Preparation for soldering copper with aluminum, brass, stainless steel, iron

The preparatory period, which includes the purchase of the necessary devices, materials, personal protective equipment, and the soldering procedure itself.

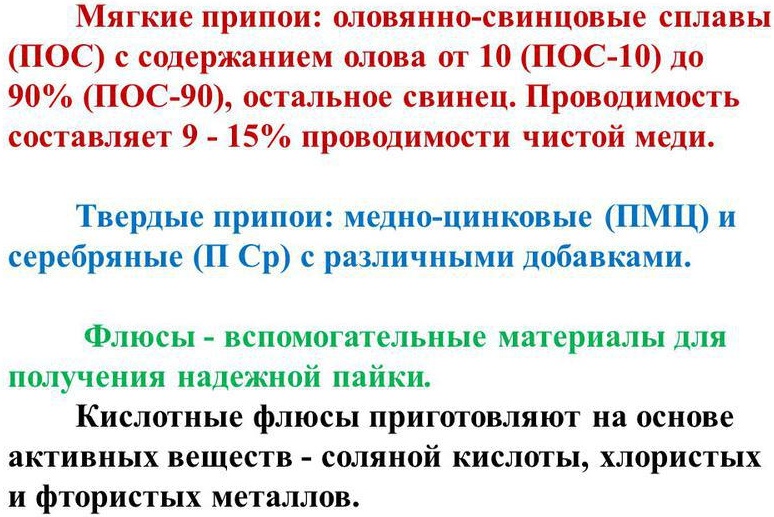

There are two ways to solder copper to copper: high temperature and low temperature. The first involves heating the metal to 900 ° C, it is used for pipelines with high pressure or temperature stress. For high-temperature soldering, the materials intended for this are used: hard solder in the form of rods (the melting point of such solder is about 900 ° C) and carbide flux.

In order to solder copper using the low-temperature method, it is enough to heat the metal to 600°C (usually 300–380°C), which is achievable in domestic conditions. For the procedure, soft solder is used for soldering copper and brass in the form of a wire or rod with a cross section of up to 3 mm and a more fusible flux. Solder is an alloy of tin, which is more than 97%, with other metals: copper, selenium, silver, antimony.

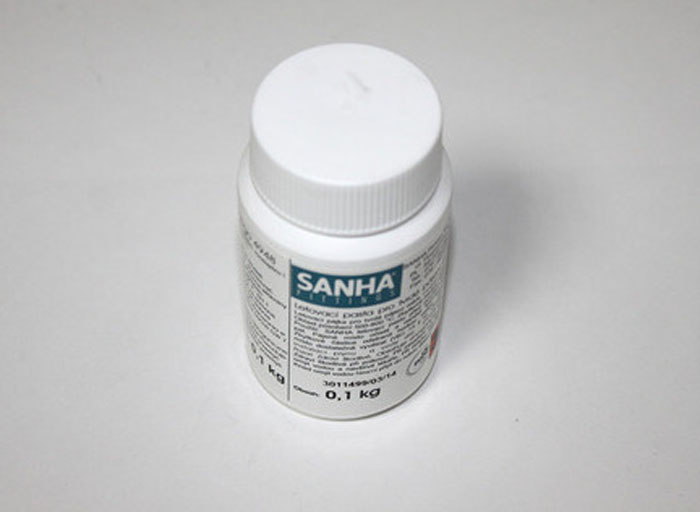

What is the flux for? Correctly soldering copper pipes is possible only with flux - a special paste-like composition (with zinc chloride), which is applied to the surface of the pipe sections to be joined with a wide strip. It performs several functions:

- prevents the process of metal oxidation by removing oxygen;

- improves the adhesion of solder to copper;

- is an indicator of sufficient heating of the metal, signals when to bring solder and solder copper;

- promotes uniform spreading of solder over the joint.

