Manufacturers

The four-way valve for heating is produced by companies such as Honeywell, ESBE, VALTEC

other.

Today it is a manufacturer that is included in the list of 100 leading world companies compiled by Fortune magazine.

Honeywell Four Way Valve

Honeywell V5442A series four-way valves are manufactured for systems where

water or liquids come out, with a glycol percentage of up to 50. They are designed to operate at temperatures from 2 to 110 ° C and at operating pressures up to 6 bar.

Honeywell manufactures valves with connection sizes of 20, 25, 32 mm. Therefore, the values of the Kvs coefficient are from 4 to 16 m³/h. The series devices work together with electric drives. For systems with higher power, the ZR-FA flanged valve series is used.

The Honeywell 4-way valve is easy to install and there are many options.

All of its products are economical, reliable and easy to use in heating, cooling and water supply systems.

ESBE offers a 4-way heating valve with internal thread. The valve body is made of brass. Working pressure 10 atmospheres, temperature 110 degrees (short-term - 130 degrees). The four-way mixing valve is produced in sizes 1/2-2″, with a capacity of 2.5 -40 Kvs.

Valtek offers mixing valves for various purposes, which are designed for long-term operation in the engineering system (water-heated floor, built-in wall, ceiling heating and cooling, hot water supply). The manufacturer's products can be found anywhere in Russia and the CIS countries.

It cannot be argued that a four-way valve for heating does not require financial investments. Installation of the device will be expensive, however, on the other hand, the efficiency of work and, as a result, profitability, justifies the money spent. There is only the main condition - the presence of a high-quality electrical network, since without it the valve drive will stop working.

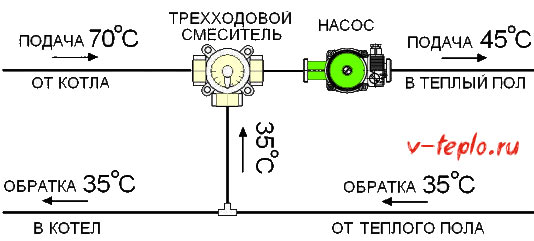

This allows you to somewhat automate the control, but does not make it possible to constantly maintain a certain temperature at the inlet to the boiler (which is necessary for the safety and durability of the heat generator). Indeed, with large temperature differences, there is a possibility of condensate formation with subsequent corrosion of the heat exchanger, and the intensity of scale formation also increases. If a cast iron heat exchanger is used, cracks may appear in the heat exchanger sections. In addition, stress increases at the joints of boiler parts, primarily at the joints and along the welds.

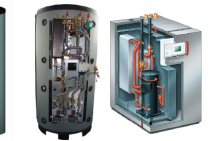

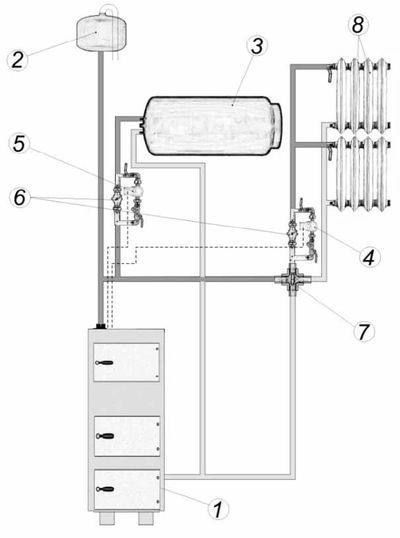

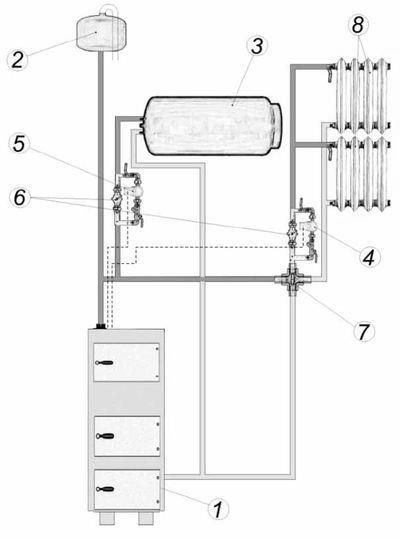

Therefore, for the safety of operation and durability of the equipment, as well as to achieve the required level of comfort, four-way valves are used to separate the heating and boiler circuits. On fig. 2 shows a typical scheme using a solid fuel boiler and a DHW storage tank (one outlet from the boiler, after which the coolant is distributed to hot water heating and the heating system). The separation of the boiler circuit and the heating circuit is carried out by means of a 4-way valve, which makes it possible to achieve constant circulation in the boiler and, at the same time, in the heating circuit.

