How to install

Most pumps are quite noisy, so it is advisable to install stations in non-residential premises with good sound insulation. If we are talking about the supply of water to seasonal residences, then equipment can be placed near the well, only providing protection from precipitation and the sun (usually they make a small pit, which is covered with a lid). If water is needed for the house or for the bath, which they are going to come to in the winter, you will have to take care of a separate room (or an insulated pit, but such that the pump does not freeze).

If the pump will be used both in winter and summer, he needs a house in which he will not freeze

When choosing a model of a pumping station for your home, pay attention to the metal from which the pump housing is made. Steel is usually very noisy, but cast-iron cases dampen almost all sounds.

They deliver less hassle, although they cost more. But the best option is a stainless steel case. With him, the least hassle, although he is more noisy than cast iron.

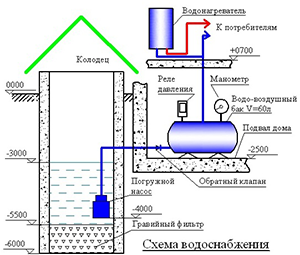

The whole system is assembled as follows: a pipe is lowered into a well or well. Water is supplied to the inlet of the pumping station, from there it enters the membrane tank, and then it is already diluted around the house and the site.

What is a pumping station

There are different options for providing a private house with water. They depend on the source of water, depth and productivity, level in the well. Pumping stations are similar in design, differing in the method of water intake and performance. The established National Assembly includes:

- Self-priming pump.

- Hydraulic accumulator with a volume of 10-50 liters.

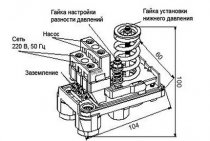

- Pressure switch.

- An anti-vibration hose connects the pump to the accumulator.

- The manometer determines the water pressure in the HC.

The pumping station can be equipped to your taste by choosing a large hydraulic accumulator and a pump that is optimal in terms of power. But a ready-made NS, assembled from factory-fitted components, has its advantages ..

How does it work

The equipment consists of a pump (type - any suitable for your conditions), a tank for storing water supply and control sensors. The comfort level of the system is largely determined by the type of tank used. It happens:

- with storage tanks;

- with hydraulic accumulators.

A storage tank is a conventional container in which the water level is controlled by a float. The level rises, the pump turns off, it goes down - it turns on. But such a system provides very low pressure. It depends on the height difference that you managed to provide. Due to the low pressure, heaters and other household appliances cannot be used. Although, if you install it high enough, you can create a height difference sufficient to take a shower. The second unpleasant detail of using such a tank is that if the float mechanism malfunctions, there is a real threat to flood the house. This problem is solved - a discharge pipe is installed, but the system is still not reliable enough.

Diaphragm tank for a pumping station in section

More modern modifications of pumping stations use hydraulic accumulators. They allow you to create and maintain stable pressure. Such a system also allows you to turn on the swap less often, which prolongs the life of the equipment.

Hydraulic accumulators in pumping stations are membrane-type tanks. In it, the container is divided into two sectors by an elastic membrane. One part contains gas (initially it is under some kind of pressure), water is pumped into the second. There is also a pressure sensor. It sets the upper and lower pressure limits.

When water is pumped in, the membrane in the tank expands, compressing the gas and creating even more pressure.When the upper threshold set on the sensor is reached, the pump is switched off. At the same time, a certain pressure is also created in the water tank. If a tap is open somewhere, water is supplied with good pressure to the distribution point. The volume of water decreases, the pressure on the membrane decreases. When the lower threshold value is reached, the relay is activated, the pump is turned on, increasing it again.

This system allows you to maintain a stable pressure, no matter how many taps are open. Therefore, when installing equipment with a membrane water tank, you can use any type of water heater, as well as automatic washing machines and other household appliances that require water pressure.

Kinds

To fit the HC, you first need to take into account the capabilities of the well and take the model just below this limit. But if the limit is less than 1.7 cu. m / h, then you will have to forget about the National Assembly: the motor will not provide constant pressure and interruptions in water are inevitable.

Household pumps have a capacity of 1.5 to 9 cubic meters. m / h, is determined by the number of water points (kitchen, toilet, bathroom, washing machine or dishwasher).

Water consumption at the point: 0.35 cubic meters m/h X 5 \u003d 1.75 cu. m/h In this case, you can limit yourself to NS with a capacity of 2 cubic meters. m / h (the stock does not hurt).

The capacity of the tank also depends on the points of consumption.

The average capacity of the tap is 12 liters, therefore, in our case, a tank of 60 liters is suitable. The instructions usually indicate the maximum that this model can provide.

Well data is obtained using any motor to measure the volume of fluid pumped out. The level of the mirror will be prompted by a nut on a thread lowered into the well.

