Where to drill

To minimize the cost of drilling, you need to determine the place where the well should be. There are several rules for drinking springs:

- The nearest building is at least 30 meters away.

- From potential sources of pollution (road, cesspool, production workshop, etc.) at least 100 m.

But this is not all that needs to be considered when it is required to drill a well for water. The cost and time costs directly depend on the depth of groundwater. Therefore, before drilling, you need to find out where the water comes as close to the surface as possible. This can be done in several ways:

- Analysis of vegetation on the site. Determine which crops grow in mass. There are catalogs on the Internet that indicate the length of the rhizome. This is the depth of the nearest layer of water.

- Frames and pendulums. This method is not particularly accurate, although the watchmen claim that earlier the place for the well was determined in this way. There is no magic here. The dowser monitors the deviations of the frame or pendulum, and draws conclusions.

- Geological exploration of the site. The most accurate method. The disadvantage is the need to spend money on test drilling. It is necessary to hire specialists who will study the cut and determine where the water approaches the surface of the earth at a minimum distance.

But there is an equally effective way - to talk to the neighbors. They will tell you whether water rises during floods, whether it floods basements. And if there is a well or well in the adjacent area, you can focus on their depth. Differences will be, but insignificant.

How to make a drilling tool

The easiest way is to buy, rent or borrow from friends. But if this is not possible, it is too early to despair. Any drilling device can be made independently. Before you drill a well in the country, you need to include in the estimate the materials that will be required for its manufacture.

Spiral and spoon drill

The bearing element of a design is an iron rod. A number of knives are welded to it. You will also need a disc sawn in half. Its edges are sharpened. Knives, beveled at 20 degrees, are welded to the rod along the longitudinal axis opposite each other. In this case, it is necessary to ensure that the diameter of the structure exceeds the dimensions of the casing.

Another way is to weld sheet metal in a spiral. For this, a strip is taken that needs to be “wrapped” around a rod or pipe. It is advisable to harden and sharpen the edges of the cutter. Of course, in the garage, with bare hands, this tool is hardly possible to make. But if all the necessary equipment and metalworking skills are available, the procedure will not be difficult.

Bailer and glass

If you plan to drill a well with your own hands using a bailer, it can be made from a pipe 2-3 meters long. The wall thickness can reach 1 cm. A shoe with a flap type valve is provided in the lower part. This is a plate of sheet metal, which is pressed by a spring of medium elasticity.

The lower end faces are sharpened inward. The upper end is sealed with an iron mesh. A bracket is attached to the bailer for attaching the cable. In this configuration, at the moment of impact on the ground, the loosened rock enters the glass, and the valve does not allow it to fall out during the lifting process. Every 5-10 lowerings it needs to be cleaned.

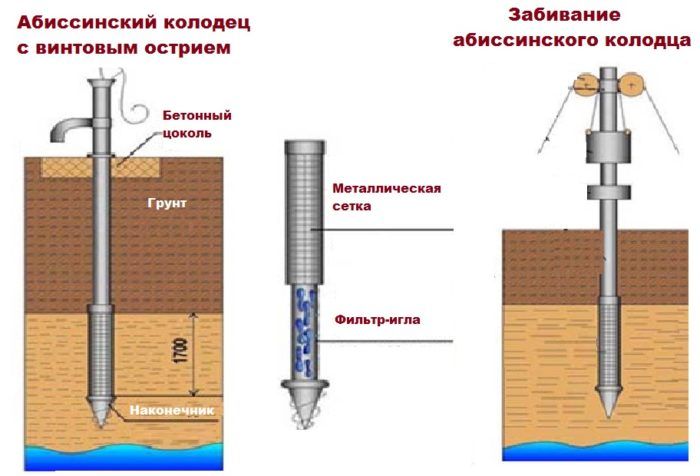

Making a needle for an Abyssinian puncture

A thick metal bar made of hard grades of steel is used. The diameter should be such that under shock loads the metal does not break, does not shrink or bend. The tip is hardened and sharpened. The essence of the method is to pierce a rod into the soil with a sledgehammer. You don't have to choose anything.It is enough to remove it after completion of work and insert a casing pipe with a filter.

