Structural elements of the external drainage system

When designing a drainage system, the following design elements must be considered:

Elements of an external drain.

Elements of an external drain.

- Gutters. They are the main element of the drainage system. Must be strong enough, tk. not only serve to drain rainwater, but also hold large amounts of snow in winter.

- Pipes. The water entering the gutters is diverted to special receivers or sewers.

- Funnels. They are used to collect water from the gutters and supply it to the pipes.

- Plugs. They are installed at the ends of the gutters and serve to protect against water overflow during heavy rains.

- Mounting brackets. They fix the gutters in the desired position and give the structure stability.

- Gutters and pipe bends. Needed to direct the flow of water in the right direction.

- Sealing gaskets and rubber rings. They provide a hermetic fastening of the gutters to each other.

- Couplings and collars. Serve for fixing pipes between themselves and fastening them to the walls of the building.

Roof flashing parameters

Installing roof tides is the last stage of work, before that you need to first select and buy them.

materials

At the moment, buying ebbs for the roof is not a problem, it is more difficult to choose them. I will talk about prices later, but now let's briefly go through the materials.

What are roof drains made of?

Photo

materials

Galvanized steel

The thickness of the sheet here does not exceed 1 mm, so the design is quite light, plus the price of drainage is quite acceptable.

Pre-painted steel

Here the steel sheet is coated with plastisol, polyester and other similar polymers. The stability of such a coating is an order of magnitude higher than that of conventional galvanizing.

Aluminum

The main advantage of aluminum gutters is their light weight, plus this metal is not subject to corrosion, so it does not need to be painted.

Copper

Manufacturers give a guarantee of 70 years for copper roof gutters, but they last much longer.

Copper is not afraid of aggressive chemicals, corrosion and other troubles, the only problem is that the price of such structures is several times higher than the cost of plastic or galvanized drainage systems.

Plastic

Now plastic reflux is chosen by every third developer. The design is light, elegant, plus modern polymers do not fade in the sun.

Envious people say that the plastic drain is fragile, but if you choose a normal manufacturer and correctly install the ebbs on the roof, then they will serve for decades.

Gutter shape

The form of drainage roofs are semicircular, rectangular and figured. Strictly rectangular gutters, frankly, for an amateur. Their curly counterparts look original, but cost an order of magnitude more expensive.

The most convenient, practical and popular are semicircular types of gutters. Their advantage is that such structures do not have internal corners where dirt and debris are constantly collected, and it is very problematic to clean the roof gutter without special equipment.

As practice shows, semicircular roof tides are the best option.

Drainage calculation

To calculate the amount of material, you need the length of the perimeter and the square of the projection of the roof on the ground (the square of the area under the house). According to the instructions, the length of one gutter directed into one funnel should not exceed 10 m, but in reality it is better to start from 5, maximum 7 m.

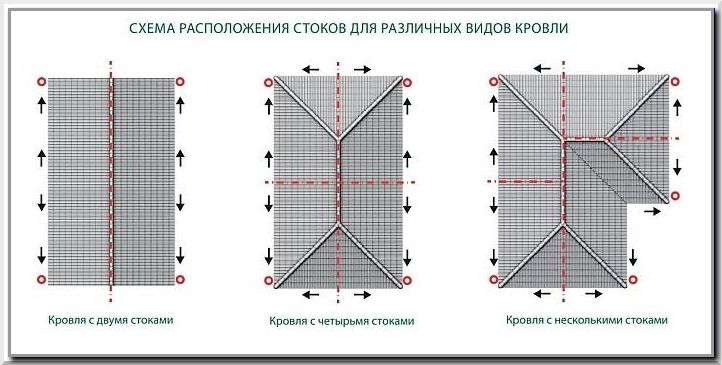

On long spans of the roof, the gutters are cut from the center to the sides, where drain funnels are installed at the corners. The arrangement of funnels and points of dissection of straight spans of the roof depends on the configuration of the structure.

Ebb installation is planned at the rate of 5 - 7 m of a straight gutter for 1 drain funnel

- After measuring the perimeter of the roof, you need to add 10 - 15% to the total footage, they will go for trimming and overlapping in the docking nodes.

- If possible, a funnel should be placed at each corner of the roof.

