Gas infrared heater for greenhouse

To grow vegetables all year round, the greenhouse needs artificial heating. After all, the sun, heat and water are the most important three factors, without which it is impossible to grow even berries.

Using heating in the greenhouse, the gardener can simply extend the seasonal work for more than three months, and grow seedlings as early as the end of February. So in a year you can harvest three crops of one crop.

But what kind of heating is better to choose? What are the pros and cons of each type? The modern construction market offers many types of heaters for greenhouses, the three most promising of which are: cable, infrared film and infrared ceiling. Why specifically these? Read on.

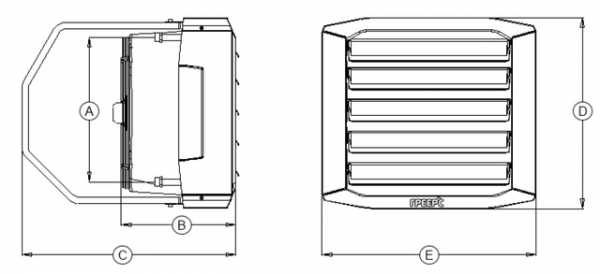

Russian water air heater 20 kW GREEERS. for heating greenhouses of poultry houses

Advantages:

+ Energy saving fan.

+ Equipped with a three-speed motor, greatly reducing the cost of purchasing control system components.

+GREEERS VS fan heater can work for air cooling (condensate collection tray included)

+5 years warranty.

+ Impact-resistant stylish black EPP (expanded polypropylene) housing.

+Easy installation on any surface and in any position, due to the mounting console, which is included in the standard package of fan heaters.

+ Mounting console

+ Condensate collection tray

Optional accessories:

- 4-way air distributor.

- Confuser.

— Thermostat

- Actuated valve.

Specifications:

|

Specifications |

Unit. |

VS-1220 |

||

|

Rated heat output* |

kW |

21,4 |

||

|

Speed |

stage |

1 |

2 |

3 |

|

Maximum air exchange |

m³/h |

700 |

1200 |

2000 |

|

Nutrition |

V/Hz |

230/50 |

||

|

Maximum current consumption |

A |

0,3 |

0,4 |

0,5 |

|

Max Power Consumption |

Tue |

65 |

85 |

110 |

|

IP/Insulation class |

54/F |

|||

|

Maximum acoustic pressure level** |

dB(A) |

36 |

42 |

47 |

|

Maximum hot water temperature |

°С |

120 |

||

|

Max working pressure |

MPa |

1,6 |

||

|

Connecting pipes |

Æ |

1/2″ |

||

|

Maximum operating temperature |

°С |

50 |

||

|

Machine weight without water |

kg |

10,2 |

||

|

Weight of machine filled with water |

kg |

11,4 |

||

|

heat exchanger |

material / row |

Cu - Al, double row |

||

|

Housing material |

EPP - expanded polypropylene |

|||

|

Case color |

Black |

|||

|

Workspace |

Indoors |

|||

|

Maximum air throw*** |

m |

14 |

* At maximum air flow, heating medium temperature 90/70°C, and air temperature at the machine inlet 0°C.

** Sound pressure level for a room with an average sound absorption coefficient, volume of 1500 m3, at a distance of 5 m from the device.

*** Isothermal air jet length, at a limiting velocity of 0.5 m/s.

| Model | Dimensions, mm | ||||

| A | B | C | D | E | |

| VS-1330 | 355 | 330 | 560 | 480 | 550 |

Installing the mounting bracket: The mounting bracket is included as standard with the BC series. It comes with the hardware needed to mount it. Expanding dowels are not included in the set. Select the appropriate type of dowels for the particular type of partition wall. Mounting options: ► On the wall in a vertical position, at an angle of 45° or 60° ► Under the ceiling in a horizontal position or at an angle of 45° or 60° ► The mounting console allows the heater to be swiveled around mounting axis by 170°.

