Tools and materials

The list of tools and materials depends on the nature of the detected malfunction and possible ways to eliminate it.

To replace sensors, regulators or other devices, a minimum of tools is required, for more serious work - removing part of the screed and opening the pipe, a very wide list can come in handy.

In any case, you will need:

- Hammer.

- Pliers.

- Screwdriver.

- Set of wrenches.

- Perforator.

- Chisel (for accurate exposure of pipes).

- Broom, scoop for immediate removal of debris when removing the screed.

- Connecting fittings.

- Pipe matching that used in the damaged circuit.

- Work gloves for contact with hot surfaces (especially in the first minutes).

In general, the tools needed are the same as for installing the system, but in the course of work, any unforeseen fixtures or tools used as needed may come in handy.

Attention! Possible contact with hot water or structural elements. Protective equipment should be used to prevent burns

Expert answers

sun hong chan:

It's hard to tell where, but the most tried and tested method is to drain the system and pressurize with compressed air. In the place of depressurization, there will be such a whistle that you can immediately determine where. We had such a case. They did a hidden wiring of the heating system in 2000, then it only came into fashion, the owner topped up the anti-freeze 1-2 liters per day. We went there all winter could not figure out where the leak was. This nasty place manifested itself only in the spring, when the laminate in one of the rooms swelled. It turned out that when laying the floors, they hammered a nail into a metal-plastic pipe, the leak is small but constant. This is what happens when Moldovans do it, though not mine.

Nikolay Malyshev:

Oleg Ivanishchev:

Most likely, where the grate or tena (depending on the type) leaks and evaporates immediately. You may not see a cold one, a leak may appear on a hot one, with expansion.

Grandfather Au:

steam or water heating? closed or open type (expansion tank of conventional or membrane type) ? what kind of automation is on the boiler? There may be several reasons, as Oleg Ivanishchev said, it can evaporate from the expansion tank, it can be bled from the valve, it is not bad to pressurize the filled system. even with a simple car pump (I think your system volume is not large), but if the expansion tank is open, you need to turn it off

Alexey Pastukhov:

maybe it boils away? ... look for the return line ....

Uncle from the Future...

Remove all mixers and the pipe outlets under them - either muffle or install temporary ball valves .. (Or, if the mixers have shut-off valves, close them, having previously expelled air from the system) Fill the system with water, expelling air .. Shut off the inlet valves. .With a special apparatus, pressurize the pipes to 8 bar.. Wait 10-20 minutes.. If there is no pressure drop, the system is tight.

If during the exposure time a pressure drop is observed, then there is a leak in the system.

Stas Shabanov:

Where can leaks occur?

Pipes, plumbing fittings and appliances (boilers, radiators, expansion tanks) leak as a result of their corrosion, aging of gaskets or mechanical damage.

When using steel heating pipes, depressurized joints lead to leaks in couplings, downpipes (battery connection areas), outlets, connection points for shut-off valves, heating and measuring devices, pumping and water heating equipment.Similar problems arise when using a metal-plastic pipeline, in addition to the above, water can flow out after some time through the threaded connections of the compression couplings as a result of their self-unscrewing.

Rice. 3 Detectors for detecting leaks in hidden pipelines

Best Answers

Roman Shved:

Only Geophysicists have such units. No one will sell it to you and no one will come with it. Too expensive pleasure. Underground water is EVERYWHERE. The bottom line is HOW to drill deep. Twigs and wires are also garbage. Biofield principle. The closer the water is to the surface, the faster they will cross. Note... WATER, NOT WATER. These "sticks" will also react to not deeply buried iron, communications, electrical cables (especially) and other materials. Even on the cork of a beer bottle.

Maxim Strelchenko:

I know that there are devices for detecting leaks in pipes underground, but I have not heard of such devices.

Said As:

I heard that there is some kind of ancient shamanic method using sticks / twigs, but I haven’t used it in practice

jonny241:

vine

Andrey Sidorov:

Devices have not seen, not used. I can advise you to use two L-shaped devices made of aluminum wire - it must first be straightened and then bent in such a way that it turns out in 1/3:2/3. Then hold the short parts in the palms so that the long ends are directed forward, in the direction of travel, as parallel to the ground as possible, which can be achieved by bending the elbows at 90 degrees. And that's it: we walk around the site, wait for your device to start moving, and hammer in a peg at the intersection of both parts - dig there! Well, do not forget about the presence of denser, compared to other places on the site, vegetation (this is usually nettles), swarming insects over a certain place on the site and, most certainly), leaving, for hours at three-thirty-four in the morning, in crawl in a squat pose looking for dewdrops on grass or leaves - dig there too! And it is better, of course, when all these factors converge in one place. In my lifetime, I dug up already darkness-dark wells - a 100% option, even in winter.

sergey surzhikov:

a device connected to a laptop gives the same probability of finding as a vine, it all depends on the operator's ability to hang noodles.

