Ways of welding communications

Polyethylene is a well-welded material due to the wide temperature range of the viscous state. For welding polyethylene pipes, three welding methods are used: in a socket, butt and using fittings with embedded electrical elements. But the first type of welding for polyethylene pipes, unlike polypropylene pipes, is used extremely rarely. Therefore, we consider only two types of welding.

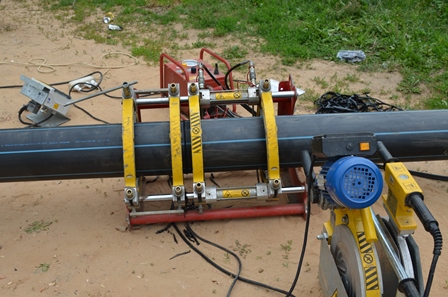

Butt welding is recommended for pipes having the same wall thickness. If it is necessary to make an exception to this rule, the thicker wall is chamfered to ensure the same area of contact surfaces.

Butt welding of polyethylene pipes consists in melting the ends of the pipes with a special tool to a viscous state. Next, the melted edges are connected under pressure and kept in this state until the pipe cools completely. The strength of such a connection exceeds the strength of the pipe itself.

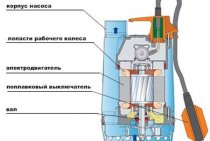

The welding machine for butt welding of polyethylene pipes consists of several components:

- centralizer,

- trimmer,

- force generating device

- power supply and control units.

For butt welding, special spigot fittings are used.

Fittings and HDPE sewer pipes can be connected using electrofusion welding.

The heating of the junction is carried out using a metal spiral embedded in the fitting, through which an electric current passes. The pressure in the welding zone and the sealing of the joint are ensured by the thermal expansion of the pipe. For the implementation of electrofusion welding, electrofusion couplings and a device that provides electric current to them are required.

Compression fittings for HDPE pipes

In compression fittings for polyethylene pipes, there is no split ring that serves to crimp the pipe on the fitting fitting, since the polyethylene can be deformed at the site of the applied force.

Compression fittings for connecting polyethylene pipes consist of a body, a union nut and a rubber seal, which is located between the pipe and the fitting. The nut is screwed onto the thread of the fitting, compressing the rubber that seals the connection.

The maximum diameter for which compression fittings can be used is a sewer pipe pnd 110. From the point of view of reliability, welded joints are optimal, and from the point of view of convenient maintenance, compression fittings. For the organization of drainage and irrigation systems, along with a smooth-walled one, a corrugated sewer HDPE pipe can be used.

What are HDPE sewer pipes used for?

HDPE pipes are high density polyethylene pipes. HDPE pipes are manufactured using the method of continuous extrusion of polyethylene, in accordance with the requirements of DSTU B V.2.7–151:2008 “Polyethylene pipes for cold water supply”.

Low pressure polyethylene is not exposed to various organic compounds, solvents, acids, alkalis and water. The higher the density of polyethylene, the more resistant it is to organic solvents.

For the production of pipes, only light-stabilized polyethylene is used., because non-light-stabilized polyethylene crumbles into dust under the influence of sunlight and will last no more than a year.Low pressure polyethylene has a high resistance to hydraulic shocks, because. has a low modulus of elasticity.

Double-layer profiled pipes for sewerage

Products made of polyethylene meet all sanitary and hygienic requirements and are allowed not only for the removal of various wastewater, but also for the transport of drinking water.

Technical characteristics of HDPE pipes

Due to the specific properties of polyethylene, HDPE sewer pipes are not subject to corrosion, the collectors are quite tight and can serve more than 50 years without accidents.

In terms of their environmental properties and technical characteristics, HDPE sewer pipes are many times higher than similar products made from classic materials. They are 6 times lighter than metal pipes, which greatly facilitates transportation and installation.

The inner surface of the pipe is ideally smooth and remains unchanged during operation, resists silt and lime deposits. The product has good thermal conductivity, emits a small amount of condensate.

And when transporting waste from industrial and municipal sewerage, due to gas corrosion, the aggressive environment increases tenfold, which quickly brings traditional metal and reinforced concrete collectors into an emergency state.

Low pressure polyethylene sewer pipes are resistant to highly corrosive gas, which is formed as a result of sewage transportation.