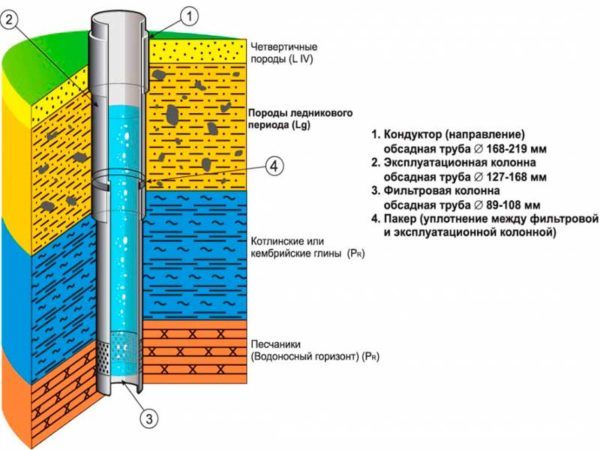

How to install casing

The installation of the casing pipe is carried out in two ways.

First option. A target is drilled in diameter larger than the casing pipe, then the pipe is lowered into the wellbore, or several. To prevent the column from collapsing, the so-called drilling gates are used - with one they hold the pipe that has already gone into the trunk, the other is placed on a new one before removing the first one. After that, the column is upset in depth, if it does not lower itself.

Second option. The casing lower pipe is provided with cutting teeth, and the drill is chosen with a smaller diameter. Having drilled a few meters, the drill is pulled out, and the pipe is forcibly upset, and the cutting teeth cut off excess soil. This method is somewhat slower, since it is necessary to select crumbled rock before a new drilling cycle.

Well bottom

The Abyssinian well can be hammered without special drilling devices. For this you will need:

- Metal or PVC mesh with small cells;

- Thick-walled metal pipes with a diameter, like a pump, and along the length to the depth of the bottom;

- Drill;

- Threaded pipes;

- The tip is sharp conical.

The lower part of the column will be a drill, therefore, a filter is installed at the end of the pipe, above the tip. Its length will be up to a meter. Along the circumference of the pipe, holes must be drilled at an angle of 45o with a diameter of 5-8 mm in a checkerboard pattern. From above, the perforated part of the pipe is wrapped with mesh and fastened with wire, clamps, or in another convenient way.

The tool for drilling wells is deepened a meter into the ground, the verticality is checked with a building level, which must be observed.

Methods for self-drilling

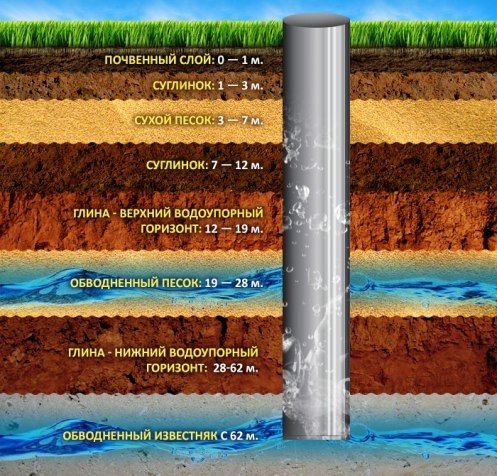

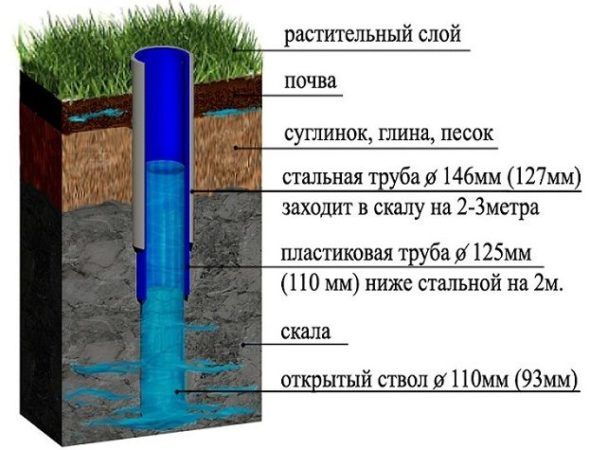

To drill a well for water in a country house, a personal plot, a rural courtyard, it must be taken into account that there are three ranges of depths at which aquifers occur:

- Abyssinian well. Before the water will have to drill from one and a half to 10 meters.

