Steam heating in a log house

The principle of steam heating is the circulation of hot water through a closed system consisting of a boiler, an expansion tank and polypropylene pipes. From the course of physics it is known that hot water has a lower specific gravity, due to this, it rises through the pipes. In the process of passing through the system, it cools down, becomes heavier and moves down. To improve circulation, it is recommended to insert a circulation pump into the system. As a coolant, it is better to use a special non-freezing liquid. In case of freezing of the heating system, in various emergency situations, nothing will happen to the pipes. If ordinary water is used, it may turn into ice and damage the system.

Advantages of steam heating

- With the help of it, you can heat almost any dwelling by area.

- The boiler is located in a separate room. There is no soot and dirt in the house

- Possibility to regulate the temperature

- Efficiency of many boilers, high enough, more economical use

- It is possible to use solid fuels with high efficiency, such as coal

- Some models of boilers can be converted to gas or choose an electric boiler, although it is not economical

- Possibility to choose a double-circuit boiler for heating and hot water supply

- One bookmark is enough for 16-20 hours

Flaws

- Complicated expensive installation

- Expensive boilers, need maintenance

- Boiler room needed

- Dependence on electricity. Without electricity, the circulation pump will not work.

In addition, do not forget that the heat from steam heating can adversely affect the wood from which the dwelling is built. If the room is heated irregularly, water may freeze in the components. In the event of any problems, it is not always possible to fix them promptly.

How to add a boiler house to the house

Attaching a boiler house to a house is often in demand in private construction. People acquiring dachas, then gradually convert them into houses for permanent residence

And organizing high-quality indoor heating is a very important component for creating overall comfort. Therefore, it is necessary to create a separate room for installing a boiler there, which in fact will contribute to partly heating the room.

How to organize such suburban construction in practice. You can completely get by even with your own efforts - but it will be much more difficult than what you might initially imagine. At the same time, it is necessary to perfectly understand the technology of work, have your own professional tool, and also do not forget about assistants, since such an object will simply not be built alone.

In addition, it is worth buying more and building material in the required quantity. It is very difficult to calculate it correctly, since each separate extension of the boiler house to a country house is unique in its own way and has its own characteristics. Next, it must be brought to the site and unloaded.

Our organization, for example, offers its client to perform frame construction most often. Such a choice will definitely save and significantly speed up the construction of the foundation. In addition, the low weight of the overall structure will not greatly disturb the main country house - especially at the junction of the roof. In addition, the frame openings are filled with high-quality insulation, which in its characteristics surpasses any other material that can be used to make walls.

The exterior finish of such an extension can be made of the same material that has the main structure. Inside, it is better to use csp - cement chipboard. It is a non-combustible material that perfectly tolerates temperature changes and various humidity.

The floors are also made insulated and covered in their purity with the same material that goes on the walls. It is necessary to provide for a place exactly where the boiler will be placed - for this, it is partially necessary to perform a separate reinforcement of the structure even in the process of building the frame of the walls and floor.

The door is best placed from the street - and it is more correct that it be metal. Of course, you can make an entrance to the extension of the boiler room directly from the house - in this case, a custom-made plastic door based on a double-glazed window is suitable. It is best to refuse wooden products. In general, this is of course only a brief part of all the information - we will tell you everything else by phone.

Popular option in Russia

The equipment is cheap and for the correct installation of the system, it is only necessary to correctly calculate the location of the radiators.

Types of heating

Gas boilers are most common in those territories of Russia where there are no problems with gas. But, compliance with the measures of safe handling of gas should be firmly established in your life.

Solid fuel boilers operate mainly on wood and coal. Nowadays, they are used less often, but not without their advantages.

Local heating of a house made of timber is carried out with the help of heat guns, convectors, fireplaces, heaters, and stoves. The disadvantage of this type of heating is that these devices can only heat a small room.

To organize an autonomous heating system for a house made of timber, it is necessary to have a centralized boiler and pipes. This installation must be stationary and warm up the room completely. To date, this is the most popular type of heating for low-rise buildings. The efficiency of this type of heating is achieved through an individual approach to the creation of heating system projects for each individual dwelling.

Gas heaters in local systems are not used very often. These designs provide for the presence of an open hearth. In addition, gas burners absorb oxygen in large quantities.