There are three types of pumps on the domestic market:

- The station with a centrifugal self-priming pump and a built-in ejector with a water pressure of up to 40 m and a suction depth of up to 9 m is the most popular. But its main advantage is its low susceptibility to air. To start the NS, open the lid and fill it with water to the brim. After pumping air, the motor will give water. Excess air escapes through a faucet or valve.

- Centrifugal self-priming pumps with an external ejector are suitable for wells with a depth of up to 45 m. They are mounted in a boiler room or other utility room. An ejector with two pipes is placed in a well. One supplies water to the ejector for suction, the second for lifting.

This type of HC is very sensitive to air and pollution, but allows it to be used in the house by lowering the ejector into the well at a distance of up to 40 m.

- Submersible pumps operate in areas with groundwater levels up to 10 m. They are lowered to the water level, pumped up and lifted up. The suction height is 8m, and they can push out to a greater height.

So, we determined the amount of water for a comfortable stay. We calculated the capacity of the pumping station and chose the type and location. Left to buy:

- Pump;

- Hydraulic accumulator;

- Pipes for external water supply (preferably polymeric);

- Automatic protection system;

- Faucets;

- Valves;

- gate valves;

- Cranes;

- Flexible hoses;

- Compression and press fittings

If there is no well on the site yet, it can be made by installing reinforcement around the rings, scalding it. This will save you from floaters and shifting rings.

The sooner you plan the water supply at home, the better the result will be. Ideally, the station operates autonomously. Every year we check the air pressure in the accumulator using a pressure gauge - that's all prevention. I really wish you were like that.

Installation instructions and connection diagram

Location rules:

- Warm place of installation.

- NS is always available for prevention and repair.

- For reliable suction of water, it is better to place it closer to the well.

- In order to reduce losses from resistance in the pipeline, place the NS closer to the distribution manifold.

- The sound of the operating NS should not be heard in living quarters.

If you use a cottage in the summer, any place will do. The only condition is the proximity of the well.

At the end of the summer season, all water must be drained: pipes may burst in winter.

Water supply on an ongoing basis from the well is carried out according to this scheme. In the utility room with a winter temperature of at least 2 degrees, a pumping station is placed.

The well is located at a decent distance from the house, so the HC type with a remote ejector is suitable. Pipes from freezing are saved by laying at a depth of 1.8 m. We put a strainer on the suction pipe and lower it to the level of the mirror.

We put another coarse filter and a check valve in front of the motor. After NS - the third filter, fine cleaning. Next - successively a pressure gauge, relay and other equipment. We connect the NS to the shield.

The power of a household pumping station is 500-1500 W, which provides water intake from 7 m depth and supply of 1-3 cubic meters. m / hour to a height of up to 30 m.

The motor must correspond to the water consumption - approximately 100 liters per day per person. It must provide at least 6 cubic meters of water per hour.

Principle of operation

The pump fills the tank with water, creating pressure in the system. A rubber membrane in the form of a pear separates the accumulator for water and air. Through the tap, water from the tank enters the sink, reducing the pressure in the water supply and tank.

When the pressure drops to 2.2 bar, the relay turns on the motor. When the initial level (3 bar) is reached, the relay starts, turning off the pumping station.

Cooling - due to the circulation of water, automatic controls the overload. If the motor overheats, the power is turned off and the pump is restored only after a certain time.

Some models have a sensor that protects the motor from load in idle mode. If there is no water in the suction pipe, it sends a signal to the control system and the motor turns off. After 15 - 40 min. NS is ready to go.

But if the working volume of water is not restored within 24 hours, the HC turns off, and it will have to be started in manual mode.

How to choose

Normal water supply at home, cottages or baths is possible only with the correct selection of all parameters. And you need to choose:

- type and performance of the pump;

- dimensions of the accumulator;

-

location.

First of all, you need to find out if the water arrives quickly enough in the well or well. If the debit of a well or well is less than 1.7 m3 / hour (the amount of incoming water in one hour), the required pressure cannot be provided. The equipment is designed for higher performance.

Selection of pump type

One of the most difficult and responsible stages is the choice of a pump. It must create enough pressure to raise the water to the required height. At the same time, its performance should meet the demand for water, but at the same time, it should not exceed the capacity of the well or well.

Self-priming vortex and centrifugal pumps are used in pumping stations. Both those and others can be in monoblock or console execution. But such pumps can lift water from a relatively shallow depth:

- a pump with a built-in injector will provide supply from a depth of 8-9 meters;

- normally suction from a depth of 7-8 meters.

If you need to supply water from a greater depth, you will need to use a submersible pump. They buy it, and on its basis they assemble a pumping station, the second way out is to install a unit with a remote injector.