- On the sand. To make a well of this type, you need to pierce the soil to a mark in the range from 12 to 50 m.

- Artesian source. 100-350 meters. The deepest well, but with the purest drinking water.

In this case, each time a separate type of drilling rig is used. The determining factor is the chosen method of drilling operations.

Shock rope

With such drilling of wells for water, the technology of the process involves raising the pipe with three cutters to a height. After that, being weighted with a load, it descends, and crushes the rock under its own weight. Another device necessary for extracting crushed soil is a bailer. All of the above can be bought or made with your own hands.

But before you drill a well with your own hands, you will have to use a garden or fishing drill to make the primary recess. You will also need a metal profile tripod, a cable and a system of blocks. The drummer can be lifted with a manual or automated winch. The use of an electric motor will speed up the process.

Auger

This technology of drilling wells under water involves the use of a drill, which is a rod with a helical blade. A pipe with a diameter of 10 cm is used as the first element. A blade is welded onto it, the outer edges of which form a diameter of 20 cm. To make one turn, a sheet metal circle is used.

A cut is made from the center along the radius, and a hole equal to the diameter of the pipe is cut along the axis. The design is “divorced” so that a screw is formed that needs to be welded. To drill a well in the country with your own hands using an auger, you need a device that will serve as a drive.

It could be a metal handle. The main thing is that it can be disconnected. As the drill deepens into the ground, it is increased by adding another section.The fastening is welded, reliable, so that the elements do not come apart during the work. After the procedure is completed, the entire structure is removed, and casing pipes are lowered into the shaft.

Rotary

Such drilling of a well in the country is not the cheapest option, but the most effective. The essence of the method is the combination of two technologies (shock and screw). The main element that receives the load is the crown, which is fixed on the pipe. As it sinks into the ground, sections are added.

Before you make a well, you need to take care of the water supply inside the drill. This will soften the ground, which will extend the life of the crown. This method will speed up the drilling process. You will also need a special installation that will rotate, raise and lower the drill with a crown.

Puncture

This is a separate technology that allows you to penetrate the ground horizontally. This is necessary for laying pipelines, cables and other communication systems under roads, buildings, in places where it is impossible to dig a trench. At its core, this is an auger method, but it is used for drilling horizontally.

https://youtube.com/watch?v=LsyyVxKLfNY

The pit is dug, the installation is installed, the drilling process begins with periodic sampling of rock from the pit. If water in the country can be obtained from a well separated by an obstacle, a puncture is made, a horizontal casing pipe is laid, and a pipeline is pulled. Everything can be done with your own hands.

Drilling methods

Before starting work, you should decide how to work, since you can punch a well with your own hands in several ways:

- Rotary drilling method - the rotation of the drilling tool to deepen it into the rock.

- Percussion method - the drill rod is driven into the ground, deepening the projectile.

- Shock-rotational - driving the rod into the ground twice or thrice, then rotating the rod and driving again.

- Rope-percussion - the drilling tool rises and falls, regulated by a rope.

These are dry drilling methods. There is also a technology of hydrodrilling, when drilling is carried out using a special drilling fluid or water, which are used to soften the soil. The hydropercussion method requires high costs and special equipment. If manual drilling is carried out, a simplified version is used, pouring water over the soil to soften it.

Let's start drilling

If we talk about step-by-step instructions for drilling a water well with your own hands from A to Z, then it looks like this:

- A pit is digging one and a half meters long and the same width. Depth - from 100 to 200 cm. This is necessary to prevent the collapse of the upper layers of the soil. The walls are lined with plywood sheets in the manner of formwork. The bottom is covered with boards. A wooden shield is mounted on top of the pit, on which you can safely walk without fear that the walls of the pit will collapse.

- Technological holes are made in the bottom and cover for the production of work. A drill rod attached to the drilling rig is threaded through them.

- The drill is driven by a special engine with a gearbox or manually. If we are talking about a puncture, a pin is installed on the pin, which is hit with a sledgehammer.

- If the technology involves the parallel installation of casing pipes, work is also carried out through technological holes in wooden shields.

- The soil removed from the well is selected manually. If it is slurry, you need to install a mud pump that will pump it directly from the casing.

- After drilling is completed and the casing is installed, it is necessary to mount the electrical equipment and start the pump, which should work until the water from the well becomes absolutely clean.