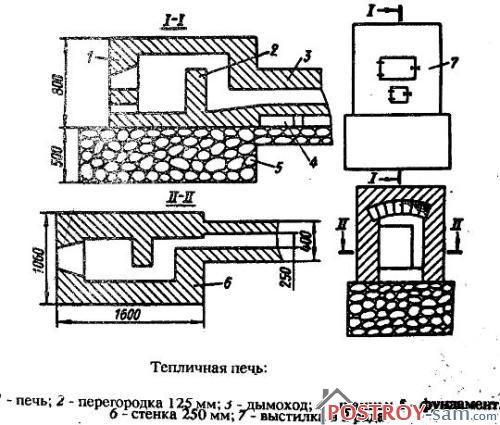

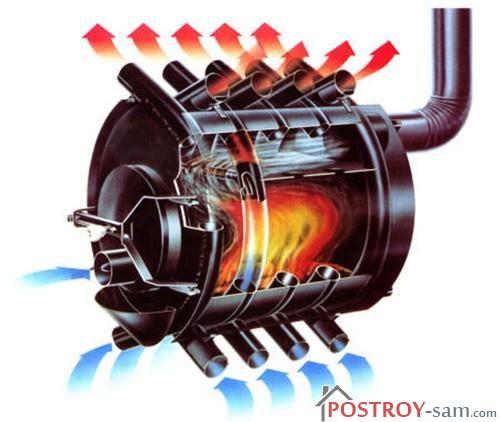

Stove heating

Furnace heating, unlike gas, is very economical in financial terms. A simple greenhouse stove with a horizontal chimney or a chimney can be easily built at no extra cost.

To do this, you need to take the following steps:

- A firebox is laid out of brick in the vestibule of the greenhouse;

- Throughout the greenhouse, a chimney is laid out under the racks or under the beds;

- The chimney is led outside on the other side of the greenhouse so that carbon monoxide and smoke do not accumulate in it, and all the heat remains in the middle of the greenhouse. The distance between the wall of the greenhouse and the stove must be at least 25 cm, and at least 15 cm from the bed or shelving to the top of the pipe.

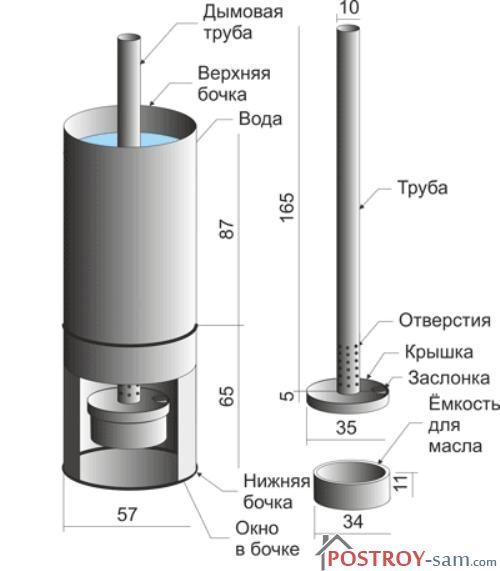

You can apply a slightly different scheme:

- As a firebox, you can adapt an ordinary iron barrel, at least 3 cubic meters in size, which is painted from the middle in several layers so that it does not rust;

- Appropriate holes are made in the barrel for the stove, chimney, expansion tank at the top and drain cock at the bottom;

- The stove is welded and inserted into the barrel;

- A chimney is drawn from the barrel, to which a pipe 5 meters long is attached;

- An expansion tank with a capacity of 20 liters is placed on top of the barrel, which is pre-welded from ordinary sheet iron;

- A profile pipe measuring 40x20x1.5 is taken, from which heating is welded. Pipes are laid on the ground so that the soil at the roots of plants warms up well;

- In order for water to circulate in such a home-made system, you need to purchase an inexpensive special pump.

Such a home-made stove can be heated with any wood, and a drain tap can serve not only to drain water, but also to water plants after the water has cooled. To control the temperature in a greenhouse heated by such a stove, an electronic sensor can be mounted inside, and a display with temperature indicators can be installed in the house so that you do not go out every time.

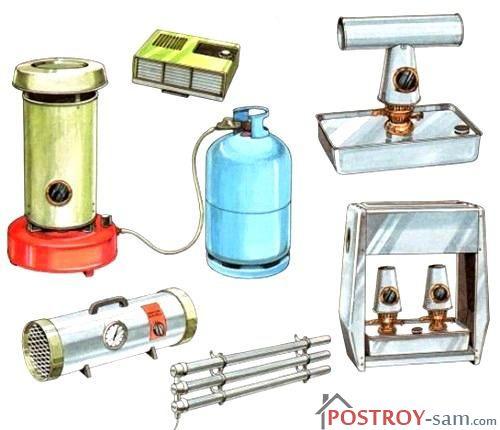

Gas heating

Gas heating of the greenhouse is very reliable in terms of supply. With gas heating, you can not be afraid for the safety of plants in the winter. But as a result, when calculating the cost of heating, the cost of the final product will be sky-high. Therefore, it is worth thinking three times whether this type of heating is beneficial for maintaining your greenhouse. To save gas, you can buy several gas cylinders, which are quite enough for some of the coldest weeks of the year. Pulling expensive gas pipes from a residential building is not at all necessary.