In autonomous heating systems for houses made of timber, gas is very popular. Heating boilers in a modern wooden house are so advanced that there is practically no need to monitor their work. The system is fully automated, the boilers are economical, they heat large areas at once.

Steam heating of a private house from a bar

Advantages

- It is possible to heat the whole house, even a large area.

- The boiler is installed in a specially designated place.

- There is a temperature control function.

- High efficiency and economy.

- You can use solid fuel.

- Installation of a double-circuit boiler for water heating and space heating.

- One bookmark of fuel is enough for a long time.

Flaws

- Complexity of installation and high cost.

- The high cost of boiler equipment and its maintenance.

- You need to look for a separate room for the boiler.

- Depends on electricity (circulation pump).

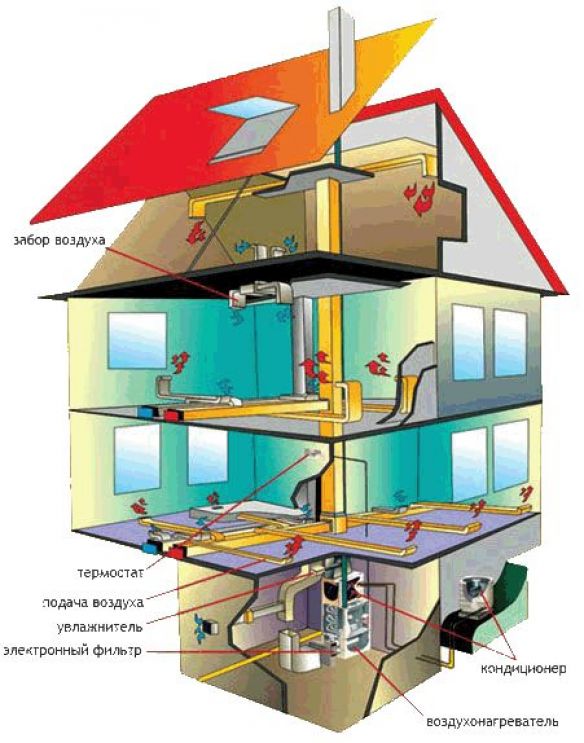

Heating "houses from a bar using an air system

Here, the coolant is the air that enters the system after heating. This type of heating is suitable for regions with a mild climate.

pros

- High efficiency.

- There is no need for additional equipment.

- You can connect the climate system.

- Ease of control.

- There is no condensation on the windows.

- Heats large areas.

Minuses

- It must be installed at the stage of building a house.Pipes through which air passes are installed in recesses in the walls, under the ceiling or in false walls.

- The system needs constant maintenance, which is difficult to do with this method of installation.

Underfloor heating

Any type of floor can be laid on top of the system. If the system fails, the floor will remain warm for several days. The disadvantage of such floors is the complexity of installation, it is necessary to first make engineering calculations.

The screed is made at the level of 8 cm, which in turn steals space. The optimum temperature for heating water should be at 40 ° C.

>

Is it possible to put a gas boiler in a wooden house

Existing SNiP allow the arrangement of a gas boiler house in a private wooden house. The exception is old-style multi-apartment buildings.

Requirements for a room for installing a gas boiler in a wooden house include the following:

- The boiler room is located on the ground floor or in one of the rooms. In a wooden house, it is forbidden to mount a gas boiler in the basement, except for a specially equipped, separate room.

- The room must comply with the requirements described in the PPB and sanitary standards.

- It is forbidden to place heating equipment in living rooms. Installation in the kitchen-living room is not allowed, installation in the bathroom and toilet is conditionally prohibited.

- It is mandatory to have personal protective equipment and fire extinguishing equipment, as well as smoke detectors and fire alarms.

Before commissioning, the heating system is checked for operability, as well as for the availability of all necessary safety components. The Gaznadzor inspector will make sure that the requirements regarding the installation of boiler equipment are met.

Separately, an audit is carried out for the availability of all documents necessary for putting the boiler into operation. The minimum package of documents includes:

- Research results of an electrical laboratory that checks the parameters of the installed grounding.

- Rostekhnadzor permission.

- House gas supply project.