Safety engineering. Despite the simplicity of the process, copper pipes must be soldered in compliance with safety rules. The danger of burns is not only the burner flame itself, but also the heated metal. Copper conducts heat well, therefore, during operation, not only the area on which the solder is placed and welding is heated, but the entire pipe, and it cools slowly. If it is necessary to solder copper pipes that are not yet built into the piping system, then the preparation includes placing them on non-flammable supports where they can cool for a long time. Before touching the soldered metal from its place, you should wait until it has completely cooled down.

The immediate danger is the open flame of the burner, so you need to purchase a tool that is convenient to work with: preferably with a movable nozzle on a long hose

Copper Soldering Safety

It should be borne in mind that the heat conductivity of copper is very high, as a result, it is not recommended to solder parts, holding them in hands without protection, most likely this will result in burns. Details shorter than 30 cm are held exclusively with tongs or in protective gloves. If during the soldering process a flux drops onto the bare parts of the body, it is necessary to immediately wash it off with soap and water, since, in addition to thermal, a chemical burn can be made.

For any work with open fire and hot metal, as well as a flux that contains acid, synthetic clothing is undesirable, since such a fabric ignites and melts much faster than others. Be sure to ventilate during operation, the smoke from the burnt flux is harmful.

If there are no soldering skills at all, it is advisable to practice on scraps of pipes or wires before performing responsible work. There are few difficulties in this work, and 2-3 times, as a rule, are enough to learn all the basic techniques. If a plumbing system is being assembled, it is recommended to pre-assemble it on the floor before putting everything in place. After assembly and soldering, the system should be thoroughly rinsed with hot clean water to remove parts of the flux and solder from the inside of the pipes.

Plumbing or heating systems made of copper pipes are expensive, but they are strong and durable.Since copper has a high thermal conductivity, good anti-corrosion and antibacterial properties, the pipeline made of it is efficient and durable. Soldering copper at home is not difficult: a socket-coupling is put on the pipes, and then the seam is sealed. Instead of using a socket, sometimes the end of one pipe is expanded and another is inserted into it. Such a connection is convenient in that it does not require fittings, and the service life is equal to the life of the pipes themselves.

Necessary materials and devices tin and others

The following tools are required for working with copper pipes:

- pipe cutter, hacksaw or grinder with a thin disk;

- beveler;

- pipe expander (expander);

- soldering flux;

- solder;

- soldering iron for copper, for example, a propane torch for soldering copper pipes;

- rubberized gloves;

- paper napkins.

To cut the pipe, pipe cutters of various sizes are used. Larger samples have a large turning radius, they are inconvenient to use in hard-to-reach places, so if there is a need to cut off a section on a finished mounted water supply, use a small pipe cutter. You can cut the pipe with a hacksaw or a grinder with a thin disk, but a better cut can only be obtained with a pipe cutter.

After the pipe is cut, the burrs are cleaned. This is necessary so that there is no swirling of the fluid flow in the system. When there are no obstacles, the water supply does not experience stress and works like a clock.

Before welding copper, the ends of the pipe are polished with fine-grained sandpaper, which can be purchased at hardware stores. Both surfaces are cleaned, preparing for soldering. Sometimes for these purposes small brushes are used, the diameter of which is Ø 22 mm, they fit almost all pipes. For stripping, the brush leg is inserted into a screwdriver or drill, with which the process is carried out faster and better.

A flux is applied to the cleaned, smoothed outer surface - a composition that prevents the oxidation of copper.

Rubberized gloves are used to protect hands, since when cutting off copper and burrs, many small metal elements are formed that stick into the skin like splinters. In addition, when cleaning the surface with a drill, a rotating brush chews up rag gloves.

In order to properly solder copper, it must be borne in mind that no more than half an hour should pass from the moment of stripping and applying the flux to soldering, otherwise the stripping must be repeated again. If the flux is applied with a brush, no bristles or hairs from it should remain on the surface - otherwise the connection will not be tight, and after the water is supplied, the pipeline will leak.