It is important to know that when heating a greenhouse with gas, it is necessary to additionally install a ventilation system, since an excess of combustion products can accumulate in the greenhouse, which has a detrimental effect on plants. Properly installed ventilation will remove excess combustion waste from the greenhouse, and will saturate it with fresh oxygen.

Ventilation is also important so that there is no lack of oxygen, which stops the combustion process and the gas does not begin to be released into the air. Therefore, heating devices must be equipped with special protective sensors that will be triggered when the gas supply to the burner is interrupted.

Heating of greenhouses and greenhouses technical heating

In addition to solar and biological heating for greenhouses and greenhouses, technical heating of greenhouses is used: water, gas, electric and stove.

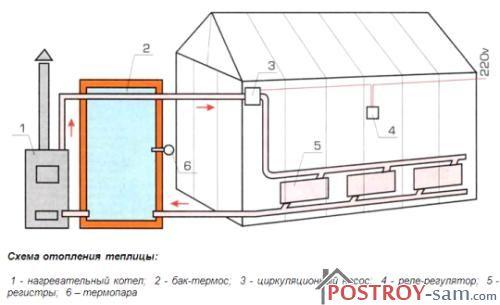

Heating of greenhouses. Water heating

With water heating, metal pipes are laid along the structure, placing them under the roof along the walls, and in excavated greenhouses and greenhouses - under a layer of soil. Hot water is supplied to the pipes from a hot water boiler (boiler), heated by burning solid fuel or gas. The boiler can also be heated by electricity.

Advice from an experienced summer resident: A boiler heated by burning solid fuel or gas should be installed outside the greenhouse so that flue gases (carbon monoxide) do not enter the building.

Heating of greenhouses. gas heating

When using gas heating, natural gas is burned directly in greenhouses with the help of gas burners of special installations and their heating is carried out by combustion products.

The carbon dioxide and water vapor released at the same time enrich the atmosphere of the greenhouse, which contributes to the growth and development of plants, and increases the yield of vegetable crops.

In addition to the main gas, bottled gas (propane or butane) can also be used to heat the greenhouse. Bottled gas is more expensive than main gas, but it is more convenient to use. The cylinders used to heat the greenhouse are recommended to be installed outdoors.

Heating of greenhouses. Electric heating

The most efficient, simple and convenient is heating with electricity. For electric heating, it is recommended to use tubular electric heaters (TEH), oil electric radiators, spiral heaters and fan heaters.

Spiral heaters consist of heating coils placed in a casing with holes at the bottom and top.

Cold air enters the unit through the lower vents, heats up and rises up through the upper vents.

Portable fan heaters consist of heating coils and an electric fan. These heaters evenly distribute heat throughout the greenhouse due to the forced movement of air currents.

Air circulation allows you to maintain the desired microclimate in the greenhouse, reduces the likelihood of various plant diseases.

In these devices, separate switching on of heaters and a fan can be provided, which ensures the inclusion of one or another device as needed.

For your information: Electric heaters have a high efficiency, do not emit toxic gases, and are relatively easy to automate - when using them, it is enough to simply ensure automatic maintenance of the required thermal regime inside the structure using a thermostat.

Heating of greenhouses. Stove heating

Stove heating provides for a metal (cast iron) or brick oven, a horizontal chimney (hog) and a vertical pipe (riser). The stove is usually installed at the end of the greenhouse or greenhouse so that its back is adjacent to the structure.

A chimney runs from the stove along the greenhouse or greenhouse - a horizontal metal or brick pipe, which is the heating device.

During the passage of hot gases through the chimney, thermal energy is accumulated by the walls of the chimney, heats the air inside the building, and then, upon slow cooling, releases the stored thermal energy. The chimney is connected to a vertical pipe.

Advice from an experienced summer resident: The massive foundation under the greenhouse works like a Russian stove: it heats up during the day, cools down at night. But the foundation of expensive materials, say, brick, is not economical.

We suggest taking note of a simple technology and making a strip foundation of clay. To do this, dig a trench along the contour of the greenhouse to the depth of the fertile layer and three times wider than the foundation.

Build a formwork along the entire length of the trench and fill it with a very thick (almost like dough) clay mortar filled with sawdust or straw. Tamp down. When the mortar dries, remove the formwork, wet the foundation walls and rub sand into them.

