Soundproofing walls and ceilings in the bathroom is not an easy combination

Traditionally, the bathroom is considered the most suitable place in the house where you can train your vocal abilities. However, the soundproofing of the bathroom will allow you to do this without harm to the nervous system of others. Ventilation and waterproofing - do not forget that these processes also need to be taken into account.

Just like with a toilet, you'll need a soundproof door that won't be afraid of moisture. Of all the soundproofing materials for wall and ceiling insulation, we also choose those that can withstand exposure to steam and do not mold. Mineral wool (glass wool, basalt fiber) is the best suited for these purposes.

Soundproofing from a suspended ceiling in combination with mineral wool or a thin insulator will be the most optimal - the ceiling film perfectly tolerates the effects of warm steam, reliably protecting the materials hidden behind it from moisture.

The floor on top of the screed should be covered with a layer of waterproofing material: a layer of bituminous mastic, sheet material impregnated with bitumen, rubber-based hydrobarriers, there are actually many options. If desired, you can lay a soundproofing membrane, but usually the thickness of the floor is enough to contain sound waves.

In the bathroom, it is very important at the finishing stage to treat all joints with a silicone sealant that does not allow moisture to pass through. You can do all this work on your own.

Features of steel bath

A bathroom or, as it is also called, a sanitary container, metal models are used in everyday life, since they are not as expensive as cast-iron or ceramic ones, and have a relatively small weight, which is especially convenient during transportation. The service life of a metal structure varies from 20 to 30 years. The inner surface of the bowl is covered with abrasion-resistant enamel. Today, products on the market are offered to customers of any color, which allows you to choose the bowl as close as possible to the main interior design. As for the features of metal baths, they include the following:

Photo: Steel bath. Manarbek Bushuev

Photo: Steel bath. Manarbek Bushuev

- small weight of the product;

- variety of sizes;

- a large selection of models;

- wear-resistant enamel coating;

- long service life.

Due to the relatively low weight, which is five times less than that of cast iron. A sanitary container can be brought to any floor without unnecessary difficulties, which is quite difficult to do with the same cast iron structure.

Today, the market offers a huge selection of models of bathtubs. Compared to cast iron structures, metal is easier to process, so the buyer is offered a different choice of product only in length or width, but also in shape. Depending on preferences, parameters and cost, you can choose the most suitable option.

The inner surface of the bathtub is covered with a special enamel, which has a strong structure and effectively protects the product from mechanical stress and abrasion. Enameling technology is applied using high temperatures, as a result of which the polymer material polymerizes and becomes very durable.

Photo: Steel bath. Manarbek Bushuev

Photo: Steel bath. Manarbek Bushuev

As manufacturers of sanitary equipment indicate, a steel product can be used for at least twenty years, but as practice shows, even after thirty years the surface remains smooth and usable.

Interesting! Steel products have a high degree of heat transfer, which in turn contributes to the rapid heating and cooling of the bowl. Also, during the intake of water, a roar is heard, which is quite loud.If you do the soundproofing of the bathroom yourself, then you can simultaneously solve two problems at the same time.

Advantages of steel baths over analogues

Many are sure that they have not yet come up with anything better than cast-iron structures, and recommend using only them. However, steel bathtubs not only do not concede to them in anything, but also surpass them in many ways. Let us make a reservation right away that we are talking about the so-called thick-walled devices, for the manufacture of which steel is from 4 mm thick.

The advantages of steel baths include:

- High resistance to deformation.

- No static induction.

- Strength and durability. A special glass-forming component, which is part of the steel, improves its properties.

- Resistance to various aggressive environments and mechanical damage in the form of scratches and cracks, thanks to a special enameling technology.

- Variety of bowl designs.

- Light weight, greatly facilitating installation and transportation.

- Excellent color fastness.

- Self-cleaning effect, which is typical for the latest generation equipment.

As a result, having opted for a steel bath, you can get equipment that is not inferior to cast-iron counterparts in terms of durability and strength. It has a variety of designs, like acrylic appliances. And at the same time, it is devoid of the shortcomings of the mentioned devices.

