Surface treatment after grinding

After surface treatment, it is impossible to proceed to further finishing immediately. First you need to remove all construction dust that has settled on the walls and ceiling during the grinding process. To do this, you can use a tool such as a construction vacuum cleaner.

The second method of cleaning surfaces from dust does not require the use of a special tool, so it is the most acceptable in many cases, although it is much more laborious. The methods used are presented as follows:

- Use a wide brush with soft bristles to brush off as much dust as possible. You can use a regular broom. The main thing is not to press hard, as the putty is a very plastic building material.

- After that, a secondary cleaning method is performed. Soak a cloth in cool water and wring it out well. Run the cloth along the walls and ceiling. Textiles should not shed, otherwise traces and stains will remain, which may later show through the paper layer or paint.

- You need to wait until the putty is completely dry, and only then proceed with further finishing. In order not to blur the building mixture, the fabric should be slightly damp.

In any case, dust must be removed completely to avoid corrosion of secondary building materials. You should not be controlled solely with a rag, since it is almost impossible to remove dust in this way.

High-quality grinding and further processing before finishing is the key to a successful repair. The surface to be sanded can be several types of sandpaper or mesh.

Grinding after puttying the walls must be done, as this solution will be an ideal option for a good basis for repair work. Even if the alignment was initially performed poorly, then with the help of further finishing, this defect can be visually compensated. To carry out such a procedure, that is, to wipe the putty, is possible without the involvement of specialists - self-processing is quite suitable.

Variety of finishing mixes

There are a large number of putties on the construction market, with which you can perform a high-quality finish.

Types of putty for leveling the ceiling:

- Starting. The mixture is used to level the surface.

- Finishing. It is used to give the ceiling color and smoothness.

- Universal. It is used both for alignment and at the final stage.

- Specific. It is used only for certain types of rough work.

Depending on the composition of the putty, there are cement-lime, sand-cement, gypsum and polymer.

- Cement-lime. Such putty is used in rooms where high humidity is constantly kept. Due to the fact that the product is inelastic, small cracks may appear on the surface after it has completely dried. Therefore, on such a ceiling, it will be necessary to re-finish in order to cover up defects.

- Sand-cement. It is used for ceilings that have small differences. Mixtures of this type have good water resistance.

- Gypsum. The tool is intended for the final finishing of the ceiling. The peculiarity of this putty is that it does not shrink like other types.

- Polymer. High quality putty, with which you can quickly and easily achieve perfect evenness. The disadvantage of the tool is the high price.

On sale there is a dry and ready-made composition. Each of them has its pros and cons. Dry mixes are easy to transport, but they need to be prepared before application. To do this, you need to stir the powder with water according to the indicated proportion on the label.

How wall sanding is done

How to sand the walls after puttying so that the surface becomes perfectly flat? It is important to know the technology and methods of how to sand the walls after puttying. But first you need to decide on some characteristics of the walls in order to choose how to grind the putty

Putty grouting begins with the choice of tool. If the question arose of which sandpaper to work with, then you should decide on the degree of processing: primary grinding with grain 60, and the last - 120. How to sand the walls of a room with a large area? A machine is best suited for this, although corners, recesses and depressions will still have to be processed manually with sandpaper.

Sanding the walls after puttying is carried out in accordance with the following instructions:

1. First, the most visible irregularities and defects on the surface of the walls are highlighted. What kind of technique is needed for this? A powerful spotlight or lantern that is installed as close as possible to the surface of the wall. Thus, shadows appear on it from the protrusions or depressions of the putty. These places should be circled with a pencil.

2. How to grind putty correctly? It is better to start cleaning the putty from the corner. You need to move from top to bottom, while occupying a strip of about one meter. After processing the designated strip, proceed to the next one. The movements should be spiral.

3. Sanding the putty on the walls should be done carefully, without much effort. In this case, it is better to use sandpaper. You can not press hard on the canvas so that holes do not appear in the putty. And you do not need to align the recesses with the general level.