Rice. 2. Installation diagram of a solid fuel boiler to a heating system with forced circulation of the coolant and a 4-way valve:

1 - boiler; 2 - boiler control automation unit; 3 - coolant temperature sensor; 4 - room thermostat; 5 - circulation pump; 6 - heat consumer; 7 - differential valve; 8 - four-way mixing valve; 9 - expansion tank; 10 - hot water boiler; 11 - boiler pump; 12 - shutoff valves; 13 - filter

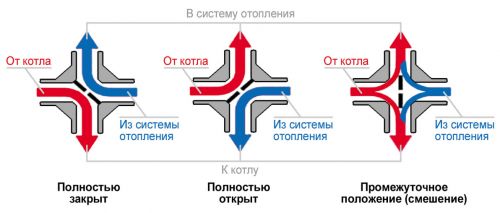

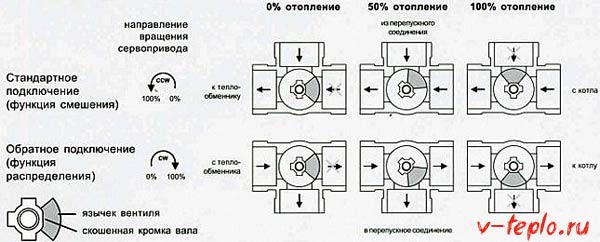

At the same time, in addition to the extreme positions, in the middle position, 50% of the coolant goes into the heating system, mixing with 50% of the coolant returning from the heating system, and the rest returns back to the boiler, mixing with the rest of the coolant from the heating system. It is also possible to maintain, in contrast to regulation with 3-way valves, the flow separation constant in other strictly defined proportions. For example, 30% of the coolant is in the boiler circuit, 70% is in the heating system. Or any other ratio (Fig. 3).

Rice. 3. 4 way valve positions

Such a constancy of consumption is very important for a solid fuel boiler, since, as we noted above, when using it, there are not so many opportunities to influence the intensity of the combustion process as in gas boilers. The use of an automatic draft regulator allows you to regulate the temperature only at the outlet of the boiler, but not on the return line.

Heating with four-way valve

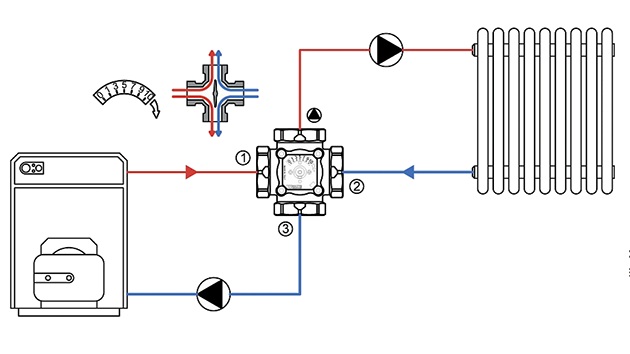

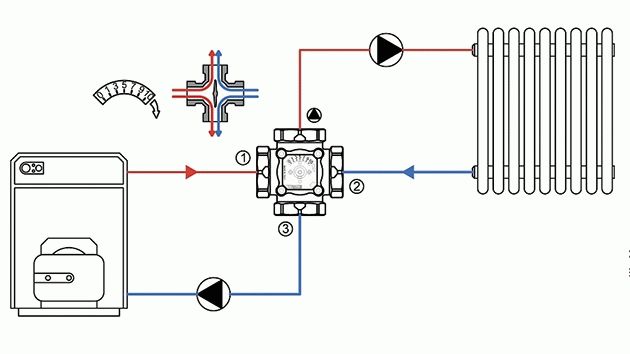

Installation of a heating system with a four-way valve:

- Boiler;

- Four-way thermostatic mixer;

- Safety valve;

- Pressure reducing valve;

- Filter;

- ball valve;

- Pump;

- Heating batteries.

