Electrical cable

When electric underfloor heating is that the electric cable converts electricity into heat. Both single-core and two-core cables can be used here. In an apartment and a private house, it is recommended to install a two-core cable, the more it is easier to install and the electricity consumption is lower than when using a single-core cable. But in this case, there is a possibility of system failure if the cable section is damaged or local overheating occurs. That is why it is better to use a self-regulating cable, which itself controls the temperature along the entire length of the cable. If in some area the temperature exceeds norm, then in this place the resistance immediately increases, thereby reducing the temperature to the desired level.

Wet and dry cable laying under laminate

Before you start installing the electric cable floor with your own hands, you must carefully prepare the surface. The floor is cleaned and, if necessary, leveled. After leveling the floor, you need to put thermal insulation and make a leveling screed using a reinforcing mesh. After the leveling layer has completely dried, the mounting tape is fixed and the electric cable is laid. After the installation of the thermostat and sensor, the cable floor is checked for operability without fail. Then you can start pouring the screed. After it dries, after about a month, you can lay the laminate.

The easiest option to make an electric underfloor heating in the house is a heating mat. In this case, installation is greatly simplified, since the cable is already fixed to the grid and no screed is required. Advantages of this type of electric floor heating:

- Durability. At least such a floor can last 20 years;

- Reliability;

- Easy installation;

- Adjustable floor temperature.

Visual video instruction for the installation of mats:

The disadvantages of this option of a warm floor include only insignificant electromagnetic radiation and energy costs.

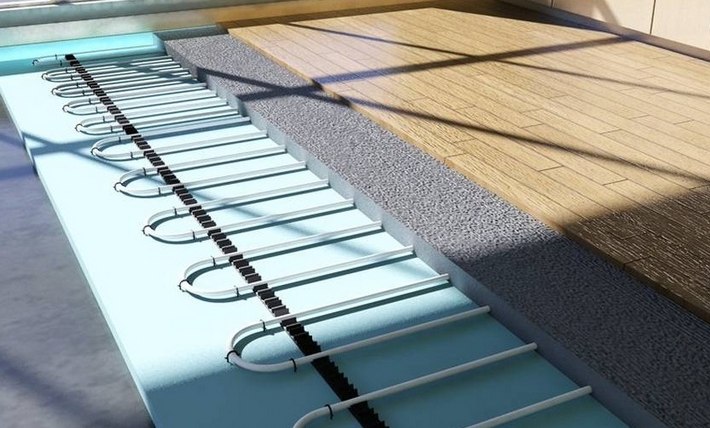

Water heated floor

It is a layer cake. The first layer is considered waterproofing, it spreads on the base of the floor. With the help of a damper tape, the possibility of expanding the underfloor cake screed is eliminated. It is necessary to lay the tape around the entire perimeter of the room. Following the waterproofing, you can lay a heat-insulating layer and only then make a screed. A floor covering is installed on top of the structure.

Water heated floor pie: leveled rough screed, waterproofing, polystyrene foam, pipes on mounting tape, cement screed, flooring

Heating arises from the circulation of warm water, which flows through the pipes. Thickness of water heated floor usually is from 5 to 15 cm, which is the disadvantage of such a floor heating system, as the ceiling height decreases. Also, the disadvantages include complex installation and problematic repairs in the house in the event of a system failure. The advantages include reliability, safety and efficiency.

Tips for Choosing Laminate

Many have heard of such a characteristic - thermal conductivity. This is the ability of a substance to transmit or retain heat passing through it.

It is important that this coefficient for laminate does not exceed 0.15 sq.m x K / W. The second prerequisite is compliance with the temperature regime of heating, the temperature of the floor surface should not exceed 26 degrees, otherwise the evaporation of the binding formaldehyde composition of the laminate begins, which is not safe for humans

This situation can be prevented by installing a thermostat or programmer to automatically control floor heating. When buying a laminate, you must definitely familiarize yourself with its performance characteristics.

Types of underfloor heating and their differences

All types of floor heating can be divided into two broad categories:

- water from heating;

- electrical.

There are two types of underfloor heating for apartments and houses: water and electric

There are two types of underfloor heating for apartments and houses: water and electric

Which one is better? And you have to look. If we take the costs in the heating season, then the water will be cheaper. But it requires a lot of installation costs, and it can not fit everywhere. And the point is not only in the increased load on the floor, the fact is that it can not be installed everywhere.

