Modern windows are quite complex in design. It allows you to provide excellent thermal insulation of the room for decades. Manufacturers of plastic windows offer many models that differ not only in technical characteristics, but also in price. How not to spend money in vain and choose a window that will guarantee indoor comfort throughout the entire period of operation? To do this, you need to figure out what materials the profile for plastic windows is made of, how many air chambers have different models, why you need a stand profile.

Material

Modern industry offers window profiles from various materials. It can be wood, aluminum or polyvinyl chloride. Each of them has its own advantages and disadvantages, besides, they differ quite sensitively in price.

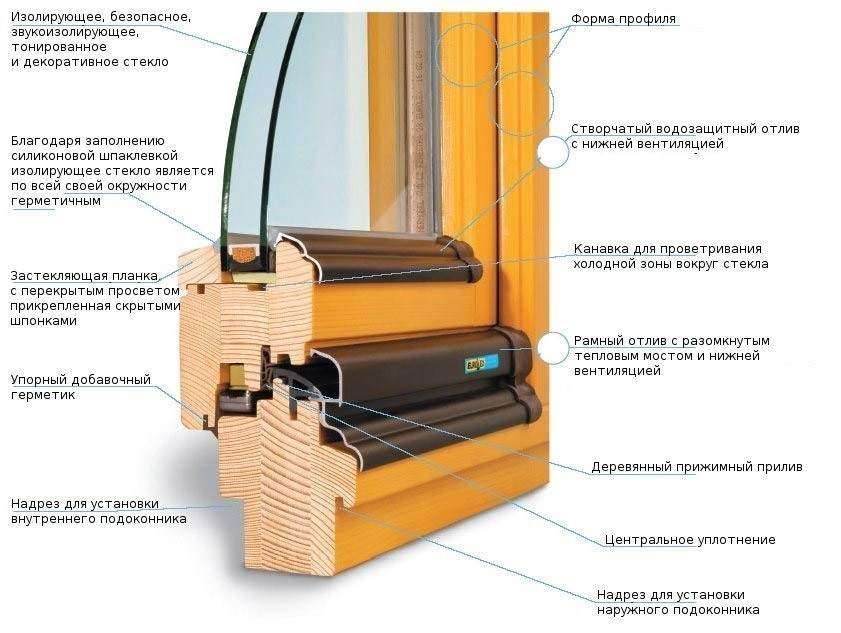

- Wood. Contrary to popular belief, it cannot be said that the time of using this material in the manufacture of window blocks has irrevocably passed. A small number of windows with a profile made of wood on the market is due to the complexity of their manufacture and high price. These are premium windows. Made from cedar, larch, pine, oak or teak, they will last at least 60 years. They are superior to PVC structures in terms of rigidity, but require regular processing: from time to time they need to be painted or varnished.

- Aluminum. Aluminum window profile can be found in office or industrial premises. Strongly inferior to other materials in terms of thermal insulation properties, window service life (15 years), fades over time. Therefore, more often aluminum is used for decorative window trim or in combination with polyvinyl chloride.

- The largest part of the market was won by windows with a PVC profile. Affordable price, excellent technical characteristics, durability, ease of installation and operation - all these factors influenced their popularity among the townsfolk. Everyone can choose from a variety of presented PVC window types the option that best suits him in terms of quality and price.

