Varieties of sound insulation for sewer networks

To suppress noise in urban sewer pipes, there are several ways:

- The use of so-called "quiet" pipes having a multi-layer configuration and made of high density polypropylene. This makes it possible to perfectly mute the sound without the use of additional devices and materials, but the disadvantage of such products is their high cost.

- The use of soundproof materials, which include polyethylene foam, fiberglass, synthetic rubber, mineral wool and a number of other porous substances.

- Use of soundproof tapes and rolls.

Soundproofing the sewer riser in the apartment

The best solution in any case would be to replace the pipeline and fittings in general throughout your apartment. Operational wear also affects the condition of the pipes, so in the end you will solve the problems of sound insulation and make repairs. Old cast-iron pipes are very noisy at all. If you just replace them with plastic ones, you will already get a strong effect.

Option number 1: noise-absorbing pipes

You can buy and install special noise-absorbing pipes, for example, such companies as Osterdorf and REHAU have them. Here, experts have already thought about how to make the passage of the drain through the pipe as quiet as possible.

Option number 2: complex soundproofing

Soundproofing in general may involve the creation of a special drywall box, which will be tiled like a regular bathroom wall. Such a box can be from floor to ceiling, hiding absolutely all pipes.

When installing, you need to take into account three types of noise: acoustic (which is removed due to the partition), structural (here you just need not to lean the pipe against other pipes or the wall) and shock (you need to buy high-quality pipes and all fasteners that will be securely fixed).

There are also special mounting clamps that reduce sound insulation. And you can also replace the doors to the bathroom with a more tightly fitting canvas so that there is no noise from the corridor. Equally important is the complete enumeration and ordering of communications.

The main problem arises with the replacement of cast iron pipes. They cannot be changed if the upstairs neighbors have not yet changed theirs. If they do, for example, in a year, you will have to tear down your trim to replace the rest.

If you still decide to cut a cast-iron pipe, you first need to make two transverse cuts at a distance of 1.5 meters to the maximum depth, and then knock out a pipe segment. Only then will you be able to cut the back wall of the pipe, since cast iron pipes are very stubborn.

Soundproofing of the entire riser

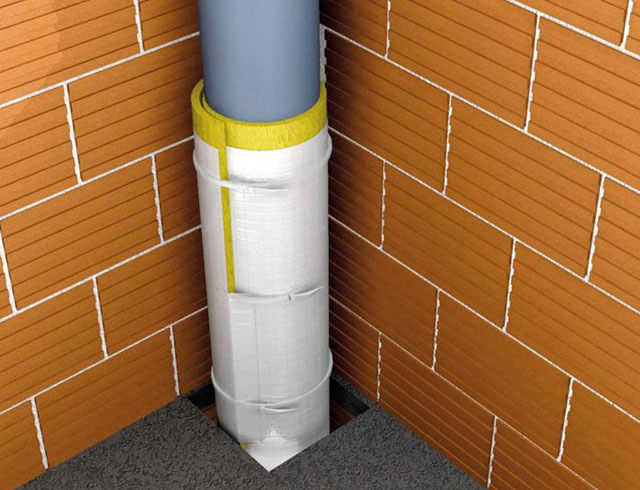

To soundproof a sewer riser, you need to perform a number of measures: put on clamps, add polyethylene foam to the free space, then check if the pipe or its fittings are in contact with anything.

You can use any insulation or mineral wool, wrapping them around the pipe and then fixing it on top. You can see the options for such soundproofing below:

If and special mounting covers with connections. They are more expensive, but are intended specifically for pipes. The result is a secure mount (see photo below).

Noise types and their causes

In modern sewer "acoustics" there can be various sources of noise and the reasons for their appearance.

The most common are:

- resonant noise. Sounds are based on the phenomenon of resonance, where plastic pipes themselves act as a resonator;

- atmospheric sounds.They occur during the penetration of air flows into the fan pipes, which are led to the roof;

- vibration noises. Their occurrence is associated with the specifics of the construction of the sewer system, in which every detail sounds the same as the whole pipeline. Vibrate not only the risers, but also the knees, couplings, joints, mounting clamps;

- impact type noise. They are among the loudest and most unpleasant. Anything that enters the sewer system falls from a certain height, which produces a loud sound. Such a sewer vertical can be compared with a resonant-oscillatory system.

