Construction of a cesspool from plastic rings

Before proceeding with the installation and construction of the cesspool, it is necessary to choose its location, and in such a way that the distance from it to the house is not less than five to ten meters. In addition, placing a cesspool at a distance of less than three meters from the boundaries of the site or the roadway is not recommended.

The cesspool should also not be placed close to sources of drinking water, wells or wells. Negatively, the close placement of a cesspool can affect the condition, quality and safety of the crop of garden trees.

After the site for the cesspool is chosen, you can begin to build it. It should be noted that the volume of such a pit must meet the needs of users of the sewer system. When calculating this volume, one should proceed from the norm, which is about ten liters per family member.

Making a form from boards

To make such a form, boards with a thickness of 2 to 5 cm are required. The outer and inner cylinders are made collapsible, consisting of several wooden rings. On the rims for the outer cylinder, well-finished boards are stuffed from the inside.

The inner cylinder should also be easy to assemble and disassemble. It is made according to the same rules as the outer part of the mold, but it is sheathed not along the inner, but along the outer diameter. After assembling the mold, a gap of 1.5-2 cm should remain between the cylinders.

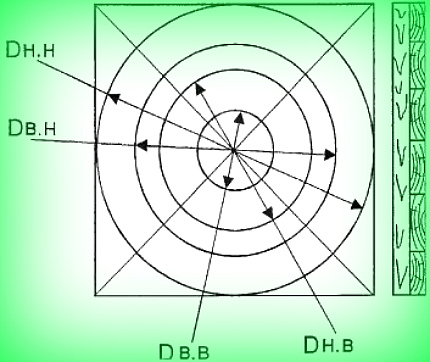

To obtain a product of the required parameters, it is necessary to first calculate the dimensions of the mold. Suppose a cesspool needs rings with a diameter of 840 with a wall thickness of 140 mm and a height of 890 mm. To calculate the inner diameter, use the formula: Dv.n. = D + 2h, where D = 840 mm, h = 20 mm (sheathing board thickness).

These values are substituted into the formula: Dv.n. = 840 + 2 x 20 = 880 mm. If we take the width of the ring equal to 100 mm, then the outer diameter of the ring Dн.н. = Dn.v. + 2S = 880 + 2 x 100 = 1080 mm. Taking into account the fact that it is necessary to make a ring with a wall thickness of 140 mm, the outer diameter of the wooden core is equal to: Dn.v. = D - 2V - 2h. Here D is the diameter of the product, B is the thickness of the finished ring, h is the thickness of the board. Dn.v. = 840 - 2 x 140 - 2 x 20 = 520 mm.

If in the manufactured formwork the width of the ring of the inner wall is also 100 mm, then the core must have an inner diameter Din. = Dn.v. - 2S = 520 - 2 x 100 = 320 mm.

Preferential parties

Due to the low price of the plastic itself, and products made from it, the construction of a cesspool in this way is much cheaper than the "classic" options. It should also be noted that:

- rust does not form on plastic or polypropylene;

- the weight of polypropylene rings is much lower than the weight of similar structures made of concrete or iron, so the installation of such a structure is much easier;

- due to the fact that plastic rings have impeccable tightness, the spread of odor, as well as the spill of sewage into the environment, is practically excluded.

Plastic rings have impeccable tightness

At the same time, such designs have some disadvantages, which are the lightness of the material, which is good during installation, but can cause problems during use. When the surface of the ring interacts with sharp edges of stones, damage may occur that will have a negative impact on the performance of the entire drain pit.

concrete rings

There are several types of concrete products, each of which has a different diameter. It can vary from 0.7 to 2.5 meters. For a toilet in the country, reinforced concrete rings with a diameter and a height of 1 meter are suitable.

To date, manufacturers can offer two types of concrete products for toilet equipment:

- flat;

- With a lock.

The first type is conventional products with flat edges. The second type uses the lock method or the tongue-and-groove connection to connect. This option is more practical, besides, installation is much easier and more airtight than the first option.

For the manufacture of concrete rings, cement is taken not lower than the M500 grade and a reinforcing metal frame. Recently, you can find not just reinforced concrete products, but also equipped with a lid and a bottom, this greatly facilitates the construction of a country toilet in the country.

Used polymers and their advantages

Modern materials used for organizing sewage are as follows:

Polyethylene. The benefits look like this:

- Rings made of this material are designed for use in difficult conditions.

