Pipe installation

After developing a pipeline scheme and purchasing consumables (pipes and fittings), it is necessary to consider a method for connecting pipes into a single system for water supply.

You can collect copper pipes:

- soldering method;

- threaded connection method.

Soldering

Soldering is a more complex way of connecting pipes and is performed with some experience with the equipment. The solder joint is one-piece, but high-strength. To connect copper pipes by soldering, you will need the following equipment:

- metal cutting tool (hacksaw or pipe cutter);

- calibrator - a special device for aligning the size of pipes;

- beveler - a device for processing pipes after cutting;

- soldering iron with additional equipment (gas cylinder, hoses)

- sandpaper;

- flux - composition for improving soldering;

- solder - a substance for filling seams when connecting individual elements.

A set of tools and accessories for soldering

The process of connecting copper pipes by soldering is as follows:

- the pipe is cut according to the previously developed drawing;

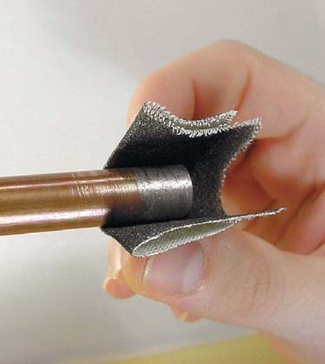

- the cut end is deburred, polished with fine sandpaper and calibrated;

The initial stage of soldering copper pipes

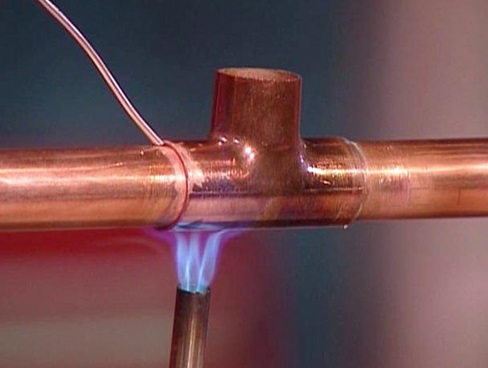

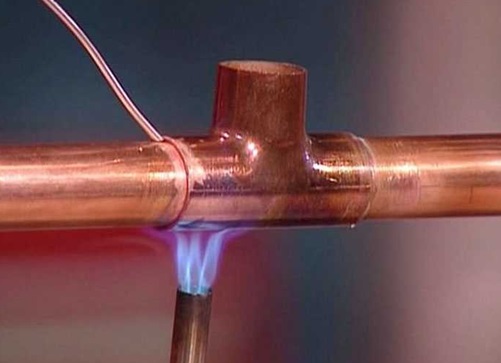

- the place of the intended welding is treated with flux and heated;

Preparing the pipe for soldering

- the pipe is connected to the fitting;

- the free space between the pipe and the fitting inlet is filled with solder;

The final stage of soldering pipes

- after complete cooling, the final cleaning of the resulting compound is performed.

When performing work, safety precautions must be observed. Work with flux should be carried out with gloves, and work with a gas burner in personal protective equipment and in a well-ventilated area.

How to solder copper pipes correctly is shown in the video.

Threaded connection

A copper pipe for water can also be assembled using ferrules, that is, a threaded connection. Unlike soldering, a threaded connection is detachable, which allows the user to replace a section of pipe or fitting where a leak is detected.

Threaded fitting with ferrule

To assemble copper piping using ferrules, you will need the following set of tools:

- pipe cutter or hacksaw. You can perform the operation of cutting pipes with any other tool;

- beveler;

- sandpaper;

- plumbing keys, the most suitable in diameter.

Work on assembling a copper pipeline with compression fittings is carried out in the following order:

- a pipe of the desired size is prepared. The places where trimming was performed are processed using a beveler and sandpaper. The surface of the pipe after processing should be as smooth as possible;

- a union nut and a split ring are put on the end of the pipe;

If it is required to connect a copper pipe to a pipe made of another metal, then the junction is additionally treated with any sealing material: FUM tape, Tangit Unilok thread, and so on.

- a pipe with a ferrule and a fixing nut is connected to the fitting;

Assembling the pipeline with ferrules

- using a wrench, the thread is gradually tightened. In the process of tightening, the ring gradually compresses the surface of the pipe, due to which a high connection strength is achieved.

Threaded connection assembly

After the pipeline is assembled, the water supply system is tested. To do this, water is passed through the pipes under maximum pressure. If there are leaks in the connections, repair work is carried out.At the last stage, all plumbing devices provided for by the scheme are connected.

Product types

When installing a plumbing system from 32 mm HDPE pipes, you will need connecting elements for various purposes and configurations. Any pipeline never consists of one straight section.

It has turns, branches, branches, muffled ends.