The installed heating system must be flushed with water. This is necessary so that various mechanical particles are removed from it. After that, the operation of the boiler must be checked at a pressure of 2 bar and with the expansion tank turned off.

It should be noted that a short period of time must elapse between the start of full operation of the boiler and its check under hydraulic pressure. The time limit is due to the fact that with a long absence of water in the heating system, it will be susceptible to corrosion

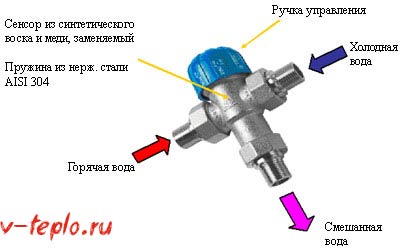

A four-way valve is an element of the heating system, to which four pipes are connected, having heat carriers of different temperatures, used to prevent overheating of a solid fuel boiler. The thermostatic valve prevents the temperature inside the boiler from exceeding 110 °C. Already at a temperature of 95 °C, it starts cold water to cool the system.

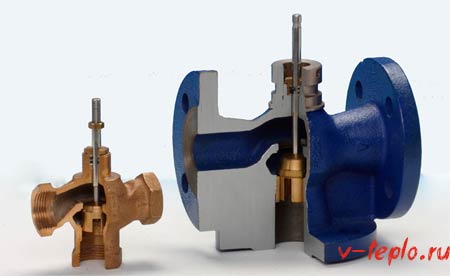

Four way valve design

The body is made of brass, 4 connecting pipes are attached to it. Inside the body there is a bushing and a spindle, the operation of which has a complex configuration.

The thermostatic mixing valve performs the following functions:

- Mixing streams of water of different temperatures. Thanks to mixing, smooth regulation of water heating works;

- Boiler protection. The four-way mixer prevents corrosion, thereby extending the life of the equipment.

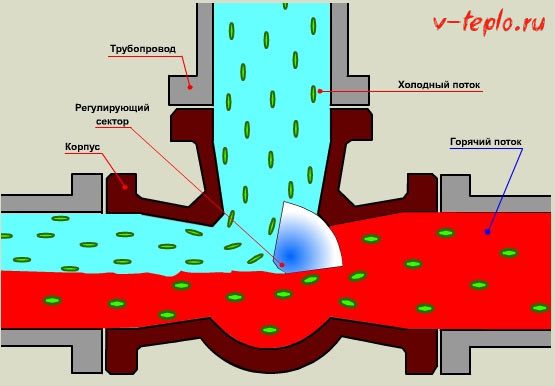

Diagram of a four-way mixer

The principle of operation of such a valve for heating is to rotate the spindle inside the housing. Moreover, this rotation must be free, since the sleeve has no thread. The working part of the spindle has two selections through which the flow opens in two passes. Thus, the flow will be throttled and will not be able to go directly to the second sample. The flow will be able to turn into any of the nozzles located on the left or right side of it. So, all flows coming from opposite sides are mixed and distributed over four nozzles.

There are designs in which a push rod works instead of a spindle, but such devices cannot mix flows.

Valve operation is controlled in two ways:

- Manual. Flow distribution requires the stem to be installed in one specific position. This position must be adjusted manually.

- Auto. Spindle rotation occurs as a result of a command received from an external sensor. Thus, the set temperature is constantly maintained in the heating system.

The four-way mixing valve ensures a stable flow of cold and hot coolant. The principle of its operation does not require the installation of a differential bypass, because the valve itself passes the required amount of water. The device is used where temperature control is required. First of all, it is a radiator heating system with a solid fuel boiler. If in other cases the regulation of heat carriers occurs with the help of a hydraulic pump and a bypass, then here the operation of the valve completely replaces these two elements. As a result, the boiler operates in a stable mode, constantly receiving a metered amount of coolant.

