Design and dimensions

The bottle siphon, its varieties and modifications, is now most in demand on the market among ordinary buyers. It gained its popularity due to its ease of operation and the simplest design. Installing such a siphon is not difficult even for the most ignorant person in plumbing matters. Ease of installation lies in the simplicity of the design. Based on the name, you can guess that this siphon has the shape of a bottle. Another name for it is flask, since the siphon mechanism itself is located inside the flask. To understand the principle of operation of a unified bottle siphon (SBU), consider what it consists of.

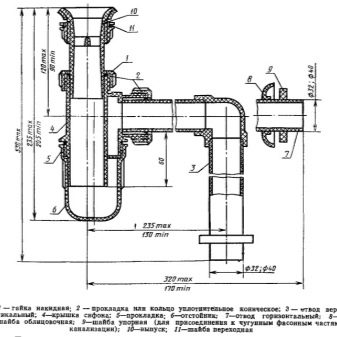

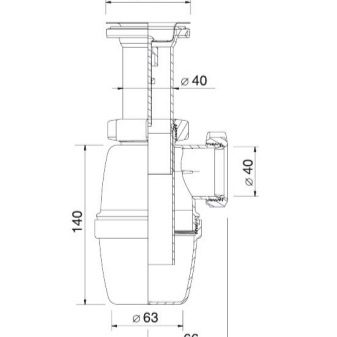

In the upper part there is a branch pipe for connecting to the washbasin. Usually this is a small piece of pipe with a diameter of 32 mm and a length of 120-150 mm with two nuts at the ends. Bottom nut with gasket. The top nut connects the pipe to the washbasin, and the bottom nut to the siphon tank.

The top half is shaped like a bowl with a 32 mm diameter pipe built into it in the center. The pipe passes through the entire upper bowl and descends into the lower bowl of the sump. When assembled, there should be a gap of 3-5 mm between the pipe and the bottom of the lower bowl. This is necessary for the flow of drain water. At the top of the tank is a drain that does not connect to the central tube of the top bowl.

Drainage through a threaded connection with a nut and a gasket is attached to the outlet pipe. This pipe is connected to the sewerage system. You can connect it with a corrugated pipe or a polypropylene sewer pipe. The sizes of bottle siphons are quite acceptable and convenient for installation. In height, they vary from 130 to 180 mm. The tank or flask of the siphon has a diameter in the range of 80-100 mm. The length of the outlet can also vary from 100 to 180 mm.

materials

According to the materials from which bottle siphons are made, they are divided into two types: plastic and brass. The latter are much more expensive, but will also last much longer than plastic ones. Polymeric materials are short-lived under the influence of water and different temperatures. Therefore, the brass siphon is also called unified. Plastic siphons are most often white, and brass ones are chrome-plated so that they do not oxidize. Therefore, most often they have a steel color.

By design, they are divided into classic, with overflow, with two bowls and with an additional drain. We examined the device of the classic bottle siphon above; other types differ slightly from it. The siphon with an additional drain or with a vertical outlet is the same classic bottle siphon. The only difference is in the connections to the washbasin. In this model, there is another drain in it, designed to connect the washing machine. The drain is made at an angle of 45 degrees upwards. This prevents washbasin drain water from entering the washing machine tub.

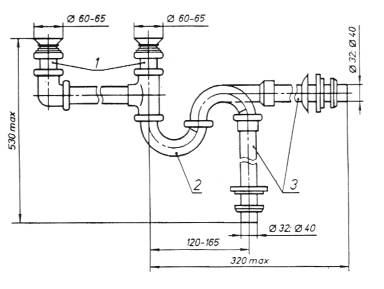

A bottle siphon with a unified outlet (SBUV) with two bowls is also a classic model with a single modified connection pipe. This detail in this model is made in the form of a T-shaped connection with a common outlet. In the upper part, the pipe connects to two washbasins, and in the lower part it converges into a siphon tank. This design is small in size and allows you to save effort and money during installation and does not take up much space.

Siphon with overflow is another kind of classic. It also differs in the upper part of the connection pipe. Here, with the help of a corrugated pipe, an additional drain is connected, the upper part of which is mounted on the side of the sink.

