Connection by electrofusion welding

For this method of connecting pipes, it is necessary to use shaped elements with electric spirals mounted inside. This coupling is put on the pipes, the spirals begin to heat up and melt the polyethylene, which at the same time is tightly soldered. Such a pipe connection is quite reliable and is used when installing segments with a diameter of less than 160 mm or when it is quite difficult to get to the junction. In this case, you need to take into account that the cross section of the joined pipes should not differ by more than 10%.

If you want to connect pipes in this way, you need to clean the edges of the pipes from dirt and align them. For the duration of the product, it is desirable to securely fix it using a positioner. After that, the two ends of the pipe are installed in the coupling and the welding machine is turned on. All data, such as soldering time and temperature, can usually be seen on the barcode of the part.

How pipes are welded using an electric coupling, see below:

Scope and characteristics of HDPE pipes

The material from which such pipes are made is dense high-quality polyethylene, thanks to which the products are quite strong and flexible. Unlike heavy metal pipes, HDPE pipes are endowed with a low weight, which makes it easy to install them yourself, without outside help. Cathodic coating, unlike the same metal products, these pipes also do not need. It is also nice that they do not require special maintenance. Let's look at their main advantages:

- Pipes are resistant to many chemical compounds and aggressive environments: acids, alkalis.

- Corrosion to products made of polyethylene does not threaten at all, and it is not necessary to isolate them.

- If the water inside the pipes freezes and begins to expand, they will not be damaged, since the material is strong enough and resistant to mechanical stress. The size of the pipes can increase by 5-7% of the original state, and then return to its original position without loss of properties.

- Excellent water hammer tolerance.

- They are not afraid of either rotting or bacteria and fungi that can affect different materials.

- Sufficiently elastic, which allows them to be used in seismically hazardous areas. The impressive thing is that they break when elongated six times!

- Relatively low cost.

- Light weight and convenient and cheap transportation, which will cost 2 or 3 times cheaper than transporting heavy metal pipes.

- Ease of operation, assembly and installation of pipes by yourself, all this can be done without the help of experts.

- The service life of HDPE pipes is more than 50 years.

- Polyethylene is a dielectric material, i.e. non-conductive electric current, which means that pipes made from it also do not conduct current.

- Unlike metal pipes, during operation, pipes do not accumulate silt and scale on the walls, and condensation rarely forms on their surface.

The only point to note is that the material begins to soften when the temperature reaches 80˚C. Therefore, it is not recommended to use pipes for hot water supply. But they found their application in such areas:

- sewerage device;

- cold water plumbing;

- protection of electrical high-voltage wires from water and other external factors.

There are two types of low pressure polyethylene pipes:

- Pressure pipes - for water systems and gas pipelines.

- Non-pressure pipes - for storm drains and sewerage devices.

If we talk about the wall thickness of HDPE pipes, then it can vary from 2 mm to 72 mm. Their diameter is also different - from 20 mm to 1200 mm.The size of the product is selected depending on where the pipes will be used and what their purpose is. If you need to provide water supply in the house or in the country, then the ideal option would be pipes whose cross section varies from 20 mm to 30 mm, and they can be connected using plastic or brass compression fittings. When you need to lay a sewer, then products with a diameter of 90 mm to 160 mm will be suitable pipes for you. It is desirable to fasten them with couplings, supplementing the sealing rings.

In order to properly install HDPE pipes, it is important to know how they need to be connected to each other. Depending on the diameter and size, three different methods are defined for how to connect pipes:

- Butt welding is an integral type of installation carried out using a special apparatus.

- Connection by electrofusion welding.

- Connection through fittings and flanges - a collapsible method of pipe installation.

Let's look at what each of the connection methods is, how it is done, and what this or that method is used for.

Plumbing assembly

Water supply from HDPE can be collected in two ways:

- With the help of compression fittings - in this case, no special equipment is required.

- With the help - for this you need a special soldering iron, which is used for mounting a polypropylene pipeline.

I must say that there are two more ways to connect this material - butt welding and using an electric coupling. However, they are not used for self-assembly, as they require special skills, so we will not consider them.

Assembly with compression fittings

The use of compression (collet) fittings is the most common way to install small diameter polyethylene pipes (up to 110 millimeters). In other words, when installing domestic water pipes, this particular assembly method is usually used.