Noise elimination

Before eliminating the noise, it is necessary to establish its cause. If the noise causes collector resonance or collector strikes against the ceiling, it is enough to install 1-2 additional pipe mounts. If the noise is caused by the thin walls of the plastic pipe, it is necessary to wrap it with soundproofing material, close it with a soundproofing panel, install thick-walled plastic or cast iron pipes.

To eliminate noise from excessive (incorrect) ventilation, contact the management company. Serious intervention in the sewerage system will be required, so specialists should work.

Sewer pipe fastening with sound insulation

Possible soundproofing options

Depending on the type of problem, there are several options for dealing with noise interference, the main ones are:

- It has been established that the noise caused by the passage of water flows through the riser was practically not present in the houses of the old building due to the use of massive cast-iron pipes, so one of the ways to eliminate it is to increase the mass of the riser pipeline.

- A popular method is related to the soundproofing of the riser and includes a lot of different ways to deal with noise using soundproofing materials or engineering structures.

- To combat structural flaws caused by poor-quality fasteners of the riser pipeline, special clamps with elastic damping gaskets are used.

- And the last, less common method of eliminating interfering sounds is to replace a light thin-walled polymer pipeline with a special noise-insulating one (the cast iron option is not considered), such products have recently appeared on the construction market.

Soundproofing in the toilet and laying a silent sewer

All work on soundproofing pipes in the toilet is carried out after finding out the place of occurrence of noise and its causes. In particular, if noise occurs in an already installed sewer riser, then its sound insulation is carried out using special noise-absorbing materials, fixing them with special tape, as indicated above.

Soundproofing of other pipes in the system, which are a source of noise, is performed in approximately the same way. As roll materials for soundproofing sewer pipes in the toilet, foam or foam rubber is often used, which are put on a pipe in the form of a casing. Such coatings, along with the sound-absorbing effect, perfectly protect pipes from damaging external influences (mechanical, corrosive, etc.). This type of sound insulation for pipes is very easy to install: the casing is simply cut lengthwise with a sharp knife, then the structure is wrapped around with it, after which the butt sections are fastened with construction tape.

In the event that it is required to lay a silent sewer “from scratch” or to replace sewer pipes, the sound-absorbing features of the materials used in their manufacture should be taken into account. In particular, steel pipes are considered the most noisy products for laying a sewer system. Unlike them, cast iron pipes are almost completely silent, which is facilitated by their large mass and significant wall thickness.Also, sewer polymer pipes, in particular, made of plastic, are practically silent.

Types of sound insulation for sewer networks

In construction stores you can find several types of soundproofing materials:

- noise-absorbing pipes;

- foil foam rubber;

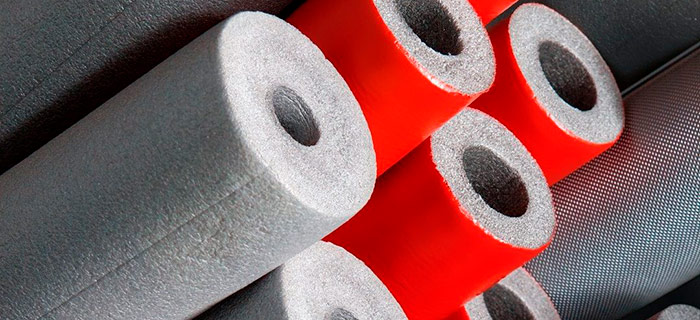

- polyethylene foam shells;

- pipes made of foamed polymer;

- soundproof tape.

Noise-absorbing pipes

Noise-absorbing pipes have a complex structure that dampens sound waves in their mass. For the manufacture of products using microcalcite (marble powder), limestone, chalk and dolomite. Pipes are made with thick walls

The soundproofing polymer dampens the entire spectrum of sound waves, which is especially important - it effectively copes with infrasound

The main advantages of the product:

- High resistance to overgrowing and corrosion of the inner surface.