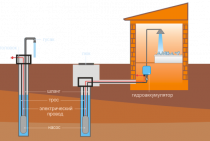

Water heated floor

Water heated floor is usually connected to the heating system. Long polymer pipes are laid in a screed and connected through a collector to a source of coolant supply. If you have a private house or individual heating in an apartment, you can make this type of floor heating. Some new buildings also have special risers for connecting a water-heated floor. These are not all projects, but there are some.

Which underfloor heating is better in terms of efficiency in operation? Water

Which underfloor heating is better in terms of efficiency in operation? Water

In ordinary houses with any type of heating distribution, it is impossible to connect a warm floor to a riser. Not only will he most likely work through a stump-deck, but also freeze all the neighbors. After all, a water heated floor is tens of meters of a thin pipe. Conventional heating is simply not designed for such hydraulic resistance. It simply will not be able to provide the desired circulation rate. The water will be cold already in half of the circuit and will go to the neighbors completely cooled down. And the cost of a water heating device is rather big. See for yourself: screed with insulation + pipes + engineering equipment (at least you need a manifold with a mixing unit) + thermostat. And plus at least a month to set up this entire economy.

Electrical connection

Electric underfloor heating is simpler in terms of connection and installation - there are different types of heating elements that can be used with different floor arrangements and for different types of flooring. But there are also limitations here: the energy consumption limit allocated for an apartment or a private house and the condition of the wiring. Of course, you can try to increase the limit, change the wiring. If you really need it, it is possible almost everywhere. But this, again, is time and cost.

What underfloor heating to choose if you need to quickly put it into operation? Electric

What underfloor heating to choose if you need to quickly put it into operation? Electric

If there is enough power and the wiring is in order, some types of electric underfloor heating can be laid and connected in just a day. In one room it is quite real. What can stop? High consumption of electricity, which is becoming more and more expensive.

In general, there is an electric underfloor heating:

- for laying in a coupler (heating cable);

- under the tile (cable mats);

- under a laminate, linoleum, carpet and other coverings compatible with heating (film heat-insulated floor).

As you can see, there are solutions for almost every occasion. Installation methods, installation time and costs differ.

Alternative

There is also an "intermediate option" - these are liquid electric floors. This is a local floor heating system from pipes with a heat carrier (closed) with a heater built into the pipes. It is laid like a water floor in a screed, and is connected not to heating, but to electricity.

The idea is not bad, but the price is not encouraging, as well as the low maintainability of the system. Pipes in the screed, they contain a coolant and a heating element. If something breaks, the heating is over. Although, as an alternative, a very good option.

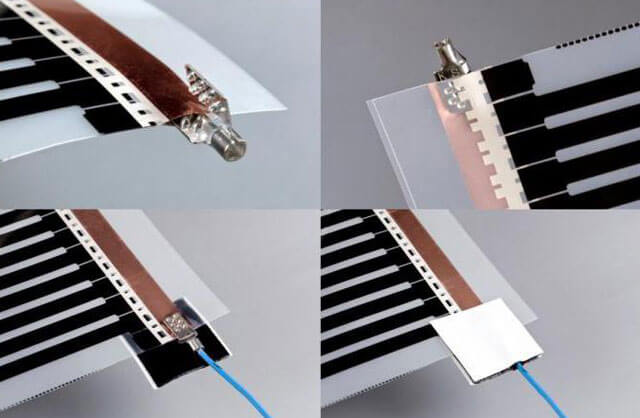

Contact clamps

This element is used as follows:

- the center of the heating strip is pierced with the tip of an awl or a hole punch, into which the clamp terminal is inserted;

- the clamp is installed in such a way that its elongated part is on the side where the copper part is located.

Before soldering, it is necessary to remove the protective plastic layer from the contacts so that the metal surface of the heating element becomes free. In this case, a soldering iron is used, with which the plastic is heated to a temperature of about 50 degrees Celsius, in order to then be cleaned with an ordinary knife.

At the point of contact, an electrical copper wire purchased in advance is soldered, the cross section of which is 2.5 square meters. mm. The place of soldering is pasted over with the help of technical adhesive tape for work with electrical wiring. The dimensions of the adhesive tape used should not be less than a square of 5x5 centimeters.

The connection of individual pieces of infrared film is carried out in parallel, and all output cables are connected to a single bus

In this case, it is important not to confuse “zero” and “phase”, and therefore it is better to use colored wires or make appropriate notes

The wiring is laid in such a way that its excessive tension does not lead to deformations of the infrared film and the entire system as a whole. It is more expedient to make a margin in the form of loops in order to get a reliable cable underfloor heating under the laminate that does not deform under possible displacements. In places where the wiring is located near the thresholds and skirting boards, it should be placed in a corrugated tube. The smooth transition from a film underfloor heating to a corrugated tube is created using adhesive tape.

