Areas of use

Corrugated pipes for sewerage are widely used by state and commercial construction organizations, with their help they mount the following types of communications and engineering structures:

- Gravity-flowing communal sewer lines are collected for the disposal of large volume wastewater in cities and large urban-type settlements.

- Corrugated sewer pipe 110, 160 mm in diameter is used for installation of non-pressure storm, sewerage in everyday life, drainage.

- Due to the neutrality of the manufacturing material to aggressive substances, they are used to remove chemically active industrial effluents from enterprises.

- They arrange passages under transport highways to protect another type of communications.

- They are used for the rehabilitation of pipelines (double-walled relining technology), laying inside damaged pipes.

- They are used at enterprises producing agricultural products for manure removal and wastewater disposal from livestock complexes, poultry farms.

- Flexible corrugated pipes are used for laying electrical cables and telecommunications networks, as shaft ventilation elements for air exhaust and supply.

- In everyday life, using corrugated pipes, wells are resuscitated from concrete rings, inserting them into the internal cavity, water intake, drainage, technical inspection wells, cesspools are made from the most rigid modifications of a large size (circumference of 1200 mm or more), cesspools, installing pipe sections in a vertical position.

- The largest outer diameter of standard popular products under the Korsis brand is 1200 mm, from a piece of such a pipe you can make a caisson chamber with electric pumping equipment placed inside, a cellar for storing supplies, a technological manhole at the point of connection to the central water supply, sewerage, or an underground chamber for other household goals.

Dimensional parameters Korsis

Advantages

Corrugated pipes for sewerage produced by many domestic and foreign manufacturers have the following features:

- Unlike metals, they have high chemical and corrosion resistance to water and aggressive chemicals (acids, alkalis, salt solutions, oil products).

- Are operated in the wide range of temperatures.

- Resistant to biological attack and mineral deposits, limescale does not form on the inner walls.

- The form of manufacture in the form of rigid corrugation gives the products strength exceeding the values of all polymer, asbestos-cement, concrete, ceramic analogues with the same cross-sectional area, and inferior in terms of indicators only to metals.

- Resistant to mechanical abrasion of internal and external walls.

- The manufacturer produces a wide range of couplings and fittings that provide convenient connection of pipeline elements when changing direction and connecting individual branches, switching from one diameter to another, connecting pipeline lines from other materials of different diameters.

- Due to their low weight, corrugated pipes are lighter and easier to install than similar products made from other materials.

- Production materials (polyethylene and polypropylene) have high impact resistance and resistance to deformation, along with high ring stiffness, they are elastic and do not collapse when squeezed.

Manufacturers

- The main dimensions of the pipes are: 6 or 12 m long, standard diameter 110 - 1200 mm, there are high-strength products with a diameter of 2400 mm (Korsis AWP). Due to a wide range of dimensional parameters, corrugated pipes are widely used in many sectors of the national economy, in the construction industry and in everyday life.

- With a two-layer structure, a smooth inner wall provides minimal hydraulic resistance to sewage - this improves patency and avoids blockages.

- The scope of corrugated pipes is much higher than that of smooth pipes, in households they are used to make water intake and drainage wells, storage sewer pits, technical and inspection wells, reanimate concrete well rings, in all the above cases they use large diameter products from 500 mm. Inexpensive two-layer products with a diameter of 110, 160 or 200 mm are used for conventional, drain and storm sewers, perforated products are used for laying in drainage fields.

- Domestic and foreign manufacturers indicate the service life of their products 50 years or more.

The disadvantages of corrugated pipes include the low resistance of the inner walls to ultraviolet radiation (during long-term storage, the pipes are closed from the ends with protective covers), insufficient heat resistance of polyethylene products, which narrows the scope of their use. And, perhaps, the main disadvantages that limit the widespread use of corrugated pipes in everyday life are the high price of popular brands, almost twice as high as smooth-walled products, as well as the complexity of the socket connection to rubber rings, which requires significant mechanical effort and special equipment.