And now the trench needs to be ... set on fire: fill the gaps between the foundation and the walls of the trench with firewood, etc. and boldly make a “ribbon” fire. For more heat, cover the trench with iron sheets.

Such a foundation “hardened” in fire will retain heat for plants for a long time.

The material was prepared by: horticultural specialist Buynovsky O.I.

(Number of views - 92, today - 1)

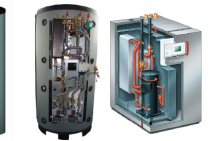

Solid fuel boiler for greenhouse heating

The boiler is installed in the greenhouse or near it, in a separate room. The second method is convenient because fuel can be thrown into the boiler without entering the greenhouse, and this retains such valuable heat in it. In addition, space in the greenhouse is saved. The disadvantage of this method is that the boiler itself heats up and becomes a source of heat, which is wasted if it is not in the greenhouse.

Fuel is thrown into the heat generator twice a day.This type of greenhouse heating is absolutely fireproof, so it can be left unattended without fear of a fire. Fuel consumption with such heating is also minimal.

Water heating in the greenhouse

This method of heating a greenhouse is one of the most cost-effective. A water heater can be easily made by hand. There are two ways to make such a device.

Method 1

- You need to find the body of an unnecessary old fire extinguisher with a cut off top.

- From an old electric samovar, take a heating element with a power of 1 kW, which must be mounted on the bottom of the fire extinguisher housing.

- A cover is fitted on the body of a homemade electric heater so that water can be poured into it.

- Two water pipes connected to a radiator adapt to the heater. Pipes must be connected with gaskets and nuts to prevent water seepage.

To automate the heater, it is best to use an AC relay, such as MKU-48, with a voltage of 220V. When the temperature sensor is triggered, the contacts (K1) will close and the heater will start heating water, which, therefore, will heat the air in the greenhouse. When the water temperature in the electric heater reaches the set level, the temperature sensor will work again, the relay supply circuit (K1) will break, and the electric heater will turn off. If it is not possible to purchase the MKU-48 relay, you can use the second scheme, where the relay has contacts that do not pass current less than 5A.

Method 2

For the second method, you will need several old pipes, a heating element and a welding machine. Everything is made quickly and reliably.

- In a suitable corner of the greenhouse, a boiler with a capacity of at least 50 liters with a 2 kW electric heater is installed. During the heating process, water will be supplied through the expansion tank to the heating system distributed around the perimeter of the greenhouse. The pipes of the heating system should have a slight downward slope.

- The boiler is made from a piece of large-diameter pipe, on which the bottom with a flange is welded.

- The heating elements are connected to each other by an electric cord with a plug, which must be well insulated.

- The junction of the flange with the housing must be sealed with a rubber gasket.

- The expansion tank is also made from pipe scraps. It must be at least 30 liters in volume. Couplings are welded from the bottom of the tank and from its two ends, which connect it to the boiler riser and the system.

- A lid is attached to the tank for the possibility of adding water so that you can periodically check its level.

- A pipeline is made from metal pipes, at the ends of which a thread is made in advance for convenient connection with the system.

- To ground the boiler body, a flexible three-core copper wire is used that can withstand voltages above 500V without insulation. Two ground wires are attached to the TENA phases, and the third - to the boiler body.

In winter, for better heat retention, it will be possible to adapt special screens made of heat-reflecting material, such as foil, or another.

The main condition for the installation of any heating system in greenhouses is strict adherence to safety precautions, as well as following the instructions. Only in this case, your efforts will be crowned with success!

Device for heating greenhouses and other premises

A device for heating greenhouses in automatic mode with increased safety.

The device for heating greenhouses and other premises is presented in the form of a catalytic air heater (KVN) - a gas air heater operating on natural or liquefied gas. The supply of heated clean air is carried out directly into the room. KVN includes a catalytic filter unit, which performs highly efficient cleaning of hot air from harmful substances - fuel combustion products.

Buy item

Description

Advantages

Application

Specifications

Seasonal cost of heating greenhouses

Description:

The device for heating greenhouses and other premises is presented in the form of a catalytic air heater (KVN) - a gas air heater operating on natural or liquefied gas. The supply of heated clean air is carried out directly into the room.

KVN consists of two independent blocks:

– gas-fired direct heating air heater – serially produced certified product,

- catalytic filter unit - passive attachment to the air heater, does not affect the gas supply system, power supply, does not make changes to the automation and control systems. Carries out highly effective purification of hot air from harmful substances - fuel combustion products.

