Recommendations for choosing a compensator

In order for the system to work for a long time and smoothly, when choosing a compensation unit, you should pay attention to the following points:

- The off-the-shelf node purchased must meet the requirements for the operation of a particular system.

- The compensator section should be selected similarly to the pipe diameter. The most popular in private use are pipes with a cross section of 20-40 mm.

- High-quality flange expansion joints for polypropylene heating pipes in the event of a system breakdown should be easily dismantled, and the fastening is assumed to be tight and reliable.

- Before starting installation, it is worth making sure whether a compensator is needed on a polypropylene pipe in principle, whether its diameter corresponds to the parameters of the pipeline, and also how appropriate the selected type of device is in a particular case.

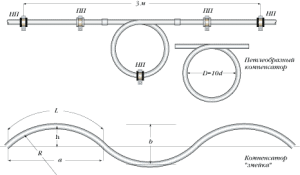

- The distance between nodes of different types is about 3 meters. In this case, a bellows or loop compensator is ideally suited for welding connections.

The use of polypropylene pipes

Due to the special properties of the materials, the polypropylene piping system can be used:

- water supply of houses;

- connection of boilers;

- water distribution;

- plumbing risers;

- distribution by floors (normal or at each sampling point with individual connection);

- connecting the pipeline to existing water supply networks, assembled from metal pipes;

- heating networks;

- connection to the boiler plant;

- distribution devices;

- heating risers;

- connection of metal radiators.

Polypropylene pipes are assembled by diffusion welding using a special welding machine using fittings for polypropylene pipes: couplings, angles, tees, etc. In polypropylene pipelines, permanent connections are used, the pipeline is assembled on welded fittings once and for all.

The long service life of the serial pipe made of polypropylene allows it to be used for all known types of pipe laying, open laying, wall laying, concealed laying.

Polypropylene pipes are gray, white, black and green. A color other than black does not mean any restrictions on the use of pipes. The black color of the pipe shows that it is the most protected from ultraviolet radiation.

Typical mistakes and practical tips for using polypropylene pipes

1. Pipe PN 10 is used exclusively for cold water supply systems.

2. It is best to install hot and cold water from a PN 20 pipe. In this case, it is imperative to calculate the linear expansion of the pipe during the installation of risers. When mounting horizontal pipe sections with a large number of turns and short lengths (up to 2 m), pipe elongation can be neglected.

3. Reinforced pipe PN 25, due to a small coefficient of linear expansion, has proven itself in hot water and heating systems (installation of risers of high-rise buildings).

4. When using fittings with a metal transition, it is better to use white teflon tape (Fum-tape) to prevent leakage through threaded connections

Care must be taken when connecting fittings with a metal transition, as excessive force when tightening the connection can damage them, which can subsequently cause leakage

5. Weld only clean polypropylene pipes and fittings. Otherwise, you will damage the Teflon coating of the heating nozzles and risk getting a poor-quality weld.

6. Always mark the required welding depth at the end of the pipe.If this is not done, then you can narrow or completely weld the passage, which is almost impossible to find after the installation is completed.

7. Welding pipes with a diameter of 40 mm or more without special equipment is best done by two people, as this requires a lot of physical effort.

8. Polypropylene pipes with a diameter of more than 50 mm can be cut with a hacksaw, after cleaning the cut with a knife.

9. Before welding reinforced pipes, the combined layer of polypropylene and aluminum must be completely stripped. This operation is often forgotten by inexperienced installers.

10. When laying hidden pipes, always make a diagram. In the future, this will avoid accidental damage to pipes when drilling walls and floors.

11. In case of freezing of the transported liquid, plastic pipelines are heated with warm air or an electric cable used for underfloor heating. It is strictly forbidden to use an open flame.

12. Pipes must be protected from oil products, they must not be painted with oil paint.

Reinforcement with aluminum and fiberglass

This is done with a solid or perforated foil, 0.01 - 0.005 cm thick. It is placed on the outer or inner edge between the layers of polypropylene. Connect the layers with special glue.

A continuous layer of foil does not allow oxygen to penetrate to the heat carrier. A large amount of oxygen leads to corrosive formations on heating devices.

PP pipe reinforced with fiberglass is a three-layer composite. In it, the middle layer of fiberglass is welded with polypropylene particles from adjacent layers.

This method creates a high-strength structure, which is characterized by a small coefficient of thermal expansion, much lower than that of the original material.

The latter feature greatly simplifies installation and reduces its time, since it is not necessary to clean the aluminum layer before welding.

Linear expansion of polypropylene pipes

Compensation methods

When designing a heating and water supply system, the coefficient of thermal expansion of polypropylene pipes must be taken into account. And during installation, such conditions are created in the attachment zone so that the pipe can move freely in the range of deformation. This can be achieved in several ways:

- through the compensating capacity of the pipeline;

- installation of temperature compensators;

- correct placement of supports.

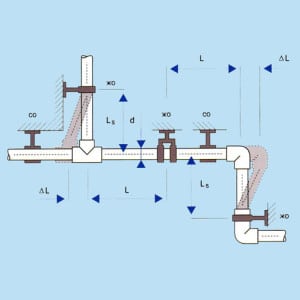

A compensator is used between rigidly fixed supports. It is loop-shaped, P or L-shaped. Sometimes pipes are laid with a "snake". In a cold water supply system, linear expansion can be neglected. The fixed supports guide the extensions towards the elements.

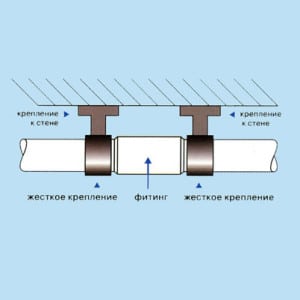

When installing the heating system, a gap must be provided between the pipe and the wall. When using fixed supports, the pipe will not be able to elongate as the temperature rises. In movable fixtures, the pipe has the ability to move longitudinally. Locking supports allow axial extension and sliding fasteners allow sliding.

For ceiling structures, supports with a strap are suitable. The best solution in this case is plastic fasteners, they cannot violate the integrity of the pipe, they must be fixed at intervals equal to 20 pipe diameters.

- Filters and taps are fixed with fixed fixtures, while the fittings should not rest against the supports.

- Straight gasket changes to gusset.

- The compensating sleeve has a length margin that will be sufficient to form a technological gap.

- Installation of polypropylene elements is carried out after calculations (SNiP 41-01-2003, SP 40-101-96). Incorrectly selected distances between the supports lead to pipe deflections, and this creates an additional load on the supports.

- When connecting pipes by welding, the foil is removed, which makes installation difficult.Pipes reinforced with fiberglass are deprived of such a disadvantage. They are durable and do not require cleaning.

Kozlov compensator

A new development that prevents deformation and extends the life of heating and plumbing systems. The device consists of an outer polypropylene casing and a two-layer stainless steel corrugation. The connection is made with adapters. The product is suitable for reinforced and non-reinforced polypropylene pipes. Working pressure: 16 atmospheres, maximum temperature of the working medium: 100°C, maximum compensating capacity for compression: 25 mm.

The bellows compensator consists of a bellows and auxiliary fittings. It balances possible movements.