4. Cleaning the finishing putty consists in the same steps as the starting one

Polishing in this case is done carefully, but with extreme care so as not to damage the putty layer. It is better to sand the finishing putty with sandpaper

For sanding walls, you do not need to have experience in the construction industry. It is enough to adhere to a certain technology that is very easy to learn and apply.

Why you need to sand the walls

All the procedures that we did before: plastering, puttying - these are all procedures for leveling the wall. Plaster - rough, putty - thin. And now the process of sanding or polishing the walls begins.

Even after applying a thin layer of putty, in any case, small bumps remain on the wall, tubercles, formed mainly by the sharp ends of the spatula, which remain when we disperse the putty and connect one part of the putty wall to another.

That is why when puttying it is better to use a large spatula so that the wall leveling area is maximized. But the joints, no matter how hard we try, are still traceable. Therefore, after you puttied the wall, you need to let it dry (at least a day) and you can start sanding the walls.

Do not try to accidentally prime the wall after puttying! Grinding begins immediately after puttying!

How to level the ceiling with plaster

How to level and paint the ceiling with your own hands.

The application of plaster is a variant of the "wet" finish of the ceilings. The surface of the ceiling is carefully cleaned and coated with a primer. For better adhesion of the plaster to the ceiling surface and to avoid further cracking of the plaster coating, a reinforcing mesh is used, which is attached with an adhesive or using special brackets.

Next, a layer of plaster no more than 15 mm thick is applied to the ceiling.

In places where a thicker layer is needed, the plaster is “combed”, the coating is allowed to dry, the surface is primed again and the next layer of plaster is applied. After the plaster has dried, the ceiling is puttied. A video on how to level the ceiling in this way will help visualize the entire finishing process.

Process details

There is nothing fundamentally difficult in grinding.This is a simple, but laborious and long process. Your main task is not to rush anywhere and not try to get an excellent result immediately, after the first pass along the plane with the tool. There is a time for everything - some areas will definitely have to be processed several times in order to achieve perfect smoothness.

It is important to note that before grinding, it is not necessary to treat the walls with a primer. It is only necessary to allow the applied layer of putty mixture to dry well.

Do not start work before the entire wall is completely dry. Otherwise, the result of your mistake will be the need to re-putty everything.

You need to start working from the top edge of the wall, gradually going down. At a time, about a meter of surface is passed - you can make the area less wide if you feel more comfortable. It is not worth taking a wide strip right away, as this leads to errors and, as a result, irregularities.

First, for grinding the walls for painting, a coarse sandpaper is used, which has a smaller number in the designation of the grain size. It needs to completely process the entire wall area, and only then switch to a finer grain. So you get a uniformly polished plane, without sharp transitions and waves.

Notches, depressions and other similar defects should not be tried to level with the rest of the surface, rubbing the areas around them. This will lead to abrasion of the putty layer. It is better to putty these areas again after the main grinding work is completed and re-polish the plane after the applied mixture has dried.

After the surface treatment is completely completed, the remaining building dust must always be removed. Even when working with a power tool with the possibility of suction of the resulting dust, it remains in small quantities on the processed surface. Subsequently, if it is not removed, the dust will greatly affect the quality of staining for the worse.

Grinding process

The sanding process is much simpler than, for example, puttying or plastering. All you need to do is to take a bar, fasten a piece of sandpaper or sanding mesh to it with special clamps and start working. This is what the sanding bars look like, ready to go. On the left is a bar with sandpaper installed, on the right - with a sanding grid installed.

It can be seen from the figure that the size of a piece of sandpaper or mesh should be longer than the plane of the bar itself, exactly as long as it is possible to fix the sandpaper or mesh with the help of bar clamps on both sides.

Remember, wall sanding is a very dusty job! Be sure, before you start working, read the recommendations in the article What are the means of protection against construction dust.

When you have installed the sanding material on the block and have taken all protective measures against building dust, you can start working. It is best to start sanding the wall from the corner and go towards the other corner. I always sand the walls from top to bottom in small strips (about a meter wide). We polished a strip a meter wide from top to bottom, moved on to the next one.