- They withstand significant temperature changes from -50 to +70 degrees. They are resistant to aggressive environments.

- Modern manufacturing technology is such that it allows to obtain models without seams, due to which the formation of deposits is reduced to zero.

- Sewer rings have a different shape.

- Due to the multi-layer, excellent structural strength is achieved.

- The material allows you to operate the septic tank for a large amount of time and in a wide range of climatic conditions.

Polypropylene also has a number of positive qualities:

- The material has increased hardness.

- Abrasion resistant.

- Due to the fact that it can withstand +140 degrees, it can be used at high temperatures.

- Not subject to corrosion and cracking.

- Sewer rings made of this material have shown their reliability in the treatment of industrial wastewater when exposed to an aggressive environment.

Fiberglass consists of various kinds of resins and has the following advantages:

- Thanks to the fiberglass in the composition, high strength indicators are achieved.

- Resistant to various aggressive environments.

- Not subject to corrosion.

- There are separation chambers.

Cesspool of 2 rings

| Reinforced concrete ring KS-10-9 | 2 pcs. | 4.800r. |

| Reinforced concrete cover D-1 | 1 PC. | 2.000 rub. |

| Polyester. Luke green. col. | 1 PC. | 2.400 r. |

| PVC Pipe 110 5 meters. | 1m. | 680 rubles |

| Cement brand m-500 | 50 kg. | 260 r. |

| Liquid glass | 1 l. | 70 rubles |

| Total: | 10.210 rub. |

| Digging a mine for reinforced concrete rings | 2 pcs. | 4.200 rub. |

| Installation of reinforced concrete rings | 2 pcs. | 200 rub. |

| Seam sealing | 2 pcs. | 400 rub. |

| Punch holes in reinforced concrete rings | for 1 resp. | 300 rub. |

| Reinforced concrete cover D-1 installation | 1 PC. | 1.000 rub. |

| Hatch polyester. installation | 1 PC. | 1.000 rub. |

| Trench digging 5 m. | 1 m / p. | 2.500 rub. |

| Installation of pvc pipe 5 m. | 1 m / p. | 650 rub. |

| Total: | 10.250 rub. |

Total (Work + Materials): 20.460 rubles. * concreting of the bottom 1.000 rub. sand for filling the customer.

Prices are valid until:

6 October 2018

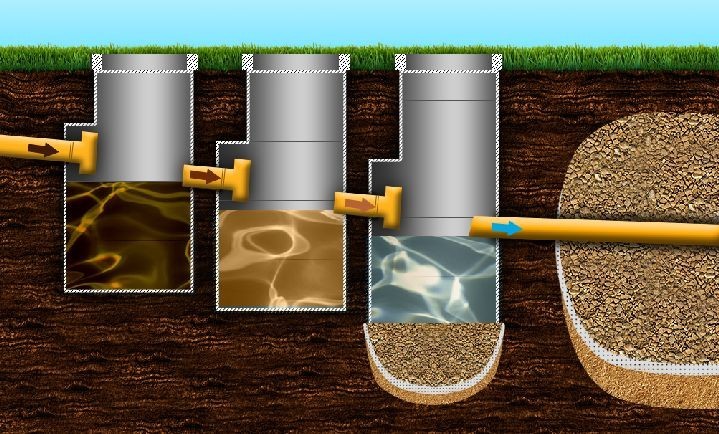

The device of drains for which such a system is needed

The development of human society involves the improvement of living conditions. People have long since left the caves and realized that living in a house with all amenities is much more comfortable. But in order for it to become so, it will take a lot of effort, and one of the main conditions is the construction of a local sewage system or a cesspool.

Previously, it was a well with brick walls and an earthen bottom so that liquid runoff was absorbed into the ground. But such a construction is unacceptable today. It can lead to ecological catastrophe. Someone will try to object. Say, after all, everyone did this before, and the question of how to properly put together a toilet in the country did not arise. But then such a large amount of water and various detergents and cleaning chemicals were not used. And cesspools were arranged only for street toilets.

Watch the video, a little about septic tanks and wastewater systems:

The modern local sewer system involves the discharge of water from washing machines and dishwashers into it after taking a bath and shower - all of which involve the use of chemicals that are not harmless to the environment. That is why a cesspool today is a whole list of conditions, without which its device is unacceptable. We will consider them below.