Types of HDPE pipes

PND sewer pipes are produced in the following types:

- pressure pipes for water and gas pipelines;

- non-pressure for storm sewers and fecal sewers.

Pressure pipes made of low-pressure polyethylene for sewerage are produced in a standard version, in coils, in coils, 6 m - 12 m long, 16 mm - 1200 mm in diameter, with a pressure of 0.4-2 MPa; in coils or bays, the size of the diameter is not more than 110mm.

Non-pressure polyethylene pipes, as a rule, are produced in lengths of 6-12 m; with ring stiffness SN4, SN8, SN16. With temperature drops, polyethylene pipes have the ability to expand by 5-7% of their original state. But in terms of mechanical properties, these pipes are inferior to metal pipes and are subject to ultraviolet radiation.

They have good flexibility, which allows the bending method to make turns in the pipeline route without using special fittings. This makes it possible to significantly save money and time during installation work.

Sewer pipes HDPE

Installation work is carried out in several ways: using couplings, fittings, socket connections, welding and electrofusion welding.

The use of HDPE sewer pipes

HDPE sewer pipes are widely used:

- during the construction of water pipelines and pressure sewerage systems, their repair;

- for transporting compressed air and other liquids;

- in household sewerage systems, both external and internal;

- in the field of melioration for drainage systems;

- for installation of drinking water pipelines;

- in agriculture (in the field of animal husbandry).

- when installing heating mains for waterproofing pipes;

- in the overhaul of external networks of non-pressure and storm sewers.

HDPE pipes are not recommended for systems operating under pressure and at high temperatures, so they should not be used for central heating and hot water.

In recent years, low-pressure polyethylene pipes have been increasingly used to protect telephone and electrical cables from mechanical damage.

Technical characteristics of HDPE pipes

In the manufacture of links and fittings from low-density polyethylene, the state standard (GOST) 22689.2-89 is used.This document regulates such technical characteristics of polymer products as strength, flexibility, wall smoothness and resistance to environmental conditions.

Pipes are produced by extrusion, when the molten raw material is forced through a hole in the form of a ring, square or rectangle. This process takes place in a vacuum chamber, which contributes to the preservation of the workpiece configuration. The material produced by this technology has a crystalline structure, sufficient rigidity and low specific gravity.

Manufacturers produce links and fittings from HDPE with the following indicators:

- purpose - transportation of water and gas;

- specific gravity - 0.92;

- diameter - 20-560 mm;

- length of 1 section - 2, 3, 5, 6, 8, 12 m;

- service life - at least 50 years.

GOST regulates the length and diameter of sockets, as well as the dimensions of fittings - tees, crosses, bends and adapters.

Each product is marked, which indicates the type of material, GOST or TU, purpose, diameter and length. It is advisable to purchase a set of material produced by one manufacturer. This approach will allow you to achieve maximum accuracy when assembling the sewer system and avoid difficulties when connecting various parts.

Types of HDPE pipes for sewerage

Since non-standard solutions and ideas are used in construction, manufacturers of polymer products work in close cooperation with engineers. The HDPE sewer pipe is best suited for use in arranging multi-storey buildings, laying a route in unstable ground, creating temporary and permanent pipelines for transporting drinking water and technical liquids, wastewater, gases and compressed air.

Produce polyethylene pipes of this type:

- Non-pressure. They are used in ventilation and drainage systems moving by gravity. They serve as channels for placing telecommunication and power cables. They are characterized by thin walls and increased flexibility. Due to this property of pipes, it is possible to lay routes with smooth bends without the use of fittings and welding. In addition, small-diameter products are wound into coils up to 50 m long. The diameter varies between 50-110 mm. For laying air ducts, links up to 12 m long and up to 120 cm in diameter are produced.

- Pressure. Products have found application in the construction of water pipelines, gas pipelines and sewer systems operating with forced pumping. The line is designed for a pressure of 2-5 MPa. The connection is carried out by welding - the use of glue and sockets is excluded. Depending on the tasks to be performed, builders make tracks with a diameter of 50-110 mm.

According to the composition, links from HDPE are divided into standard ones, which can be laid underground and inside buildings, and protected from ultraviolet radiation - they are used to make open-type sewer systems and sections of pipelines that go to the surface.