How to sand walls? Take the bar in your hand and start with a little pressure to pass it along the puttied wall. Movements: up-down, left-right. Most importantly, make sure that in the place where the wall is already smooth, you do not need to continue rubbing for a long time. You must remember that if you rub for a long time, then you can thus wipe off all the putty, which of course is not included in the plans. We made sure that the section of the wall was smooth, almost polished - we went further.

It happens that you come to a section of the wall where for some reason a deep hole has formed. In this case, you do not need to rub hard and long around the hole to grind the putty around the hole to its bottom. Leave this small area alone.Then, when you sand everything and prime the wall again, you just take the rubber spatula, which I mentioned in the article How to putty walls in an apartment, and once again putty this hole with a thin layer of putty flush with the wall.

Of course, I must tell you that wall sanding can be done faster if you use a special grinder.

When you are done, pick up the building level and attach it to the wall. At any position of the level, its plane should fit snugly against the wall along its entire length. There should be no gaps. If, nevertheless, gaps are formed, then you put too much putty in some places. Identify these places and try to grind them off with the same bar.

That's all. In this article, we learned how and with what to grind the walls. However, do not rush to paint the wall or glue the wallpaper. After grinding, the final operations with the wall remained. Did you have sanding problems? How often did you change the sanding on the bar?

wall polishing technology

Sanding the walls after puttying occurs in several stages. First, it is polished with a coarse-grained sandpaper, and then with a fine-grained one. For the draft layer, paper with a grain size of P100-P120 is suitable. A coarser one should not be used, as it can ruin the coating. The finish layer can be sanded with P150 grit paper for a flat wall. If there are still many defects left, then use P120. Finishing grouting occurs using sandpaper under the number P220. If it leaves traces, then use P240.

If there are still many defects left, then use P120. Finishing grouting occurs using sandpaper under the number P220. If it leaves traces, then use P240.

Before you start sanding, you need to allow the putty to dry completely. The process sometimes takes several days. Manufacturers indicate detailed instructions on the packaging. The dried putty changes its color, there are no wet spots on it.

Set the lighting, it is better to have several light sources to illuminate the surface from different angles. Too large flaws can be removed with a spatula, such as bumps and protrusions. Cut off all their flaws. Hold the spatula at an angle and apply a little pressure to the desired area.

When you go shopping, it is best to take several grit options for emery. Do not sand a large area at once, first try walking on an inconspicuous area and see if it leaves scratches. If there are any, then it is better to take a tool with a large number. Depending on the facing coating, the grain size is also selected. So under the wallpaper, small scratches are not terrible. But painting requires smoothness.

Work on a small area, and after grouting it, proceed to the next. In the process, you do not need to press hard on the beam, apply pressure with a small force. When rubbing the area, do not overdo it, so you can erase much more than you need. Lighting should fall exactly on the area that you overwrite.

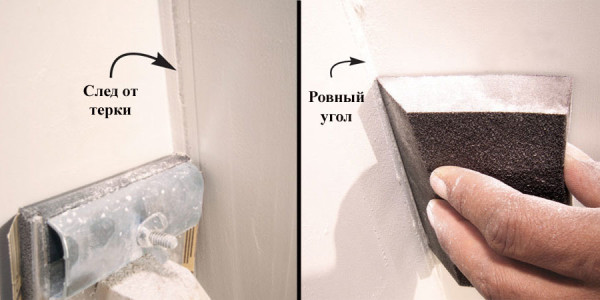

If you managed to do everything right, then move on. If you find large depressions, do not sand them. After finishing, they will need to be puttied again. When the main surface is ready, work is done in the corners. To do this, use a special sponge. First process one corner from top to bottom, and then the second. No need to rub both at the same time.

Take care of the lighting. Lamps should shine through the area from several sides for a better result. After grouting the main surface, start working with hard-to-reach places. If the bar does not fit, then you can simply wrap the sandpaper on your finger and work in this way.

In addition to the manual method, there is also a mechanical one. It is done with a grinder. So the work can be done much faster and its quality will be noticeably better. The machine is quite heavy, but the whole process can be done in one go.