- With proper operation, the service life of pipes is more than 25 years.

- A light weight.

- Rubber seals expand under pressure, which creates a tight connection of pipeline parts.

- With an average noise level, additional sound insulation is not required.

Foil foam rubber

Rolls of products are designed for soundproofing car interiors. As practice has shown, rubber proved to be an effective insulator for sewer risers. It is covered with two layers of aluminum foil and three layers of polyethylene film.

Features of rubber insulation:

- Sound waves get stuck in the elastic mass of rubber. The coating has high thermal insulation performance, so that condensation does not appear on the surface of the insulated sewer riser.

- Foil rolls have an adhesive backing covered with a protective film. Before installation, the protective coating is removed from the cut sheets. Pipes are wrapped with overlapping rubber sheets.

Polyethylene foam shells

The insulating pipes are, as it were, cut lengthwise into two parts. The riser is “hugged” with shells on both sides. The longitudinal edges of the shells are made in the form of a locking system (thorn-groove). After installing the polyethylene foam shells, the tightness of the joints is carefully checked. For greater reliability, the seams are treated with a sealant.

Advantages of soundproof shells:

- The material has a low specific gravity.

- Easy to install - does not require much effort.

- High levels of sound absorption and thermal insulation.

- Long service life - more than 25 years.

Foam pipes

Polymer foam shells have a soft structure. Pipes are made with a longitudinal section. They are easy to put on the riser. The foam material is adjusted to the desired length using a sharp knife and scissors. The seam is glued with adhesive tape or soundproof tape.

Product advantages:

- A light weight.

- The porous structure of the shell provides a high degree of viscosity for sound waves.

- The material lends itself to any type of processing, without requiring a special tool.

- When provided with UV protection, foamed polymer shells will last 30 years or more.

Due to the porous structure of the shells, the pipes need additional coating. You can use foil insulation or a simple polyethylene film.

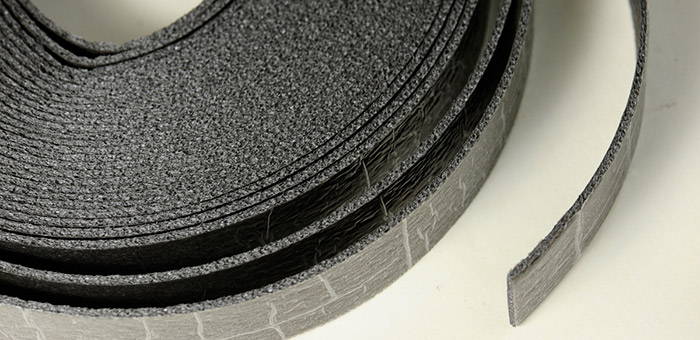

Sound insulation tape

Adhesive-based tape serves as a good heat insulator, not passing noise from 10 to 15 dB through itself. This is a low figure, but in the combined composition it creates a highly effective sound barrier.

Advantages of soundproof tape:

- Thanks to the tape form, it is possible to paste over fitting connections and couplings of any configuration with a coating.

- The tape has a long shelf life. Within a year - a year and a half does not lose its properties.

- Easily cut with ordinary scissors.

Noise insulation of sewer pipes in the apartment, find out which is better

Noise isolation of sewer pipes in an apartment is an urgent problem.The high rate of sound transmission in urban apartments is a well-known fact and the noise of water that passes through pipes greatly reduces the comfortable living of residents.

Therefore, it is necessary to take drastic measures to reduce the sound that the sewer produces.

Noise in sewer pipes occurs for many reasons, these are:

- insufficient wall thickness of the pipes of the drain system.

- Manufacturing material.

- Improper placement of walls and pipes in the apartment.

- Incorrectly selected sealant.

Cast iron or plastic

Today, plastic pipes are gradually replacing cast iron sound-absorbing products. Although cast-iron risers have a great advantage over plastic counterparts: they are not a source of noise, which means that they almost completely absorb sound.

The psyche of not every person can withstand the high noise level of non-insulated plastic pipes of the sewer system, especially in a panel house. And if it were not for the high-quality sound insulation of sewer pipes in the apartment, then ensuring comfort in living rooms would be a big question.

