Description of the computational process

The main purpose of pumping stations is to take water from a source and supply it to consumption devices. Since the surface pump is a noisy device, they try to place it at some distance from the living quarters. In this regard, the distance from complex systems to places of water consumption can be quite large.

When using the presented calculator, first of all, you should indicate what difference there is in height between the plumbing fixtures and the station itself. Further, it is required to note the length of the horizontal sections of the water supply network of a residential building. Moving through pipelines, water experiences a certain resistance, so there is a decrease in pressure in these places.

With a decrease in the cross section of the pipes, the resistance increases. If the diameter exceeds an inch, then the horizontal sections can be ignored. The reduction in pressure in them is not significant.

The pumping station is located in the utility room

The calculator has an item where the horizontal length of sections from pipelines with different sections should be indicated. You will also have to note what material the elements are made of, because the resistance of products can vary greatly. For example, steel counterparts hold back the flow about 1.5 times stronger than plastic ones.

At the final stage, it remains to determine the required pressure at the points of water consumption. For simple mixers, 1.5 atmospheres is usually enough, but for special equipment, a stronger pressure may be required. Its value is reflected in the passport, which is supplied with the device. For convenience, the answer is displayed in three units of measurement at once.

Save Time: Featured Articles Every Week by Mail

Criterias of choice

A pump for a well, for example, Malysh, is the main element of the water supply system of a country house. The correct operation of the entire system depends on the correct choice of this unit. When selecting pumping equipment, several criteria must be taken into account at once:

- The main indicators influencing the choice of device are the level of liquid in the hydraulic structure and the depth of the well. The passport for pumping equipment must indicate the depth of water intake for which the pump is designed. If you do not know how deep your hydraulic structure is, it is better to measure it yourself using a special device or an ordinary rope. Also, with the help of a rope (its wet part), you can find out the height of the water column in the well. Next, we will consider the features of choosing a unit for wells with a depth of 30 meters.

- Water needs. The choice of pumping equipment without knowing this value is simply impossible. Depending on the type of pump, this figure can be in the range of 20-200 l / min. The calculation is made taking into account that one person uses 200 liters of water per day. Therefore, a family of four will need a pump whose power is in the range of 30-50 l / min. You can choose the simplest unit, for example, the Whirlwind or the Kid, but you should provide for a small power reserve. If, in addition to water supply at home, the device will provide irrigation of the garden, then an even greater power pump is needed. As a rule, about 2 thousand liters of water may be needed to water the garden per day, so the power of pumping equipment should be 50 l / min more.

- Well productivity. It is impossible to accurately calculate the volume of water produced for a certain period. For an approximate assessment of this parameter, the time during which all water is pumped out of the hydraulic structure is recorded, as well as the time during which a completely empty well is filled with water again.After that, the second indicator should be divided by the first. The result obtained will be the debit of the water intake. For the selection of pumping equipment, this approximate value will be quite enough.

- Well water pressure. This indicator is especially important for water intakes with a depth of 30 meters or more. To determine the pressure, you must know how many meters deep your well has. To this value add 30 and increase by 10 percent. As a result, you will get the height of the water column. According to this indicator, the pump is selected. For example, if your hydraulic structure is 30 meters deep, then the height of the water column will be 60 m + 30 + 10% = 66 m. In this case, it is better to choose a model of pumping equipment, for example, Malysh or Whirlwind, with a head of 70 meters.

- The diameter of the shaft of a hydraulic structure. This indicator is needed to determine the power of pumping equipment. If your well was drilled by professionals, then this value can be found in the water well passport. If you did the water intake yourself, then the diameter can also be measured independently. This value must be in inches, so to convert from centimeters, know that there are 2.54 cm in one inch. Most pumps, including the Malysh unit, are designed for 4-inch wells. If the diameter of the trunk of your structure is non-standard, the desired model can be ordered from the catalog. That is why, before making a water well, it is worth choosing a suitable 4-inch casing diameter in advance.

- The price of pumping equipment is an equally important indicator when choosing a unit. Also, when calculating costs, it is worth considering that you will need a steel cable to hang the pump in the well and an automatic connection. It is not necessary to choose the most expensive unit. There are relatively inexpensive domestic models, for example, the Malysh pump, which do an excellent job with the tasks.

What hydraulic accumulator is needed

Hydraulic accumulator selection table.

For the correct choice of the pump, attention must be paid to which accumulator will be used. Its purpose is to accumulate a certain amount of water to prevent the pump from turning on frequently.

When a certain amount of water is reached, the pump turns off until the water is used up. Each pump has a permitted number of starts per hour, which should not be exceeded.

Usually these are 20 starts, which, in the absence of a hydraulic accumulator, will be carried out every time the tap is opened. But if there is a tank, such inclusions will be rare, which will extend the life of all equipment.

- Qmax is the maximum value of water flow;

- Pset - pressure when the pump is turned on;

- ΔР is the difference that is observed when the pump is turned on and off;

- Nmax - the number of on and off allowed per hour, usually it is indicated by the manufacturer for each model separately;

- K = 0.9.

When choosing a pump, it must be taken into account that the pressure of the air mass in it is always 0.8-0.9 bar.