Watch a video about bathroom soundproofing

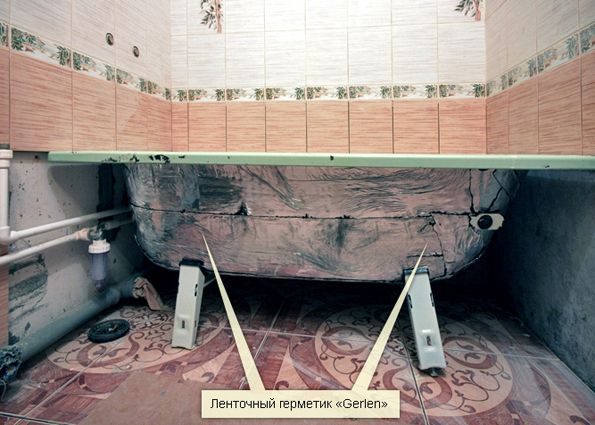

To ensure soundproofing of the bathtub, a gasket made of vibroisol is suitable, you can find it on the windows of car dealerships, since these gaskets are used to ensure soundproofing of cars. Sticking of vibroizol is facilitated by the fact that one of its sides is covered with special glue.

The fastening of this gasket must be carried out in those places where water usually falls, and to enhance sound insulation, the material can also be applied to the side walls.

There is another way to soundproof bathtubs - liquid nails are applied to the outer surface of the bottom in the form of a grid. After they dry slightly, mounting foam is applied to them in several stages, and a polyethylene film is applied on top of it, which needs to be pressed a little. This method can not only soundproof the bath, but also significantly slow down the process of cooling water.

You can also resort to reducing the noise level by reducing vibration - this is done with a bitumen-based mastic. Its layer when applied to the bath should be up to a centimeter thick. Before installing the bath in place, you must wait until the mastic becomes solid.

For the implementation of these soundproofing operations in the bathroom, material costs are very small.

The layout of many apartments in houses of the end of the last century leaves much to be desired, that is, in terms of the location of rooms for personal hygiene and relaxation, they impose certain inconveniences.

Thin partitions and walls of bathroom cabins, especially in panel-type houses, practically did not fully absorb the noise in the sewerage and water pipes, the operation of the toilet drain mechanism, when the bathtub was filled with water and other sound factors that irritated the household with an excessive level of decibels. Such problems can be solved if a bathroom soundproofing complex is carried out.

liquid acrylic

The essential difference between it and all of the above materials is the consistency of the substance - it is liquid, also in use. Liquid acrylic is freely available at any hardware or hardware store.

How to use - it processes the inner surface of the steel bath. The only negative is its pungent smell, also the long time required for drying (48 hours).

For soundproofing, a mixture of components is usually used:

- semi-finished product from acrylic enamel;

- hardener No. 144.

Plus - in addition to soundproofing, the material improves the external aesthetic qualities of the bath.

Processing technology:

- finish the surface using sanding paper or cleaning material;

- wash off the dirt;

- degrease the walls with a simple alcohol-containing solvent;

- dry the surface;

- remove the siphon, and carefully wrap the taps with a film;

- apply acrylic in bulk, covering the inner surface;

- processing continuously, making circular movements.

Draining, the mixture will leave a thin (about 6 mm) layer. Acrylic is durable and wears slowly. The procedure itself, if performed by hand, takes 2 hours. There are many shades of the substance on the market, it is easy to choose your own.

Acrylic advantages:

- no leaks;

- no stains (during and after processing);

- high strength;

- durability;

- no bubbles;

- improving the external aesthetic qualities of the bath;

- ease of application;

- slipperiness reduction.

Soundproofing the bathroom step by step to silence

Now let's come close to the soundproofing of the bathroom - so that extraneous sounds do not prevent you from concentrating on the secrets of being, and so that the sound of serenades (what if you want to sing?) Do not reach outside the toilet. But seriously, quite often the toilets are located in inconvenient places, for example, opposite the living room or next to the kitchen. It is unlikely that the sound of water drain will decorate your conversation with guests or a family dinner. At the same time, the soundproofing of a bathroom and bathroom has a lot of differences from the soundproofing of a room.