Heating with four-way valve

Installation of a heating system with a four-way valve:

- Boiler;

- Four-way thermostatic mixer;

- Safety valve;

- Pressure reducing valve;

- Filter;

- ball valve;

- Pump;

- Heating batteries.

The installed heating system must be flushed with water. This is necessary so that various mechanical particles are removed from it. After that, the operation of the boiler must be checked at a pressure of 2 bar and with the expansion tank turned off.

It should be noted that a short period of time must elapse between the start of full operation of the boiler and its check under hydraulic pressure. The time limit is due to the fact that with a long absence of water in the heating system, it will be susceptible to corrosion

How to make a heating system with a four-way valve

Morphological analysis of the word four-way

FOUR-WAY - inanimate

FOUR-WAY - animated

Basic word form: FOUR-WAY

All word forms with grammatical information:

| Word | Information |

|---|---|

| FOUR-WAY | singular, nominative, masculine, inanimate, animate |

| FOUR-WAY | accusative, singular, masculine, inanimate |

| FOUR-WAY | singular, feminine, inanimate, animate, genitive |

| FOUR-WAY | dative, singular, feminine, inanimate, animate |

| FOUR-WAY | singular, feminine, inanimate, animate, creative |

| FOUR-WAY | singular, feminine, inanimate, animate, prepositional |

| FOUR-WAY | singular, masculine, inanimate, animate, genitive |

| FOUR-WAY | accusative, singular, masculine, animate |

| FOUR-WAY | singular, inanimate, animate, genitive, neuter |

| FOUR-WAY | dative, singular, masculine, inanimate, animate |

| FOUR-WAY | dative, singular, inanimate, animate, neuter |

| FOUR-WAY | singular, masculine, inanimate, animate, creative |

| FOUR-WAY | singular, inanimate, animate, neuter, creative |

| FOUR-WAY | dative, plural, inanimate, animate |

| FOUR-WAY | singular, masculine, inanimate, animate, prepositional |

| FOUR-WAY | singular, inanimate, animate, prepositional, neuter |

| FOUR-WAY | singular, feminine, nominative, inanimate, animate |

| FOUR-WAY | accusative, singular, feminine, inanimate, animate |

| FOUR-WAY | singular, feminine, inanimate, animate, creative |

| FOUR-WAY | singular, nominative, inanimate, animate, neuter |

| FOUR-WAY | accusative, singular, inanimate, animate, neuter |

| FOUR-WAY | nominative, plural, inanimate, animate |

| FOUR-WAY | accusative, plural, inanimate |

| FOUR-WAY | plural, inanimate, animate, genitive |

| FOUR-WAY | accusative, plural, animate |

| FOUR-WAY | plural, inanimate, animate, prepositional |

| FOUR-WAY | plural, inanimate, animate, creative |

| FOUR-WAY | inanimate, animate, comparative degree (for adjectives) |

| FOUR-WAY | inanimate, animate, comparative degree (for adjectives) |

| FOUR-WAY | second genitive or second prepositional, inanimate, animate, comparative degree (for adjectives) |

| FOUR-WAYS | second genitive or second prepositional, inanimate, animate, comparative degree (for adjectives) |

Popular manufacturers

There are many manufacturers of three-way valves on the domestic market. The choice of a particular model depends primarily on:

- type of mechanism (and, we recall, it can be mechanical or electric);

- areas of use (DHW, cold water, "warm floor", heating).

The most popular device is considered to be Esbe

is a Swedish valve from a company that has been around for over a hundred years. This is a reliable, high-quality and durable product that has proven itself in many areas. Combination of European quality and modern technologies.

Another popular model is the American Honeywell - a true brainchild of high technology. Simple operation, convenience and comfort, compactness and reliability are the distinguishing features of these valves.

Finally, relatively "young", but promising devices are valves of the Valtec line - the result of a joint collaboration between Italian and Russian engineers. All products are of high quality, sold with a warranty period of seven years. They differ in that they have a very affordable price.

Valve classification

Without lengthy introductions, we note that the device can be of two types according to the principle of operation. It can be:

- separating;

- mixing.