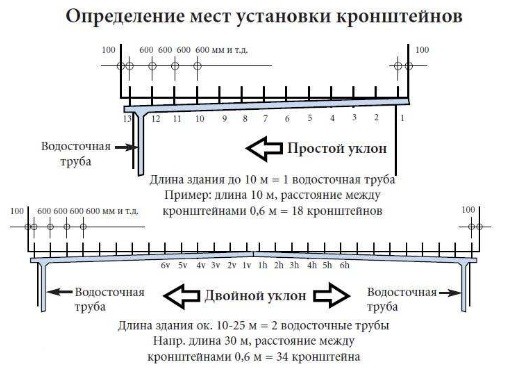

- On average, support brackets are installed in increments of 600 mm.

With the calculation of the width of the gutter, this is the case. According to the rules, for every square meter of the roof plane, there is 1.5 mm of width. That is, a gutter of 150 mm is placed on a roof of 100 m². But in reality, professionals usually do it easier.

- On the roofs of residential buildings with a roof area of up to 100 m², a gutter 100 mm wide is placed.

- With a quadrature up to 120 m² - the width of the gutter is taken 120 mm.

- With a square up to 150 m² - the width of the gutter is taken 150 mm.

As for drainpipes, brackets and other fittings, usually in stores this is all included. You say the width of the gutter and the whole system is selected for it. When selecting fittings, it is advisable to take pipes with a large diameter, so there is less chance of blockage.

Metal roof drains can have several fittings

Price questions

No matter how beautiful the roof tides are, their price depends on 2 things. Firstly, brand awareness, and secondly, the price level in the region. I deduced the average cost of drainage for the roof, you can be guided by it, but you should not make final calculations.

The average price of a roof tide

Material

Price for 1 m (Russian rubles)

How to make do-it-yourself drainage

Zinc drain

Without inviting a specialist, dewatering is easy to do on your own and quite inexpensive. In their manufacture, plastic, aluminum or galvanized sheet metal are most often used.

The simplest thing is to cut along a thin-walled metal pipe with a diameter of about 150 mm. The result will be: two gutters for collecting water. It is recommended to prevent corrosion by coating these parts with special compounds or varnish of the desired color.

The last stage of work will be the direct installation of the gutters with the help of fixing material in places where moisture accumulates.

Not particularly difficult and the manufacture of ebbs from galvanized sheet steel. To do this, you will need: a sheet of galvanized metal seven millimeters thick, a machine to bend metal structures. It is possible to do this without a machine tool with a hammer and a mallet, using a corner or a piece of rail, but the appearance of the drain will be poor.

The galvanized sheet is cut into strips of the required width and the appropriate length of the sheet. Then the strip is placed in the machine, where the ebb is made from it. Finished elements are covered with a protective compound, dried and prepared for installation.

Calculation of materials for drainage from the roof

You can set the required sectional area of the groove using SP 17.13330.2011. The document states that per square meter of roofing area should account for 1.5 cm² of the gutter section. Any competent installation of low tides on the roof is also accompanied by a calculation of the average annual rainfall in the region. The procedure makes it possible to find out the cross-section of downpipes in accordance with the recommendations of SP 32.13330.2012. It remains to determine their diameter in accordance with the instructions of SP 30.13330.

Some manufacturers provide their own tables for selecting an effective drainage system. Having decided on the standard size of the drainage system, it remains to select the elements of the kit. For example, on a straight wall for a riser you will need:

- Funnel groove.

- One elbow for the bottom outlet.

- Two elbows for supplying pipes to the wall.

- One mount for the funnel assembly and two for each pipe.

To get around the ledges on the wall, you will need 4 more elbows and 2 pipes for connection. The ends of the gutter must be closed with plugs. The segments are arranged in such a way as to obtain a minimum of waste. The number of joints counts the number of connecting elements with seals.

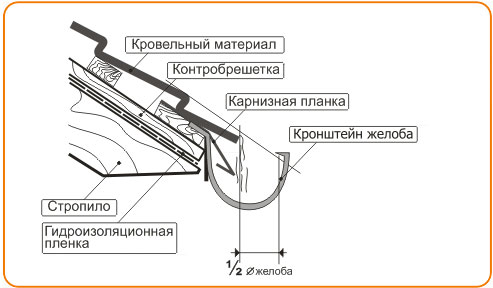

Each component of the gutter is fixed with brackets at the ends with an offset of 150 mm.For the rest of the length, the fasteners are distributed at a distance of no more than 600 mm from each other, which corresponds to the pitch of the rafters. To mount the gutter at 3 meters, you need 6 brackets with a pitch of 500 mm.

How to calculate the diameter of the tides

In order to properly install the ebbs on the roof, it is necessary to correctly calculate its dimensions, since the ebbs of insufficient depth and width may not be able to cope with the function assigned to it.