Calculation of pump performance for a well

When calculating the performance of a pump for a well, it is also worth considering the natural fluctuations of the fluid, which for one reason or another can affect the water level in the well. As practice shows, during the year, under the influence of such meteorological factors as drought, heavy rains and floods, the liquid level can increase or, on the contrary, decrease from 1 to 5-6 meters, depending on the intensity of the above phenomena. Pumps in such wells must be installed several meters deeper than the lowest possible dynamic liquid level. Thus, it is possible to additionally insure the downhole equipment in case of a possible shallowing of the source.

Having analyzed the main characteristics of the well, you can begin to select the desired pump model. Here we will be interested in the operational parameters of the equipment, namely:

-

Performance

- this is the ability of a well pump to pump a certain volume of water for a set period of time.On a note

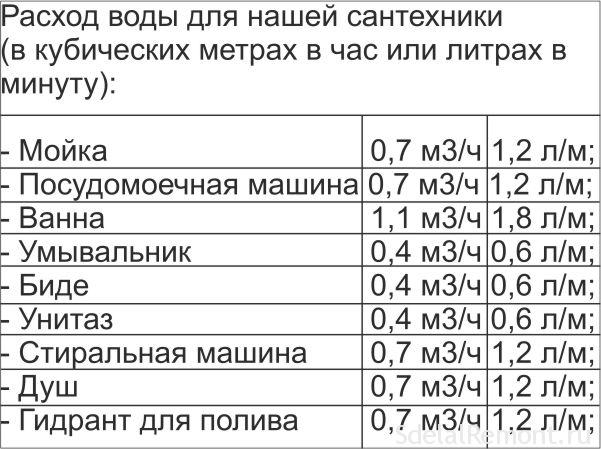

To determine the required volume of liquid, you can use the average value, where one person consumes about 1000 liters of water or one cubic meter per day. But do not forget that, as a rule, in a country house there are several points of water intake. These can be taps, faucets, washing machines and dishwashers, bathrooms, shower rooms. And there is always the possibility of their one-time use. Of course, not all at once (although there is also such a possibility), but several - that's for sure. In general, we need the pump to cope with the possible peak load in addition to the average flow. -

pressure

, if you do not go into details, then the pressure of a well pump is an indicator of the generated pressure that a particular pump can provide when pumping a certain amount of liquid. If you are interested in what pressure is required, then this means what pressure the pump needs to provide in order to pump a certain volume of liquid from the initial suction point to the final water distribution point, while overcoming all the hydraulic resistances of the plumbing system.

What you need to know when choosing a pump

Scheme of installation of a borehole pump.

When choosing a pump, it is necessary to take into account such parameters as:

The total depth of the well. This information is contained in the attached passport. It is customary to install the equipment at a height of 1 m from the bottom level.

Dynamic water level. The pump must be placed below this level, it is also indicated in the passport

The static level is also important to consider.

Well diameter in order to correctly select the size of the deep pump, its adapter, head, cover for the wellhead.

The flow rate is data on the productivity of the source, the well pump should not have a productivity greater than that of the well. Ideally, the choice should be made in such a way that the productivity of the equipment is approximately 5-10% less than the flow rate of the source.

Size, filtering depth

The downhole pump must be positioned so that the motor is above the filter. Only in this case the system will work without failures.

The distance from the house to the well. Not only the horizontal value is taken into account, but also the height to which the pipes rise.

Floors, the location of the highest point of the water intake.

The place where automation is installed to control the pump.

A power supply option that powers the well pump.

General criteria for choosing a pump for a well in a suburban area:

- Equipment power. The selection of the unit depends on the depth of the source, the required pressure and the planned water flow for the house. You cannot make a selection without taking this parameter into account.

- The depth that the well has. This parameter is important for choosing a pump, many consider it one of the first. For example, surface pumps can only be used for shallow springs and wells, while only deep models are used for water wells.

- The choice is made on the basis of what the planned water flow will be, that is, what the pump performance should be.

Calculation of a centrifugal pump

The calculation of a centrifugal pump consists in determining the two parameters necessary for the operation of the system - flow and pressure. Depending on the installation scheme, the approach to calculating the given parameters should be different.

Booster pump calculation

for the water supply system is carried out according to the load of the hour of maximum water consumption, and the pressure is determined by the difference between the given pressure at the inlet to the water supply system and the pressure at the inlet of the water supply.

The pressure at the inlet to the water supply system is equal to the sum of the excess pressure at the upper draw-off point, the height of the water column from the pump to the upper point and the pressure loss in the section from the booster pump to the upper point. Excessive pressure at the upper draw-off point is usually taken as 5-10 m.

Feed pump calculation

for the heating system, they are performed based on the maximum allowable filling time of the system and its capacity. The filling time of the heating system is usually taken no more than 2 hours. The head of the make-up pump is determined by the difference between the pressure at which the pump is turned off (the system is full) and the pressure at the connection point of the make-up line.

Calculation of the circulation pump

for the heating system, they are performed based on the heat load and the calculated temperature graph. The flow of the pump is proportional to the heat load and inversely proportional to the calculated temperature difference in the supply and return pipes. The pressure of the circulation pump is determined only by the hydraulic resistance of the heating system, which must be indicated in the project.