Grinding mechanically is also done in a circular motion. It is not necessary to press hard on the tool. After you have walked all over the wall, look at the result and, if necessary, repeat the process in the desired areas. In hard-to-reach places, it is advised to use the manual method.

How to sand the walls after puttying

The first step is to get the right tools and supplies. You will need:

- Several varieties of abrasive mesh or sandpaper.

- Sanding bar.

- Sanding sponge (used for hard-to-reach places).

- Ladder.

- Good lighting: spotlight or pendant lamp.

- Construction spatula small size.

- Personal protective equipment: respirator, goggles, headgear.

Experts recommend sanding the walls after puttying them, before painting the surface or before wallpapering. Often grinding is carried out in other types of construction work. The grinding process is relatively simple, but quite laborious and dusty. How to sand the walls after puttying? For manual grinding, you can use sandpaper or a special abrasive mesh. The choice of material depends on the personal preferences of the master.

- Abrasive (grinding) mesh for putty - its advantage lies in the perforated structure. All construction dust will pass through the holes, so it does not clog as much as ordinary sandpaper when working. It is necessary to change the mesh in the course of wear, which can be determined by its appearance: if it starts to tear or you feel that the grinding process is no longer as effective, then it should be replaced. the size of the bars, so you just have to install it and get to work. But remember that the bars are also different, so when purchasing a mesh, consider this factor. The disadvantage of the sanding mesh is a higher price than sandpaper.

- Sandpaper for puttying - its main drawback is that during operation it will constantly clog with building dust, so it will have to be changed much more often than a mesh. You can buy sandpaper in a variety of ways: ready-made pieces, small rollers or large rolls. If you decide to stick with sandpaper in rolls, then you need to decide how you will cut it, taking into account the size of the bar, in order to get a minimum of waste. Of course, you can buy already cut pieces, but such a purchase will cost much more.

In addition, sandpaper has such a thing as graininess, which is indicated by a numbered marking. The choice of grain causes some difficulties for inexperienced craftsmen. The larger the serial number of the sanding belt, the higher its grain size (the number of grains per square centimeter), and vice versa. For example, coarse-grained tapes include tapes in the following range: from P20 to P220, fine-grained - sandpaper marked from P240 to P2500.

Sanding the walls after puttying is performed in two stages. Here you need to remember that the first grinding is done with a coarse-grained emery, and the final grinding is done with a fine-grained one. To carry out repair work in the apartment, sandpaper with a grain size of P80–P280 is mainly used. Not so often (for "jewelry" processing) smaller abrasives can be used - P320-P360. After treating the wall surface with a starting putty, it is recommended to polish it with a coarse sanding P100–P180. Sometimes emery marked P80 is used for primary processing, but this is too rough material and, for example, it is not suitable for painting. After processing the walls with a finishing putty, the surface is polished with fine-grained sandpaper P220-P280.

Preparatory work

Before leveling any ceiling, it is necessary to carry out preparatory work on the surface. To do this, remove all the old plaster with a spatula. Then you need to wash off the remaining chalk with water.

To quickly cope with the rough work, before starting to remove the plaster, it is worth sharpening your spatula.

To remove water-based paint from the ceiling, you can use a solution with iodine. In 10 liters of water, you need to stir one bottle of this substance. The resulting liquid must be well impregnated with the ceiling. To do this, it is better to use a roller or a wide brush. After complete cleaning of the surface, it is necessary to start sealing the interpanel seams.

Sewing sequence:

- The space must be filled with mounting foam and left to dry completely.

- Excess material must be cut off with a construction knife.

- Lubricate the seams well with a primer solution.

- Seal the recesses between the panels with the help of "Rotmand".

- Lay a layer of sickle mesh on top of the mixture.

In order for the putty to fit and hold well, the ceiling in the apartment must be covered with a layer of primer

When choosing a liquid, you need to pay attention to the type of surface and the level of humidity in the room. For the bathroom and kitchen, it is worth buying a primer with waterproofing

Useful information: "How to putty the ceiling yourself"

Wet floor leveling

Well, let's evaluate the pros and cons of such a solution. Let's go in reverse order and first talk about the disadvantages of the wet ceiling leveling method. They exist, and a lot of them.