Features of the action of each type are already clear from their name. The mixing device consists of two outlets and an inlet. In other words, it is necessary for mixing fluid flows, which may be required in order to reduce its temperature. By the way, this is the best option for setting the desired mode in the "warm floor".

The procedure for adjusting the temperature regime is extremely simple. You just need to know about the current temperature indicators of the incoming fluid flows, accurately calculate the required proportions of each of them so that you get the desired indicators at the output. By the way, this device, subject to proper installation and adjustment, can also function for flow separation.

But the dividing valve divides one flow in two, therefore, it is equipped with one inlet and two outlets. This device is mainly used to separate the flow of hot water in DHW systems. Although quite often it is also found in the piping of air heaters.

Outwardly, both options are almost identical. But if you look at their drawing in section, then their main difference is immediately visible. The stem, which is installed in the mixing type device, has one ball valve. It is located in the center and blocks the main passage.

As for separating devices, in them the stem has two such valves, which are installed at the outlets. They function according to the following principle: one of them is pressed against the saddle, closing the passage, and the other opens passage No. 2 in parallel.

According to the management method, modern models can be:

- electric;

- manual.

In most cases, a hand-held device is used, which looks like an ordinary ball valve, but is equipped with three outlet pipes. But electric models with automatic control are used mainly in private homes, namely in order to distribute heat. For example, the user can set the temperature regime by room, and the working fluid will flow in accordance with the distance of the room from the heater. As an option - you can combine it with a "warm floor".

Video - Device in the boiler group

Three-way valves, as well as other devices, are defined according to the system pressure and inlet diameter. All this is regulated by GOST. And if the requirements of the latter are not met, this will be regarded as a gross violation, especially when it comes to the pressure indicator in the line.

Tadiran air conditioner repair. Replacing the four-way valve in the Tadiran air conditioner

Consider replacing the four-way valve in the Tadiran air conditioner, as well as the possibility of adapting the four-way valve bu from another air conditioner. By tradition, we install the external unit of the air conditioner on the stand and check the parameters. If the valve fails, the following problems are detected:

the air conditioner does not switch to heating mode,

The air conditioner does not switch to cooling mode,

The compressor runs but nothing happens (no heating, no cooling on any of the radiators). In this case, most often there is a strong hiss in the external unit.

In this case, it does not switch to heating mode. We disassemble the external unit and pump out the old freon into the freon bottle bu.

Next, I cut the tubes to size and a suitable pipe from below, we pass a pipe expander of the appropriate size. Next, we solder with an oxygen torch and solder with a silver content. Pictured is the compressor discharge tube. We also bend, expand and solder the suction pipe of the compressor.

The operating parameters of the outdoor unit in heating and cooling mode are not ideal, but close to it. Let's summarize the work - disassembly, three solder seams and four

How it works

The three-way valve is mounted on those sections of the pipelines where it is required to divide the flow of the circulating fluid into 2 circuits:

- with variable hydraulic regime;

- with constant.

In most cases, a constant flow is required for those for whom a liquid of high quality and in the indicated volumes is supplied. It is regulated in accordance with the quality indicators. As for the variable flow, it is used for objects where quality indicators are not the main ones. There, the quantity factor is of great importance. Simply put, the supply of coolant there is carried out according to the required amount.

Note! The shut-off valves also include an analogue of the device described in the article - a two-way valve. How is it different? The fact is that the three-way option works on a completely different principle.

The rod included in its design is unable to block the flow of fluid, which has constant hydraulic performance.

The stem is open all the time, it is adjusted to one or another volume of liquid. Consequently, users will be able to get the volume they need, both in terms of quantity and quality. In general, this device is unable to stop the supply of liquid to a network in which the hydraulic flow is constant. At the same time, it may well block the flow of a variable type, due to which, in fact, it becomes possible to adjust the flow / pressure.

And if you connect a pair of two-way type devices, you can get one, but three-way. But it is necessary that both work on the reverse, in other words, when one valve is closed, the next one should open.