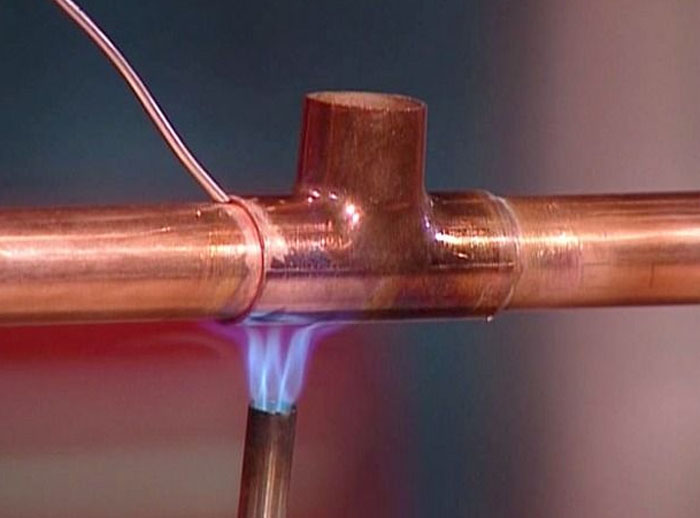

After inserting the pipe into the socket, the flux residues are not completely removed with a napkin, it remains on the connection in the form of an edge of 1–2 mm, and when soldering, the solder is pulled inward - a capillary effect is triggered. First, the joint is heated with a burner, while the moisture between the walls is evaporated. Then the burner is brought a second time, gradually the copper heats up, and the flux takes on a tin look. At this moment, solder is placed on the front side, soldering occurs, while the molten alloy flows down to the wrong side, solidifying in the process of movement. The excess overhangs of metal formed from below are separated by themselves. There are many ways to solder copper.

Preparation for soldering copper with aluminum, brass, stainless steel, iron

The preparatory period, which includes the purchase of the necessary devices, materials, personal protective equipment, and the soldering procedure itself.

There are two ways to solder copper to copper: high temperature and low temperature. The first involves heating the metal to 900 ° C, it is used for pipelines with high pressure or temperature stress. For high-temperature soldering, the materials intended for this are used: hard solder in the form of rods (the melting point of such solder is about 900 ° C) and carbide flux.

In order to solder copper using the low-temperature method, it is enough to heat the metal to 600°C (usually 300–380°C), which is achievable in domestic conditions. For the procedure, soft solder is used for soldering copper and brass in the form of a wire or rod with a cross section of up to 3 mm and a more fusible flux.Solder is an alloy of tin, which is more than 97%, with other metals: copper, selenium, silver, antimony.

What is the flux for? Correctly soldering copper pipes is possible only with flux - a special paste-like composition (with zinc chloride), which is applied to the surface of the pipe sections to be joined with a wide strip. It performs several functions:

- prevents the process of metal oxidation by removing oxygen;

- improves the adhesion of solder to copper;

- is an indicator of sufficient heating of the metal, signals when to bring solder and solder copper;

- promotes uniform spreading of solder over the joint.

Safety engineering. Despite the simplicity of the process, copper pipes must be soldered in compliance with safety rules. The danger of burns is not only the burner flame itself, but also the heated metal. Copper conducts heat well, therefore, during operation, not only the area on which the solder is placed and welding is heated, but the entire pipe, and it cools slowly. If it is necessary to solder copper pipes that are not yet built into the piping system, then the preparation includes placing them on non-flammable supports where they can cool for a long time. Before touching the soldered metal from its place, you should wait until it has completely cooled down.

The immediate danger is the open flame of the burner, so you need to purchase a tool that is convenient to work with: preferably with a movable nozzle on a long hose

What is needed for soldering copper pipes

Soldering copper pipes, which is not difficult to do with your own hands, does not require expensive equipment and any special materials. In order to properly implement it, you will need the following devices.

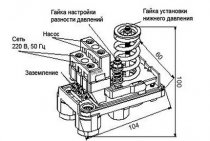

A burner, due to which the solder and the pipe section where they will be connected will be heated. As a rule, propane gas is supplied to such a burner, the pressure of which is regulated by a welding reducer.