The work of stretching the ceiling with plaster is quite messy. You must be prepared for the fact that for some time the apartment will be practically uninhabitable. And ahead of you is waiting for a big general cleaning.

In addition, this process is quite laborious and time-consuming. If stretch ceiling you will be mounted in a few hours, then in this case you will have to stock up on considerable patience.

The more irregularities and drops, the more expensive the ceiling will cost, as the layer thickness increases. Accordingly, the consumption of building material increases.

So why, having a number of disadvantages, has the wet method of leveling the ceiling still not sunk into oblivion?

Everything is simple.

Firstly, the ceiling drops only to the required minimum.

As we have already noted, for some it is very important

And secondly, it has good strength. For example, you can safely attach a built-in wardrobe to it. And it is not possible to spoil such a ceiling, if it is made in compliance with all technologies.

This concludes our short review of how to level the ceiling.Which option do you lean more towards? And why?

The house is a cozy family hearth where you want to return every day. Today, the demands of modern residents regarding the interior decoration of apartments and houses have increased markedly, but one common problem of many residential premises remains - uneven ceilings. In this regard, there are several proven tips from experienced craftsmen on how to level the ceiling with your own hands.

What to be guided by when choosing a bar and grinding material sandpaper, mesh

There is no iron recommendation. Someone uses a sanding grid, someone sandpaper.

Grinding mesh

The advantage of the sanding mesh is that it does not get clogged with putty dust during operation. The mesh itself is perforated and all ground putty will pass through the mesh. It must be changed during normal wear and tear, which is determined by the appearance of the used mesh. If the mesh is torn in places or you already feel that grinding is not going as efficiently, change the mesh to a new one.

Usually the mesh is sold in ready-made pieces right to the size of the bar and you just need to install it on the bar and work. But, you need to remember that the size of the bars is also different, as shown in the picture. Therefore, taking the grid, immediately pick up the bar for its size. Mesh is more expensive than sandpaper.

Sandpaper

Sandpaper during operation will become clogged with ground dust and the sandpaper will have to be changed more often than the mesh. You need to be aware that sandpaper, although cheaper than mesh, is also not a cheap material. It is sold in completely different versions: large rolls, small rollers, rectangular pieces.

If you decide to sand with sandpaper, then you need to figure out how you will cut it, taking into account the size of the bar, so that there is as little waste as possible. Of course, you can refuse to cut the sandpaper, and buy cut pieces directly ready for the bars, but it will be more expensive! There is the concept of sandpaper graininess (paper with different grains).

In order not to blow your mind on this topic, buy paper with a grain of 60, 80 and 100 in a small amount in the store and try to work with it. There is no exact recommendation on which grain to take. But it’s better not to take less than 60 for sure, because it will be a very rough sandpaper. More than 100 is also not very good, because it will be very clogged with dust during processing and it will have to be changed very often.

There is one more recommendation. If you have sandpaper with suitable grit from old stocks, then by all means use it. No need to run to the store for a grinding mesh.

IMPORTANT! The walls that you will be sanding usually go further either for wallpapering or for painting. In the case of painting, the wall must be absolutely smooth, I would even say polished.

In this case, the craftsmen grind the wall 2 times. The first time, for example, with sandpaper 60, in order to remove obvious large frozen pieces of putty, and the second time they take even finer sandpaper, for example, with a grain of 120, and already polish the wall with it. But in the case of wallpaper, this is clearly a redundant operation. For wallpaper, it is enough to go through the wall once.

Ceiling grinding rules

How to sand the ceiling after puttying correctly, what tools and methods should be used for this? The ceiling is polished using almost the same technology as the walls. To perform the work, sandpaper should be prepared. An abrasive mesh may also be useful.