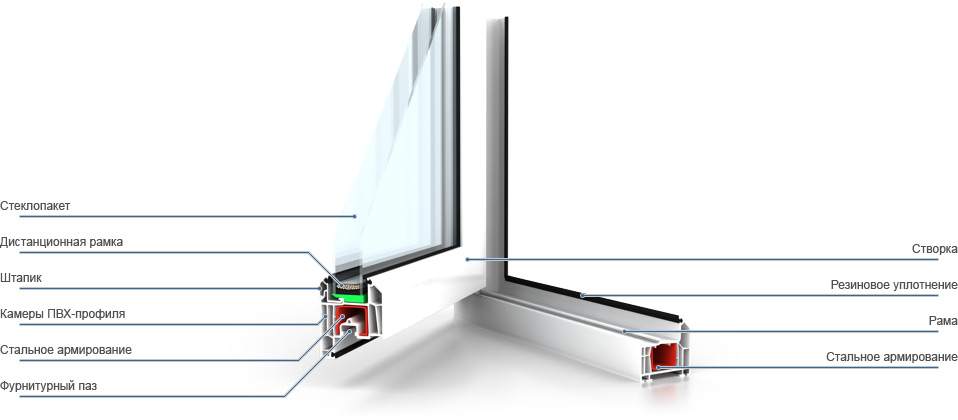

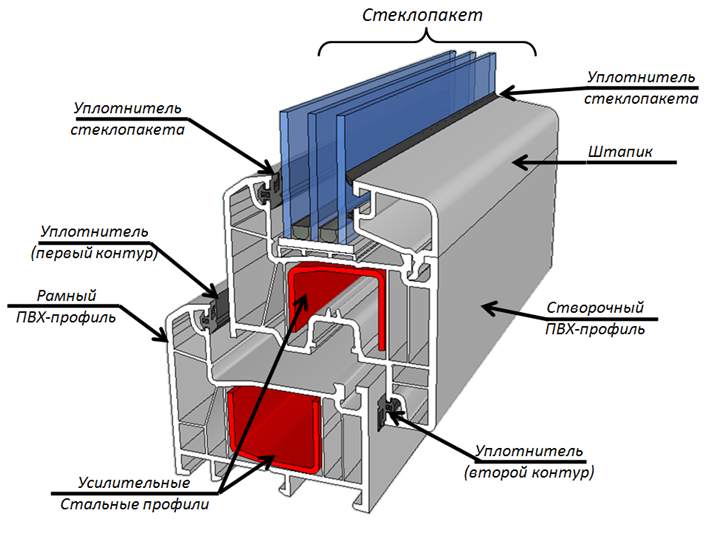

PVC profile design

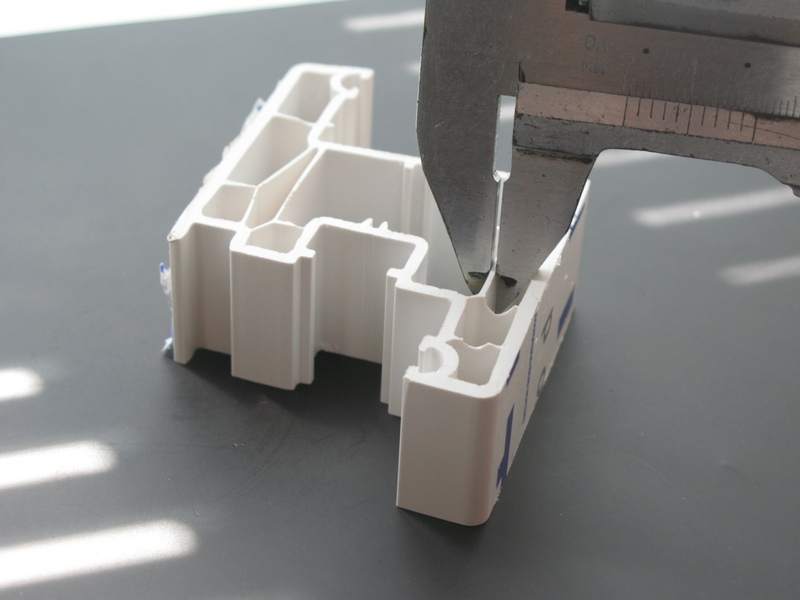

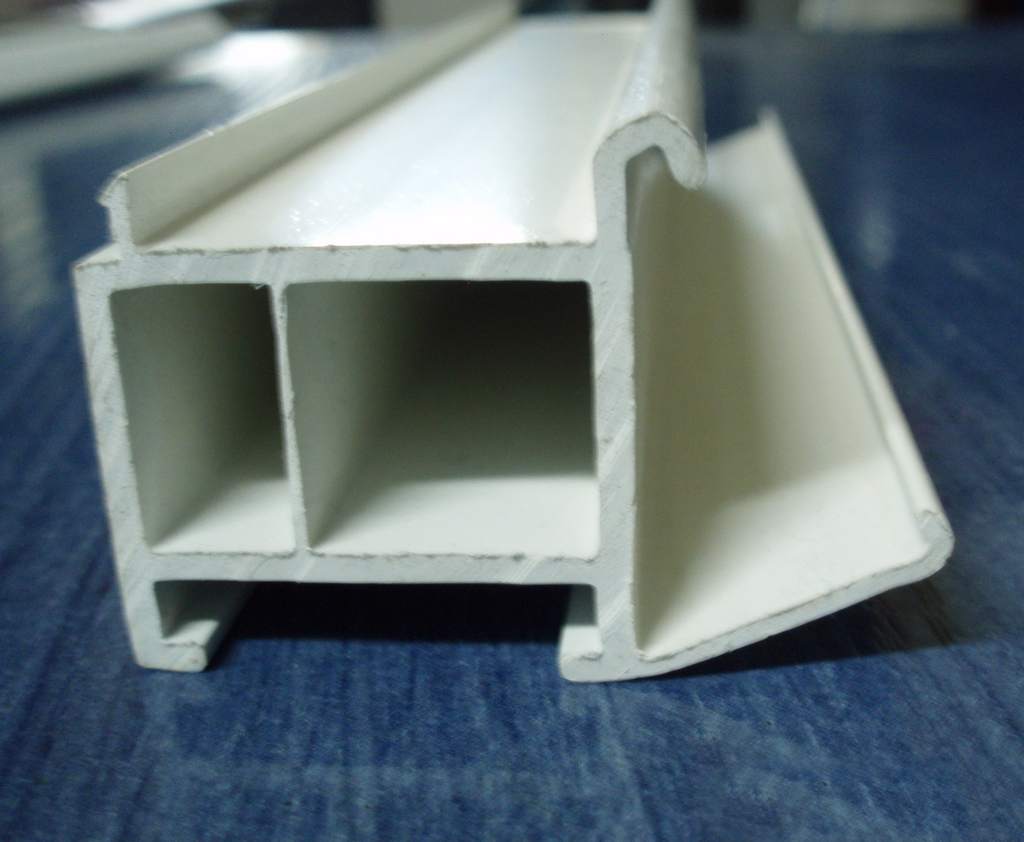

Inside, the PVC profile has special air cavities formed with the help of longitudinal partitions. Their number directly affects the thermal conductivity of the profile: the more chambers, the better the heat and sound insulation. Therefore, for cold climates, it is better to choose a window with a large number of air chambers. In different types of profile, they can be from 1 to 8. The greater the thickness of the structure, the more these cavities can be placed in it. So, in a profile with a thickness of 90 mm, there are usually 6 chambers, and in a structure with a thickness of 58 mm, no more than 3 are placed.

Profile classes

The wall thickness affects not only the thermal conductivity of the window block, but also the degree of its susceptibility to deformation. According to this parameter, the following types of profile are distinguished:

- Class A - the most reliable, provides the best thermal insulation. The thickness of its outer walls starts from 2.8 mm, internal - from 2.5. An ideal option, but at the same time the most expensive.

- Class B - inferior both in terms of thermal insulation and strength. The inner walls have a thickness of 2 mm, the outer - from 2.5 mm.

- Class C - does not have strict parameters. The cheapest and most “cold” and unreliable windows are made from such profiles. They are often installed in non-residential premises or in warm climates.

With the same number of air chambers, preference should be given to a wider profile, since a simple increase in the number of partitions, albeit slightly, will affect the thermal conductivity of the plastic window structure.