2 Characteristics

0.15 - release from

siphon for washbasins, sinks, sinks, bidets;

0.25 - release from

siphon for bathtubs and shower trays, overflow for washbasins and sinks;

0.35 - overflow

for bathtubs and deep shower trays.

1 - release; 2 - siphon body; 3 - withdrawal

Figure 4 - Pipe siphon with a unified outlet, vertical

or horizontal outlet for washbasins and sinks with two bowls (type STU2)

5.2.6 Bottled

siphons must provide the possibility of vertical movement of their branches

relative to the outlet, and pipe - the ability to rotate the branch to change

the distance between its axis and the outlet axis.

1 - overflow; 2 - release; 3 - siphon body; 4 —

withdrawal

Figure 5 - Siphon with outlet and overflow for baths and deep

shower trays (SVPG type)

1 - release; 2 - siphon body; 3 - withdrawal

Picture 6 - Siphon with outlet for shallow shower trays (type SPM)

5.2.8 Limit deviations of free dimensions of metal

reinforcement parts should not exceed those specified in GOST 2689 for products of the 7th accuracy class, plastic - in GOST 11710.

- resistant to

exposed to fluctuating temperatures and ensure proper operation under

variable exposure to hot (temperature up to 75 ° C and for a short

up to 80 °С) and cold water;

- resistant to

the influence of internal stresses;

- plastic.

ledges and

recesses in the places of removal of sprues should not exceed 1 mm.

Not allowed

warpage of parts, affecting the quality of their interfaces.

Parts cast

in metal and sand molds, must be cleaned of burnt molding

and core mixture.

On the invisible

after installation of reinforcement, the surfaces of cast parts should not be more than five

unsealed shells up to 1 mm in diameter. Welded and ground shells are not

should degrade the appearance of the parts after they have been electroplated

coatings.

5.2.15 Details

fittings made by stamping must be smooth and free of

lubricants.

5.2.16

The inner surface of cast iron siphon bodies must be coated with silicate

enamel of any color.

outdoor

surfaces of steel and cast iron fittings (overflow pipes, tee,

union nuts, siphon body and overflow body) must have paintwork

coatings of the same color, corresponding to GOST

9.032.

5.2.17 Protective and (or) protective and decorative metal and

non-metallic coatings should be selected according to GOST 9.303.

Technical

requirements for coatings and for the surface of the base material should

comply with GOST

9.301. Designations of coatings - according to GOST

9.306.

5.2.18

The surface of the rubber parts must be smooth, must not have irregularities.

and burrs.

5.2.19 Basic dimensions of pipe threads on metal parts

must comply with the requirements of GOST 6357 (accuracy class B), the main dimensions of the metric thread - the requirements

GOST 24705 with tolerances in accordance with GOST 16093, degree of accuracy 7.N - for internal thread and 8g - for

external thread.

Thread should

be clean and must not have damaged threads. On separate parts

polished threads with a total length of not more than 10% of the thread length are allowed.

Not allowed

displacement of threads and flash in the places of closure of the form, warping, sinking,

thread damage.

How to choose

When choosing a bottle siphon, the question inevitably arises - which is better: plastic or brass? By choosing plastic, you can save on purchase and lose in quality. Such models are short-lived, the temperature difference and dirty water will do their job. The plastic will fade, become brittle and at some point begin to leak water. The only plus of such models is the low price compared to brass ones.

Regardless of which model you choose (plastic or brass), the bottle siphon still has a huge advantage over other designs.

- Versatility in use. Possibility to connect several units to one device.For example, in the kitchen, two washbasins, a washing machine and a dishwasher can be mounted to one product.

- Due to its universal dimensions, it fits any models of washbasins, sinks, sinks. Even in such a model as "Tulip" it is easily placed.

- Due to its uniformity, if one element of the model breaks down, it can be easily replaced without replacing the entire siphon. All elements of the model are easily changed and do not require complete dismantling of the structure.

- Having a removable sump bowl, you can easily carry out maintenance of this siphon and easily remove settled dirt and grease from it. Even if you accidentally drop your favorite piece of jewelry into the sink, it won't go anywhere. It will simply remain lying at the bottom of the sump, from where you can easily remove it.