First, take care of a door with good sound insulation. An ordinary wooden door is not suitable here, since wood does not have the best sound absorption coefficient. In addition, the tree is not very resistant to moisture - although there is not as much of it here as in the bathroom, it is still better to take it with a margin of safety. So plastic or metal doors will do just fine. You can buy such doors and carefully disassemble them by filling the internal voids with mineral wool, or you can ask the craftsmen who will install the door to do this. In addition to mineral wool, it does not hurt to make a layer of sound-reflecting membranes - they are very thin and at the same time enhance the effect of sound insulation in combination with other materials.

A mandatory item of the program is the soundproofing of the riser. To begin with, check for yourself how your business is - perhaps the builders were smart enough to make soundproofing when installing pipes. In this case, a piece of pipe (sleeve) should be installed in the ceilings, the diameter of which is several centimeters larger than the diameter of the riser. The void between the sleeve and the riser must be filled with soundproofing material or acoustic sealant, and preferably both. Consider yourself lucky if such a simple design takes place - usually the riser pipe is cemented into the ceiling. Impact and structural noise is transmitted through pipes just fine, and air too, if the sound source is close enough.

If the most negative forecasts come true, do the soundproofing yourself. To do this, it is necessary to remove as much cement as possible around the pipe, at least 10 centimeters deep and as wide as it will be enough for convenient winding of the riser with sound and vibration insulating material. In this capacity, the Texound membrane is suitable. If financial possibilities allow, you can wrap the entire riser with this membrane, or, at worst, only the part that goes under the floor. After wrapping the pipe, fill the area around the pipe with cement.

It will be sufficient to insulate the walls and ceiling of the toilet with mineral wool (a layer of at least 5 cm), covering it with drywall. It is best to decorate the floor with ceramic tiles and put a soft rug - it will also participate in the process of dissipating extraneous sounds. So in the reflection room, as the bathroom is often jokingly called, really no one can interfere with the flow of your thoughts.

Alternatives

There are other options for heat and sound insulation of steel bathtubs. You can install a steel container on a hill, and then overlay the entire structure with bricks and soundproof boards that do not react with the aquatic environment. Basalt wool is the best solution for such insulation. This material does not rot, in addition, it resists the formation of fungus and mold. The outer part of the structure can be overlaid with ceramic tiles or other finishing materials. Thanks to the insulating layer, not only sound, but also thermal insulation will be provided.

There are a lot of options for processing steel bathtubs, and everyone selects sound insulation according to their preferences and budget.

Soundproof bath set BWS

Recently, special soundproofing kits have appeared on the market that help to significantly reduce the noise level. The set consists of special linings that are installed on a steel product. Despite the simplicity of the seals, they provide high protection against the sound of rising water. The only thing that an insulation kit cannot provide is thermal insulation so that the water does not cool too quickly.

Modern technologies and materials allow you to create comfortable conditions in the apartment and in particular in the bathroom. Having made heat and sound insulation of a steel bath, in terms of its qualities it will be no worse than cast iron products. If you put your hand, you can use improvised means to make high-quality soundproofing of the bath, especially since there are a lot of processing options, and everyone can choose exactly what is right for themselves.

If the water pouring in the bathroom is getting on your nerves, there is no need to make major repairs or change the bathtub. It is required to organize sound insulation, the specifics and installation methods of which will be discussed.

Steel baths are popular in the plumbing market. The products have a number of advantages, but the sound insulation of such containers leaves much to be desired. Modern building materials allow you to solve this problem quickly and fairly budget.

Soundproofing methods

Soundproofing foam

Conventional foam used in construction to seal gaps and seams is also suitable for soundproofing. Repairers and builders often use polyurethane foam because it swells well and is resistant to high temperatures.