Grounding is connected by analogy with the previous cables, and the cable is also sent to the ground through a corrugated tube.

The thermal sensor must be placed in the center of the warm floor, since it is at this point that the heating temperature will be the highest. This is the only way to protect the thermal film from overheating. The sensor is located on the inside of the layer. To avoid a height difference at this level, it is necessary to cut the heat-insulating material and insert the sensor into it. In this case, fastening should be carried out using construction tape.

Which underfloor heating is more profitable electric or water

In general, heating costs depend primarily on the amount of heat that a house or apartment loses. Therefore, to reduce costs, a heater is laid in the floor scheme. But the cost of energy is one of the cost components. And then there are the installation costs.

Which underfloor heating is more economical at the operating stage? When used, a water-heated floor is cheaper. It is usually mounted in addition to radiators, as an additional source of heat. Much less often - it is the only heating. In any case, the system still works - with or without a warm floor, it needs to give out the required amount of heat. If there is no underfloor heating, more heat will go through the radiators.

Underfloor heating cost chart. But something the cost of an electrical device is too high. Apparently taken for a cable in a screed

Underfloor heating cost chart. But something the cost of an electrical device is too high. Apparently taken for a cable in a screed

How about electric underfloor heating? Usually it is needed as a means to increase comfort or when the main heating does not cope with the task in the coldest period. Installation of electrical elements is much easier, does not require such high costs. If the base is solid and even, cable mats and film flooring are laid directly under the coating. Mats in a layer of glue, and a film heater on a substrate, even if it is a cable heater that fits into the screed. The minimum screed layer is less than when using pipes with a heat carrier, which means less costs.

The right choice of laminate

An important characteristic is the indicators of the limiting heating temperature. Without damaging the characteristics of the material, its surface must be heated to at least 30 degrees

Accordingly, depending on the selected temperature class of the coating, in the future it will be necessary to configure the temperature sensors that control the operation of the electric underfloor heating.

Today, many manufacturers offer customers a special laminate designed for use with heated floor material. Such a coating will have a special marking, which greatly simplifies the choice of material.

Substrate for underfloor heating laminate

Choosing the right underlay for underfloor heating laminate flooring is critical to the efficiency of an electric underfloor heating system.

Substrate characteristics (distinguishing features):

- high reflectivity;

- resistance to temperature changes;

- environmental Safety.

The optimal thickness is 1.5-3 mm.

What underlay can be used for underfloor heating laminate?

extruded polystyrene with perforation;

polystyrene substrate Arbiton Izo Floor Thermo (Poland), which is distinguished by the presence of a system of gutters and holes.

Many manufacturers offer a special substrate for underfloor heating laminate. For example, in the Quick-Step line there are substrates: Unisound Pro, Transitsound Ultra, Uniclic Plus. Special underlays distribute heat more evenly over the floor surface.

penofol, technical cork, isolon - can be used as a substrate only when installing an electric cable underfloor heating under a laminate (cable or heating mats).

Attention. When installing a film underfloor heating, the use of penofol is prohibited

Is it possible to put a warm floor under the laminate

How safe is laying a laminate on a heating surface, is such a “neighborhood” harmful?

The laminate board consists of two parts: a polymer front coating and an MDF panel, which serves as the base. It is in the composition of MDF that the main danger lies. The fact is that formaldehyde will perform the function of a binder here. Due to the fact that its concentration is low, the laminate can be used even in children's rooms. However, even in the normal (not heated) state, the lamella emits a certain amount of this substance (within the permitted norm), which is quite safe for users.

When the board is heated, the amount of formaldehyde released increases. And the higher the temperature of the heated surface, the more intense the process of formaldehyde release. Its action causes symptoms similar to those of poisoning: nausea, headache, inflammation of the respiratory tract.

Manufacturers who value their reputation, monitor the level of formaldehyde in their products, those who offer cheap coatings cannot guarantee its safety. Thus, it is impossible to buy a cheap laminate and get a high-quality and safe coating.