- Ease of installation is simply captivating with its simplicity. You can assemble and install this model almost effortlessly.

- The design of this model is such that the collection of dirt and grease residues does not clog the main wastewater passages. Timely maintenance will only increase the life of the product.

- The pricing policy of this model corresponds to the quality and performance properties.

- The materials used and neat stylish design do not spoil the general appearance of the room, and in some cases emphasize its originality and complement the interior.

In the next video, you will see the assembly of the bottle siphon A 3202.

11 Manufacturer's warranties

11.1 The manufacturer must guarantee the compliance of the fittings with the requirements of this standard, subject to the conditions of transportation, storage and operation of products.

11.2 The warranty period for fittings is one year from the date of putting the object into operation or sale through the distribution network, but not more than one and a half years from the date of its shipment by the enterprise-ie*gotoeitem.

13

GOST 23289-2016

Annex A (recommended)

Nomenclature of quality indicators of sakitarko>technical spillway fittings

AL is the height of the hydraulic seal.

A.2 Waste water consumption.

A.3 Test water pressure.

A.4 Resistance to alternating exposure to cold and hot water.

A.5 Impact strength.

A.6 Resistance to internal stresses.

A.7 Plasticity.

A.8 Connecting dimensions.

A.9 Appearance indicators.

ALO Roughness of visible surfaces.

A.11 Type of coverage.

14

GOST 23289-2016

Annex B (informative)

List of materials for the manufacture of sanitary drain fittings

B.1 Plastics: low-pressure polyethylene of the first and highest grades with stabilizing additives according to GOST 16338: high-pressure polyethylene of the first and highest grades with stabilizing additives according to GOST 16337; injection molded polypropylene according to GOST 26996; sevilen according to specifications.

B.2 Metal: brass according to GOST 17711: brass tubes according to GOST 494; gray cast iron according to GOST 1412; steel pipes according to GOST 3262; carbon steel of ordinary quality in accordance with GOST 380 with a protective coating in accordance with GOST 9.306; stainless steel according to GOST 5582 or according to specifications.

B.3 Rubber: rubber sealing rings in accordance with GOST 9833: rubber in accordance with GOST 7338: molded rubber according to specifications.

B.4 Details of fastening the outlet plug: nylon thread according to GOST 15897. nylon sand according to the current technical conditions or a chain made of polyethylene according to GOST 16338 or brass according to GOST 15527.

15

GOST 23289-2016

UDC 621.643.4:696.14:006.354 OKS 91.140.70

Key words: sanitary fittings, spillway, siphons, outlets, overflows

Rshaktor B.S. Khromov Technical editor V.Yu. Fotieva Corrector RA. Mentove Computer imposition EL. Kondrashova

Handed over to the set 15.N.2016. Signed and stamped 12/26/2016. Format 60*64'/8. Ariap headset.

Uel. oven l. 2.32. Uch.-ed. l. 2.10. Circulation 31 echo Zak. 3296

Prepared on the basis of the electronic version provided by the developer of the standard

Published and printed by FSUE STANDLRTINFORM. 12399S Moscow. Garnet lane.. 4

Kinds

By design, siphons are as follows.

- Pipe - the very first design. It is a curved pipe in the form of a snake.

- Corrugated - an analogue of pipe. Instead of a pipe, a corrugated pipe is used here, which increases the elasticity of the structure and reduces the service life.

- Bottle - the most reliable in operation.

- Dry - a modern type of siphon, which is a piece of pipe with a built-in plastic membrane. In fact, this is the result of nanotechnology.

- Flat - designed for places with rare use of water, because it has a limited capacity.

3 Terms and definitions

In this standard, the following terms are used with their respective definitions:

3.1 siphon

3.2 hydraulic seal: A column of water in a siphon, blocking its passage channel.

3.3 outlet: Drainage fitting assembly designed to receive waste water from a sanitary appliance.

3.4 overflow: A drain fitting assembly designed to drain excess water from a sanitary appliance when it reaches the maximum water level.

3.5 capacity

3.6 connecting dimension