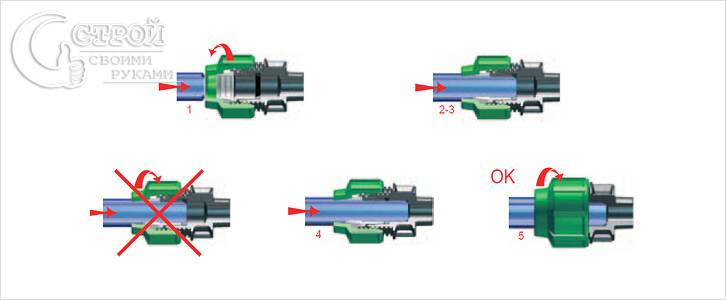

Instructions for or other fittings are as follows:

- First of all, you need to carefully cut the pipe so that the cut is perpendicular to its axis. Ideally, this work should be done with a special pipe cutter.

- After that, you need to eliminate burrs and other irregularities.

- Next, you need to chamfer a width of two to three millimeters from the edge to get a cone.

-

After that, the elements of the compression connection must be put on the pipe in this order:

- clamping nut;

- Clamping ring, which is also called a collet;

- retaining ring;

- And lastly, the sealing ring is put on the edge of the chamfer.

- Then the end of the pipe, which will be immersed in the fitting, must be lubricated with plumbing grease.

- Next, the pipe is inserted into the fitting pipe, after which the clamping nut is screwed on.

All other plumbing connections are installed in the same way. After starting up the water system, make sure that all connections are tight. If necessary, they should be slightly tightened.

Diffusion welding

HDPE plumbing using diffuse welding is assembled quite simply:

First of all, the device must be warmed up to operating temperature. To do this, you need to plug it into the outlet and wait until the green indicator lights up.

- Then, the parts to be joined are inserted into the heated nozzles. In this position, they must be held until the plastic melts. The exact time is indicated in the table that comes with the soldering iron.

- After that, the parts are pulled out of the nozzles and connected. In this position, without moving or turning, they must be held until the molten polyethylene solidifies.

According to this scheme, all elements of the pipeline are mounted. After completing the work, as in the previous case, you need to test the system.

Rating of types of water pipes

Galvanized

This is the oldest type of pipes, they are assembled with threaded connections, which must be sealed with special materials.To make such connections, you need some time to study and train. Galvanized pipes are not very pretty. They are overgrown with rust and salts from the inside. Their reliable service life does not exceed 25 years. Galvanized pipes are very dangerous to use with non-ferrous metal parts. With such a set of qualities, these pipes are not at all cheaper than more modern ones, and taking into account threading, they can be even more expensive. I would not recommend using galvanized pipes in plumbing.

metal-plastic

These pipes have a plastic inner layer, thanks to which their service life is more than twice that of galvanizing. Metal-plastic pipes have thin walls and, accordingly, a small outer diameter. Assembled with collets. This is not a very reliable type of connection, but quite simple, and even a beginner can master it. Practice has shown that over time, collet clamps can leak, and the pipe itself loses its elasticity, which makes repairs difficult. When installing such a pipe, space must be left for the thermal expansion of the pipe. Reliability strongly depends on its quality, and quality depends on the manufacturer. Collet connections are very expensive and have to be saved.

Polypropylene

Plumbing from such pipes is very reliable, it can be safely hidden behind wall cladding. Pipes are assembled only by soldering, which requires special but inexpensive equipment. The soldering process is very simple and reliable.

The pipes themselves and especially the fittings are quite cheap. Our country is one of the world's leading producers of polypropylene, and a wide range of domestic products of excellent quality can be found on the market.

Polypropylene pipes have thick walls (5 mm or more), which leads to a large outer diameter of the pipe. This quality does not allow hot water to cool quickly in them.

Polypropylene pipes elongate significantly when heated and can sag.

Contrary to the prevailing myth, such pipes also freeze and burst in the cold. They are for residential use only.

Copper

Such pipes can be assembled both on collets and by soldering. Assembly with collets is very difficult, because it requires both skill and equipment. Soldering requires only a gas torch, a metal brush, flux and solder. It is possible to learn how to solder in half an hour of work.