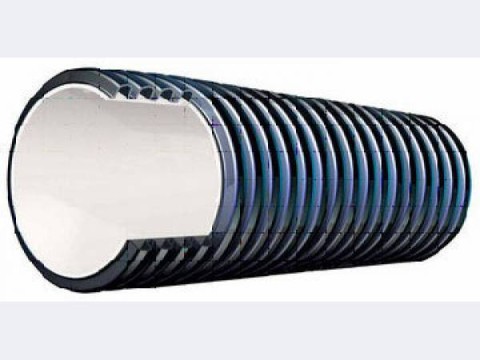

Cross-section and scheme of corrugated pipe joining

Types of corrugated pipes and their areas of application

Manufacturers offer one- and two-layer corrugated pipes for arranging internal and external pipelines. Single-layer are characterized by lightness and practicality. They are used when laying a gas pipeline, acting as a protective shell. Double-layer - have stronger walls and are used for laying electrical cables.

For external sewerage, corrugated pipes with the most durable walls are used, which differ not only in resistance to mechanical stress, but also in the ability to withstand the effects of chemical reagents.

The diameter and shape of the corrugations may be different

According to the material of manufacture, corrugated pipes for sewage are of two types: PVC and HDPE.

Polyvinyl chloride is characterized by high performance. PVC pipes are designed for laying in areas where an increased load on the walls of the structure will be created, as well as in places where it is planned to lay the pipeline at a considerable depth.

The inner surface of the walls is perfectly smooth, which prevents the formation of plaque and blockages.

Manufacturers produce PVC pipes in compliance with established standards. According to the type of stability, products are divided into three groups:

- light - thin-walled structures for outdoor installation;

- heavy - dense walls of products have increased mechanical stability, can be used when laying underground pipelines;

- super-heavy - the most durable structures are designed for laying communications under roads.

To give high strength characteristics, the pipes are made three-layer and reinforced with a frame made of mineral, synthetic or steel fibers. It is made in the form of a braid and placed on the inside of the pipe.

Corrugated sewer pipes are characterized by increased rigidity combined with the ability to retain their original shape without sagging.

On sale, products are presented in a wide range, starting with electrical corrugated pipes with a diameter of 16 mm to 63 mm and ending with sewer elements with a cross section of over 800 mm.

The only drawback of PVC corrugated pipes is low frost resistance. Under the influence of low temperatures, they become brittle. Therefore, for the arrangement of autonomous sewage in areas located in the northern regions of the country, it is better to use polyethylene corrugation.

Modern material has a stable structure and is among the polymers that do not contribute to the spread of combustion. It is resistant to acids and retains its properties at temperatures from -40°C to +90°C.

The material does not contain harmful substances and is therefore considered environmentally friendly.

HDPE products are used for laying sewer pipelines and constructing drainage systems. The outer surface of the pipes is made of corrugated HDPE, and the inner side is made of smooth PVD.

For the arrangement of free-flow sewerage of a private house, corrugated pipes with a diameter of 110 mm and 200 mm are used.

Although HDPE products are much more expensive than PVC counterparts, the high price fully pays off during a long service life. Sewer lines made of HDPE corrugated pipes are famous for their reliability and durability.

The use of corrugated pipes for different types of sewerage on the example of Korsis

The Polyplastic group of companies, headquartered in Moscow and with numerous subsidiaries in the former CIS countries, is the leader in the production of polymer pipes in the domestic market, produces a popular product line with the Korsis brand. The main areas of use of Korsis products, depending on the series:

- About SN8 - polyethylene and polypropylene corrugated pipes of this series are used for laying highways for household, household and industrial purposes, for storm sewers of cities and towns. In individual housing construction, corrugated pipes are used when summing up the intra-quarter (common house) sewerage to central communications.

- Pro SN16 - increased axial strength allows this brand to be used when laying all types of sewer communications for public and domestic purposes, they are also used as passage pipes under roads and as cases for less durable pipelines and cable lines.

Corsis Structure: Pro, Protect, IS, Perfocore

- Protect SN24 - the outer shell of the product is made of light and thermally stabilized polyolefin, which provides increased protection against ultraviolet radiation during operation. The series is used for laying sewers under highways with a high load on the ground and as a protective shell for any type of communications, its distinguishing feature is increased light protection, designed for use in southern regions.

- IS SN8 - wear-resistant (IS) corrugated pipe is used in sewers to drain storm water with a high content of large particles (stones), its abrasion resistance index is higher than that of other types of polyethylene and polypropylene pipes.

- Perfocore - pipes with partial or full perforation made of polyethylene or polypropylene with axial stiffness SN4, SN8 (parameters SN16, SN24 are possible in custom-made production) are intended for use in drainage systems. The perforation has several types of application and is located in the hollows of the corrugations; to protect the surface from silting up with particles of the outer soil, the surface is wrapped with synthetic non-woven fiber (geotextile).