Brass fittings for HDPE pipes 32 mm (as well as for lines of other diameters), the following types are used:

- bends - these elements are designed to change the direction of the pipeline at an angle from 45 to 120º;

- tees - allow you to create a separate branch on the main line at an angle of 90 degrees;

- cross - connects four segments in two mutually perpendicular directions;

- coupling - connects two pipe segments of the same diameter, which are laid in one straight line;

- adapter sleeve - allows you to reliably connect two sections with different diameters lying on the same straight line;

Brass fittings of different types (tees, bends, straight lines)

- plugs (caps, plugs) - allow hermetically sealing the free end of the pipe;

- fitting - a connecting element for connecting to the main pipeline (water source) or the container in which it is located;

- nipple - a specialized tube with an external thread at both ends, which allows you to make a connection with a pipe or fitting.

The system, consisting of 32 mm HDPE pipes, can be mounted using polyethylene fittings. And many builders do just that, arguing such actions with the low cost of materials. But for HDPE pipes 32 mm, it is preferable to use connectors that are made of brass.

One of the reasons why it is worth paying a little more is the strength characteristics of the materials and the possibility of repeated use.

Brass fittings can provide a hermetic connection of HDPE pipes with a diameter of 32 mm and a wall thickness of 2.4 mm, with a guaranteed absence of leaks.

This is due to the fact that the compression ring (it is also made of brass) has a kind of thread on the inner surface, which, when the nut is tightened, is pressed into the polyethylene structure. Thus, when the pipe is stretched (deformed) under external physical impact, the connection will not be broken.

Installation steps

Before proceeding with the process of assembling the pipeline, you must do the following:

- Cut HDPE pipes 32 into sections according to the required length in separate sections.

- Prepare brass fittings of the required type (configuration) for connecting individual segments.

- Check compliance with the general plan by laying out the individual elements of the pipeline in the required sequence at the place of its passage.

After making sure that everything is in place, you can start assembling. The principle of connecting pipes with a brass fitting is the same for all its configurations:

Step-by-step installation of brass fittings on HDPE pipe

- it is necessary to clean the ends of the pipes after they have been cut with a pipe cutter or a hacksaw for metal;

- apply a mark that shows that the pipe has entered the fitting as far as it will go;

- lubricate the end of the pipe for easier entry into the fitting;

- unscrew the union nut of the fitting by 3-4 turns;

- insert the pipe (according to the label);

- tighten the nut.

The sequence of application of parts when installing a brass fitting

In order to be sure of the future tightness of the connection during the installation of each individual element of the pipeline, experts recommend unscrewing the union nut completely. This is due to the fact that, after almost complete disassembly of the connecting node, it will be possible to verify two important circumstances:

- all internal parts of the fitting are in place and in working order (the rubber ring requires special attention);

- during the subsequent final assembly, it is possible to visually check the correct position of all rings (crimp, inner, rubber).

Types of fitting products

Connecting elements made of metal and plastic are manufactured in the same modifications as steel and plastic products:

- Straight couplers. The simplest type of product for connecting two pipes of the same diameter.

- Transition couplings. Products used to connect pipes of different section sizes.

- Squares. Fittings that allow you to connect two pipes at right angles.

- Branches. Products that allow you to change the relative position of pipes from 45 to 120 °.

- Crosses. Connectors designed to connect four pipes at an angle of 90°.

- Tees. Fittings connecting three pieces of pipe, one of which is installed perpendicular to the other two.

- Plugs. Products designed to close the end section of a pipe. They have an internal or external thread for screwing into a pipe.

- Nipples. Fittings, which are products with external threads at both ends, with the help of which they are connected to other sections of the pipeline.

- Futorki. Products used to connect pipes to measuring instruments. They have an internal thread on one end and an external thread on the other.

- Fittings. Elements that allow for connecting a pipe to process equipment (boiler, boiler, filter, heat exchanger, collector).

- Drives. Used to increase the length of the pipe using an internal or external thread.

- Americans. Products resembling spurs with a union nut. They can be straight and angular, allowing you to change the direction of movement of the connected pipes.

All listed types of fittings have a thread - external, internal or combined. In addition to them, there are also one-piece connecting elements, as well as products connected by welding or capillary soldering.

The connecting elements from the list above are the most popular types of fittings that are used in the installation of pipelines. When installing more complex and highly specialized engineering systems, other special fittings can be used - locknuts, barrels, extensions and other elements.

Copper pipes in household communications

Copper pipes

The growing demand for copper pipes for heating and water supply is the second wave of popularity. Pre-revolutionary buildings were equipped with copper units due to the lack of an alternative. Now plumbers have a range of materials at their disposal - steel, cast iron, plastic and reinforced pipes, copper.

The choice of copper is based on the characteristics of the material. Heating with copper pipes and plumbing from this expensive material has a number of indisputable advantages.

