Tools

You can also increase the diameter of a soft and elastic copper pipe manually by simply pulling it onto a conical blank of a suitable size.

However, it is very difficult to get a bell with the correct geometry in such an artisanal way. Walls can be uneven in thickness, causing thinner walls to stretch too much and thicker ones not to stretch at all. The force exerted by a person is also uneven, therefore, the pipe may be bent during operation and the blank may be skewed, as a result of which the socket will turn out to be asymmetric and skewed.

To make the disassembly neat and form a socket of the desired shape from the edge of the pipe, which can further ensure a reliable connection of the structural elements, various tools are used.

Expander

This is a manual mechanism in which flaring is done by the simple application of force, just as with the use of a conical blank. The expander consists of two handles and an expander - a sliding conical element that is inserted into the pipe. When exposed to the levers, the parts of the expander diverge in different directions, stretching the pipe.

The expander is inexpensive and allows you to get the job done quickly and without much effort. However, it is difficult to get a qualitative result using this tool. The walls are stretched unevenly, thinner sections may break.

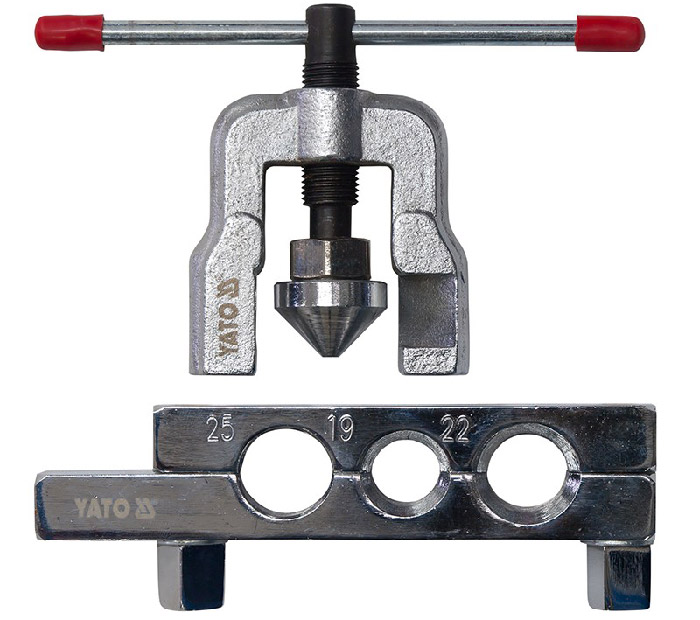

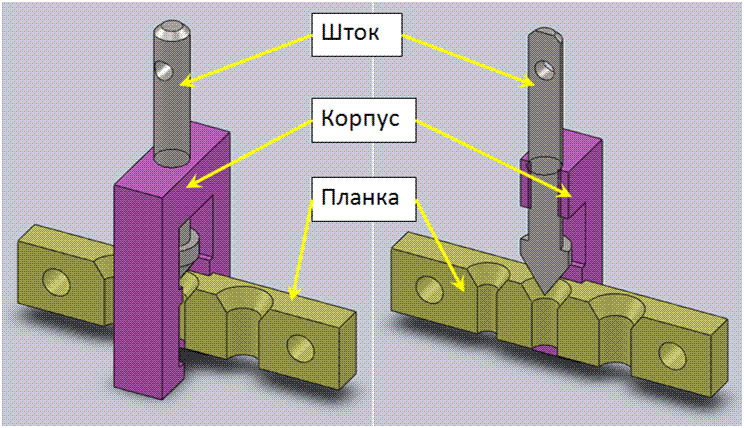

cone flaring machine

This is a small set of two tools: a die and a flaring tool itself.

The matrix is a vise with several cylindrical holes, expanded from above to 45⁰. Hole sizes correspond to standard pipe diameters.

The spreader consists of:

- housings with guides,

- cone expander,

- control mechanism,

- power screw.

When the power screw, which drives the control mechanism, is rotated, the expander is gradually screwed into the pipe edge, expanding it. The guides ensure the invariance of the relative position of the pipe and the expander, due to which there are no distortions and an even and neat socket is obtained.

Mechanical flare

This tool is similar to the previous one, but its working body is not a cone, but a set of rollers. Rollers do not stretch, but roll out the walls of the pipe, expanding it evenly and gradually, due to which the metal has the same thickness on the entire flared surface, and the socket is neat and symmetrical.