Copper pipes do not rust, have the smallest outer diameter of those considered, slightly elongate when heated, and do not create much noise. Water supply from such pipes is very reliable, it can work for more than 50 years.

Copper pipes for soldering are the undoubted favorite of our rating. In contrast to its exceptional merits, one can indicate a very high price for both the pipes themselves and the fittings.

Water with increased hardness or iron content reduces the reliability of the plumbing system, so it is advisable to use dirt filters

No type of pipe should be left with water in winter. It is a myth that some type of pipe does not crack and withstands a long and severe frost.

Continued .. Country water supply. How to choose a boiler?

Which pipes to choose for country water supply?, 4.0 out of 5 based on 1 rating

Installation of plumbing in the country

It is most advisable to use polyethylene pipes for low-pressure irrigation, with a diameter of 20.0 - 40.0 mm, with a wall thickness of up to 2.0 mm. For branch branches, products with a diameter of 25.0 mm will suffice. Such pipes fully cope with their task and will not require replacement for a long time. They are also able to withstand mechanical stress, even such as hitting garden equipment.

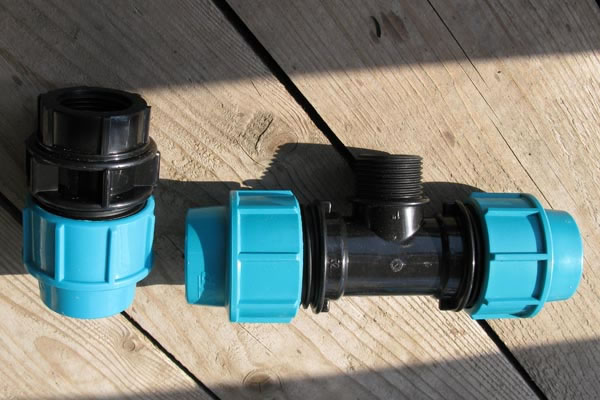

Compression fittings for connecting PE pipes

Laying your own garden water supply from polyethylene pipes is quite simple. From the tool it is necessary to prepare only an adjustable wrench.The connection of pipe products will be carried out using compression fittings, they are the most practical and effective for country conditions.

The laying of the pipeline is carried out in several stages:

- First, as with the installation of any other water supply system, a detailed laying diagram is drawn up, including the future irrigation system. It allows you to more accurately navigate the number of pipe products and compression fittings.

- Two methods are used for laying the pipeline:

- open on the ground. With this method, the installation and dismantling of PE pipes is greatly facilitated, but at the same time, the likelihood of product damage increases;

-

at shallow depths in the ground. In this case, the HDPE pipe for giving is more protected, and it will not be difficult to dismantle it.

Laying PE pipes on the ground

- The second method is preferable. The main HDPE pipe in the country is laid in the ground. In this case, you can not be afraid for its accidental damage.

- Branches can be laid on the ground, and even better mounted on special holders for more convenient connection to sprinklers.

When laying the pipeline, it is necessary to ensure a slight slope of the system in order to drain water from the pipes at the end of the season. To do this, it is enough to mount a conventional valve at the lowest point of the line.

- It is recommended to install valves at branch points. Then you can precisely control the water supply exactly to the right places of the summer cottage.

Buried piping

- Buried piping.

- The necessary pipe sections must be securely connected using compression fittings.

- For connection, the ends of the products must be cleaned of dirt and it is desirable to remove the end chamfer. Loosen the union nut of the fitting a couple of turns.

- On the pipe itself, mark the depth to which the coupling should enter the pipe.

- Applying a certain force, the fitting is inserted into the pipe and the union nut is tightened.

When tightening the fittings, the recommended tightening torque of the nut must be obtained. Otherwise, in case of insufficient tightening, the tightness of the connection is not guaranteed. If you apply more force than normal, then there is a chance of damaging the pipe.

It can be concluded that self-mounted country water supply from HDPE pipes is an effective way to provide water supply to a country house for domestic needs, as well as organize a practical and reliable watering system for a summer cottage, while you can significantly save money and time.

A simple scheme of water supply in the country

Advantages in working with polypropylene pipes.