Advantages of plastic risers:

- ease;

- thin-walledness;

- elasticity;

- ease of installation;

- long service life;

- resistance to sudden temperature changes;

- low cost.

In addition, no growths can form on the inner surface of perfectly smooth plastic pipes. Due to this, plastic products are cleaned much less frequently than metal or asbestos-cement counterparts.

Disadvantage: the appearance of structural noise.

What needs to be done, or how to glue the sewer pipe so that unpleasant noises are not heard?

What materials need to be purchased for complete soundproofing of a fan pipe?

These and other questions related to getting rid of noise in pipes in the kitchen, in the toilet, bathroom, and in general with soundproofing work, are discussed in more detail in this article.

Soundproofing of sewer pipes recommended coatings

Sound insulation of PVC and polypropylene sewer pipes in the apartment is made with a variety of materials. At the same time, roll films, soundproof tape and foamed polyethylene products are very popular. The main thing! Do not use foam for installation work for soundproofing. It can strongly transmit sound vibrations around the house or apartment. This type of noise protection will bring more problems than good.

The most effective soundproofing material is polyethylene foam. It will not only protect you from foreign sounds, but also eliminate the likelihood of mold and fungi in the toilet, condensation on sewers. Moreover, such a coating creates the role of a good insulation. Polyethylene foam is produced in the form of a film with inner and outer layers. There is one point here. If you want to achieve the greatest result of noise protection measures, purchase material with a hard outer layer. This type of coating will be used for a really long time.

The most effective for soundproofing is polyethylene foam

Sound insulation tapes are also very popular among our customers. They are the easiest to work with. All measures for noise protection of the bathroom are carried out with their own hands. It will be enough for you to wrap several layers of sewer pipes or a riser with this tape in order to get rid of the annoying hum of the system. There is only one main thing here. The tape should be wrapped as tightly as possible. Also, when choosing the described material, you need to look at the amount of decibels that the coating can absorb. This indicator just determines the effectiveness of the use of noise-protective tapes.

You can use classic roll insulation to protect sewers from noise.In terms of cost, it is more affordable than more innovative materials (tape, polyethylene foam), and the effect of its use is very often not worse at all. Materials in rolls are wrapped around pipes, and then fixed with a plastic clip and adhesive metallized tape.

Soundproofing the riser of the main source of the rumble

Very often, third-party loud sounds and vibrations come from the riser. It is through it that plums from all apartments pass. Due to this, soundproofing the sewer riser with your own hands must be carried out carefully and competently. We will explain the whole execution algorithm.

The riser is very often considered a source of foreign sounds and vibration.

Do-it-yourself sewer soundproofing

First of all, you need to choose a soundproof material (depending on the coatings recommended above). Cut it to the size of the riser. The insulator must fully go around the main sewer pipe. If roll-type products are used, they must overlap the riser. After installing the soundproofing, first of all, fix it with adhesive tape for construction work. Materials in rolls, as noted, are fixed with a specialized aluminum tape. It is recommended to additionally fix polyethylene foam with plastic fasteners or tightly tie it with a thin but strong wire. When installing fasteners, keep a distance of 0.25 m between them.

As a rule, on this, the noise protection of the riser can be considered finished. However, if the area of your bathroom is very large, it makes sense to hide the pipe in isolation so that it does not spoil the interior with its unattractive appearance. This can be done using plastic wall panels or by landscaping a drywall box. The last of these designs will be additional noise protection.

The box is installed like this:

- Mark the dimensions of the masking structure on the surface of the walls. Decisive moment. The walls of the box should be 55-60 mm away from the riser.

- Install, using dowels or screws, metal profiles on selected areas.

- Fix another profile product from the wall surface to the floor surface. Its location is determined by the intersection of lines drawn perpendicular to the two previously installed profiles.

- Place jumpers (the distance between them is about half a meter) on a metal frame.

- Screw the GKL sheets to the completed skeleton. Advice. Get waterproof products. For operation in plumbing units, they are better than the usual gypsum in terms of properties and thickness. Don't forget to cut out a small window. It will play the role of an inspection hatch.