The following values are used in the calculations:

- distance between drains and gutter turning points;

- roof area.

To determine the roof area, it is conditionally divided into elements in the form of geometric shapes (rectangles, triangles, etc.) and the area of \u200b\u200beach of them is calculated. Then the results are summarized.

For each slope, two gutters must be installed with a slope towards the pipe intended for drainage. The diameter of the gutter can be 100 or 125 millimeters, it is selected based on the intensity of the expected load on the drainage system. If the building is small, smaller diameter gutters can be installed.

materials

Due to the constant impact of adverse environmental factors (precipitation, temperature changes, sun, wind), the right choice of material for ebbs is extremely important.

Modern ebbs are made from different materials.

Galvanized steel

. For the manufacture of ebbs, steel is used in sheets up to 1 mm thick. Polyester, pural or plastisol coating is used for additional protection against corrosion and aesthetics of the structure.

Aluminum

. The thickness of the original sheets is 0.8-1 mm. To protect against corrosion, a special multi-colored varnish is used, which also improves the appearance of ebbs.

Copper

. It can be used both without processing and with oxidation or brassing. It is considered the most beautiful, high-quality and durable material for the manufacture of ebbs. It has a significant disadvantage - a high price.

Polymers

. Due to low cost, increased strength, noiselessness, UV resistance and durability, polyester and plastisol have become widely used in the manufacture of ebbs. Due to its low weight and ease of installation, it is quite possible to mount roof tides.

Stages of installation of ebbs

Installation of the ebb is considered a fairly simple process, but it, in turn, requires responsibility and care, so that in the end the result suits not only you, but everyone living in the house.

Training

First you need to prepare all consumables and tools so that the installation process does not stop for a moment. You will need the following consumables and items:

- Brackets (special mounts);

- Pipe at the height of the house;

- Connecting inserts;

- Self-tapping screws that are suitable for fixing the material used;

- Clamps for fastening pipes to the walls of the house;

- Funnel;

- Gutter.

First you need to prepare and tools for work:

At the initial stage, you need to prepare a place for the water to drain from the roof. Drainage of water should not harm either the green spaces that grow in the yard, or the foundation of the house, or paving slabs. If sewerage is already installed on your site, then this problem in itself is removed.

lane markings

Installation must be carried out from the marking of the strip where the ebb will be fixed. First, a water intake funnel is installed, therefore a transverse line is indicated for it. Holders are installed with a distance of 15 centimeters from the edges of the funnel, while on both sides.

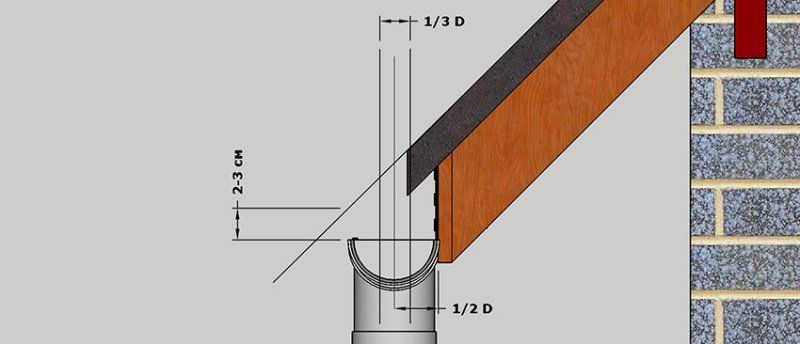

The vertical drawn from the edge of the roof must fall closer to the wall of the building, and not to the very center of the gutter, this must be taken into account when mounting the holders and the funnel.

This design helps water not to pass through the edge during heavy rainfall. To do this, you also need to give the gutter a certain slope angle.

Marking the fastening line of the holders and the inclination of the gutter

You will need to calculate the difference between the mounting height of the final and installed holders. This distance is multiplied by three. The bracket must be fixed, taking into account all the calculations done. This line is beaten off with a tracer cord. The holders are installed at a distance, this distance is approximately half a meter. First, markings are made for all holders, and only then their fasteners are made.

Installation of gutters in length

It is necessary to install the parts of the gutter into the holders so that there are places for connecting inserts directly between the holders. Correctly installed segments are fastened with inserts that have boundary marks. The distance between the edges of the gutters must be 7-12 cm.

The assembled gutter is placed in the holders, the slope is checked using water. Even a large amount of liquid must easily pass through the chute, if this does not happen, then it means that the system needs to be rearranged again.