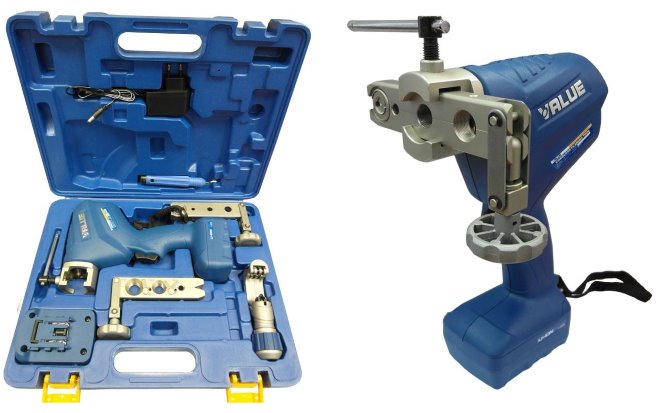

Electrically driven flare

Such a expanding machine is electrically driven in addition to a mechanical expanding machine, so that pipe expansion work is carried out faster and with less labor.

When is it necessary to flare brake pipes?

Through the brake pipes, as mentioned above, high-pressure brake fluid is supplied to all elements of the system. When the capacity of such tubes deteriorates, the entire system begins to work inefficiently, which leads, in particular, to a significant increase in the braking distance. The fact that the elements of the brake system, including the tubes, require diagnostics (and, possibly, repair) may be indicated by the following characteristic features:

- the appearance of extraneous sounds and pulsating movements when you press the brake pedal;

- free movement of the brake pedal when pressed;

- leakage of brake fluid, which leads to a decrease in pressure and, accordingly, to inefficient braking and intensive wear of the brake pads;

- driving the car to the side when braking (this situation, although an indirect sign, can also indicate that the brake pipes need to be repaired).

Old brake pipes in a terrible state should be replaced urgently, even if there are no leaks.

However, the main sign that the brake pipes do not fully perform their functions and require flaring is an increase in braking distance. The most common causes of deterioration in the performance of brake pipes are:

- violations in the design of the hexagonal heads with which such tubes are equipped;

- deterioration in the quality and reliability of threaded connections, ingress of litter or coked liquid into them.

Such malfunctions, negatively affecting the technical condition of individual elements of the brake system, significantly reduce the efficiency of its operation. That is why experts and automakers recommend diagnosing it every six months. If you are tied to mileage, then such a procedure must be performed every 50,000 kilometers, and rubber tubes, regardless of their technical condition, must be replaced every 125 thousand kilometers of the vehicle.

Execution features

Flaring of tubing made of copper may be required if:

- the cut end of the tube must be given the required configuration;

- the end of the product must be prepared for its connection using a coupling (in this case, using flaring, they adjust such geometric parameters of the tube as the inner diameter, bending angle, etc.);

- it is necessary to prepare the ends of the copper tubes for their connection by soldering.

Pipes are cut to length with a special tool - a pipe cutter. for copper or aluminum pipes

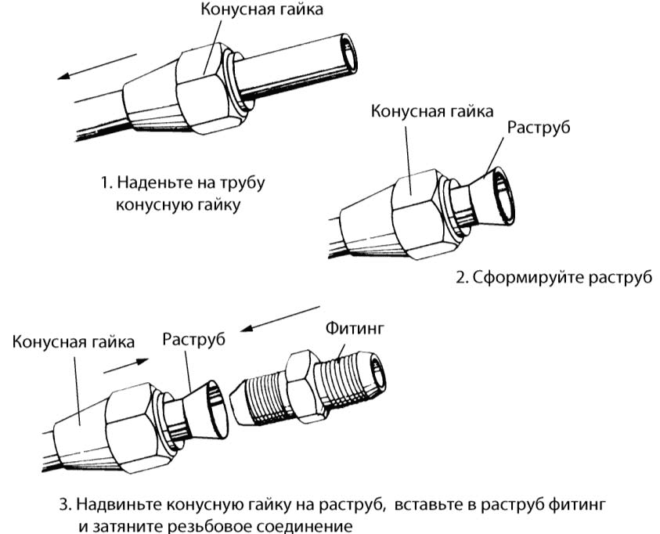

To qualitatively flare a copper tube using special tools and fixtures, you must perform the following steps.

- The end of the tube, the connection of which must be made, is carefully cleaned.

- A special sleeve is put on the stripped end.

- Using a special tool or fixture, the end of the tube is flared until the angle of its expansion is 45 °.

- After the end of the procedure, the end of the product is removed from the fixture. You can then start connecting right away.

Reamer - devices for stripping the ends of copper tubes

If copper is necessary in order to connect it by soldering, then the sequence of actions for implementing such a procedure will look like this.

- The surface of the end of the tube to be flared is thoroughly cleaned (it is best to use a special brush for this).

- Using a special device, the end of the copper tube is expanded to such an extent that it is possible to insert the end of another tube into it and at the same time maintain a gap of 0.124 mm between the connected elements. Naturally, this requires the use of a measuring tool.