Vladimir Petrov:

There are devices, but they are all expensive. When we were digging a well, they did this, they took two copper wires, made frames with the letter G from them, took them in their hands and walked around the area where the water would cross there. Then we ourselves walked and even strangers and always crossed ourselves in the same place. Now we have a well there. Always full and

Oleg:

Most likely a lie. There are no such devices.

Olga:

There is a hydrological map. All underground water is taken into account. And some walk around the site with a vine

Cat smile:

Digging a well is an expensive pleasure, and even more so if you miss a couple of times)) ... Contact the office - the price will be the same, they will miss or not)

... The “chief” arrives, walks around the site and puts a cross on the map. Then they drill for verification, and only then they dig. You can also turn to sharamygs, but I personally know a case - they “buried” 20 rings, stumbled upon a stove and threw it away, and the owner pays for each ring.

Anatoly Bondar:

The experience of neighbors is the best remedy. But you can ask for a map of geological exploration. The rest is from the evil one.

A.N.Anime:

you to the shamans!

Anatoli:

I can easily find water at a depth of up to 10 meters. At the dacha, the mother-in-law showed where to dig, he was not mistaken. And all the neighbors too.

Alexander Militsin:

Yes, they exist. It is called, if I am not mistaken, a magnetometer (measures the strength of the earth's magnetic field). It costs quite a lot. You can identify water by indirect signs - geologists know. And with the help of the "vine", although the vine itself or the wire is not looking for anything - you need to have the ability to do this: to be a dowser.

Geoinside:

There is such a device! The method itself is called (RAP), but it does not determine the presence of water, but shows the boundaries of weakened rocks, and they are 90% flooded. I have been working with the device for five years. For a very long time I was looking for professional drillers ready to work FAIRLY!!! Now they give 85-90% of the accuracy of the method, and I, in turn, give a 100% guarantee for my work.

alpha pol:

Best Answers

Gennady Karpov:

If there is no leak in the form of a liquid (its leak is detected in a wet place), then it is necessary to look for a soapy solution (you can use a brush, or spray from a spray gun ...) in places where air pressure can be released at the top of the system. There will be bubbles. Is the excess pressure going somewhere? There is no wet leakage of liquid (you did not write whether everything is dry under the batteries, pipes, boiler ...). Seen from above: Boiler, expansion vessel, pressure gauge connection... . It is strange that the valve is simply drawn in the middle of the pipe! If there is excess pressure, then it should flow directly into the room?? ? So they look for punctures in the wheel, check the tightness of gas equipment ...

Expert answers

Damir Kashapov:

ask a question more precisely, do you want to find a leak or just find out if there is a leak or not?

Natalya Abrosimova:

The water pressure drops.

Igor Shkurny:

water will find a way out by itself ... just wait until it appears ....

Vladimir-Vladimir:

if the puddle needs to be dug

Igor Velikanov:

Now pipelines are dressed in thermal insulation, on supports before filling with foam, a bare remote wire is pulled along the entire length of the tube, when installing the pipeline, the wires on all pipes are connected into a single circuit .... in the event of a breakthrough, the body of the pipe through the water closes to this wire, and by the resistance of the section, you can determine where the leak is ....

husky:

if you mean a method for detecting a leak, then there is a very good device, the operation of which is based on the detection of this very place by noise (sound). And the accuracy is good. The specialist hangs a device on his belly, puts on headphones, walks along the track and listens. It happens without headphones, only then the device transmits information to the beech. After processing the data, the location of the gust is indicated. This device is no longer a rarity in more or less reputable pipeline maintenance organizations. Learn about it in your village.

Horacio Montekki:

call a mobile laboratory to search for breakthroughs

Lexa:

Call the Housing Office on Monday

Murakami:

most often the water rises outside at the break point plus or minus 2 meters dig

EastIdiaTradingCompany:

Try to arrange a drain of water in some place and see the approximate direction of water movement.

Roman Yakhniy:

Shut off the valve, dig out the pipe.

Locksmith-Intelligent:

In any case, you will have to dig. If it oozes heavily, close the “valve” if there is a well and it has it and has not rusted.

dima dorofeev:

someone can find a breakthrough with special aluminum frames

Obormot cat:

Location, using a microphone system.

Alexander Tolmachev:

There is only one technology - to dig, but it is not a fact that the breakthrough will be exactly above the place where the water protrudes.

Gennady Stepanov:

Go around the house and locate the leak.

Rashid Gabbasov:

Echo sounder.