The ceiling is usually rubbed with the help of a tool such as a grinder. Sometimes the procedure is done manually. How to sand on the ceiling:

Sandpaper for puttying the ceiling is the same as for puttying the walls. First, with a grain of 60, and as a polishing tool, sandpaper - 120. If you use the surface for wallpaper, then grinding is done carefully and fully.

It is necessary to produce a backlight that will highlight all the defects, in relation to which the skin will be produced. The grater is carried out along a dedicated strip from one corner to another.

Secondary putty should be disposed of in the same way. The choice of tool is the same as for the first layer of putty surface.

After that, the ceiling is primed and treated with antifungal agents.

It does not matter whether the ceiling will be painted or wallpapered in the future.

To process the corners between the walls and the ceiling, a tool such as a round grinding block is used. We use this technology for overwriting protrusions and curly objects.

In any case, the grout base should be sandpaper or graters in the form of a sanding grid. If it is necessary to paint the ceiling, it is necessary to process it with the moments of puttying.

How to sand the walls after puttying

Sandpaper or sanding mesh is the easiest option. The grid is much longer clogged with dust, which means it will last longer. But it's harder to find. Sandpaper costs little and is sold everywhere. In addition to grinding tools, you will need others.

- Bright lamp. With its help, you can identify wall defects. Cast shadows will indicate flaws. The luminaire must be mobile so that it can be installed anywhere and moved back and forth;

- Stepladder or table to reach the top. It is more convenient to work on the table, since you can move freely on it, and the stepladder will have to be rearranged constantly;

- Protection. Sanding is a very messy process, so take care of special clothing. Wear goggles to protect your eyes. And to close the airways, use a respirator.

Features of leveling ceilings with plaster

Plaster is well suited for leveling differences of no more than 50 mm. The technology is used for preliminary preparation of surfaces, but can also be used as a decorative finish.

Plastering is ideal for a standard living space with low ceilings.

Unlike suspended structures, this finish does not “steal” space. In addition, this material is durable and environmentally friendly. After leveling, the surface can be covered with a finishing decorative layer of plaster, wallpaper or slabs.

Before starting the repair, the room is vacated, the floor is covered with a film. Finishing work begins with a thorough cleaning of the ceiling. First, the old coating layer is removed from the surface, if necessary, the base is washed.

To carry out the work it is necessary to prepare:

- rule (for beacon alignment)

- container for mixing solution

- plaster spatula

- putty knife

- grater and half grater

- rubber sponge

- electric drill with metal and mixing nozzle

If there is high humidity in the room, due to which mold forms, it is better to treat the ceiling with a special composition, for example, Homeenpoisto from Tikkurila, before starting repairs.

For priming work on concrete, Knauf "Betokontakt" is used, which improves adhesion to the treated surface of the plaster layer. To reduce the likelihood of peeling and cracking of the coating, the primed ceiling is reinforced with a reinforced mesh.

For repairs, it is better to purchase materials from one manufacturer, this will allow you to get a durable coating without peeling.

The composition necessary for leveling the plaster is prepared from a dry mixture, gradually adding water and stirring thoroughly. The solution should have a consistency like thick sour cream.

The easiest way to level the ceiling qualitatively is to install beacons.

This is especially true for surfaces with significant curvature. Beacons are installed at a distance of half a meter from each other. To check the deviation from the horizon, you need to attach the rule to the surface of the ceiling.

To begin with, a wall is marked with a laser level, then the opposite points are connected with a fishing line, which will serve as a guide. To put a mark, the plaster mortar is thrown onto the ceiling with a wide spatula, after which it is leveled with a rule.

The stretched fishing line should cross the lighthouse in the center. It is necessary to wait 12 hours for the solution on which the beacons are held to dry. After that, you can start.

The solution is thrown onto the area between the beacons, distributing the mixture using the rule. After the plaster has set, the surface is washed with a damp sponge and smoothed with a facade spatula.

When the site is completely processed, the marking is removed, and the resulting crack is sealed with putty. After the leveling layer dries, it is once again treated with a primer.

Plastering the ceiling is a long process, the time for a full cycle is sometimes up to three weeks. If wallpaper or tiles act as a decorative ceiling covering, it is better to wait a month.