Advantages:

– automatic maintenance of the temperature in the heated room,

– Ensuring increased safety due to the double valve,

– the air heater works in automatic mode,

– does not require the constant presence of the operator,

– the security system provides automatic shutdown of the gas supply in the event of: air supply to the burner is cut off, the gas pressure at the heater inlet drops below 0.8 kPa, the flame goes out, the power supply is turned off,

– possibility of operation of the air heater in two modes: ventilation mode and heating mode,

- the presence of light signaling in case of violation of the operating modes of the air heater.

Application:

– autonomous heating of greenhouses, livestock farms, storage facilities, hangars, industrial and auxiliary premises,

- use as a basic element of local heat supply of residential buildings and industrial facilities under construction.

Specifications:

| Specifications: | Meaning: |

| Rated productivity, kW | 80 |

| Natural gas, nm3/h | 8,2 |

| Propane, kg/h | 5,4 |

| Connecting gas pressure, kPa | 2,0 |

| Air capacity, m3/h | 5 000 |

| Rated electrical power consumption, W, max | 400 |

| Supply voltage, 50 Hz, V | 380 |

| Overall dimensions (length x diameter), mm | 1150 x 400 x 576 |

| Weight, kg | 45 |

| Efficiency,% | >96 |

* the concentration of harmful substances emitted during the operation of KVN-1 "EcoKat" is significantly lower than the MPC (maximum permissible concentrations)

Seasonal cost of heating greenhouses:

| KVN | Thermal energy from CHP | Heat guns on diesel fuel |

| 500 – 600 actual costs) | 1 600 | 2 000 |

* in thousands of rubles

** based on the results of the operation of a greenhouse facility in Novosibirsk with a volume of heated greenhouses of 22,500 m3 (Novosibirsk).

site `s map

independent heating of hangarsindependent heating of non-residential premisesindependent heating of premisesindependent heating of industrial premisesindependent heating of greenhousesindependent heating of farmsunit catalytic filterair heaters gas manufacturersair heaters gas industrial manufacturers and premisesindustrial gas air heatersdirect air heatingindustrial space heating systemsenvironmentally friendly air heater 7012

Demand rate

218

comments powered by HyperComments

Air heater Volcano VR1 with bracket heating greenhouses, farms, animals

Volcano VR1 fan heaters are the best equipment for efficient and low-cost space heating. The resource of the fan heater is designed for many years, thanks to the wear-resistant materials used in the design.Ideal for rooms of various sizes ranging from car repair shops, garages, shops, poultry farms, ending with the heating of large workshops. The Volcano VR1 heating unit heats the air in the room in a short time and maintains it at a given level throughout the day, without human intervention. The power of the built-in fan allows you to direct a jet of warm air to certain areas of the room without spending precious kilowatts on heating the entire room. The Volcano VR 1 air heater has a pleasing design and low noise level, making it suitable for use in supermarkets and showrooms.

An excellent solution for maintaining the required indoor climate in the field of animal husbandry and poultry farming. And also in agricultural areas.

What are the differences and advantages from conventional pipe or radiator heating.1. Batteries are located near the walls and part of the heat is wasted on heating the letter - fan heaters heat only the air2. With pipe heating, the heat rises to the ceiling and heats the roof in vain. The difference in temperature under the ceiling and at floor level can reach 10 degrees. Fan heaters provide uniform heat distribution .3. The use of air heaters makes it possible to maintain a lower temperature at night and on non-working days, which leads to a significant reduction in the cost of fuel, gas or electricity.4. The possibility of maintaining the required temperature exactly in the places where the animals are located in the agricultural sector. premises or workplaces

|

Number of heater rows |

— |

1 |

|

Maximum air flow |

m³/h |

5500 |

|

Heating power range |

kW |

5-30 |

|

Air temperature increase* |

°C |

20 |

|

Maximum coolant temperature |

°C |

130 |

|

Max working pressure |

MPa |

1,6 |

|

Maximum air throw |

m |

25 |

|

The volume of water in the heater |

dm³ |

1,7 |

|

Connecting pipes diameter |

„ |

3/4 |

|

Equipment weight |

kg |

29 |

|

Supply voltage |

V/Hz |

1 x 230/50 |

|

Engine power |

kW |

0,61 |

|

Rated current |

A |

2,8 |

|

Engine speed |

rpm |

1310 |

|

Motor protection class IP |

— |

54 |

If you want to buy a Volcano VR1 fan heater in Chelyabinsk, contact Wacker Ing! Based on the characteristics of the room, we will select for you the most optimal configuration and number of fan heaters, as well as the power and type of heating boiler.

You can also download the data sheet from Volcano.