Downpipe installation

If there are no damages or shortcomings, then you can start installing the downpipe, the installation of which comes from the funnel itself. You can fix the pipe with an elbow, it will depend on the distance to the wall

It is important to pre-prepare the required number of pipes and all fasteners so as not to interrupt the installation at its final stage.

Properly installed ebbs will give the house an attractive appearance and protect your home from the negative effects of moisture.

But even roof tides made of the highest quality material need constant care. It consists in the periodic cleaning of the gutters from dirt and debris. This is all the more true with the advent of cold weather, since if there is water in them, then when it freezes, it can damage the entire system. Constant maintenance of drainage systems will protect not only the structure itself, but also the walls of the house.

Roof drains

Types of ebbs for the roof

Roof drains can be made of various materials - plastic, metals (galvanized steel, copper). They have different shapes. The purpose of the tides is to collect water from the roof and divert it with the help of special devices into the drainage system. This element of the drain must have such characteristics as: increased strength, resistance to loads and mechanical stress, the presence of an anti-corrosion coating, and an attractive appearance.

Outflow from galvanized steel has a thickness of not more than 1 millimeter. Such products are additionally covered with polyester, pural, plastisol. If the steel does not have such a coating, it is not very comfortable to live in the house: the sound of raindrops is greatly amplified.

The outflow from aluminum has a thickness of 0.8-1 millimeters. In order to protect against corrosion, it is varnished on all sides. Varnishes of various colors can be used to improve the appearance of the product.

Copper ebbs are brass-plated or oxidized. Elements made of this metal are durable and have an attractive appearance. They will last a long time, but their cost is quite high.

Device and purpose of drainage

The drain system is a combination of the main and auxiliary components of the structure. The main ones include gutters, funnels and pipes, and the auxiliary ones include plugs and fasteners.

According to the placement, internal and external drainage systems are distinguished. Internal is used for buildings with a flat roof. In this case, the roofing material is laid with an inclination towards the funnel. Water flowing down the roof is collected in a funnel, then it enters a pipe located in the wall of the building or in a technical channel.

An external drainage system is used for pitched roofs.All structural elements are installed from the outside of the building.

The main purpose of drainage is to divert melt and rain water from the roof of a building to a place intended for this.

If there are no low tides, water falling from the roof will destroy the concrete pavement or paving slabs around the building.

The accumulation of excess water in the soil around the house will lead to underflooring of the basement and basement floors. Soaking into the soil, the water will wash away the foundation of the house. As a result, it will begin to sag, and cracks will appear on the walls. The operation of such a building will become unsafe.

Drip materials

The drainage system consists of a set of standard products. Before making a choice of one or another material, it is necessary to familiarize yourself with the parameters of this system.

Correctly determine how unified elements fit the facade of the house. The main elements of the drainage system are gutters and pipes.

The video below shows the installation of a roof drainage system.

There are various types of these products on the market today. The kit necessarily includes brackets, plugs, clamps and other elements.

When planning to install the ebbs with your own hands, you need to carefully read the parameters of the products that are offered for sale.

Outflows from galvanization

Until recently, galvanized steel was widely used for the manufacture of ebbs.

The main advantage of products of this type is the low price.

The destruction of the zinc coating occurs under the influence of acid rain, which has become more frequent in recent decades.

Cast aluminum

Aluminum products have a longer service life.

They can be made independently or bought ready-made and painted in a color suitable for a particular building.

Gutters are fastened with rivets or aluminum glue.

Sealing joints can be done with silicone or a special paste.

Outflows from copper

Copper ebbs are considered the most durable.

Products are made of pure metal and do not have additional coatings.

The elements are connected to each other by soldering or folding.

Installation of copper drains must be carried out in such a way as to avoid contact with other metals - copper or steel.

PVC drains

To date, plastic products have become the most widespread.

For the installation of such systems, couplings, latches with a rubber seal and special glue are used.

Plastic ebbs are not subject to corrosion, retain their characteristics at the maximum temperature difference.

Varieties of ebbs

Ebbs can be made from absolutely any materials, as well as in any form. The main task of this design is to collect water from the roof surface, and then transport it to the drainage or sewer system.

Differences of ebbs according to materials:

- Outflows from galvanized steel. The thickness of this design does not exceed one millimeter. For these ebbs, a coating using plastisol or polyester is provided, this is done in order to drown out the noise of falling raindrops, otherwise the steel surface will only amplify this sound;

- Outflows from aluminium. The thickness of this design is also about one millimeter. Aluminum sills are treated with a special varnish on both sides in order to preserve the product from possible corrosion;

- Raw copper is also a material for the manufacture of ebbs. These structures are additionally processed with an alloy of zinc and copper. They are characterized by attractive appearance and high quality, although the price of ebbs can be very high for some consumers.