After all stages are completed, a caisson is mounted instead of a protective box. A cap, pumping and filtration equipment is installed, a pipeline is connected.The system is being tested. The equipment depends on the type of well.

Abyssinian

The upper water layers are suitable for irrigation, but are not used for domestic use. This is due to pollution that penetrates the soil with floods. Such a well has a depth of less than 10 meters. Water must pass through a multi-stage filtration system. Only in this case, the liquid turns from technical into drinking.

A hand pump can be used as pumping equipment. It is allowed to use any type of electrical equipment (submersible, surface). The pumping station does not have to have a large capacity, and this makes the well the most inexpensive. It is advisable to equip a storage tank into which the daily supply of water is pumped.

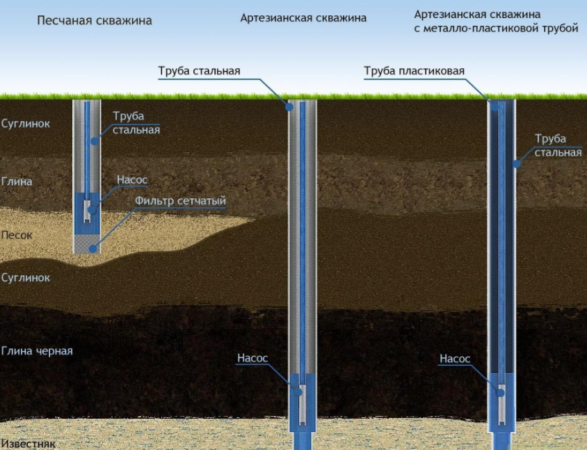

Well on the sand

At a depth of 10-40 meters, there are layers in which water undergoes natural filtration. Passing through the sand, it is cleared of part of the impurities. It does not contain large inclusions, clay and a number of chemical compounds. For domestic purposes and for irrigation of crops, such water can be used, but additional filtration is required to make it suitable for food use.

The best option for electrical equipment is a pump. Surface pumping stations are also used. If the depth is more than 10 meters, the use of an ejector is allowed, which will increase the performance of the pump, accelerating the flow of produced water in the pipeline.

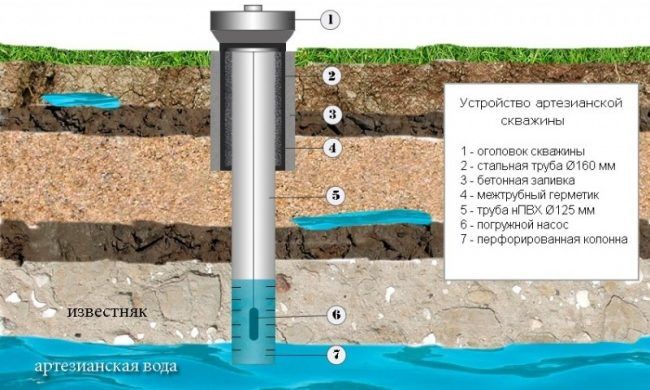

Artesian

These are wells with absolutely pure water, enriched by nature in limestone cut ground plates. The depth can vary from 100 to 350 meters depending on the location of the site, the geological features of the soil and the terrain. Water does not require filtration. The threat is contaminants that can get inside the casing from the outside. The minerals contained in the solution are beneficial to humans.

It is necessary to install a submersible pump for the well. It can be a centrifugal or vibration type device. The latter is preferable, since it breaks less often, and its performance is greater. The main thing is that the pump has a coarse pump that prevents solid particles from entering the working chamber.

Needle hole drilling

For the rotational method, you will need a drill with metal blades at the bottom, arranged in a spiral. At the drilling site, a recess is made with a shovel.

To soften the soil, it is poured with water, but keep in mind that at the same time, the drill is pulled out more often, every half a meter, and cleaned of adhering earth. The penetration of dense clay, however, will require the use of a percussion-rotary method.

You will also need a metal pipe with a diameter that allows you to place a drill with blades in it. We get a pipe and a drill inside it. When the drill is rotated inside the pipe, the earth collects in the pipe and can be easily removed.

The tool used for drilling is called an auger. As you go deeper into the ground, it becomes more difficult to manage, so help may be needed. A well or well is lined with factory concrete rings above the ground, strengthening the sediment.