The space between the riser and the box can be filled with mineral wool. But do not forget that it will play the role of a heater. Mineral wool does not protect against foreign sounds. The ideal option is to fill empty spaces with the same polyethylene foam. The cost of soundproofing in this case will increase. But the effect of them will be impressive. Unpleasant sounds from sewer pipes will stop worrying you and your family members!

Thematic publications:

Installing a shower tray with your own hands - the main ways

Sink installation - good do-it-yourself installation

Cleaning the sewer in a privatized house - how to clean the clogging at home

Noise insulation of the sewer riser and vent pipe

Most of the questions usually arise about the noise that comes from the sewer riser, as well as regarding the soundproofing of the fan pipe connecting the sewer riser to the atmosphere. It is the sewer riser that is the place where the greatest amount of noise occurs.

The sounds generated during its operation are conditionally divided into several types:

- impact, formed during the passage of a fluid flow through the walls of pipes;

- air, appearing during the passage of water flows through the air;

- structural, resulting from fluctuations and contact with each other of pipes and other elements of the sewer network.

Airborne noise creates less inconvenience compared to other types. Percussive sounds can be greatly reduced, though not completely eliminated. But structural noises usually create the most problems, and in practice you have to deal with them first of all.

To do this, you will need to do the following:

- Prepare a piece of soundproofing material that matches the dimensions of the circumference of the indicated pipes.

- Fasten the soundproofing material on the pipe with construction tape. It is important to ensure that its edges are butted to achieve greater efficiency.

- It is recommended to tightly cover the pipes with soundproofing material in several layers for maximum damping of sound vibrations.

- If necessary, a duct can be built around the sewer riser, which improves the appearance of the structure and enhances the noise reduction effect.

Why is the sewer noisy

Third-party sounds that come from the sewer system do not allow a person to fall asleep or simply annoy him. Because of this, many owners of residential real estate in high-rise buildings are concerned about how productive and, if possible, affordable soundproofing of drainage pipes in a living area is being done. There are no big difficulties here. At the moment, the construction services market offers a lot of materials for soundproofing pipelines. But before starting work on soundproofing the system of interest to us, it is necessary to figure out why it makes noise that irritates a person. The appearance of foreign sounds in the sewer is caused by the following factors:

- Vibration of pipes, their internal defects, poor-quality fastening of individual elements of the system. Such noise is called resonant or structural.

- Leakage of water from taps, high (when compared with the calculated) speed of movement of drains along the riser. This is, in other words, weather background noise.

- The occurrence of deposits in the pipe, which leads to a decrease in its diameter.

Currently in demand polypropylene pipes and plastic are considered quite loud

There is also the concept of impact noise. It will appear in variants where sewer pipes come into contact with adjacent tubular products (for example, plumbing) or with wall surfaces.

The volume of sounds emitted by the sewage system depends on which pipes were used for its improvement.

Previously, cast iron products were installed in most apartments and houses. Such pipes had a large thickness. Thanks to this, they absorbed sounds that irritate a person. There was no need for additional soundproofing of pipelines. The situation changed when much cheaper and primitive in installation products made of polypropylene and plastic (PVC) appeared on the market. They certainly have a lot of positive characteristics, but they are really loud. This became the basis for the fact that the sound insulation of sewer pipes in the apartment was required for many people.

How to make soundproofing with your own hands

Soundproofing a sewer riser with your own hands is a completely doable task for any home master.

Buildings from silent pipes are mounted as follows.

- The vertical height of the pipe network is measured and pipes of the required length are cut.

- The cut points are cleaned with a file. And they do it at an angle of 45 degrees.

- Mounting clamps with damping gaskets are placed on the wall.

- The assembly is performed taking into account the individual characteristics of the silent network.

- In the ceilings, the holes are closed with polypropylene sleeves. Their diameter should be 0.5-1 cm larger than the cross section of the silent drain pipe.

IMPORTANT! It is strictly forbidden to install monolithic plugs that tightly compress the sewer network. It is advisable to use components that have the properties to absorb vibration