The list of materials from which window systems are made is not limited to plastic. PVC windows are very popular, but wood and metal structures have appeared that surpass them in many ways. New technologies have eliminated the shortcomings of these materials, so the aluminum profile for windows is increasingly used in the glazing of houses and apartments.

Advantages of aluminum windows

Modern windows made of aluminum profiles are different from those used in construction a few decades ago. The list of their advantages is long:

- High material strength. This allows the frames to be made thinner than plastic, which increases the illumination. The frame made of aluminum is less susceptible to mechanical damage, and the margin of safety is designed for double-glazed windows with a large weight. The risk of sagging or deformation of the sashes is minimal.

Magnesium and silicon are added to aluminum during production. This alloy makes the profile more rigid and resistant to corrosion.

INTERESTING FACTS!

- Aluminum is the most abundant element in the earth's crust after carbon and oxygen, accounting for 8%. It has also been found on the Moon and Mars.

- In the 1860s, aluminum jewelry was at the height of fashion in France and was valued more than gold and silver.

- In the 19th century, aluminum was worth more than gold, because the process of obtaining the metal without impurities was difficult and expensive. And 100 years ago, a kilogram of aluminum cost 1,000 rubles in terms of modern money.

- Durability: the manufacturer's warranty is 50–80 years, but with timely replacement of the seal and fittings, the windows will last longer. Aluminum is not afraid of exposure to moisture and the sun, calmly withstands significant temperature changes (from -80 to +200 C °)

- Lightness: Important glazing of remote structures on balconies, loggias, when decorating windows in doors, whose weight is highly undesirable to increase.

- Burglary resistance. An aluminum frame, even without special fittings, can withstand a burglar's hand tool for at least 10 minutes.

- Repairability: if damaged, the frame can be easily repaired. Seals, fittings - handles, locks, latches - are easy to replace yourself. You don’t have to drill or mill anything: the old element is removed, and a new one is put in its place.

- Wide choice of color, durability of a covering. The aluminum profile is painted by powder spraying in any shade from the RAL catalog. Another option is anodizing the elements.

- Plasticity: allows you to create curvilinear frames - lancet, round, oval.

- Many varieties of designs: frames are deaf, swivel, folding, sliding, combined.

- Safety: aluminum does not burn, unlike wood or PVC, does not emit harmful fumes or impurities.

Flaws

There are disadvantages, although they are not so many:

- High price: 2–2.5 times higher than plastic structures. Given the long service life, it is justified, but you will have to spend money during installation. This moment scares off potential buyers.

- In terms of heat retention, budget segment frames are inferior to wooden or plastic counterparts.

- Aluminum profile windows do not "breathe", so you will often have to ventilate the room or equip it with forced ventilation.

Aluminum window profile cold and warm

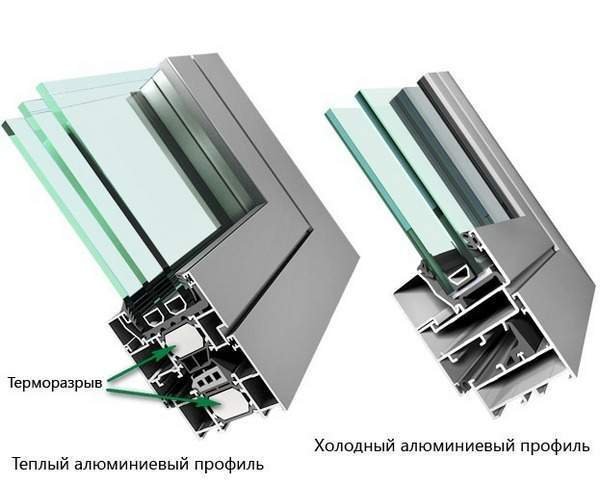

There are two types of aluminum window profile: warm and cold. With the same thickness, they differ in internal structure. To see this, it is not necessary to cut the element in half: manufacturers post on the Internet drawings of model cuts in DWG format. And the following photo will help to understand the difference between the two varieties.

The cold profile does not contain insulating elements. Inside there is only one chamber without additional layers, so in winter it will freeze. Cold-type aluminum structures are suitable for balconies, unheated loggias, utility rooms, and verandas. The advantage of this option is the minimum weight and light fittings.

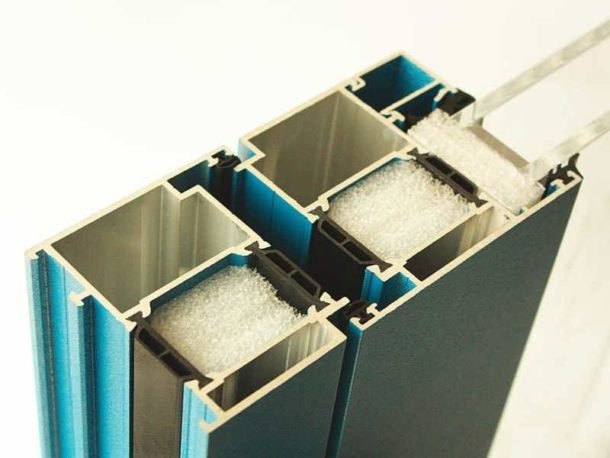

The warm profile contains a longitudinal insert made of polyamide with fiberglass. These materials have a low coefficient of thermal conductivity: 150 lower than that of aluminum itself. An insert with a thickness of 1.8 to 3.5 cm - thermal break - does not let the cold through. This design allows aluminum windows to come closer in terms of heat retention to wood or PVC frames, so they are installed in residential premises. The heat transfer resistance coefficient (R0) is 0.55–0.57 m2 • °C/W. With a thermal break made from a multi-chamber fiberglass profile 30–40 mm wide, R0 rises to 0.62 m2 • °C/W.