How to install a mixing valve with your own hands

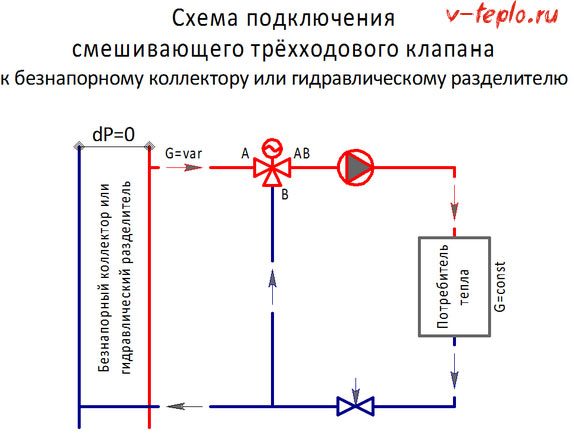

This installation scheme is used mainly in boiler rooms of those heating systems that are connected to a hydraulic separator or to a non-pressure collector. And the pump located in circuit No. 2 provides the required circulation of the working fluid.

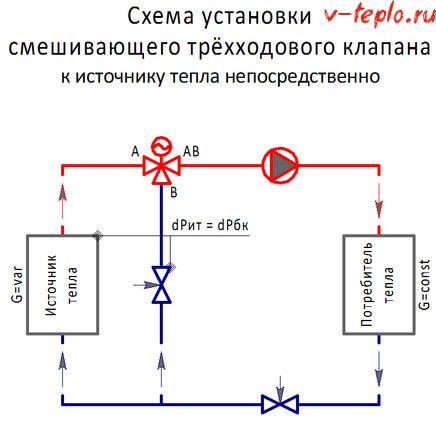

Note! If the three-way valve will be connected directly to a bypass heat source connected to port B, then a valve with a hydraulic resistance equal to the same resistance of this source will also be required.

If this is not done, then the flow rate of the working fluid in the segment A-B will fluctuate in accordance with the movement of the rod. We also note that this installation scheme provides for the possible termination of the circulation of liquid through the source, if the installation was carried out without a circulation pump or a hydraulic separator in the main circuit.

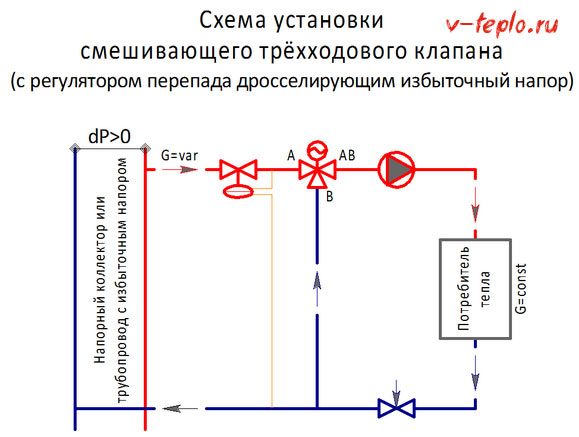

It is undesirable to connect the valve to heating networks or a pressure manifold in the absence of devices that throttle excessive pressure. Otherwise, the flow rate of the liquid in the section A-B will fluctuate, and significantly.

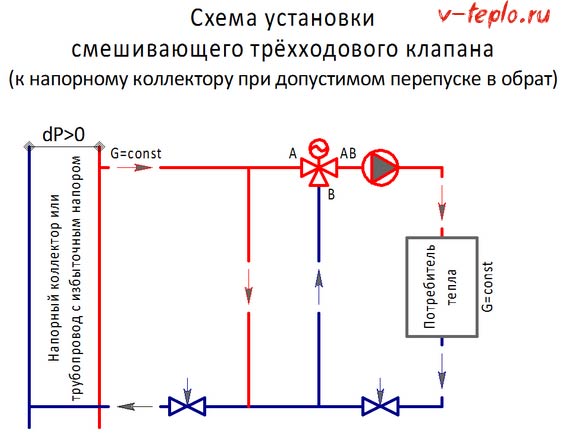

If overheating of the return is allowed, excessive pressure is eliminated by means of a jumper installed in parallel to the valve admixture in the circuit.