Alexei:

In order to find a leak, first, according to the tracing schemes, I specify the location of the pipe. and then, with the help of devices that react to the sound of water, they determine the place of damage, hidden leaks of hot water can still be searched with the help of thermal imagers.

Alexey Poluboyartsev:

you don't have to look for anything. Urgently call utilities, emergency situations and city authorities. They have everything they need for this.

Causes of leaks

- Corrosion;

- Violations in the system installation technology;

- Illiterate operation.

Metal corrosion is caused by two types of chemical reactions: oxidation under the influence of oxygen and an electrochemical reaction that occurs when metals are docked with a different number of negative and positive ions in the atomic structure of a substance.

Technological violations during the installation of the system, which lead to leakage of the coolant, include, for example, the use of electrodes of the wrong brand and the occurrence of local centers of electrochemical corrosion in the places of welding seams.The most sensitive to violations in the installation technology are metal-plastic pipes connected by threaded fittings. Such a leak is practically unrecoverable and requires a complete replacement of the pipeline section along with the fitting.

Incorrect work and selection of materials

Excessive pressure in the system also leads to water leaks from the pipes. It does not affect the efficiency of its operation in any way and even harms it, leading to the boiling of water at temperatures below 100 ° C. Pressure is needed to pump coolant to the upper tiers of multi-storey buildings or to activate sluggish thermal convection in single-pipe systems with bottom wiring. In one-story houses, it is better to use circulation pumps with a working pressure of no more than 1.5 atmospheres.

Metal-plastic pipes, which have become popular recently, are very sensitive to the mode of operation. They do not withstand sudden changes in temperature, overheating and water hammer. Their structure is stratified, as a result of which the pipes lose their strength, cracks and fistulas appear in them.

Possible malfunctions

The most common sources of problems are:

- contours;

- mechanical devices - pump, valve, etc.;

- controllers, sensors.

In general, two types of breakdowns can be distinguished:

- Visible. Problems that have arisen on system elements that are not difficult to access.

- Hidden. Problems located in the thickness of the screed or under the layers of the underfloor heating cake (mainly pipes).

Problems that have arisen on the visible elements of the warm floor are quite simple to eliminate - you should replace the failed element with a new, working one. It is more difficult to resolve issues with pipes, since they are not visible, and access to them is significantly difficult.

Even the very fact of detecting a leak does not occur immediately, especially if there is not a gap, but a small crack or puncture. Such malfunctions are detected only by visible traces, when a wet spot appears on the floor surface or by a drop in the amount of coolant in the system.

How to find a water leak in a warm floor if a pipe is broken

If there is a scheme for laying underfloor heating pipes, then finding a water leak will not be a huge task. Where greater difficulties can arise with the removal of floor finishing materials and with the installation of the coupling. It is the coupling that should be connected to the punched floor heating pipe if it was damaged during operation.

Certain difficulties with finding leaks can arise if there are absolutely no underfloor heating wiring diagrams at hand. In this case, you can act in reliable and proven ways.

In order to find a water leak, you should use automotive fluid, which is poured into the car washer reservoir. This tool has in its composition special dyes, and it is they who will help to find the place where the warm floor was broken.

To use this method, in addition to the “colored” liquid, you will also need a pressure test pump. What is a pressurization pump? This is a special device that makes it possible to fill the heating system with water, air or antifreeze, in the absence of electricity or the required water pressure, in the water supply.

To find a leak, you will need to block all circuits on the underfloor heating comb, and then individually pressurize them with dye liquid. During this procedure, all the time you need to watch in which part of the room a colored spot appears. Of course, this way to find a leak in a warm floor is not entirely ideal, but this is already something from which you can start looking for damaged areas.

In addition to a special liquid, you can find a leak in the pipes if you fill them not with water or a special agent, but with ordinary air. To do this, you need to perform all the same manipulations: close the contours of the warm floors, and then start pressing them with air, separately. In the place where the pipe is damaged and repair of the warm floor is required, an air jet will escape with noise.

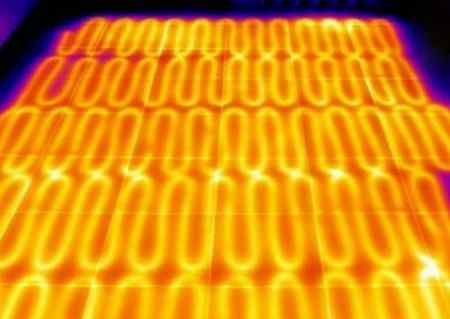

Search for leaks in a warm floor with a thermal imager

A special device, a thermal imager, will also help detect a leak in a warm floor. If you look at the warm floor when it is working, through a thermal imager, you can see exactly how the pipes of the circuits are located. Accordingly, the leakage of warm water will be visible as a large red spot on the thermal imager.