The full list of documents is coordinated in the local department of the Gas Economy.

How to hang a gas heating boiler in a wooden house

The technical conditions for installing a gas boiler in a frame or log house are significantly different.

In the first case, we are talking about a hollow material, therefore, special mounting rails are used for fixing. With a large weight of boiler equipment, it is recommended to install a gas boiler in a frame house on through studs that are fixed outside the building.

Hanging a boiler in a frame house significantly increases the load on the wall. There are restrictions on the weight of the equipment. If it is planned to install a model with a built-in buffer tank, floor-standing boilers should be preferred.

Methods of fixing the boiler on a wooden wall of a log or log house are easy to fix. For installation, special wood bolts are used to ensure reliable fastening.

When installing attachments, you will need to comply with the PPB standards and maintain minimum distances to door and window openings.

What substrate to use on a wooden wall

If the boiler room is lined with wood, fire protection is provided. The substrate on a wooden wall under a gas boiler is performed in several ways:

- A layer of basalt insulation is hung on the wall, after which it is sheathed with a steel sheet.

- Use special basalt fireproof sheets. The advantage of this solution is the minimum thickness of the protective layer, while ensuring maximum fire protection.

Installation of a hinged boiler in a wooden house without first making a protective layer is prohibited!

Distances from the boiler to the ceiling, windows and doors

When planning a house, they take into account the future location of the boiler room and think over the exact installation site, taking into account the minimum requirements regarding distances to the ceiling, window and door openings. The boiler is placed taking into account the following requirements:

- The boiler is located on a blank wall, without window and door openings.

- For optimal air flow and air exchange of the room, the boiler is installed opposite the doorway. Minimum distance 2-3 m.

- The distance to the floor is kept within 0.8-1.8 m. In this gap, it is allowed to install the boiler. The minimum distance to the ceiling is not less than 0.8 m.

- The ceilings are sheathed with non-combustible material. GVL plate is optimally suited. Further finishing with gypsum mixtures is allowed.

If all requirements are met, a gas boiler house in a wooden house will be highly safe. After the examination, the Gaznadzor inspector will issue all the necessary documents and fill out an act on putting the heating equipment into operation.

Calculation of power and temperature of a warm water floor

The device of a boiler room in a private house some requirements

A boiler room is needed to heat a country house. The arrangement of such a room requires an absolutely competent approach. It is this device that creates coziness and comfort of your home, as well as its safety.

Therefore, it should be approached with special attention.

You can not save on some materials, and especially equipment. It is better to entrust the installation of the boiler and some additional equipment to professionals. They will do their job competently and efficiently, with all acceptable standards.

The most important for this process is the interior decoration of the room. It must be so fireproof that it can withstand an open flame for about 25 minutes. There are also some specific nuances that must be foreseen in advance, regardless of where your boiler room will be located.

Boiler requirements:

- Calculate the power of the boiler, taking into account the area of \u200b\u200bthe room;

- Equipment is best purchased in advance;

- Choose the door of the required size, be sure to fireproof;

- All dimensions of the boiler room must comply with special standards;

- Give preference to finishing material - tiles.

Before starting the construction of the hotel room of the boiler room, a plan is made, which must be coordinated with the gas service. Then, of course, this object must be added to the technological plan of the entire site.

Air heating of a house from a bar

In this case, air itself is used as a heat carrier. It is supplied after heating to a heated room through special air ducts. Such systems are widespread in Western Europe with a temperate continental climate and mild winters.

Heated air here is generated in the air heater. The principle of operation of a heat source is based on the combustion of fuel in the form of a liquid or gas in a special chamber. Cold air flows with the help of a special fan enter the exchanger where they heat up. Additionally, before heating, they can be cleaned of dust and enriched with oxygen. Further, the heated air enters the room through special air ducts.

Air System Benefits

- High efficiency;

- The absence of additional components, in the form of pipes, hoses, for transferring the coolant

- Possibility of connecting additional climatic equipment, with which you can maintain an optimal microclimate;

- Easy control and switching to different temperatures;

- No condensation on windows;

- Great for heating large areas.

Flaws

The negative aspects of such heating include:

The need for installation during the construction of the building

Therefore, when designing, this should be taken into account immediately, since air ducts are carried out in special niches in the walls, mounted under a false ceiling or in false walls.

