally work at temperatures up to 120 degrees.

- Availability of prices.

- The ability to resist freezing.

- Tolerates high temperatures and pressures.

- Convenient installation.

- Light weight.

- A high rate of sound insulation for Bir Pex, Rehau and other companies. Thanks to this, the room itself is protected from extraneous sounds. Pressure surges are completely absorbed by the system itself.

- Long service life combined with high strength. You can forget about rotting and corrosion when working with this material.

- Environmental friendliness. Polyethylene does not emit harmful substances, even when it is strongly heated.

- Elasticity.

Mounting process

The installation technology includes several steps.

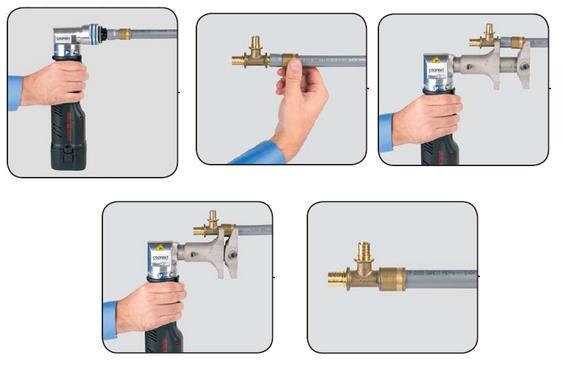

- We wind the nozzle with the required diameter onto the expander.

- After that, we put compression rings on the pipes themselves with our own hands. And we do it so that the pipe expansion site is not occupied.

- An expander must be inserted into the pipe. It expands when the installer presses the special handle. The next step is to turn the pipe itself, or the expander, by 30 degrees. And then press the handle again. You can repeat the operation to fix the result. After that, they proceed to the use of the fitting.

- The shutter is retracted from the press with your own hands. Next, pull out the pins used for fastening. The next step is to thread the nozzles fixed with pins. The shutter is latched.

- The connection is ready. The product must be pulled out of the press.

Installation of a XLPE pipe

materials

Before starting work, prepare the necessary tools and consumables. You will need:

- Vice.

- Fittings: couplings, adapters, elbows, tees, retractable sleeves (when installing a retractable sleeve, it is not necessary to use rubber gaskets, which increases the reliability of the structure).

- expansion device.

- Roulette.

- Pipe cutting tool.

Rehau pipe - construction

Pipe connection

Direct installation is performed as follows:

- First of all, measure the required length of the pipe and cut off the excess.

- Then put a special sleeve on the place of the cut.

- Next, you need to expand the inlet with an expander. It must be inserted into the hole as tightly as possible and connected until the handle stops for a while (it will take only a few seconds).

- Install the fitting on the structure.

- Finally, press with a vise.

- In order for the pipe to have the required stiffness and shape, fix it with guides.

You can install pipes using compression fittings. Using a wrench, screw the compression nut onto the end of the pipe, then place the split ring at a distance of 1 mm from the pipe cut and complete the installation by screwing onto the fitting nipple.

Installation of cross-linked polyethylene pipes

All components (fittings) and working equipment must be of the same brand as the polyethylene cross-linked pipe itself. Only in this case, the manufacturer guarantees the reliability and quality of the material.

Polyethylene pipes receive the highest reviews. The owners of communication systems in which this material is used speak of its reliability and long service life. “Installed and forgotten” - this is how experts and ordinary users speak about polyethylene pipes. The main thing is to perform the installation correctly and then your system will really work “like clockwork” for many years.