1 Determination of network water consumption

Estimated consumption

network water, t/h, in closed systems

heating supply to determine the diameters

pipes in water heating networks at

quality control of vacation

heats should be determined separately

for heating, ventilation and hot

water supply according to the formulas:

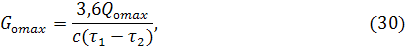

On the

heating

where

and

– supply and return temperatures

pipelines of the heat network at the calculated

outdoor temperature for

design of heating systems and

ventilation.

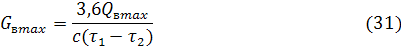

On the

ventilation

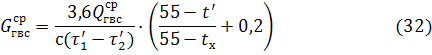

Estimated

hot water consumption

water supply, t/h

depend on the connection scheme

water heaters. With a two-stage

connection diagram water flow

determined by the following formulas:

where

hourly average

hot water consumption,

t/h

and

supply and return temperature

heat pipelines at the breakpoint of graphs

water temperatures.

Formulas

to determine the estimated flow

network water in a parallel circuit

heater connections are given

v .

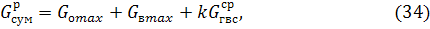

Total

estimated consumption of network water, t/h,

in two-pipe heating networks with

quality regulation of heating

load:

where

coefficient,

taking into account the share of the average water flow

for hot water supply, accepted

depending on system power

heat supply (k=1.0

at k=1.0

at ).

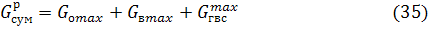

For

consumers with a heat flow of 10 MW

and less total estimated consumption

water should be determined by the formula:

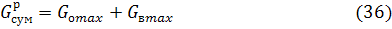

At

central quality regulation

heat release by combined load

heating and hot water supply

the estimated consumption of network water is determined

as the sum of water consumption for heating and

ventilation without taking into account the load of hot

water supply:

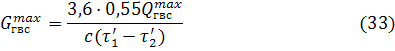

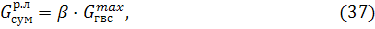

Estimated

network water consumption in non-heating

period, t/hdetermined

according to the formula:

where

define

according to formula (33), taking into account the fact that

maximum heat load

hot water supply

taking into account the increase in the temperature of the cold

water up to 15oC;

coefficient,

taking into account the change in water consumption by

hot water supply in non-heating

period in relation to heating,

accepted for housing and communal

sectors equal to 0.8. For resort and southern

cities,

for industrial enterprises.

EXAMPLE

4. For two

quarters of the district of the city to determine

estimated total network consumption

water. Data on calculated thermal

flows from example 1. Temperature

water in the supply pipe,

in the opposite

Heat supply is controlled

by combined heating load

and hot water supply.

Solution:

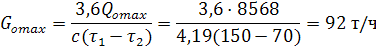

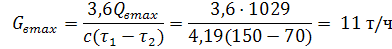

Estimated

consumption of network water for heating for

quarter No. 1 we find by the formula (30):

By

formula (31) for quarter No. 1 we find

estimated water consumption for ventilation:

Note.

Estimated heat fluxes are taken taking into account

5% heat loss to the environment.

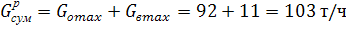

Total

the estimated flow of network water we calculate

by formula (36):

Similar

we will make calculations for quarter No. 2,

and put the results in table 4:

table

4 - Estimated consumption of network water for

two city blocks

|

quarter number |

|||

|

1 |

92 |

11 |

103 |

|

2 |

153 |

18 |

171 |

|

Total: |

274 |

Head of VET

____________

N.I. Chapurin

Boss

chemical shops

____________

I.A. Abramova

This instruction

is intended for the personnel of the chemical shop when they perform operations on

operation of a water treatment plant for feeding the heating network (clarification

on mechanical filters, single-stage Na-cationization).

The instructions include:

- characteristic

installation equipment,

— modes of operation of various

its knots

- security measures,

- starting, stopping and

maintenance of equipment during normal operation and emergency

situations

—

conditions

efficient operation of the water treatment plant.