Special tool for cutting copper pipes. Since products made of this metal are very soft, they should be cut gently enough so as not to wrinkle the walls. Pipe cutters of various models are offered on the modern market, differing both in their functionality and technical capabilities.

The design of individual models of such devices, which is important, allows them to be used even for work in hard-to-reach places.

A pipe expander is a device that allows you to expand the diameter of a copper pipe, which is necessary in order to better solder. In various systems mounted from copper pipes, elements of the same section are used, and in order to connect them qualitatively, it is necessary to slightly increase the diameter of one of the connected elements

It is this problem that such a device as a pipe expander solves.

Copper pipe flaring kit

Device for chamfering the ends of copper pipes. After trimming, burrs remain on the ends of the parts, which can interfere with obtaining a high-quality and reliable connection. To remove them and give the ends of the pipes the required configuration, a beveler is used before soldering. There are two main types of chamfering devices on the market today: placed in a round body and made in the form of a pencil. More convenient to use, but also more expensive, are round devices that can process soft copper pipes with a diameter of not more than 36 mm.

To properly prepare copper pipes for soldering, it is necessary to remove all impurities and oxides from their surface. For these purposes, brushes and brushes are used, the bristles of which are made of steel wire.

Brazing of copper pipes is usually performed with hard solder, which can be high and low temperature. High-temperature solder is a copper wire containing about 6% phosphorus in its composition.Such a wire melts at a temperature of 700 degrees, while for its low-temperature type (tin wire), 350 degrees is enough.

The technology of soldering copper pipes involves the use of special fluxes and pastes that perform a protective function. Such fluxes not only protect the formed seam from the formation of air bubbles in it, but also significantly improve the adhesion of the solder to the pipe material.

In addition to flux, solder and other basic elements, additional tools will be needed to solder copper pipes, which can be found in every workshop or garage. To solder or weld copper products, additionally prepare:

- regular marker;

- roulette;

- building level;

- a small brush with stiff bristles;

- hammer.

Before starting work, it is also important to decide how to solder copper pipes. There can be two main options: brazing copper (less commonly used) and using soft solder

When solving this issue, it is important to proceed from the fact that there are requirements for the use of one or another type of solder. So, hard solders are used for soldering elements of refrigeration units and air conditioners. In all other cases (water supply systems, heating systems, etc.), tin wire can be used. But whatever technology is chosen, it should be remembered that the flux is necessary in any case.

Brushes for stripping the inner surface of a copper pipe before soldering

Rules for soldering copper

When it is necessary to solder a copper product or a product containing copper components, it is impossible to give an unambiguous answer as to how and what is the best way to do this. The choice of method and tools depends on many factors, such as the size and weight of parts, their composition. The load to which already soldered products must be subjected is also taken into account. There are several soldering methods, and it is better to know them all in order to choose the most suitable one if necessary.

Soldering large parts

Scheme of capillary soldering of copper.

If you need to solder massive or large parts that cannot be heated to the desired temperature with a soldering iron, a torch and copper solder are used. The flux in this case is borax. The strength of copper-phosphorus solder is higher than that of standard tin solder.

A thin layer of flux is applied to the mechanically cleaned pipe or wire. After that, a fitting is put on the pipe, also mechanically cleaned. Using a gas burner, the junction is heated until the flux-coated copper changes color. The flux should become silvery in color, after which you can add solder. The solder melts instantly and penetrates into the gap between the pipe and the fitting. When drops of solder begin to remain on the surface of the pipes, the solder is removed.

Do not overheat the pipes, as this does not contribute to the appearance of a greater capillary effect. On the contrary, copper heated to blackness is less solderable. If the metal begins to blacken, the heating should be stopped.

Soldering wires or wire

Zinc chloride solder should not be used to solder thin copper wires, as this will destroy the copper. If no flux is available, in this case you can dissolve an aspirin tablet in 10-20 ml of water.

Scheme of copper welding in an inert gas environment.