In addition, this heating method must be constantly maintained, and it is quite difficult to make changes to an existing wiring.

Stove heating in a wooden house

Since ancient times, people have used stoves to heat their homes. This heating method is designed to heat the room in which the heat source itself is located. An undoubted advantage of stoves is that they can use various types of fuel for their operation, which is why they have been popular in many countries of the world for many centuries.

However, many are mistaken in thinking that with the help of only one stove, you can heat the entire building. This principle is applicable only to buildings of a small area. It is necessary to take into account the power of the furnace and correlate it with the heated area. Therefore, such heating is suitable only for one-story houses and small buildings with an attic.

Consider the disadvantages of stoves

- Low efficiency, not economical

- You have to keep adding fuel

- Do not use high-calorie coal

- With periodic (non-constant) heating throughout the day, the temperature can change dramatically;

- Stove installations and fireplaces occupy a significant area that could be used for other useful purposes;

- The constant presence of pollution due to the fuel used;

- Increased risk of fire

For large buildings, the stove can be used as a backup source of heating. The best solution for such buildings is steam heating.

Requirements for gas boilers

We list the main requirements for boiler rooms when installing gas boilers:

- Dimensions of the room for the boiler room in height - at least 2.5 meters, in volume not less than 15 m3.

- Only heating units with a power of up to 150 kW are allowed to be installed in the boiler room located within the building. If a boiler with a power of more than 150 kW is selected, then for the equipment of the boiler room the rules govern the construction of a separate standing structure or annex. But such an extension can adjoin and have common external walls only with non-residential premises (with a garage, workshops, bathrooms, a pantry or a dressing room).

- In the case of installing a boiler model that does not operate on gas from the main pipeline, but from a liquefied gas cylinder, it is unacceptable to store gas cylinders in boiler rooms. Cylinders can only be stored separately, and pipelines are laid to supply gas to the boiler.

- An extension for the boiler room, in the case of a common external wall with non-residential premises of the building, can be equipped with two entrance doors, for convenience - both to the street and to the building. But the requirements for the internal door to the building must meet fire safety standards (heat-resistant materials and a high degree of fire resistance).

- A separate boiler room or annex should be built from fire-resistant materials. Structures must have fire safety characteristics - fire resistance of at least 45 minutes, and the impossibility of igniting internal surfaces during fires from the boiler.

- Equipment with a gas boiler (and any solid fuel boiler as well) requires a solid separate foundation, as an option - concrete floors reinforced with mesh are arranged.

- In the boiler room, the presence of water supply and sewerage is mandatory, since the heating system must be provided with make-up, and water draining is periodically necessary. Thermal insulation of the premises and provision of thermal insulation and / or heating of water and sewer pipes are also required.

- Requirements for the illumination of the boiler room - the organization of natural lighting, as well as electric lighting, is mandatory.The minimum illumination values are 0.03 m2 of translucent glazing per one cubic meter of boiler room volume. The smallest boiler room (15 m3) requires a window area of 0.45 m2.

- The requirements for ventilation and air conditioning are standard, the air exchange rate for boiler rooms is normalized = 3 (complete change of air in the volume of the room three times per hour). Natural ventilation is provided by a vent built into the window frame and an air vent in the lower level of the entrance doors. As an option, a ventilation window with a mesh is made in the doors. The area of both the gap and the ventilation window must be at least 0.025 m2.

It is possible to place a gas boiler in the kitchen, for which you will need to fulfill the special requirements of the building regulations. As a rule, the most compact models of gas units are installed in kitchens.

For the installation of gas boilers in the kitchen, the standards require:

- Only heating units with a power of up to 30 kW are allowed to be installed in kitchens.

- The unit is installed or suspended on brackets on the outer wall of the house. The material of the wall structure is allowed only for the NG group (non-combustible), cladding with heat-resistant panels is allowed.

- Dimensions of rooms for boiler rooms in height - at least 2.30 meters, in volume from 15 m3.

- Lighting requirements - the minimum area of translucent glazing should be 1/3 of the floor area.

- Mandatory device for forced ventilation with mechanical stimulation, also for the used models of boiler units with closed burners, and when installing coaxial chimneys.