Making a belt from reinforcement

It will be necessary to prepare round ribbed steel with a thickness of 0.8-1 cm, from which the reinforcing ring is knitted.

Rings, the number of which depends on the height of the product, are interconnected vertically using pieces of reinforcement. It is advisable to maintain a distance between the reinforcing belts of about 25 cm. It is recommended to observe a step of 35 cm between the pieces of reinforcement installed vertically.

For the convenience of transporting the finished product, a workpiece in the form of wire loops is tied to the top of the reinforcing frame. It is also possible to use a steel mesh with a thickness of at least 0.4 cm for the reinforcing cage. A ring is formed from it and the edges are fixed with a wire.

Device and installation

Installing plastic manhole rings is not a difficult task. For the device of well rings, specialized equipment is not needed. All joints and seams are thought out in advance, as a result, assembly does not take much time. The cover and the ladder for the plastic well are made in advance according to any required dimensions.

The process of installing a plastic well ring begins with digging a hole. Look at the photo and video of the installation of plastic rings. It should be slightly larger than the diameter of the well or well rings. The bottom of the pit is covered with crushed stone 15 cm thick. A plastic well is already being installed on it. From above, the tray part of the structure is installed, and pipes are connected. The seams of the well rings must be carefully treated with sealants. The plastic ring itself is mounted on the tray through a rubber seal and pressed with a board until it clicks.

Outside, the plastic rings of the well are covered with sand, formwork is made and the entire site is poured with concrete. To seal the gap between the neck and concrete, a resin rope is installed and installed. Finally, a cover is installed on the plastic well. More details about the installation of plastic rings can be seen in the photo and video.

Well rings made of plastic can not only be installed in new places, but they are also used to restore or repair existing concrete wells. Old structures can be removed or left in place if they do not interfere with the installation of plastic well rings.

For the tightness of the connections of well rings, modern fastening materials and means are used.

- Welding is done with an extruder. In the photo and video you can see in more detail about plastic rings for drinking wells.

- Good quality mounting mastic is used for plastic well rings, although they have a higher price.

- Use a set of fittings and rubber seals of different sizes for the plastic rings of the well.

- When installing plastic rings in an old well, the gaps between the walls are filled with concrete.

Advantages

Sewer plastic rings have the following advantages:

- Environmental friendliness. After all, they are made from sheet HDPE. This material is used for containers that store supplies of drinking water and food.

- Tightness. This design does not have conditions for the formation of dirt in the seams and its alluvium through them. As, for example, in concrete septic tanks.

- Doesn't need cleaning.

- There is no need for large equipment for installation.

- The rings are joined in place, which allows you to build a deeper septic tank.

Compared to other options, sewerage from plastic rings occupies a higher position:

-

Wooden rings. During the operational period, the log house is destroyed, the consequences are the collapse of the soil. Moreover, water rots, which leads to the termination of use. In this case, repair with the use of plastic is needed. It is better not to carry it out on your own, as it is dangerous.

- Reinforced concrete. The main disadvantage of reinforced concrete structures is their heavy weight. The mass of the ring, with a diameter of 100 cm and a standard thickness of 8 cm, is 600 kg. Therefore, a construction crane is indispensable. It is also not easy to ensure the tightness of the well structure, because it is necessary to remove all the gaps between the individual sections and seal the joints.Moreover, in order to bring the drain pipes, you need to make a hole in a thick concrete wall, and then carry out a thorough sealing job. However, rings made from this material often leak. Therefore, the way out of this situation will be the use of plastic rings. The design is inserted directly into the concrete septic tank.

- Parched. Sometimes the well dries up. In this case, you can deepen it with concrete rings. The work is a laborious process, as you need to use special equipment. Moreover, the volume of water will decrease. If you resort to the help of a plastic ring, then the work will noticeably decrease, it will become easier, and the volume of water will disappear only a little.

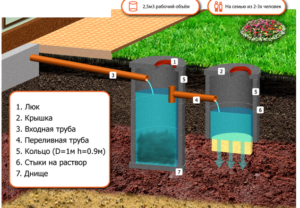

Installation of concrete rings

To equip a cesspool with concrete products, it is necessary to prepare the following materials:

- Concrete rings (depending on the intended depth).

- cement mortar.

- Materials for a small foundation.

- Sand, based on the area to be filled, if its layer is 50 cm.