With the advent of the possibility of installing water pipes using polypropylene products, steel pipes faded into the background. Polypropylene products are not threatened by rust, and their service life is almost 50 years. Polypropylene pipes in no way affect the chemical composition of water, and the installation of these pipes is quite simple.

What to take into account when choosing equipment for water supply and installation of this station.

Based on the daily volume of water consumption and on the initial conditions of an independent source, a water supply station is selected. The decision on the installation site of the equipment is influenced by the distance from the house to the well or well. Installation of the station is also possible in the building itself, if the distance is small. With a considerable distance of the water source from the house, it will be necessary to install the station on the street, having previously insulated the equipment, in order to maintain functionality even in cold weather.

Why is it necessary to install filters and a scheme to build a water supply system in the country.

The filters installed in the well not only protect the permanent water supply from early wear, but also deeply clean the water entering the house through the pipeline.In addition, the water becomes drinkable.

As soon as the filters are installed, they begin to check at the points of their connection. After that, the entire system is checked. If the checks are successfully passed, then you can use this water supply on an ongoing basis.

To provide year-round water supply to your home, a simple plumbing structure is also suitable. This is the best option with minimal investment. The bottom line is that when the operation of the water supply system takes place during the cold season, through a small slot located in the reserve drain, the water that enters the pit is absorbed into the soil. Thanks to this simple combination, water in cold weather is protected from freezing in the pipeline. In summer, the winter valve should simply be kept open.

This scheme of the structure of the water supply system allows you to supply water to the country house throughout the year, but there is one drawback - there will always be moisture in the pit.

We will be glad if, thanks to this article, you learned how to independently install a water supply system in the country. In the case when you do not want to do this or are not sure that you will be satisfied with the results obtained, you can always turn to specialists for help. In any case, the installation of a permanent water supply will ensure the availability of water in your country house for several decades.

Choosing a material

As already mentioned, plumbing and sewerage in the country is most often mounted from what is at hand.

A study of the existing sewer facilities made it possible to determine the main types of pipes used in summer cottage construction:

Steel pipes for sewerage

-

-

- Steel pipes - such material often remains after the installation of other communications or building structures, it can be bought at scrap metal collection points at a residual value. But, before you conduct sewerage in the country from such pipes, you should also familiarize yourself with the shortcomings of this material.

- Firstly, finding a material of a suitable diameter is quite difficult.

- Secondly, the installation of a line from such pipes requires welding, which leads to the need to hire professional performers.

- Thirdly, steel pipes are largely susceptible to corrosion, a significant layer of various deposits forms on their inner surface, so such a line often has to be cleaned.

That is why it is worth using steel pipes only if you have an excess of this material and you do not know where to use it.

- In some cases, when deciding which pipes to use in the country, they stop at asbestos materials. Asbestos-cement pipes, in principle, withstand heavy loads, therefore, they can be used when laying external lines; they should not be used for intra-house networks. Such pipes are resistant to aggressive environments, do not give in to corrosion. The disadvantages include the significant weight of the material, the complexity of installation and the tendency to "overgrowth".

- Steel pipes - such material often remains after the installation of other communications or building structures, it can be bought at scrap metal collection points at a residual value. But, before you conduct sewerage in the country from such pipes, you should also familiarize yourself with the shortcomings of this material.

-

Sewerage from cast iron pipes

-

-

- Traditionally, the installation of pipes in the country (for sewerage) was carried out using cast iron. Such pipes perfectly tolerate the effects of groundwater, they are more resistant to corrosion (compared to steel), and are highly durable. To reduce flow resistance, such pipes can be coated with bituminous compounds, due to which the amount of deposits on the inner walls is significantly reduced. The disadvantages of cast-iron pipes are also traditional - heavy weight, complex installation (the need for chasing), in addition, cast iron is difficult to process, so cutting it can be significantly difficult.

- PVC sewer pipes are considered the best option today.The bell-shaped construction with the use of rubber seals makes installation very simple, even a person who does not have construction skills can handle it. Working with this material will allow you not to think about how to lay pipes in the country under the sewer. Plastic is easy to cut, and the presence of a variety of fittings allows you to mount a line even of a complex configuration. PVC does not rot, is not subject to corrosion, the service life of such pipes is practically unlimited (subject to the installation technology). Another advantage of plastic is its low flow resistance, which negates the amount of deposits inside the pipeline.