- Castings made of plastisol and polyester have high durability and strength.In addition, they are resistant to ultraviolet rays and light weight. Due to these characteristics, they are very popular today. Also pleased with the convenient installation of products that you can do yourself;

- Plastic moldings will help to highlight the individuality of your home, offering a huge range of colors for the manufacture of structures. These products do not need special care, they are not afraid of temperature changes. The huge popularity of plastic ebbs is also explained by the fact that they almost do not create noise in the rain and have an affordable price.

Factors that influence the choice of tide

- high resistance to external factors, including precipitation and sudden changes in temperature;

- an aesthetic function that provides a beautiful appearance to your home;

- protection of the roof and walls from moisture.

The choice of low tide depends precisely on the absence or presence of these basic characteristics. Each of the above materials has its own specific advantages, but some are more pronounced, others are not so visible.

To date, preference is given to ebbs made of plastic and metal. Such products are covered with a special layer that protects them from corrosion. The quality of the product greatly depends on the grade of steel and its thickness.

Ebbs made of non-ferrous metals are also popular due to their high quality, attractive appearance and durability. But their price is an order of magnitude higher than conventional products, therefore they are available only to those people who are ready to allocate the necessary (considerable) amount of money for the installation of this system.

Plastic ebbs

These ebbs will serve perfectly if the attic of the house is used as a living room.

The main advantages of installing plastic ebbs include:

- Ease of use and speed of installation are achieved due to the low weight of the product;

- Affordable price;

- The size of the ebb is equal to the length of the perimeter of the structure;

- A convenient connection method is a kleimer lock;

- Corrosion resistance;

- Several types of material - polyethylene and PVC;

- Resistance to temperature changes and weather phenomena;

- Plastic ebbs are varied in color and design, this makes it possible to choose the required option clearly for the project of the house.

It should be noted that ebbs made of PVC are a little more reliable, this is due to their heat resistance. But still they can not withstand low temperatures. Also, when installing as a supplement, you will need a pipe with a cross section of at least 45 mm.

Calculation of the required drainage diameter

Before starting work on the installation of the ebb, you need to make calculations of its dimensions, otherwise you risk building a structure that will not perform its main functions.

The roof area can be calculated according to this principle: the area is equal to the length of the roof, including the height of the roof plus the length of the slope, this value is divided in half.

It is also necessary to take into account the distances between the drains and between the turning points of the gutter. Gutters must be above the drainage system.

For each roof slope, it is necessary to consider installing two gutters, the diameter of one structure should be no more than 125 millimeters.

Drainage system installation

Installing a drainage system for the roof of a private house is a simple procedure. This work can be done by two people.

At the same time, it should be borne in mind that in any case related to installation or finishing, there are always subtleties and nuances that you need to know about in advance.

At the first stage, it is determined what material the structure will be assembled from, the shape and color of the gutter.

The next step is to calculate the required number of elements and fasteners.

Then the whole kit is purchased and delivered to the place where the installation will be carried out.

The view below shows how to properly install a drainage system.

Often, a container is installed near the house to collect rainwater. There are other solutions for this as well.

The water collected from the roof is directed through a drainpipe along a special gutter into a sewer or gutter. Installation begins with marking and securely fixing the brackets.

First, the uppermost bracket is attached, which is located at the opposite point from the downpipe.

The distance between them should be within 50 cm, with a tolerance of ten centimeters in one direction or another.

The next step is to assemble and install the gutters. The industry produces elements with a length of 1, 2 and 2.5 meters. If necessary, these segments are connected to a line of the desired length.

The joints are sealed with special gaskets. At the extreme points of the assembled gutter, the plugs are securely fixed.

In a previously marked place under the roof, a receiving funnel is attached, which is also called a storm water inlet.

It is necessary that the axis of the funnel coincides with the hole in the gutter. And it should have a slope towards the storm water inlet and a slope away from the house.

This reduces the chance of damage to the ebb when snow falls off the roof.

In the process of fastening, the verticality of the pipe should be controlled after fixing each clamp. To do this, it is enough to use the usual carpentry plumb line.

The pipe is attached to the wall with special clamps or holders. Fasteners are selected depending on what material the wall of the house is built from.

The most commonly used screws, screws, dowels or nails. Nails are allowed to be used only for wooden walls. The holders are placed at the joints of the pipes.

The maximum distance between them should not exceed two meters.