Core types

If the profile was made only from polyvinyl chloride, then it would not have the necessary rigidity. Therefore, its reinforcement is necessarily carried out, for which a steel core is used. Basically there are two varieties of this part:

- in the form of a square;

- in the shape of the letter P.

It is better to choose the first option, although it is more expensive. The square core will provide better strength and stiffness of the profile. It is required for windows of significant dimensions.

sealant

The quality of the seal is of great importance. It is better to give preference to a rubber seal. Retaining elasticity for at least five years, it will provide excellent tightness of the window block. You just need to remember to regularly care for the seal, for example, treat it with silicone grease.

accessories

You should also pay attention to the quality of fittings attached to the window profile.

- It must be durable and comfortable.

- Elements of fittings should ensure a snug fit of the frame to the profile in the closed form and ease of its transfer to other modes.

- You should also make sure that the fittings allow you to adjust the window when switching between winter-summer modes.

Why do you need a support profile?

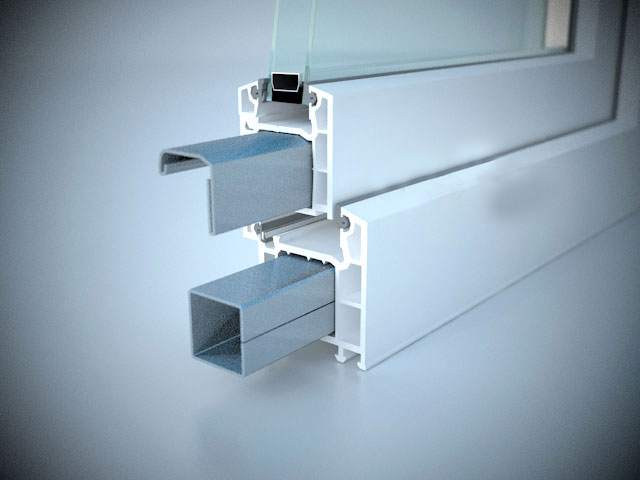

Often there is a situation when installation of plastic windows it is not possible to achieve the desired thermal insulation of the room. Even with a high-quality profile, the room can be blown through the gaps between the window block and the window sill. The support profile helps to solve this problem. It is often overlooked by window installers, but any professional will attest to the importance of installing this extra element.