INSTRUCTIONS SHOULD KNOW:

—

Chief

chemical shop shifts;

—

apparatchiks

HVO 5 category;

- HVO apparatchiks

4 digits;

- head of the CHL;

—

CHL engineer.

In the text of the instructions adopted

the following abbreviations:

PTS - feeding of the heating network;

VPU - water treatment

installation;

HVO - chemical water treatment;

BUV - softened water tank;

BOBV - tank of desiliconized

water;

NObV - desilicon pump

water;

SW - softened water;

DKV - decarbonized

water;

BDKV - tank

decarbonized water;

NDKV - pump

decarbonized water;

VDR - upper

drainage distribution device;

NDRU - lower

drainage distribution device;

HOW - chemically purified water;

RU - distribution

device.

GENERALI am a PART

CHP-2 chemical water treatment serves

for the preparation of chemically purified water according to two technological schemes:

1. For additives in

boiler feed water.

2. To feed the heating system.

Water for feeding the heating system

prepared according to the scheme:

clarification of raw water on mechanical

filters - Na-cationization - collection of water in BUV No. 1,2 - with UV pumps in

deaerator for feeding the heating network of the turbine shop.

The source of water supply is

river Ob.

Raw water is supplied to

chemical water treatment with raw water pumps installed in the ash room

boiler shop.

Raw water control

produced by an automatic control valve depending on the water level in the

BUV or manually through the bypass valve C-1.

Soft water consumption

is regulated by the duty personnel of the turbine shop.

With a normal flow pattern

raw water for cold water treatment (for clarifiers - along the line D 377 mm after PSV:

to feed the heating network - after the condensers of turbines No. 3 or No. 4 according to

line D 500 mm) the raw water temperature should be:

- for brighteners

+30º С ± 3 º С (winter-summer);

- to feed the heating system up to

+ 40 ºС.

With an emergency scheme for supplying raw

water at the WLU PTS clarifiers from the line DN 377 mm after PSV (at

disconnection of the line DN 377 mm after PSV mm after turbine condensers No.

3.4) should not be lower than 15o and not higher than 40ºС. Water temperature

40ºС is limited by PTB (RD 34.03.201-97 p.3.7.35), used

at CWT, the strongly basic cation exchanger KU-2-8 is operable at t up to 120-130o (Kostrikin

page 21), lowering the temperature below 15o-20o reduces the effect

regeneration of the cation exchanger, and also worsens the process of water softening (Golubtsov

p.217). The best effect of cation exchanger regenerations is achieved at a temperature

35-40o.

Raw water temperature at

clarifiers supported by automatic water temperature controller

for PSV.

Raw water temperature at

feeding of the heating network is supported by the driver of turbines No. 3,4,5 by

changes in the position of the turbine control diaphragm, in the condenser of which

raw water is heated.

Water for preparation

chemically treated water for feeding heating networks, heated in the condenser

turbines No. 3 and 4 and is supplied through the raw water pipeline D=500mm.

Raw water pipelines (D=377mm

and D=500mm) and chemically treated water

(D=500 mm and D=273 mm) pass along the outer

flyover.

9. Calculation of the deaerator for feeding the heating system.

rice. 2.6. Calculation scheme of the vacuum deaerator.osignVD2.10. Calculation of the HDPE system.424dr4525dr5626dr6727dr7’T Fig. 2.7. Calculation scheme of the HDPE system.6T5TpsOUuplTdvut’etcTnot raisedTT7ohTToToo2.11. Determining the steam flow to the turbine and checking its power.3. Thermal calculation of HDPE and optimization of its characteristics on a computer.Initial data for IPA 4:

- heated water flow Gv=0.84102=85.7 kg/s;

- inlet water temperature tin 1\u003d 136 ° C;

- heating steam pressure Р=0.52 MPa;

- heating steam saturation temperature tn\u003d 153 ° C;

- temperature difference of the heater t=2 оС

- latent heat of vaporization r=2102 kJ/kg;

- average heat capacity of waterR=4.19 kJ/kg оС;

- internal pipe diameter dext=0.018 m;

- pipe thickness =0.001m;

- thermal conductivity of brassst=85 W/m K;

- distance between partitions H=1 m;

- water velocity c=2 m/s;

- price of a ton of standard fuel Chere.=60 $/tce;

- specific cost of the heater surface kF=220 $/m2;

- extraction heat value coefficients j+1=0.4 and j=0,267;

- number of hours of use of installed capacity hSpanish=6000 h;

- Boiler efficiency ka=0,92;

- Heat flow efficiency tp=0,98.