Tips before you start

To approach well drilling technology reasonably and without disastrous consequences, you should pay attention to several important nuances. Intensity

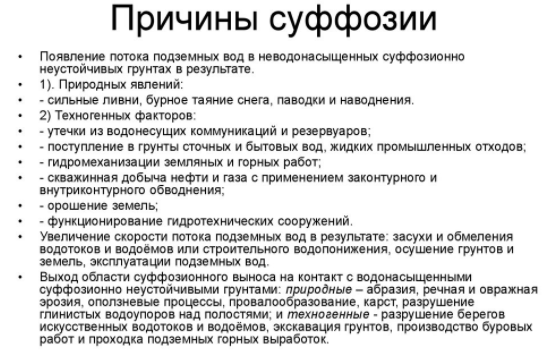

With uncontrolled and massive water intake, the so-called soil suffusion can begin, as a result of which it falls deep enough, which is especially deplorable for areas with residential buildings

Intensity. With uncontrolled and massive water intake, the so-called soil suffusion can begin, as a result of which it falls deep enough, which is especially deplorable for areas with residential buildings.

Depth. When drilling independently on a plain in Russia, twenty meters is considered a critical depth.If you want to drill deeper, ask the experts how much such work costs, and you will be pleasantly surprised, since drilling a deep well on your own will cost much more.

Term of use. The period of operation of any well depends heavily on how often and how much water will be taken from it. If you rationally use a sand well, it can last 15 years, and an artesian well will wither in five years if water is pumped out of it uncontrollably.

Well design

A borehole is a long, narrow hole in the rock, also known as a shaft. Drilling consists in the fact that a drilling tool is lowered into the shaft on a rod made of pipes or on a rope.

A pipe is lowered into the shaft - casing, which will ensure the integrity of the walls of the shaft and prevent their collapse under the pressure of the rocks. The casing sits tightly in the hole or with an annulus. It is filled with clay or concrete.

The lower end of the trunk is muffled, open or with a slight narrowing - bottomhole. The upper part of the trunk is the head. Around it, the arrangement of the well is installed.

Advice from an experienced summer resident

When calculating the pump power, two quantities must be taken into account:

- The height of the water column. This is the distance from the water table to the surface of the earth.

- Distance of water transmission horizontally. The calculation includes the distance from the well to the distant consumer.

The height of the water column is an indicator that must correspond to the power of the pump. It is generally accepted that each kilowatt allows you to raise water by 10 meters. The power of the pump provides for the creation of the required pressure in the pipeline so that each consumer can function in normal mode.

When calculating the required amount of water, it is necessary to take into account the consumption rate in the region when it comes to irrigation. And for domestic use, you need to add up the entire flow, as if all points are included. In this case, the performance of the pump cannot be greater than the flow rate of the well. Therefore, when the well is ready, they measure how much fluid enters it in one hour.

Well type selection

The wellbore can be:

- Filter - sandy well;

- Filterless - artesian well;

- Tubular well.

Artesian

Drilling an artesian-type well involves drilling to a depth of up to two hundred meters - porous limestone lies at this depth. The advantage of artesian wells for water is the uninterrupted supply of water, regardless of the time of year, since at such a bottomhole depth the water will not freeze. The life of the well reaches fifty years.

Sandy

Wells on the sand are drilled to a depth of thirty meters. Such a well consists of a buried pipe, at the end of which a filter is installed that traps large mechanical impurities and sand. A sandy well can provide water to a summer cottage or a small country house.

The advantage of a sand well is the ease of drilling and the relatively low cost of arranging and maintaining the well. The disadvantage is:

- poor performance;

- the likelihood of silting;

- ingress of ground or surface water into the well.

In addition, a sand well usually lasts no more than ten years.

Well

A well installed for the extraction of clean water is called an Abyssinian or tubular well. It is drilled to a depth of up to fifteen meters, and the face is built with factory concrete rings. If there is a good spring on the site, the well quickly accumulates water.

When deciding on the type of well, consider the amount of water you need for consumption and the regularity of water consumption. For example, a sandy well will fully provide a summer cottage, where they live only in the spring and summer.

If it is required to provide water to a house in which they live all year round, an artesian well is suitable as the most acceptable option for autonomous water supply.