In budget products, the thermal break chamber is hollow, so already at -10 ° C they are covered with condensate. Such structures are the coldest, the coefficient R0 does not exceed 0.45 m2 • °C / W.

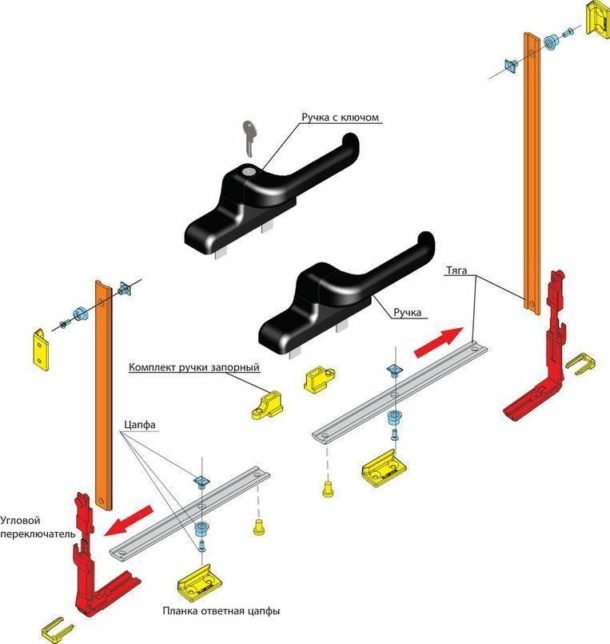

Fittings for aluminum profiles

Fittings for aluminum window frames differ from elements for PVC structures. It is divided into 2 types:

- With fastening the hinges to the frame with screws that are screwed into pre-made holes.

- With fixation of loops by clamping terminals. They do not need additional holes, a template, so they are considered more technological.

sealant

The seal protects against drafts, and also protects the profile from mechanical damage, prolonging the life of the entire structure. It is used on all windows and doors with any opening method and is divided into three types:

- TPE - considered to be of high quality, but cracks in severe frosts;

- VMQ - not afraid of any temperature, suitable for harsh climates, but expensive;

- EPDM - successfully resists heat, frost, moisture, aggressive substances, relatively inexpensive, but inferior to VMQ in terms of service life. The most popular option.

When replacing the seal, it is advisable to buy material from the same company that the manufacturer uses. In the store, you need to make sure that the seal stretches a little and does not have cracks.

Manufacturers of aluminum profiles for windows: which ones are better

Quality criteria for aluminum window systems are set by GOST 21519-2003. The rating of the best manufacturers, based on customer reviews, includes:

- German company Schuco ("Shuko"). It produces window, door, sliding and post-transom systems with a maximum, high and low degree of thermal insulation. Models contain built-in ventilation systems, protection from sunlight, condensate removal, noise reduction.

- Provedal (Spain). Profile products are made using an anodizing process. After it, a protective film is formed on the surface of the element. The main area of use is cold glazing. Provedal profiles are used by many manufacturers in their window blocks, for example Kaleva-Light. This is a glazing system for loggias and balconies that allows you to effectively use the available space and ensure maximum light flow through the windows. Kaleva-Light is indispensable on "broken" loggias, while various window opening schemes are possible.

- Belgian company Reynaers. They are slightly inferior to Schuco profiles in terms of quality and manufacturability, but they are cheaper. A wide range, including warm and cold types of profiles in various colors (more than 400 shades), wood-aluminum windows.

- Russian manufacturer Vidnal Prof. It produces facade profiles for cold glazing, insulated options for windows, doors and stained-glass windows. The company's products are adapted to Russian conditions, and the price is lower than foreign models with fairly good quality.

How much does an aluminum profile window cost: what is the price of

To choose a suitable design and immediately understand how much it will cost, you need to consider the parameters on which the final price depends. These include:

- The thickness of the profile and insert-thermal break. The larger it is, the warmer the window and the more expensive it is.

- Accessories, seals. The cost depends on the quality of the components. Multi-circuit seals will increase the price of the structure.

The best fittings manufacturers are Roto (Germany) and Giesse (Italy).

- Type of double-glazed window. The price is affected by the number of cameras, the presence of a coating, an energy-saving layer.

- Brand. The reputation of the company - the manufacturer of the profile and the company that assembles the windows matters.

The cost of a window structure made of cold-type aluminum with a single double-glazed window or with glass starts from 3,700 rubles/sq. m. A warm window with a double-glazed window will cost from 4,300 rubles / sq. m.

When ordering a design, pay attention to the guarantee. It should be given to all the details of the window block.

The high price does not guarantee long-term operation of the window without breakage. The right choice, installation and care come to the fore here. Under these conditions, the aluminum structure will last for many decades.