Advantages

Copper is a soft and ductile metal. The copper pipe for heating can withstand high external and internal pressure without corrosion and cracking of the walls. The medium up to +250 degrees does not melt the walls, does not expand the diameter and does not lengthen the knot. The lower operating temperature threshold is -100˚.

The lower density compared to steel simplifies the installation of copper heating pipes. It is easier to thread the ends to create a collapsible connection, cutting copper elbows is less laborious.

Smooth, seamless inner walls are not subject to overgrowth, bacteria do not multiply on them. For drinking water supply, copper nodes are optimal: copper has bactericidal properties. Passing through the system, the water is disinfected and purified. At the same time, chlorine does not damage the inner surface of the pipe: the copper pipe for heating does not react with the composition of the medium.

The quality and use of copper nodes is regulated by GOST, copper pipes for heating and water supply applications are used:

- for hot water and space heating;

- for cold drinking water;

- gas.

Flaws

Heating with copper pipes is an expensive idea.This is the main disadvantage that stops from such a choice. Copper pipes require similar fittings, which also increase the cost. The remaining difficulties are explained by the properties of the material:

The difference in the density of copper and steel does not allow mounting combined communications. Steel or cast iron pipes are connected only with fittings, while the steel section must be predisposed to copper.

In buildings where solid inclusions are found in the composition of the medium, the installation of copper pipes is impractical. Impacts on soft walls under the pressure of the carrier lead to deformation.

Installing outdoor communications made of copper is a temptation for intruders. Non-ferrous metals are expensive recyclables.

What are the opponents saying?

First of all, pay attention to the significant cost of the material. Of course, it is difficult to argue with this, but it is worth considering other factors, the price should not always play a decisive role when choosing

You can hear many statements that copper pipes for plumbing are potentially dangerous, as this metal can cause the formation of toxic substances. When applied to water pipes, this statement is not true. Similar substances can appear when copper comes into contact with certain media, and under many other conditions.

Another feature of the copper pipeline is the ability to form  galvanic couple in direct connection with aluminum or steel. In the presence of an electric potential, which is often found in systems for collective use (residents use grounding on pipes for various purposes), after a while such a joint will definitely leak.

galvanic couple in direct connection with aluminum or steel. In the presence of an electric potential, which is often found in systems for collective use (residents use grounding on pipes for various purposes), after a while such a joint will definitely leak.

In addition, copper water pipes have excellent electrical conductivity, so there is a risk of electric shock if the equipment is not properly grounded.

The list of advantages is also significant, these include the following qualities:

- Durability that has been tested for centuries.

- Plumbing copper pipe can be used in a significant temperature range (250-400 degrees), depending on the solder used.

The material is plastic, easy to process, bends.

Copper is resistant to ultraviolet radiation and oxygen, which is part of the atmospheric air.

Copper pipes are not subject to corrosion processes.

But a simple listing of characteristics cannot give a complete picture of the material, so let's try to compare copper plumbing and a polypropylene system.

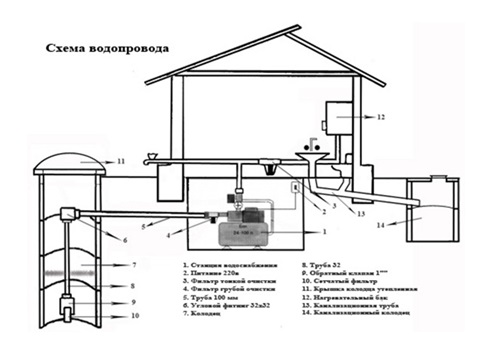

Pipeline development

Before the direct assembly of pipes and installation of the pipeline, it is necessary to develop a general scheme of the system, according to which it is possible to calculate:

- the number of required pipes of a certain diameter;

- the number of fittings that will be installed at the branching of the system, at the places where pipes are bent, at the places where plumbing equipment is connected;

- the number and installation locations of additional equipment (water heaters, pumps, mixers, taps, valves, and so on).

Plan of the plumbing system of a country house

A well-designed scheme is the key to the successful operation of the system. Therefore, it is more expedient to develop the scheme together with qualified specialists.

Rules for the installation of brass pipes

Installation of pipes made of brass can be done in two ways:

- welding;

- threaded fittings.

Welding of brass pipes

The connection can be made:

gas welding using oxyacetylene. Welding can be done end-to-end or using fittings;

Acetylene oxygen welding using fittings

arc welding with tungsten electrodes;

Butt welding of pipes using electrodes

soldering using hard solders made of silver or an alloy of copper and zinc, as well as fittings of various shapes.

Pipe connection by soldering

The welding connection technology is the same, regardless of the method, and is performed in the following sequence:

- preparation. At this stage, pipes are cut, deburred and cleaned from dirt and other types of similar deposits;

- heating and direct connection;

- cooling, during which the pipes must remain stationary.