Water swing

To obtain the required amount of water, you must either open the aquifer, or swing it. When opening a reservoir, drinking water flows during the first day, but such a process requires small-sized drilling equipment.

Opening can be direct and reverse. In the direct method, water is pumped into the casing and drilling fluid is pumped out of the annulus. When reversed, the water flows by gravity, and the solution is pumped out of the barrel.

The buildup takes two to three days with a submersible centrifugal pump, as the vibrating one quickly becomes clogged with silt.

Water is pumped out each time the pump is covered. Before switching on, the pump is raised and lowered on a cable to raise the sludge. Swinging, add gravel backfill, as it will settle.

When the transparency of the water rises to half a meter, the buildup is considered over. Dip an enameled plate or a white lid into the water - its edges should be visible with a strictly vertical observation.

This completes the well. Further, it is equipped with a filter, an automatic pump and other devices for supplying and purifying water.

Related video: We got to the water

https://youtube.com/watch?v=4vxUTZDVNBQ

A selection of questions

- Mikhail, Lipetsk — What discs for metal cutting should be used?

- Ivan, Moscow — What is the GOST of metal-rolled sheet steel?

- Maksim, Tver — What are the best racks for storing rolled metal products?

- Vladimir, Novosibirsk — What does ultrasonic processing of metals mean without the use of abrasive substances?

- Valery, Moscow — How to forge a knife from a bearing with your own hands?

- Stanislav, Voronezh — What equipment is used for the production of galvanized steel air ducts?

The nuances of installing casing pipes

It can be metal, asbestos cement or plastic. Each of the materials has its own advantages and disadvantages. Concrete casing pipes are rarely used. This is usually production. The material is heavy, brittle, prone to splitting. Therefore, in the process of drilling wells, either steel or HDPE is used.

The metal oxidizes unless it is stainless steel, which is expensive. Oxide causes deterioration in water quality. Over time, it becomes brown and has a metallic taste. You will have to install a filter and clean the well. Connections are welded. It is they who are the weak point, and after depressurization, groundwater with dirt enters the casing pipe.

Low pressure plastic (HDPE) is lightweight, which simplifies installation. The inner surface is smooth and no deposits appear on it. Corrosion is not terrible, connections are tight. The sections are twisted by means of the provided thread, and no special tools are required for this. The only drawback is the limitation on the depth of the well. This material is not suitable for an artesian well.

Site selection

Manual drilling of water wells is often required to provide irrigation in a summer cottage or house adjoining area. It is possible to provide such a site with industrial water by the shock method.

First, they check whether it is possible to equip a sand well. If there are sand wells in neighboring areas that do not dry out in the summer season, conditionally connect them with a line and extend it to your site. Approximately in this area, look for a source of water.

When choosing a place for drilling, consider the following nuances:

- The wells of your and neighboring sites should be no closer than 45 m. Otherwise, in the summer, none of them will have a normal water supply.

- Find the highest point on the site - on a slope or depression, there is a greater chance of water pollution after heavy rainfall.

- The well should be located at least thirty meters from the septic tank or sewer well.

Common Mistakes

Most of the problems are due to the fact that people who do not have experience are taking on the job. The thing is that you need to drill a well on the site with your own hands with filigree accuracy. The hole must be vertical. Tilting, bending, breaking leads to the fact that it is impossible to install the casing.

But even then, some make the following mistakes:

- We overdid it. This is when the casing pipe penetrates the aquifer and goes into formations in which there is no water. In this case, the casing is raised, the upper element is changed to a smaller one. It is necessary to ensure that the well is deepened to the middle of the aquifer.

- Unfinished. Too short casing leads to the fact that the soil below is not loosened. It collapses and blocks the flow of water, clogging the casing. A bailer is used for cleaning. After that, the casing pipe is extended to the missing length.

Some incorrectly install a submersible pump. If it is too low, the sand clogs the inlet, preventing water from getting in. Exit - raise the pump. Before that, it is removed, the coarse filter is cleaned, and the well is cleaned of sand with a bailer.

To properly install the pump, the switched on pump must be smoothly immersed in the casing. The presence of water indicates that the aquifer has been reached. Then you need to lower it slowly until water with sand comes out of the pipe. As soon as this has happened, the submersible pump is raised half a meter and fixed at this mark.