Copper wire or parts made of wire of various sections can be easily heated to the desired temperature using a soldering iron. The temperature regime should be the one at which the solder melts, tin or lead-tin, and soldering is also performed by it. Fluxes must contain or be made from rosin, soldering oil or even rosin itself can be used.

The surface of the wire is cleaned of dirt and oxide film, after which the parts are tinned.This process involves applying a thin layer of flux or rosin to the heated copper, and then solder, which is distributed over the surface as evenly as possible with a soldering iron. The parts that need to be connected are connected and heated again with a soldering iron until the already solidified solder begins to melt again. When this happens, the soldering iron is removed and the joint cools down.

Parts can be clamped in a vice so that the distance between them is 1-2 mm. Flux is applied to the parts and heated. Solder is brought to the gap between the hot parts, which will melt and fill the gap. The melting temperature of solder for soldering in this way must be lower than the melting temperature of copper so that the parts do not deform. The part cools down, then it is washed with water and finished, if necessary, with sandpaper until smooth and uniform.

Soldering dishes or soldering holes in copper

When soldering dishes, pure tin is used, the melting point of which is higher than that of tin or lead-containing solder. Sometimes, for soldering large parts, hammer soldering irons are used, heated on an open fire with a gas burner or blowtorch. In the future, everything happens according to the standard scheme: cleaning, fluxing and tinning, joining parts and heating with a soldering iron. It is for this soldering iron that pure tin solder is convenient.

From the inside, the fitting, as a rule, has a border that prevents it from being threaded through the pipe. It can be removed with a coarse file if the fitting needs to be pushed onto the pipe further than intended and the unnecessary hole must be soldered in this way.

Features of soldering with soft and hard solders

Copper pipe connection has a number of characteristic features. They are especially pronounced when using various materials.

Soldering of links with fusible solder is carried out at a temperature of 175–315ᵒC. Soldering with solid compositions is carried out when the joint is heated to a temperature of 650–815ᵒC.

Soft soldering is used for soldering copper pipes with an inner diameter of up to 22 mm, and hard alloy with a diameter of 22 mm or more.

With sufficient heating, the applied flux layer boils. During the melting of soft solder, a molten drop is formed, which plays an important role in the strong connection of pipes. Boiling flux pushes the molten composition out of the joint space. Under the action of capillary forces, the solder alloy is drawn into the joint as it cools.

When soldering with hard solders, a thin soft metal gasket is inserted between the elements to be soldered. The connected parts are securely and firmly fixed with a guide gasket.

A simple technique for soldering copper pipes and the availability of all materials allows you to do this work yourself at home.

Related video: Soldering copper pipes "my experience"

A selection of questions

- Mikhail, Lipetsk — What discs for metal cutting should be used?

- Ivan, Moscow — What is the GOST of metal-rolled sheet steel?

- Maksim, Tver — What are the best racks for storing rolled metal products?

- Vladimir, Novosibirsk — What does ultrasonic processing of metals mean without the use of abrasive substances?

- Valery, Moscow — How to forge a knife from a bearing with your own hands?

- Stanislav, Voronezh — What equipment is used for the production of galvanized steel air ducts?

soldering process

It consists in performing sequential operations:

- the pipe is cut into segments of the required dimensions, which are marked for convenience - supply or return;

- chamfer is removed from the edge;

- the edges are cleaned by 2 cm: external on the pipe, as well as internal in the socket;

- flux is applied with a strip along the cleaned surfaces (external and internal);

- the connection is assembled: the pipe is inserted into the socket;

- excess flux is removed with a paper towel, but not completely - an edge of 1-2 mm is left;

- the burner is ignited, the flame is brought to the junction;

- the surface is heated for 10-15 seconds to a certain temperature - the flux should acquire a tin color;

- solder is placed on top of the joint, when heated, it will be drawn into the joint, spread along the seam, filling it.

If the joint of the joint has not been cleaned of bristles or dust, and as a result the soldered seam of the copper water pipe leaks, then the tightness can be restored using one of two methods:

Using a soldering iron

- the surface is cleaned, treated with phosphoric acid, heated with a soldering iron, tin is applied;

- using a torch: flux is applied to the cleaned surface, heated, solder is placed, melted.