Welding requires special equipment and minimal skills to work with it.

How to solder brass pipes, see the video.

https://youtube.com/watch?v=qTDDAng7shE

Connection with threaded fittings

The easiest way to assemble brass pipes is to make a threaded connection, which requires threaded fittings. As a rule, the connecting elements are also made of brass, but in some situations, for example, when building a plumbing system in a country house with a minimum water consumption and a minimum level of pressure, HDPE fittings can also be used.

Threaded brass fittings

The mounting technology is as follows:

- preparatory stage: cutting in accordance with the scheme of the pipeline system, cleaning from dirt, dust and other deposits, deburring;

- thread cutting. The work is done with the help of taps (for internal threads) and dies (for external threads). The size of the tools used must match the size of the thread applied to the connecting fitting;

Preparation for installation with threaded fittings

- joint sealing. For water supply and heating systems, for example, as insulating materials, FUM tape, linen thread or Tangit Unilok thread can be used;

Thread insulation thread Tangit Unilok

- connection of elements. Thread tightening.

Properly selected and installed brass pipes can last more than 50 years. If you can’t do the installation on your own, you can use the help of specialists.

COPPER PIPES IN SPB FOR HEATING SYSTEMS

Modern copper pipes St. Petersburg are very popular for heating systems.

An important factor is the aesthetic appearance of this material, which allows you not to hide such pipes. In addition, the copper pipe is resistant to high temperatures. Also, copper pipe is known for its thermal conductivity.

Accordingly, buying a copper pipe for a heating system will be an excellent solution, since heat transfer will be maximum. If a copper pipe is suitable for prices, it should be borne in mind that such pipes are not allowed to be combined with aluminum radiators

For heating systems, it is very important that the annealed copper pipe is impermeable to oxygen, which means that by purchasing St. Petersburg copper pipes, you can avoid such a common problem as air congestion

Copper is a valuable metal. Works of art, various objects and even building materials are created from it.

Pipes are considered building materials made of copper. Copper plumbing pipes are a great choice if you can afford them.

Copper pipes of different diameters

They have a lot of advantages. What are these advantages and how to work with copper pipes for water supply in general? Now we will tell you everything.

The nuances of mounting and soldering pipes of all diameters

Copper pipes and fittings for plumbing are connected by threading or soldering, the first method is considered simpler and more accessible to non-professionals. Work begins with drawing up a wiring diagram and counting the footage; in the absence of experience, it is recommended to provide a margin of 3-5 m.

Do-it-yourself step-by-step work in 7 steps

Do-it-yourself copper plumbing with threaded connections is assembled in the following sequence:

- Pipe cutting.

- File cleaning of burrs in the cut area, on pipes with PVC insulation, the insulating layer is cleaned.

- Chamfer removal.

- Putting a union nut and a ferrule on the pipe.

- Preparing the fitting, mating it with the nut and tightening the connection (first by hand, then with a wrench).

- Connection of steel pipes (if necessary) using transition fittings, mandatory sealing of threaded connections.

- Leak test.

Copper pipes and fittings for plumbing must be properly installed.

Checking the condition of the joints and correct installation

The assembly of a copper water pipe using press fittings is considered to be quite reliable, the quality of sealing depends on the strength of the twist. It is recommended to use special pneumatic or hydraulic pliers for this operation. The disadvantage of this method is the deterioration of the appearance of the water pipe at the joints, if the appearance plays a decisive role, then the sections should be connected by soldering.

Soldering is considered the most reliable way to connect copper pipes. The sequence of actions is almost the same as the assembly with press fittings: the pipes are cut and carefully protected from burrs

It is important to wipe the products from dust and residues of the oxide film (inside and outside). Then flux is applied to the outer surface of the pipe, a fitting is inserted with a mandatory gap, the joint area is evenly heated with a burner or blowtorch, when choosing the second option, overheating should be avoided

To check that the desired temperature has been reached, it is enough to lightly touch the solder, if it melts, then the area has already warmed up. After that, the solder is inserted into the left gap and the seam is sealed.

An important nuance of soldering: during heating and connection, the section of the future pipeline must remain motionless. Any efforts and movements are allowed only after the solidification of the solder. At the end of the assembly, the system must be washed from flux residues.

WATCH VIDEO

Heated products are easy to bend; special springs are used to give the desired shape while maintaining the section. The optimal equipment for producing bent elements is a special pipe bender; its purchase is advisable for large volumes of work. The sections assembled by soldering the system look neater than those bent when threaded. But, despite the obvious advantages and reliability of this method, soldering is not carried out in explosive places due to open flames. Fire safety measures are mandatory. Copper pipes and plumbing fittings are widely used in construction.