The places where the drain pipes will be connected in the future are pasted over with mounting tape. In order for the foam to securely attach to the walls, the outer surface of the bath is treated with a sealant. A thin mesh of silicone or "liquid nails" is enough. Next, the foam is applied - slowly, in a circular motion, starting from the edges and rising up to the bottom of the bath.

From time to time, you need to take short breaks, during which the foam will dry out and will not slide down the smooth surface. First, the walls are covered with foam, after 8 hours - the bottom. After a day, when the mixture completely hardens, the excess foam is cut off. For an additional effect, you can use a dense greenhouse film: it is applied over the applied foam and pressed tightly, forming a shell.

Unfortunately, the downside of foam is susceptibility to moisture and fungus.

Soundproofing with polyethylene foam

The thickness of the layer and the structure of the cells filled with air create a material suitable for noise and waterproofing.Stores offer both ordinary cheap polyethylene and more expensive ones with a metallized or foil coating. The latter option perfectly reduces thermal conductivity.

Mats are glued onto the surface of the bath, cleaned of grease and dust, removing the protective film from them and gently smoothing to avoid the appearance of bubbles. Experienced craftsmen, in order to reduce material costs, advise not to glue the entire surface, but only those areas that get water from an open tap - this is the area of \u200b\u200bthe drain hole and adjacent sides.

Vibroizol

Vibroizol can be found in car markets and in specialized stores selling spare parts. Until recently, it was used exclusively in the automotive industry - to restore sound insulation in cars. But recently they began to use it for repairs in bathrooms. It consists of a rubberized base and bitumen, on one side it has an adhesive composition that adheres firmly to any smooth surface, regardless of the ambient temperature. To save them, as well as foamed polyethylene, it is possible to process individual sections of the container. The material does not absorb moisture, does not react with chemical irritants and withstands temperatures from -45 to +100 degrees.

technical traffic jam

The most expensive and time-consuming option, which is often chosen by users. Processing with a technical cork allows you to get an environmentally friendly result: even filled with hot water, the bath will not emit toxic fumes. Yes, and moisture resistance is high here.

Pasting is carried out according to the instructions attached to the package.

Acrylic

The advantages of this material are as follows:

- long service life (at least 10 years);

- high impact resistance;

- during application, air bubbles and smudges do not appear;

- over time, spots do not appear on the surface;

- the bath becomes less slippery, more pleasant to the touch and looks.

There are not many cons: acrylic dries for a long time (2-3 days) and emits a sharp unpleasant odor.

The composition should contain 2 components: a semi-finished product of acrylic enamel and hardener No. 144. The surface is preliminarily finished with abrasive material and sanding paper, cleaned with a solvent from grease and dirt, and dried thoroughly. Acrylic must be applied to the entire surface in bulk, while the mixture, flowing down, leaves a layer 6-7 mm wide. Processing is carried out in a circle, without interruptions. Average working time is 2-3 hours.

other methods

Another option is to install the bath on a specially built pedestal, after which it is lined with slabs (or bricks), and tiles are laid on top. A layer of foam placed inside the wall of the room will help keep the heat in the bath.

Features of steel baths

The popularity of expensive and bulky cast-iron bathtubs is gradually declining. They are replaced by more affordable options: acrylic and steel. The latter are chosen because:

- steel baths are much cheaper than both acrylic and cast iron;

- the enameled coating is resistant to deformation and lasts a long time;

- the metal heats up quickly;

- the design is stable, despite the relatively low weight;

- you can choose a bath for every taste;

- it is easy to deliver and install.

The design also has disadvantages: a steel bathroom quickly loses heat and has low sound insulation. Loud noise from running water or falling objects is often annoying, but this problem can be easily solved with the upgrade process.

Materials for soundproofing in wet conditions

Advertising has a very big influence on us, no matter how we deny it. Exploring the forums, you can stumble upon the considerations of people who are ignorant in construction, who consider mineral or basalt wool to be obsolete materials for soundproofing, but some newfangled thin sheet of polymer material with fibers of an intricate mineral is the best way out.