How to solder copper with a gas torch

You can solder the copper tube as follows:

- Clean the soldering area with a fine file, sandpaper or a metal brush.

- Crush the rosin and sprinkle the place of soldering.

- Heat the tube over a gas flame until the rosin melts.

- Put solder POS-30 or 40 and melt it with a soldering iron, distributing it over the surface.

In everyday life, copper processing is encountered not only when it is necessary to solder copper pipes for heating or plumbing, but also in car repair, if a crack or leak appears on the car radiator. In this case, do-it-yourself soldering of a copper radiator is done. Instead of a gas burner, motorists use a powerful 250 W electric soldering iron for copper pipes. For stripping copper, a sandpaper or a metal brush is used, and for soldering tin, rosin or orthophosphoric acid is used as soldering acid.

Soldering with a soldering iron at home

Soldering copper with a soldering iron is easier than using a torch. The procedure is as follows:

- The surface of the radiator is cleaned with a fine-grained sandpaper or brush.

- A few drops of acid are evenly applied to the edges of the damaged area.

- The crack is heated with an electric soldering iron, solder is brought. Melted, tin fills the hole.

Self-soldering copper pipes for heating or water supply, repairing cracks in radiators is a simple technology process that can be done at home with a small set of tools.

WATCH VIDEO

Soldering copper at home is within the power of every man.

Tools and materials for soldering copper

- pipe cutter;

- beveler;

- pipe expander;

- metallic wool;

- vise;

- pliers;

- tweezers;

- soldering iron;

- solder;

- flux;

- borax;

- soldering oil;

- gas-burner.

Diagram of an electric welding machine.

A pipe cutter is required in order to cut pipes to length. The principle of operation of pipe cutters is the same, although there are a lot of models on sale. The pipe for cutting it is clamped between the rollers and the blade, then the pipe cutter is rotated around, tightening the bottom bolt a third of a turn. To get a smooth edge, the pipe is held strictly perpendicular to the tool. The pipe is usually cut in 5-6 turns. It is possible to produce low-temperature soldering of copper with a gas burner, since its temperature does not exceed 450 °. Not all commercially available torch designs are suitable for soldering.

Before choosing a burner for soldering copper, you need to pay attention to the instructions, since those burners that begin with the ignition of the barbecue are not suitable for this purpose. How to solder copper correctly? You need to do this with a soldering iron or a burner with a narrow flame

Such a burner will heat the pipe in a matter of seconds, and the gas cartridge will last for a long time with economical use. When choosing a burner, you need to look at the composition of the gas in the cylinder. As a rule, this is a mixture of propane and butane, but the higher the butane content, the higher the flame temperature.

Metal wool is used to clean copper before working with a torch and soldering iron. She tightly compresses the end of the pipe or wire and makes several rotational movements with effort. This is enough for the wire, and the pipe should also be cleaned from the inside. Narrow tubes (fittings) can be cleaned with special brushes designed for this, while it is strictly forbidden to use sandpaper, especially large fractions, and even more so a file. Copper is a soft metal, and when using sandpaper, the components of the sandpaper will remain on the surface, preventing adhesion and good bonding.

Scheme of spot welding of copper.

Solder can be purchased coiled for ease of use. This is a tin wire with a diameter of about 3mm

It is advisable to pay attention to the absence of lead in the solder, which should be indicated by a special inscription on the coil. An important component for soldering is the flux, which wets the base metal (copper in this case) before soldering, penetrating into all capillaries

The flux spreads over the surface under the action of capillary forces. Before soldering correctly, the surface must be perfectly clean and free from oxides. The seam will only be strong if the components are protected from the oxygen present in the air. The use of flux increases solder adhesion on a par with mechanical cleaning of surfaces.

When using a flux, it doesn't really matter if it's for lead-free or lead-free solder, these varieties are interchangeable. Fluxes for brazing stainless steel are not suitable for use with copper. Ordinary rosin can also be used, but there may be problems with its application.