LtdPhysical properties of water at tvf.322Physical properties of the condensate film at tn.3222ooo2ntr4. Determination of heat value coefficients.Calculation of power change factors.The coefficients of the value of the heat of extractions are calculated by the formula:Analysis of technical solutions using CCT selections.

- Reducing the temperature difference in HPH 6 by 1 °C.

- Installation of superheated steam cooler.

- Installation of a drainage pump on HDPE 2.

- Extender installation.

- Increase in pressure losses in the selection pipeline to LPH 4 by 2 times.

Ltd

- Atinstallation of a drainage cooler at the HPH 6.

5. Calculation of technical and economic indicators.6. Choice of auxiliary equipment of the turbine plant.

- We select feed pumps for supplying feed water at the maximum power of the installation with a margin of 5%:

Monpv

- Condensate pumps are selected according to the maximum steam flow into the condenser with a margin:

bookTo

- We select drainage pumps without a reserve (reserve - cascade drain) of the KS-32-150 type (PND 6).

- We choose low pressure heaters of type PN-200-16-7 I in the amount of 4 pieces.

- High pressure heaters in the amount of three pieces of type PV-425-230-35-I.

- We select deaerators with a deaerator column of the DP-500M2 type and a deaerator tank of the BD-65-1 type.

Conclusion.o2Literature.

2

2.6. Main and auxiliary equipment of heating plants

Water,

supplied to the heating network for the needs

consumers, at the CHPP it is heated in

network heaters of turbine units,

in peak heaters and in peak

hot water boilers, which are

to the main heating equipment

CHP. To the auxiliary heating plant

equipment include: make-up

heating network installation, network pumps,

storage tanks, recirculating

hot water boiler pumps, etc.

Peak

hot water boilers (PVK) are designed

for installation in CHP plants to cover

peaks of heating loads. Peak

hot water boilers are usually installed

in separate rooms at large thermal power plants

or in the main building at small CHP plants.

The fuel of these boilers is more

part of oil or gas. In view of the small

usage during the year peak

boilers are simple in design

and inexpensive. The building can be carried out

only for the lower part of the boilers, the upper

some of them remain open.

air. Before the commissioning of CHPPs, water-heating

boilers can be used for temporary

district heating

district. Network water is heated

in series in network heaters

up to 110÷120С,

and then in PVC up to 150C

maximum.

In

avoid corrosion of the boiler metal

the temperature at the inlet must be

not lower than 50÷60С,

what is achieved by recycling and mixing

hot and cold water. Estimated efficiency

hot water boilers for gas and oil

reaches 91÷93%. Produced and used

PVC on coal. They have their own dust preparation,

exhausters and other equipment.

steam-water

heaters for heat treatment

installations

designed for heating network

water steam from turbines or from boilers through

reducing and cooling plants

(abbreviated ROW).

Network

pumps

used to supply hot water

heating networks and depending on

from the installation site are used as

first lift pumps supplying water

from the return pipeline to the network

heaters; second lift for

water supply after network heaters

to the heating system; recycling,

installed after peak hot water

boilers.

Network

pumps must have a high

reliability, as interruptions or malfunctions

in the operation of pumps affect the mode

operation of CHP and consumers.

Basic

features of network pumps

are fluctuations in the supply temperature

water over a wide range, which in its

queue causes a change in pressure

inside the pump. Network pumps must

work reliably over a wide range

innings. Usually

network pumps are centrifugal,

horizontal, driven by

electric motor.