However, in fact, the main advantage of modern soundproofing materials is their thinness, which can save a lot of space. But the degree of sound insulation and the sound absorption coefficient are an order of magnitude lower, whatever one may say. So if the area of \u200b\u200bthe apartment allows you to turn around, then do not be fooled by advertising tricks - buy mineral wool, make a crate and arrange the highest quality heat and sound insulation

Consider that you will kill two birds with one stone on the spot! It is very important that there is still an air gap between the drywall and the laid cotton, however, in this case, the thickness of the entire structure will be about 10 cm

Mineral wool is so good for the bathroom and toilet that when wet it does not start to rot, mold, and only slightly loses its properties, which return after drying. True, do not forget to protect the crate itself with a layer of waterproofing - it just molds and rots.

It is important not to fasten the crate and drywall guides to the wall that you want to soundproof, otherwise they will act as a resonator. It is necessary to fasten to the ceiling and floor, while using special sound and vibration insulating pads to protect the structure from shock and structural noise

Otherwise, this process is no more difficult than solving a school problem - you will succeed!

Silence is an important factor in comfortable living in an apartment. The choice of materials for soundproofing walls in the bathroom, as well as for warming the riser. The phased implementation of soundproofing the bathroom bowl and bathroom.

How to isolate sound in the bathroom

If we talk about the elimination of noise effects on the scale of the entire bathroom, then we can note several common points, namely:

- soundproofing of the bathroom - when the walls, partitions, floor and ceiling of the room are isolated;

- insulation of equipment, in particular bathtubs;

- isolation of sewer and water pipes.

The first task of working with walls is to eliminate those problem areas where sound can seep through. Cracks and holes are carefully sealed with plaster or sealant.

Significant sound leakage occurs through technological connectors for sockets and switches, a smart solution would be to install electrical outlets with protective covers, designed specifically for rooms with high humidity.

In building markets, in a number of modern materials, there is a huge choice for any type of finish, including sound insulation

For wall decoration, it is important to remember that there is high humidity in the bathroom, so the choice of materials should be in favor of the appropriate products, taking into account this criterion.

For this purpose, glass wool, basalt fiber with a thickness of at least 5 mm are suitable. On top of the insulating coating, sheets of moisture-resistant gypsum board or a gypsum-fiber panel are installed on a pre-prepared metal profile frame. These materials are not hygroscopic, perfect for finishing with ceramic tiles. Soundproofing the ceiling can be equipped in a similar way.

As for the floor, the thickness of the slab with screed and tiled lining is sufficient, but if desired, an additional barrier can be installed in the form of a moisture-resistant membrane film, which will increase the resistance to the passage of noise.

Noise elimination in pipes

A large proportion of the noise in the bathrooms comes from the sound in the risers, especially the sewers. Recently, they began to replace sewer risers with plastic pipes. The strength and durability of pipes are indisputable advantages, but the noise effects cover all the advantages of this product. Therefore, during the replacement process, the question of sound insulation involuntarily arises.

It is possible to produce high-quality sound insulation of pipes using rolled tape materials, for example, Texound membranes.Soundproofing will also prevent condensation from forming on the pipes, which will reduce the level of humidity in the room. During installation, polyethylene shells of suitable diameter can be put on the risers and the entire water supply tape during installation, which will also reduce the noise level of water in the pipes.

Vibroplast

A special plastic material, the basis of which is a polymeric adhesive substance, covered on the outside with a light but resistant aluminum foil. It serves as an excellent noise or heat insulator, so it can be used to treat the bath. Use does not require knowledge of special skills or special mechanisms.

How to use:

- the bath is measured, then a piece of the desired size is carefully cut from the vibroplast;

- the item is thoroughly heated with a hairdryer;

- now it is necessary to remove the outer film and, having applied it more tightly to the metal surface of the bath, heat the material again with a hairdryer. It is more convenient to press with a roller or a wide spatula.

Hold until the vibroplast tightly “grabs”.

Material advantages:

- safe, does not emit any hazardous substances;

- available at a cost;

- resistant, withstands -45 +100 temperatures;

- water-repellent;

- does not react to possible chemical irritants.