The area between outer and inner window sill requires special attention when installing windows. In a strong wind, the air, colliding with the wall, begins to rise along its surface. The ebb, fixed on the window, blocks his way and drives a stream of air under the window sill. If a support profile has not been installed there, then this can lead to a draft in the room. Even the highest quality plastic windows will not save if this important detail is missed during their installation.

The stand profile is installed directly between the frame and the window sill. Its length must exactly match the length of the window.

It is better to choose a stand profile with a wall thickness of at least 2 mm and with at least two air chambers.

This additional profiled strip will not only increase the thermal insulation of the room. To it without any problems in the future, you can attach both window sills and drainage. Their installation directly on the window profile will require drilling holes for fastening, and this will negatively affect not only the strength of the structure, but also its heat-insulating properties. So, conscientious companies involved in the installation of plastic windows will definitely offer to install this additional element (if it is not included in the delivery set). Refusal in this case is not worth it.

Leading manufacturers of plastic windows

The pioneers in the production of plastic windows were the Germans. Their pedantry, precision and accuracy ensure the highest quality of products. Therefore, the German profile is considered the best, although it should be noted that most of the products manufactured by firms from Germany have long been produced outside of Germany. However, this did not affect the quality of plastic windows.

In the market of plastic windows, the following manufacturers can be distinguished:

- Rehau is a symbol of German quality. The company has been operating in the plastic window market for over 60 years. It is its engineers who set the direction for the development of the entire industry with their innovations. In production, only environmentally friendly materials are used; it is not for nothing that the windows of this particular company are recommended to be installed in medical institutions.Excellent sound and heat insulation, a wide range of models.

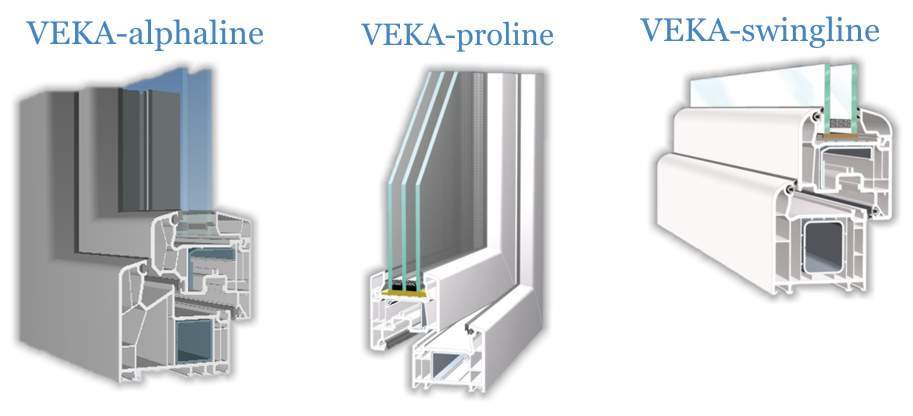

- VEKA products are perhaps the most famous in Russia, as they are produced on its territory using German technology. The windows made by this German giant are perfect for our climatic conditions. They are distinguished by excellent functionality and ease of maintenance. The company pays much attention to the use of the most environmentally friendly materials.

- KBE produces profiles operating at temperatures ranging from -50 to +50 ˚С. The production does not use such an element hazardous to health as lead. The profile width of this German company is from 58 to 70 mm. Excellent sound insulation and tightness. Both expensive elite models and more budget options are produced. The service life of KBE plastic windows is more than 50 years.

- Russian manufacturers of plastic windows are also present on the market. Despite their youth, Russian firms are not much inferior in product quality to well-known European brands. As a rule, they work according to foreign technologies, adapting their products to local climatic conditions. Of the Russian manufacturers, we can name such companies as Novotex and Proplex.

It should be remembered that the profiles of well-known companies are often forged by unscrupulous manufacturers. In this case, the buyer should be alerted by the low price. Many well-known companies use various labels that are almost impossible to fake. You can find out about them on the official website of the manufacturer.

A competent choice of a plastic window profile, taking into account the peculiarities of the location of the room, the local climate and other conditions, its competent installation and operation guarantee the comfort of your apartment for a long time.