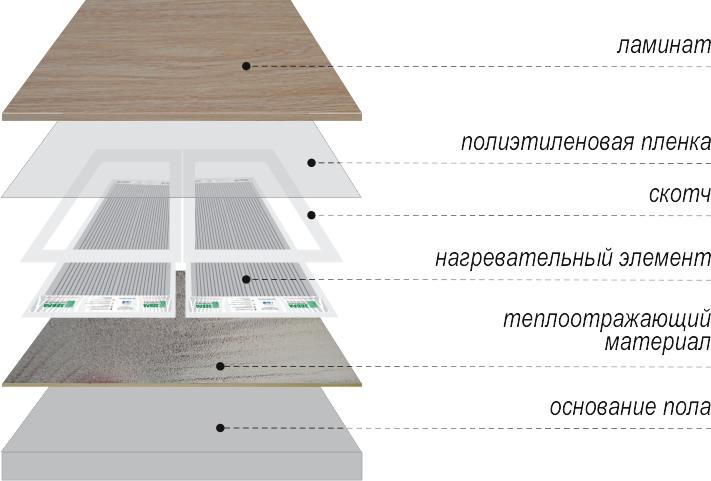

Infrared film

Infrared film underfloor heating is the latest successful development in the field of floor heating. The infrared film spreads on a heat-reflecting base. Immediately after that, you can proceed to the installation of the finish coating.

Film underfloor heating has a lot of advantages:

- Durability;

- Reliability;

- Ease of installation;

- Lack of additional repair actions, such as pouring the screed;

- High installation speed.You can lay the laminate immediately after laying the film underfloor heating;

- Since the thickness of the film underfloor heating is insignificant, it will not affect the height of the ceilings;

- Gentle consumption of electricity.

There are also negative aspects of the film version of underfloor heating:

- The mounting base must be perfectly level;

- Installing a film underfloor heating is possible only in a house where the humidity is not too high;

- High price.

Installation of infrared floor heating

Underfloor heating film cake

It is difficult to make a choice which option of a warm floor is still better to choose. But if you analyze all the pros and cons, infrared floor heating can be considered the best option.

Before installing the infrared film underfloor heating, you need to calculate how much thermal film and reflective substrate you will need. The area of the substrate corresponds to the area of the floor in the house for which heating will be carried out, and thermal films need less, since it cannot be placed under furniture.

Of the materials and tools you will need:

- thermostat;

- Temperature sensor;

- Underfloor heating kit;

- Thermal reflective backing;

- Protective film;

- Screwdriver;

- pliers;

- Scissors;

- Scotch;

- Knife.

The base for installing a warm floor is thoroughly cleaned and dried. Then the thermal insulation material is placed

It is very important that it does not contain aluminum foil, since aluminum is unacceptable for infrared floors. Parts of the film are fixed to each other with adhesive tape

After that, the place where the thermostat will be located is determined.

The film floor is first cut into strips of the required size. To minimize trimming, it is better to lay along the length of the room in the house. The strips should not be tightly pressed. It is better to keep the distance between them at 10 mm, and the distance from the strips to the wall is about 50 mm. Do not forget that the copper strip should be at the bottom.

The location of the contacts near the wall on which the thermostat will be fixed will reduce the length of the wires for connection. The strips are connected in parallel, thanks to which the wires can be hidden under the baseboard.

Having considered all the options for underfloor heating, assessing the complexity of their installation, how much they cost, and other features, we can conclude that it is more suitable for a particular room in the house. If you plan to install it yourself, then you must follow the advice of professionals and follow the instructions. Add your comments and opinions!

Which underfloor heating is better to choose for laminate flooring - professional advice

Underfloor heating options for laminate

Are there any restrictions on the choice of the type of heating element? In general, no. You can use water heating or electric heating cable, mats from it, laying the heating elements in the screed. But the screed is a labor-intensive business, requiring significant investments and a lot of time. In addition, the efficiency of such heating is low, since the screed is heated, and the laminate is heated from it.

Installation of a laminate on a film warm floor is simple - you just need to fix the heating element (with adhesive tape), connect it electrically, and bring out the wires. And lay the cover on top

Installation of a laminate on a film warm floor is simple - you just need to fix the heating element (with adhesive tape), connect it electrically, and bring out the wires. And lay the cover on top

There are faster installation options. They are more economical, since the laminate is heated directly, and not the screed under it. The most convenient film infrared warm floor in this regard. It can be spread on a flat base (any), and immediately steal a laminate from above. You can mount this type of underfloor heating for laminate in one room with your own hands in half a day. If you have absolutely no experience - in a day. Most of the time is usually taken by the electrical part and the installation of thermal sensors. The rest of the installation of film underfloor heating is very simple.