- On the inner surface of the pipe section, which is already flared, a flux is applied in a uniform layer, which is necessary in order to ensure the formation of a reliable and tight connection.

- The end of the second connection element is inserted into the flared part to a depth equal to the diameter of the pipe.

- Using a gas burner, an electric soldering iron or a blowtorch, the place of the future connection is heated until the moment when the solder begins to melt.

- Molten solder fills all the gaps between the edges of the connected copper pipes, as a result of which a reliable and tight connection is formed.

Pipe expansion

An increase in the diameter of the product is necessary when performing a fitting-free connection of pipeline elements, for example, capillary soldering of copper pipes. The resulting expansion allows you to insert one pipe into another.

The simplest flaring tool is an ordinary cone that is screwed into a fixed pipe, expanding its edge.

The improved model is equipped with a ratchet, which allows you to adjust the force,

Flaring with the tools described above is the easiest way, but the quality of the resulting sleeve is far from perfect.

The highest quality flaring is obtained when using a tool whose working body is an eccentric cone. When the handle, which is also equipped with a safety mechanism, is turned, the cone begins to roll along the inner wall of the pipe, reducing its thickness and bending the edge. The resulting extension is of high quality.

Such devices are mainly used for pipes made of soft metals. Steel pipes can also be expanded, but this process requires considerable effort when cold. Therefore, it is desirable to preheat such pipes, after which flaring with a hand tool will become much easier.

CLAIM

1. Expander-calibrator, including a body with a central channel, threads for connection with downhole equipment and recesses on the outer surface, in which rollers are placed, mounted on axles and made in the form of cylinders with chamfers, the upper ends of the axles are made with the possibility of limited movement outward, in the annular cavity formed between two body parts there is a spring-loaded annular piston mounted with the possibility of axial movement, and the under-piston cavity of the annular piston is in communication with the central channel, characterized in that the axes are equipped with prismatic ends at the top and bottom, inserted into the body with the possibility of limited longitudinal movement upward and radial movement outward under the action of the thrust and inclined surfaces of the piston, which are spring-loaded downwards and configured for limited longitudinal movement upwards, interacting with the lower end of the axis, the central axis of each the second axis is located in the corresponding plane, parallel to the axis of the body, while the body is made with inclined surfaces for the corresponding upper prismatic ends of the axes, and the central channel of the body below the piston is provided with a technological narrowing.

2. The device according to claim 1, characterized in that the prismatic ends of the axis are made symmetrical about their central axes.

3. The device according to claim 1 or 2, characterized in that the axles are located in the housing in such a way that the top of each axle is displaced along the circumference forward in the course of rotation of the device relative to the bottom of the axle.

4. The device according to claim 1 or 2, characterized in that the axles at the points of contact with the rollers are equipped with wear-resistant inserts.

5. The device according to claim 3, characterized in that the axles at the points of contact with the rollers are equipped with wear-resistant inserts.

6. The device according to claim 1 or 2, characterized in that the axles are provided with lateral closed longitudinal cavities for lubrication.

7. The device according to claim 3, characterized in that the axles are provided with lateral closed longitudinal cavities for lubrication.

8. The device according to claim 5, characterized in that the axles are provided with lateral closed longitudinal cavities for lubrication.

9. The device according to claim 6, characterized in that the axles are provided with a cylindrical channel communicated with the side closed cavities and filled with grease, and in the central channel there is a piston spring-loaded to the opposite end of the cylindrical channel.

10. The device according to claim 7, characterized in that the axles are provided with a cylindrical channel communicated with the side closed cavities and filled with grease, and in the central channel there is a piston spring-loaded to the opposite end of the cylindrical channel.

11. The device according to claim 8, characterized in that the axles are provided with a cylindrical channel communicated with the side closed cavities and filled with grease, and in the central channel there is a piston spring-loaded to the opposite end of the cylindrical channel.

Tools and fixtures

In order to flare tubes made of copper with your own hands, special tools are used. Such devices can have both manual and electric drive. They are used for the installation of air conditioning, water supply and heating systems. Tools equipped with an electric drive often combine several functions: with their help, you can not only expand the copper tube, but also bend it to the required angle.

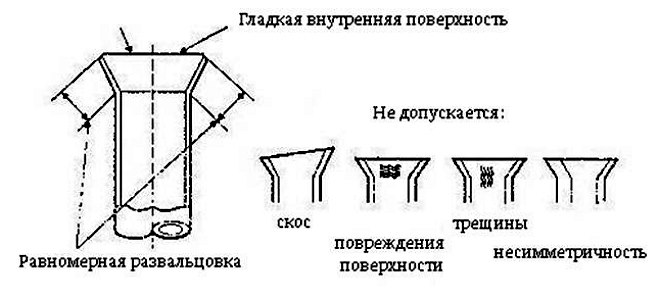

Any device used to expand tubes made of copper works on the principle of plastic deformation, so it is very important that it cope with such a process as carefully as possible, without violating the uniformity of the material structure, maintaining the uniformity of the wall thickness of the products, as well as the smoothness of their internal surfaces

Scheme of correct flaring and examples of incorrectly performed operation

Sample

This is a cone-shaped blank made of a harder metal alloy than copper. The advantages of such a device are low price and ease of use. Meanwhile, its use may be accompanied by ruptures of the walls of the copper product, which gives a low quality of flaring.