- Gravel, based on the area to be filled, if its layer is 20 cm.

- Cover with hatch.

Installation of such rings is carried out without waterproofing. The installation process consists of the following items:

- Preparation of a round pit with a small margin for the diameter of the rings.

- The bottom of the pit must be filled with concrete. Only after the solution has completely solidified, work can be continued, usually it takes about 5 days.

- Now it remains to install the rings. For this, it is recommended to use special equipment, since their weight is very large.

- The free space between the walls of the rings and the pit must be filled with gravel or crushed stone from granite.

- The inner surface must be plastered, having carried out internal and external waterproofing of the seams.

- It remains to install the cover and the ventilation duct.

Pouring concrete mix

You can start making rings at a temperature not lower than 8⁰ and not higher than 22⁰С. The formwork elements are inserted one into the other, having previously been lubricated with machine oil - this will subsequently facilitate their dismantling. A reinforcement frame is inserted into the gap between the cylinders.

To give stability to the reinforcement, it is fixed with wedges. Subsequently, the wedges are removed as the mold is filled with concrete. Prepare the solution in the following proportions:

- Fresh cement not lower than M400 - 1 part.

- Granite or limestone crushed stone with low-rounded grains no larger than 0.2 cm in size - from 4 to 5 parts.

- Quartz sand with a maximum grain size of 0.22 cm - from 2 to 3 parts.

- Water - a maximum of 0.7% by weight of cement.

Specialists have their own secrets of preparing concrete mix. Sometimes they add potash glass to it in order to increase the water resistance and plasticity of the mass. To increase the strength of the composition, a component such as PVA glue is introduced into it. The fluidity of the mixture is increased by adding detergent.

It is important to immediately consume the prepared concrete, therefore it is better to immediately calculate the right amount of the mixture for one pour

By eye, stiffness can be determined by placing the mixture on a horizontal plane. If, when tilted, it will drain quickly, the mixture is very liquid. The average plasticity of the mixture is indicated by its slow creep. When the mixture sticks and does not slip, it means that it is not very plastic, and if the mass does not even change its shape and remains lumpy, this indicates its rigidity.

Since the rings for the cesspool are a reinforced structure, concrete of low rigidity is more suitable here. When using Portland cement M500, the norms for M400 are multiplied by 0.88. For other brands, other coefficients are taken.

Having prepared a mixture that resembles a thick dough in consistency, the first layer about 10 cm thick is sent to the formwork. Then they beat it off: they take a steel bar with a diameter of 20 mm and diligently compact the material. In this way, the entire volume between the two cylinders is filled. After completing the work, close the product from direct sunlight, throwing a piece of dense fabric on top.

The formwork is removed after 14 days, left in the same place for another 4 days, not forgetting to periodically water it. If filling is performed with a less dense mixture, then the process is called casting. Formwork from products obtained by the second method is removed after a week.

Shells will remain on the surface and they are filled with cement mortar. On products made by the second method, fewer shells are formed. The oil that covered the surface of the cylinders is removed. A tighter connection of the rings provides a lock.

To obtain this element, 2 more rings are added to the form, forming a combined mounting chamfer in the form of a protrusion on one product and a neck on the other. This will allow the rings to be firmly fixed during installation, preventing them from shifting.

A known method for the manufacture of rings, excluding from the process such a laborious operation as the transportation of the finished product. To do this, the form for the ring is made on the spot, where they subsequently plan to dig a cesspool. First, a ring is cast, and then soil is selected under it and gradually lowered to the bottom, immersing it completely in the pit.

When the upper edge of the product is flush with the ground, a new formwork is constructed on it. The next ring is made and the soil is selected again until the edge of the product is flush with the ground. Continue to make new rings until the desired depth of the cesspool is reached.

The highest quality products are obtained if it is possible to use vibrocompression technology, which involves installing the mold on a special vibrating plate with a drive. The slab performs oscillatory movements of small amplitude and high frequency, which allows the maximum compaction of the concrete mass.