-

If we talk about the cost of the material, then plastic pipes are rightfully considered one of the most profitable options, while there is a real opportunity to save on installation, which can be done independently.

Which pipes to choose, of course, you decide.

Which pipes are better

The water supply system for giving can be made of copper. The main advantage of copper structures is their high service life of 70 years. At the same time, copper is expensive. Not every person can afford such a water supply.

You can also choose polypropylene pipes for summer cottages. Their service life is more than half a century. Their cost is quite democratic. A universal option for water supply in the country are stainless steel structures. Their service life is quite long, they can be used for cold and hot water supply systems. The downside, again, is the high cost.

Metal pipes have a long service life. However, they are rarely used in the arrangement of a private house due to a number of disadvantages, and in particular:

- risk of corrosion;

- Risk of deposits;

- Installation will require a welding machine;

- Insufficient level of environmental friendliness.

A worthy alternative for arranging water supply in the country are plastic pipes. Consider their advantages:

- Resistance to chemicals;

- Resistance to corrosion;

- Resistant to deposits;

- Service life more than half a century;

- When transporting hot water, practically no heat is lost;

- Ease of installation.

Plastic pipes are just a common name for many groups of these structures. Which system is better to choose? It all depends on your needs and operating conditions of the system. You can see all the variety of these designs in the photo.

PVC pipes are recommended to be used for organizing open wiring, as they differ in the required rigidity, as well as UV resistance. During their installation, gluing technology is used.

Polypropylene pipes are universal. They can be used to transport both cold and hot water. With their help, you can also organize a heating system and underground sewage. Their advantages are the same as those of structures made of cross-linked polyethylene. At the same time, the price of the product is lower. During installation, welding equipment is used. It should be borne in mind that when organizing the transportation of hot water, structures with metal or fiberglass reinforcement are used.

Metal-plastic pipes differ in their structure: outer and outer polymer layer. The middle layer is made of aluminium. To organize the transportation of cold water, designs of blue or light blue are used. If you want to equip a hot water system, you should choose white structures. Consider the advantages of metal-plastic structures:

Corrosion resistance;

- Neat appearance;

- Ease;

- Plastic;

- Long service life;

- Ease of installation.

You can also choose PVC pipes. For the arrangement of cold water transportation, PVC-marked structures are designed, hot - CPVC.

Additional Recommendations

You can see the entire range of designs for giving in the photo.In addition, we have a video on our website with instructions for choosing the right pipes. For the arrangement of the water supply, designs from Western brands are usually selected. Manufacturers from Germany, the Czech Republic, Austria enjoy confidence. When buying, be sure to check the certificate for the product.

Connecting pipes with fittings

The easiest and most affordable way to connect HDPE pipes is to connect using fittings. Usually, pipes for water supply and sewerage in city apartments and houses are connected in this way. Usually the diameter of such pipes is small - 110 mm or less.

If we talk about the previous two methods, then their disadvantage can be called the fact that it is no longer possible to disassemble the welded pipes. They can only be cut. But the connection on the fittings allows you to disassemble the pipe system at any time and replace some parts. Moreover, it is possible to do this not once, but as much as you need.

It is also important that there is a wide range of connection elements on the market with different diameters, and this will allow you to collect various necessary branches and wiring in the pipeline system.

To assemble the pipeline using fittings, you need to purchase them at the store. They can be plastic or brass compression type. In the same store, you need to take socket plugs with a flexible seal. Now everything is step by step:

- First you need to cut the pipes to the right size, just like when welding. In this case, the ends must be cut clearly perpendicular to the pipe body.

- Now loosen the union nut on the fitting with a few turns.

- Insert the pipe into the fitting until it stops. It should enter the reinforced rubber seal.

- Then put on the collet, elastic ring and tighten the nut. Small parts can be scrolled by hand, and when you need to connect pipes with a large cross section, it is better to use a wrench.

- As always, after installation, it is imperative to check the tightness of the connection by filling the pipe with water.

This is how you can easily and effortlessly install HDPE pipes by connecting them through fittings.