Price list for Korsis SN8

Corrugated plastic pipes for non-pressure sewage are designed for use in industrial, construction, agricultural sectors of the national economy for transporting significant volumes of wastewater and laying to great depths. In individual households, for domestic purposes (restoration and installation of various types of wells), segments of large diameter corrugated pipes are used. Due to the complexity of installation and high cost, domestic sewage from high-strength corrugated pipes is very rarely laid, preferring cheaper smooth-walled PVC-U pipes or multifunctional corrugated pipes for pulling an electrical cable and draining sewer and storm drains.

Classification of corrugated pipes by the number of layers

Communications are divided into groups based on the structure:

- single layer;

- two-layer.

The first of the options has a narrow scope. So, a single-layer corrugated sewer pipe is used when laying an electrical cable. This is due to the need to protect electrical networks from moisture. In addition, such a corrugation is prone to rapid clogging. When installing an external sewage system, this variety is not used due to insufficiently high strength and the presence of irregularities inside. Such communications can be used to connect a smooth-walled pipeline and plumbing fixtures.

The two-layer corrugated pipe has a more complex structure: the outer surface consists of stiffeners, the inner walls are smooth. Communications differ in diameter. The value of this parameter varies from 40 to 1200 mm. Pipes are divided into types according to their intended purpose:

- household: 40, 50, 90, 110 mm;

- production: 160 and 200 mm (the most common options), 250, 315, 400, 500 mm;

- utility: 630, 800, 1000, 1200 mm.

Thanks to this design, it became possible to use corrugated pipes for external sewage. They can be laid to a depth without losing properties.

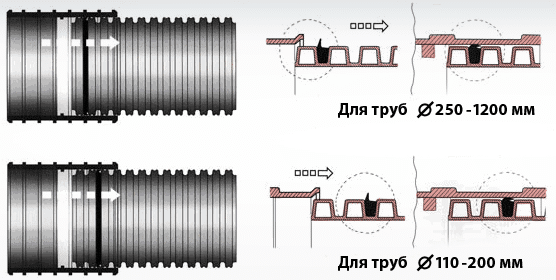

How to connect

Depending on the connection method, corrugated pipes are made of three types:

- Without flare. The sections are joined together with the help of overhead couplings using sealed sealing rings (coupling method).

- With flared end. During manufacture, a socket is welded to one of the sides of the pipe, and a sealing rubber ring is used when joining.

- With integrated heat shrink sleeve. This technology is designed to connect pipes operating in the pressure sewerage system, when joining, the coupling is heated with a blowtorch, sealing from the inside is provided by inserting a polyethylene rod.

Since the outer and inner shells of most corrugated pipes are made of polyethylene, they are also connected by the conventional method of joining polyethylene pipelines using electric couplings or butt welding when used in a pressure sewer system, the latter method of connection is laborious and impossible with large diameters, therefore, it is not used during installation.

In most cases, pipes in a free-flow sewer are connected by a branch pipe method using sealed rubber sealing rings, while inserting the end of the pipe into the branch pipe with large diameters requires the application of significant physical efforts that are inaccessible to an ordinary person. The pipeline fragments are connected by special devices fixed on the surface of the pipe and branch pipe, after which they are brought together by applying mechanical force. In some cases, the pipe is pushed into the pipe with special equipment - this significantly speeds up the docking work.

Connection options

Features of installation of sewerage using corrugated pipes

The arrangement of an autonomous sewage system is carried out in accordance with the norms of the current SNiP. The installation of a corrugated pipeline is carried out in several stages.

A trench is laid between the house and the pit under the sewer well. To do this, dig a ditch with inclined slopes 25-50 cm wide. The distance between the outer wall of the pipe and the trench wall should be at least 20 cm.

The bottom of the trench is examined for the absence of obstacles in the form of boulders, and leveled in such a way that, when laying branch lines, a slope of 2 cm per linear meter is maintained. This is necessary in order to ensure the correct functioning of the gravity system.

To create a solid foundation, the bottom of the trench is carefully compacted by constructing a sand or gravel "cushion" up to 20 cm high.

Lining the sand and gravel layer, small indentations are made at the intended locations for the socket.

The corrugation is laid manually, carefully tamping the cavities between the walls of the structure and the bottom of the pit. Pipes are placed in such a way that the sockets look in the opposite direction relative to the slope.