The pump is one of the main components of the system

When using a remote injector, it will be possible to raise water from a depth of about 42 meters, but the efficiency of the system is low, and the cost of electricity is much higher - in fact, two pumps work simultaneously. But sometimes it's the best way out.

A system with a submersible pump with a large depth of the well will be the best option. It is efficient and "draws" a little energy. The only caveat: submersible equipment is quite sensitive to the purity of the water. To prevent sand, silt and other foreign particles from getting inside, a special filter mesh is installed on the pump inlet pipe.

Power selection

Productivity is selected taking into account the maximum water flow. Estimate how many taps can be open at the same time, count the volume of water that leaves through them. This will be the required pump power. In general, it is better to take this parameter with a margin, since working at the limit sharply reduces the “life” of the equipment.

On average, for a family of 3-4 people, the consumption is 2-4 m3 / hour, and the equipment is selected accordingly.

The choice of the volume of the accumulator

In general, it is desirable to install as large a tank as possible. This will ensure that the pump is turned on more rarely. After all, the less often it turns on, the longer it will serve: starting currents on the motor are destructive. On the other hand, a large hydraulic accumulator needs to be installed somewhere, and it also costs decent money. But when the power is turned off, you will have a supply of water in the system equal to the volume of your tank.

The larger the water tank, the less often the pump will turn on.

Just be careful. There are membrane expansion tanks for gas boilers. They are much cheaper, but make the water undrinkable. And they are not designed to work with liquid, so they will soon fail.

Having picked up all these components, you can start choosing a pumping station that will meet your requirements.

Connection of a pumping station

As mentioned above, the system is simple: a pipe is immersed in a well or a well (more often 32 mm polypropylene, but sometimes 40 mm - it depends on the performance of the pump). It is supplied to the entrance of the station, and from the exit it is supplied to the water supply manifold.

- Do everything so that you can overlap unnecessary branches.

- Provide for the possibility of draining water for the winter. Since a check valve is necessarily present in the system, it is required to make the outlet a little higher.

- Install shut-off valves at the inlet and outlet of the pumping station. Having blocked them, it will be possible to remove the equipment for maintenance without any special difficulties.

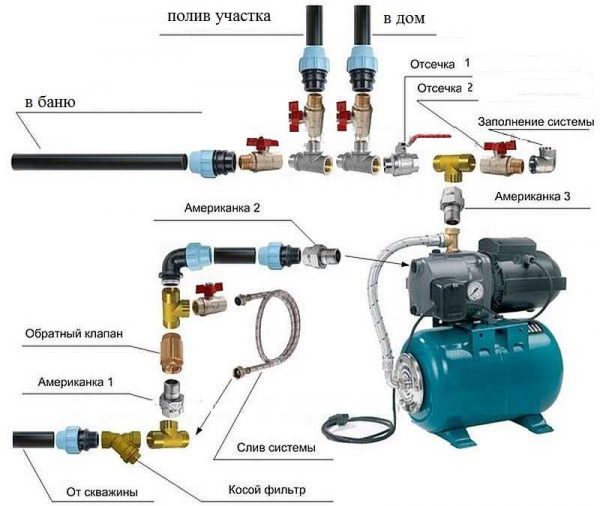

Since most of the components of the system are motionless, the connection of all elements occurs with the help of American women with union nuts. Otherwise, it is very, very difficult to assemble, and then, if necessary, disassemble.

Detailed connection diagram of the pumping station. A system for expelling air from pipes and equipment has been implemented

One of the connection diagrams of the pumping station is shown in the photo. The purpose of most of the elements is clear, with the exception of the "cut-off 1" and "cut-off 2" taps. They are used when filling the system during the first start-up. Here's how the process goes:

- The "cut-off 2" valve and the drain valve are open, "cut-off 1" is closed. With this position of the valves, pouring water into the corresponding inlet, we fill the lower part of the system. Part of the air then exits through the drain cock.

- Now we close the "cut-off 2" and the drain valve and turn on the pump for 5-7 seconds. After 5 seconds, open "cut-off 1". In this way, increased pressure is created in the system, which squeezes air out of the system (a couple of taps must be open).

- The second start-up cycle: the “cut-off 2” valve is open, the “cut-off 1” is closed and the drain valve is closed. Turn on the pump again for a short time.

- After 5-7 seconds of pump operation, open the “cut-off 1” valve. The system should start. If there is still a lot of air left, you can repeat the second start cycle.

In working condition, “cut-off 2” and the drain cock are closed, “cut-off 1” is open.

In this scheme, more attention was paid to purification - there is a fine filter at the entrance to the house

This system is interesting with a well-thought-out cleaning system: a water filter is installed on the branch that goes into the house. As a result, we have clean water in the tap without impurities.

How to make a shower in the bath with your own hands, read here.