The only problem in the way of detecting leaks in a warm floor with a thermal imager can be a thick screed, more than 12 cm, and a glossy floor covering. From such a surface, the thermal imager beam is simply reflected, and does not make it possible to track any temperature fluctuations on the floor surface.

In order to avoid problems with the operation of underfloor heating, you should always have a plan for laying pipes, with their exact location and distance from walls, doors and plumbing fixtures. The customer has the right to demand such a scheme from the installers, so that in the future, to provide it to the master finishers who will lay the flooring.

general information

The design of water heated floors is a complex system of pipelines, a pumping and mixing unit, control and measuring equipment and devices. The working body (heater) of the warm floor consists of a complex of pipes of small diameter (15-20 mm), placed evenly under the floor covering (linoleum, laminate or tile). The pipes are divided into segments of approximately equal length, called loops or, more commonly, contours. Each circuit is a separate heater connected to the manifold of the mixing unit.

The contour is laid on the floor surface in a certain shape (spiral, snake, snail) in such a way as to distribute it as evenly as possible over the entire area. All pipes have an equal distance (step) between themselves, on which the heating efficiency largely depends. The number of circuits is determined by the total heating area, for one system the maximum is 9 circuits.

Each circuit is connected to the collectors - a direct one, which distributes a coolant with a certain temperature, and to a reverse one, which receives the cooled coolant and directs it to the network or to the boiler for heating. In this case, part of the return flow is mixed with the direct flow in order to obtain a mixture of the desired temperature. This is done in the mixing unit, using a two- or three-way valve.

For stable circulation and overcoming the resistance of pipes, a circulation pump is used, located in the mixing unit. It has several connection options, most often it is located immediately after the mixing unit in order to pump a colder coolant, which increases its service life. The underfloor heating is connected either to its own boiler (for example, gas or electric), or to the central heating network.

The most vulnerable and dangerous, in terms of the possibility of malfunctions, are the contours of the underfloor heating. They are located in the thickness of the concrete (screed), or under the floor covering with a layer of durable sheet material that protects the pipes and creates a rigid base for the floor.Detection of a loop failure means the need to access the pipe at that location, which would require laborious opening of the loop.

Repair process

If suddenly the temperature of the warm floor began to rise, then the reason most likely lies in the three-way valve. When it receives a signal from the sensor, full operation is possible, which opens up the maximum access of the hot coolant to the circuit system.

In this case, shut off the direct pipeline and give the valve time to reset. This is the danger of three-way valves, since a sharp influx of hot coolant causes the mixture to expand, which can cause rupture of pipes or connections.

If a leak is found:

- Clean the area of the floor from the floor covering.

- Visually determine the boundaries of the wet spot (if there is a screed), or remove the protective layer and find the problem area.

- Using a perforator, carefully remove the screed layer along the marked boundaries. To do this, you need to make a hole in the center of the problem area and gradually expand it in a circle until the first section of the pipe is found. Then it will be possible to roughly navigate in its location.

- After cleaning the floor area, you need to find the place of the leak - a pipe break, a bad connection, etc.

- A damaged section of the pipe is found to be replaced. To do this, you need to prepare two fittings, cut out the damaged area, connect a new whole piece of pipe to the circuit using fittings.

- An attempt should be made to determine the cause of the leak. In any case, a connection is more dangerous than a solid, without connections, circuit. If a gap occurs, then it can happen again. Sometimes it’s better to work hard and replace the entire circuit.

- If copper pipes are used, soldering will most likely be required. Its possibility must be organized so that there is no long downtime of the system.

- After the repair of the pipe is completed, all actions should be performed, as at the first start - pressure testing, performance check, elimination of detected shortcomings.

- Then the screed area is restored. Filling is carried out with filled pipes under working pressure.

Malfunctions of visible elements of the system - a mixing unit, manifolds or a pump are much easier to fix, since there is no need to open the floor. In this case, mandatory actions should be taken - shut off the coolant supply, turn off the circulation pump and remove water from the system.

Attention! Replacing elements while the system is running is fraught with the danger of a sudden breakthrough of hot water and burns. Before any action, the heating medium supply must be interrupted!

First steps

If there is a leak, it will pump a lot of water into the ceiling or it will remain without lubrication and fail. Then it is necessary to drain the coolant using a special drain valve, which must be equipped with a floor heating system.

A warm floor without a coolant is absolutely safe and does not bring trouble, but if everything happens in winter in cold weather (and most often it happens), then you need to worry about temporary heating of the house for the period of repair. All this must be done as quickly as possible so as not to increase the damage from the failure that has occurred.

In some cases, it is possible to turn off only the problematic circuit without stopping the entire system. In this case, you must be sure that the cause of the malfunction lies precisely in it, so as not to aggravate the problem that has arisen.