Image galleryPhoto from With your own hands, you can make reinforced concrete and concrete rings of different diameters. Including rings for the device of the neck of the sewer well

Sources

- http://promtu.ru/biotualetyi/koltsa-dlya-yamyi-tualeta

- http://stoki.guru/kanalizaciya/emkosti-i-kolodcy/cena-plastikovyh-kolec-dlya-kanalizacii.html

- http://septicov.net/kanalizacija/plastikovye-kolca-dlya-kolodcev.html

- https://www.aquacop.ru/vygrebnye-yamy.html

- http://VashBiotualet.ru/dlya-dachi/trebovaniya-dlya-obustrojjstva-dachnogo-tualeta-iz-betonnykh-kolec-ehtapy-rabot.html

- http://sovet-ingenera.com/kanaliz/sliv-vygreb/kolca-dlya-vygrebnoj-yamy.html

Step by step installation instructions

Having decided on the place and amount of materials, we proceed to the next stage - preparing the pit for the cesspool. It is dug out taking into account that not only the septic tank chamber, but also the filtering well can fit. How to dig - on your own or using special equipment, it's up to you. But the second option, although it requires financial costs, is much easier and faster.

We watch the video, we start how much in the pit:

The bottom of the pit must be concreted so that sewage does not seep into the ground. A pillow of sand is preliminarily poured with a layer of 40 cm or more. The bottom for the filtering well is covered with crushed stone, gravel and sand within half a meter thick.

We watch the video, the stages of the construction of a cesspool from the rings:

However, the task can be simplified by the purchase of concrete rings for a toilet in a country house with a bottom - today such structures are sold on the construction market. In this case, it is installed at the very bottom, and ordinary ones are mounted on top of it.

Installation of rings is possible only with the use of special means of mechanization, since the weight of one reaches 400 kg and it is impossible to lower it manually. After installing the entire structure, each of its elements is fastened with the next one using a concrete solution. Additionally, you can use staples or metal plates. This is necessary to avoid cracks in the structure during spring soil movements.

Then pipes are laid to organize the flow and to make an overflow pit. Experts recommend making an eyeliner with a bend or a water seal in which liquid will remain.

As a waterproofing for this design, the Aquabarrier composition or special plastic cylinders, selected according to the inner diameter of the septic tank, are used. They do not allow runoff to seep into the ground. From above, the structure is covered with a concrete slab in which there is a hatch for pumping sewage.

The cost of the toilet from the rings

Price has always been and remains a decisive factor in choosing a method of manufacturing a particular design. Talking about how much a country toilet made of rings can cost, it should be noted that it is unlikely that it will be possible to carry out all the installation work on your own. It is impossible to do without special equipment in such a case. Therefore, perhaps the best option would be to order his device from a special company. Usually their price is about 4000 rubles for one ring. Although a home-made design, the final cost will be much lower.

What to pay attention to when setting up

Installation scheme

Although a cesspool with concrete rings is considered the best option in terms of quality and price, it is still necessary to follow certain rules when constructing it.

A pit for a septic tank is made with perfectly even walls and a bottom for a better fit of the rings to the ground. It is better to entrust the installation of rings to the company.

Very often, those companies in which they order the manufacture are ready to help with the installation for an additional fee. If you still decide to do it yourself, then first dig a pit. Then, according to its size, order rings. Because if they are larger and get stuck, you will have to spend a large amount for dismantling and reinstalling.

Watch the video, a little about this design:

Don't forget to punch holes in the piping rings. It is best if this work is done prior to installation.

Taking into account all sanitary and building standards, as well as being guided by the rules set out above, you can arrange a cesspool with concrete rings on your site. But given the above calculations, this option of local sewage is more suitable for country houses with seasonal residence. Since it quickly fills up and requires pumping.

Therefore, for a country cottage, it is better to choose a more modern septic tank, the work of which is based on the treatment of wastewater and their subsequent use for irrigation. This will help to avoid unnecessary costs and hassle with finding and ordering a sewer truck and significantly reduce the cost of a toilet for a summer residence.

How plastic rings are installed

They are installed directly into the ground. The installation process consists of several stages:

- Preparing a place for a toilet.

- Digging a pit for a plastic container.

- Preparation of the bottom of the pit, which consists in laying alternately layers of gravel, sand and geotextiles.

- Now you can start installing polymer rings. They are lowered one by one into the hole.

Their order is:

- Bottom.

- One or two rings.

- with pipe hole.

- with lid.

To connect, light pressure is enough to ensure that each element is firmly seated in the grooves provided.

The cesspool equipped in the summer cottage should be pumped out periodically, so you need to monitor its filling. For these purposes, you can buy a special float that will signal the degree of filling of the pit.