You can make a warm floor under the laminate and from the heating cable. But it must be laid in special plates

You can make a warm floor under the laminate and from the heating cable. But it must be laid in special plates

The second option for quick installation of a warm floor under a laminate is a heating cable.But here a special system will be needed. The cable is laid in metal heat-dissipating troughs, which are placed in a heat-insulating substrate. Laminate is laid on top. In general, the system turns out to be more expensive - due to the cost of the plates.

The choice of laminate for underfloor heating

Not every type of laminate provides for installation on underfloor heating. Before you buy the material and start laying it with your own hands, you need to know exactly which laminate is better to choose. And for this there are certain characteristics:

- Good strength and board thickness 8-10 mm;

- The marking must indicate that this laminate is intended for laying on a warm floor;

- The H2O symbol indicates that the laminate is suitable for water floor heating systems;

- It is imperative to evaluate the thermal resistance of the laminate. Its value can be found in the passport;

- The marking also indicates the maximum temperature for heating this floor covering. It must be at least 25 ° C;

- Possibility to lay the laminate both with laying adhesive and with the help of locks. But experts for installation still recommend choosing the option with glue.

We have a short video on the topic:

Which electric underfloor heating is better for laminate

There are three electric floor heating systems that can be used for under-laminate installations:

1.Cable floor heating

The heating resistive cable is unwound from the coil. The user independently calculates its length and determines the laying method. The laid cable is mounted on special tapes with clamps or on a metal mesh.

Installation of the cable floor requires a mandatory tie device. The height (thickness) of the screed reaches 40 mm, which is the main factor that limits the distribution of floor heating cable systems.

Based on the physical parameters and technical characteristics of the system, it is possible to justify the inexpediency of using a cable system for laminate:

high power consumption, a significant part of the energy costs falls on heating the screed itself;

higher, in comparison with other systems, the complexity of temperature control;

the need to know the exact location of the furniture in order to avoid overheating the floor.

Installation of the cable under the laminate is carried out in the same way as the installation of an electric underfloor heating under the tile. And due to the presence of a thick screed, there is no specificity in the installation of the laminate itself.

2. Heat mats (floor heating mats)

Underfloor heating system, in which the heating cable is initially laid in mats. A distinctive feature is that the mats use a thinner cable fixed at a given distance, which eliminates the calculation of the laying step.

Installation of electric mats is fast, and the thickness of the screed is reduced by 5-10 mm. However, from the point of view of installing a warm floor under a laminate, the disadvantages of this system are similar to the disadvantages of the previous one.

3. Film or infrared floor heating

According to the masters, installation of a film underfloor heating under a laminate. is the preferred option.

Advantage in efficiency and economy (both during installation and during operation).

When installing an infrared floor, such shortcomings of the laminate are leveled, such as:

the release of formaldehyde, which in most cases is used as a binder in the manufacture of lamellas;

cracking of the lamella along the seam or delamination in thickness. Appears due to uneven or sudden heating;

Mounting infrared film

Rational and economical is the option of laying the heating film in a longitudinal manner (along the length of the room). At the same time, the set of places where the connection will be made must be made as small as possible. In this case, the film will be cut into fewer sheets.Special lines are marked on the surface of the film, along which cutting can be carried out.

Sheets are fixed with construction tape to avoid their mobility while working on laying the remaining layers of the floor. Another mounting option is the use of self-tapping screws or a construction stapler. Naturally, fasteners that cause deformation of the film should be used in those areas where there is no heating layer (for more details: “How to lay an infrared warm floor under a laminate - installation instructions“).

Recommendations for the installation of various underfloor heating systems with laminate

To maintain the set temperature in the room, its smooth adjustment and saving electricity or boiler fuel, it is advisable to use electronic temperature controllers in such systems. They will also provide heating zoning with thermal sensors built into the floor.

The most popular are programmable controllers that can comply with the daily, weekly heating regime.

And now it's time to dispel the myths of radiator dealers about the dangers of underfloor heating:

The degree of electromagnetic radiation of the electric floor does not exceed the radiation of any household electrical appliance

pay attention to pets, cats and dogs like it very much;

They say that he collects ardor, no more and no less, you just need to wash the floors;

Expensive, but installing traditional heating with radiators, valves, peeking pipes costs no less;

To fix it, you need to disassemble the entire floor. but modern technologies guarantee its reliable operation for at least 10 years, by which time it is time to change the laminate.