Soundproofing a bathtub is a useful and inexpensive process, especially if you do not want to change the steel tank. But then taking a bath will bring more pleasure. The loudness will decrease and the heat will be stored longer. What material to take for soundproofing is chosen by the owner himself, most are sold in ordinary hardware stores.

Another non-obvious way to use automotive noise and vibration isolation is bathroom soundproofing. Many of us are accustomed to and perhaps still use Soviet cast-iron baths, reliable as a Kalashnikov assault rifle. Happy owners of cast-iron bathtubs need not read further, because they know nothing about the shortcomings of modern metal and acrylic bathtubs.

If you still changed your cast iron to an “ultramegasuperduper” metal or acrylic bathtub, then you probably encountered or will encounter the following problems:

- Poorly retains heat due to rapid heat exchange with the environment. (applies to metal bathtubs)

- When filling, it rumbles as if I am taking water into a zinc bucket. This is especially felt at first after replacing the cast-iron bath.

So let's do the tuning of our metal bath:

To eliminate unpleasant sound and give the flimsy metal structure additional rigidity, we will cover the bath with a layer of vibration isolation. There is no limit to perfection in the approach to this issue. a bathroom, unlike a car, no matter how much it becomes heavier and, accordingly, if finances allow, you can cover it with a thick layer of vibration isolation.

As a result, we have:

- more rigid construction

- significant noise reduction

- The bath will keep warm better

How much vibration isolation is required for a bath? There is no single answer to this question. bathtubs vary greatly in size, in most cases 1 sq.m will suffice.

To improve the performance of heat preservation, a metal bath on top of the vibration isolation layer can be covered with a sound insulation layer. Due to its porous inhomogeneous structure, the material will prevent the heat exchange of the bath with the environment. As in the case of vibration isolation, the thicker the better 🙂

Excellent preservation of heat in your metal bath.

Does it make sense to soundproof a metal bath?

Undoubtedly! The reviews are unequivocal - soundproofing your metal bathtub of a low or medium price range will turn it into a premium model, eliminating almost 100% of birth defects!

Mounting foam

Construction foam is actively used by craftsmen for the repair or construction of a new building. It is also suitable for creating noise absorption in the bathroom. You can buy it at any hardware or hardware store.Before use, protect hands, head (put on a hat or scarf), face. Read instructions.

How to use - turn the container over, degrease the surface. It is enough to treat it with an alcohol-containing composition. Then slowly cover the bath with a thick layer of this mounting foam. Gently apply in a dense, even layer, trying to avoid gaps. Act slowly, then the foam has time to harden without draining. Having finished processing the side of the bath, turn it over to the second, but after the foam has completely dried.

Polyethylene film will help to enhance the effect. Suitable polyethylene used by summer residents to create greenhouses. It is dense, inexpensive and quite elastic. After applying the foam, cover it with a piece of film prepared in advance. Pressing more tightly with your hands, form a crust resembling a shell.

Important instructions:

- foam suitable for indoor installation;

- it is better to carry out a very presentable treatment in the summer;

- to make the layer uniform, it is worth buying a special nozzle or “gun”;

- before processing, preheat the cylinder (hold it under the tap, turning on the water hotter) and shake;

- leave the place of overflow free;

- view the indicated expiration date and use the foam before it expires.

Conclusion

Soundproofing a bathtub is a simple procedure for which you do not have to hire specialists, and the costs are low. The result is a design that is not inferior in its characteristics to acrylic and cast iron models.

Steel bathtubs are no longer considered an unconditional standard of convenience and quality, but most modern people have them. Someone inherited from their parents with furniture and apartments, others bought it themselves, considering the steel bath traditional - it is cheaper, more familiar and lasts a long time. True, the tank has a significant minus - a high noise level. Any thing accidentally falling into the bath makes a deafening roar. Even pouring water is accompanied by a loud sound. There are two options to solve the problem: replacing or soundproofing the bath. What does the process itself look like, how complicated and expensive is it? It's worth looking into it in more detail.