With this simplest device, you can flare one tube, but there is no need to talk about any quality of work

Mechanical flare

The main working body of this device is a hard alloy roller, which, rolling along the edge of the copper tube, gives the latter the required configuration. The use of a mechanical expander makes it possible to perform uniform deformation of the processed section of the tube, to form walls of the same thickness at its end with high quality of their inner surface.

Hand tools are able to provide high quality flaring and good work speed

Electrically driven flare

Such a device with a whole set of interchangeable nozzles, having all the advantages of a mechanical tool, allows you to flare copper tubes with higher productivity and less labor. Perhaps the only drawback of an electric flaring machine is its rather high price.

The battery of this flaring machine lasts approximately 100 operations.

Expander

Such a manual device, working on the principle of a lever mechanism, allows you to flare the end of the tube in one movement. Having a simple design, such a device also has a number of significant drawbacks, the most significant of which is the inability to control the wall thickness of the workpiece. Thus, the use of an expander, which is most often chosen by those who do the flaring with their own hands, does not guarantee a high-quality result.

Getting a conical bell

To understand the technology of the process, we can take the example of expanding copper tubes. The order of work is as follows:

- The pipe is carefully trimmed. For high-quality flaring, the angle between the end face and the plane must be strictly 90 degrees.

- Metal processing of the working part consists in cleaning and removing burrs and oxides.

- A threaded sleeve is put on the tube.

- The workpiece is clamped in the bed in the landing hole of the appropriate diameter. The end of the pipe (working part) should protrude a few millimeters above the bed.

- Screwing the screw, rest the flaring cone against the end and apply pressure until the deformation of the section reaches the limit - a skirt beveled at an angle of 45 degrees will be formed.

- The workpiece is removed from the frame, the sleeve is moved to the machined edge.

To make it easier to work with a cone on the workpiece, it is better to cover the working surface with a lubricant.Move the screw back and forth, gradually achieving the desired result - this will help to avoid possible metal rupture in the deformation area.

Working with a manual expander has its own algorithm of actions:

- The end of the workpiece is mounted on a suitable diameter of the head until it stops (there are several diameters).

- While holding the stationary handle, the movable handle is moved around the circumference, thereby spreading the jaws of the head. The work is carried out without violence, so as not to break the pipe.

- After obtaining the expansion of the diameter, the workpiece is removed from the tool.

- Check the ease of entry of the second pipe into the resulting socket.

Tool Selection Tips

Expanding a copper tube, given the high ductility of its material, is not difficult. However, in order to achieve high quality performance of such a technological operation, only a specialized tool should be used. Performing flaring using the simplest devices, which include blanks and expanders, can be accompanied by a number of negative consequences.

- The walls of the tubes, if they are of small thickness, will jam.

- Breaks can occur in the walls of tubes that will be affected by such an instrument.

- In this case, it is practically impossible to achieve a uniform thickness of the tube walls, which will ultimately affect the reliability of the joint being formed.

In a special device, the copper tube is fixed strictly perpendicular, and the deformation occurs exactly along the cone

Meanwhile, the use of devices specifically designed to perform flaring has the following advantages.

- Due to the gradual (performed step by step for each pass of the tool rollers) deformation of the pipe walls, the occurrence of ruptures in it is practically excluded.

- The uniformity of the wall thickness of the copper tube is achieved, even if initially this parameter was not uniform.

- The inner surface of the tube after flaring becomes perfectly smooth and even.

The use of a special device, in addition, allows you to quickly and efficiently flare the end of the tube, even for those who have never performed such a procedure with their own hands.

The flaring kit may include: eccentric flaring, reamer, pipe cutter, pipe expander and pipe bending springs

In order for the flaring to be performed efficiently, special attention should be paid to the choice of tool. In this case, it is necessary to take into account such parameters as:

- characteristics of the material from which the tube is made, in particular the degree of its plasticity;

- internal diameter of the product;

- its outer diameter;

- flaring depth;

- the distance at which the product will protrude above the working part of the tool;

- the distance between the centers of the inner holes of the copper tubes (if the selected device allows you to flare several products at once);

- wall thickness of workpieces;

- the need to form grooves on the processed part of the copper tube;

- the presence of connecting seams on the surface of the workpiece.