When laying the elements of the pipeline, it is necessary to monitor the tight fit of the concrete mix or soil embankment to it. If it is laid over voids, there is a high risk of deformation of structural elements after the system is started.

All joints are carefully cleaned and sealed with rubber rings.

Sealing rings are placed in such a way that the seal profile is directed in the direction opposite to the pipe entry line into the socket.

Elements with a diameter of 110 mm to 800 mm are connected using a socketless method using special couplings. Pipelines D 315 mm and above are connected through funnel-shaped extensions - sockets. When connecting a polymer corrugated pipe with other materials, special adapter fittings are used.

In some cases, a welding method is used to connect elements end-to-end. The work is performed by a welding machine designed for ordinary polyethylene pipes. To obtain a uniform and tight seam, the end sections are heated to a temperature at which the polymer material begins to melt, and then connected under a set pressure.

The trench is covered with sand, lining a layer 8-10 cm thick. The embankment is compacted only along the side walls of the trench. For backfilling, you can also use finely fractionated gravel.

The top layer of the sand embankment is lined with ordinary soil, removed when digging a ditch. To create a uniform embankment, the soil is pre-cleaned of stones and large lumps.

The process of installing corrugated pipes for sewerage is not particularly difficult, but it is better to entrust the development of a system project and the choice of materials to specialists.

Varieties of corrugated pipes for sewerage

For sewerage, smooth-walled corrugated two-layer pipes are used, the outer shell of which is painted in various colors to protect the inner surface from solar radiation. A single-layer corrugated pipe, due to its uneven ribbed inner surface, is not used to drain sewage; in exceptional cases, in order to save money, they make a drainage pipeline with holes in the walls with their own hands or buy a finished similar product from one of the numerous manufacturers.

A distinctive feature of all corrugated pipes is an indication in their technical characteristics of the ring stiffness parameter, expressed in conventional units SN, corresponding to a load of one kiloNewton per square meter (kN / m2). The ring stiffness class indicates the load on the area (in square meters) of the pipe in the radial direction, at which its deformation will not exceed 4%, depending on its value, all pipes are conditionally divided into the following categories:

- Lungs. Sewer pipes have a ring stiffness of SN 2 - 4 - 6 class, are designed for laying in the ground to a depth of not more than 6 m, are made of two-layer HDPE and PVD polyethylene. This category includes two-layer flexible corrugated products made of polyethylene, the main purpose of which is the laying of cable electric lines (red outer sheath), telecommunications (blue sheath), as well as storm, drain and drainage sewage (green or black outer sheath).

- Heavy. The ring stiffness of products of this class is 8 - 10 - 12 SN, the pipes are made of polyethylene or polypropylene, they are laid in the ground to a depth of 15 m, they are widely used for laying most types of utility and industrial sewer networks.

- Superheavy.High-strength pipes with a ring stiffness index of 16 - 24 SN are made of polypropylene, they are designed for laying sewer networks under soil areas experiencing high loads: roads, railways, airfield runways.

In the Korsis product line, the super-heavy ones include the APM series, with an outer diameter of 800 to 2400 mm, products have a yellow inner shell, are made of two-layer polyethylene, inside which steel inserts in the form of rings are placed in the corrugation to increase strength. This pipe is able to withstand axial loads of 24 SN when manufactured to order, pipe sections are usually interconnected by means of heat-shrinkable sleeves and a polyethylene rod, which is extruded by a manual extruder and is firmly joined to the sleeve when its surface is heated with a gas burner.

Characteristics and requirements for Korsis products

What are corrugated pipes

The main difference between corrugated pipes is the ribbing of the outer surface, while on the inside they have smooth walls. The material for the manufacture of corrugated pipes are complex polymers based on PVC and polyethylene grades PE63 and PE80. Thanks to this, finished polymer products are characterized by increased resistance to the chemical effects of wastewater and excellent impact resistance.

When arranging household sewerage, it is convenient to use corrugated pipes in filtration zones, in drainage systems - to collect and remove excess moisture from the soil

The main indicator of the performance of corrugated pipes is rib stiffness, i.e. the ability of the structure to withstand mechanical loads created by soil on the outer walls. High ring rigidity allows corrugated pipes to be laid at a depth of 20 meters.

Products have gained wide popularity due to a number of undeniable advantages, including:

- Ease of installation. For transportation and installation of lightweight structures, there is no need to use special equipment.

- Versatility of application. Corrugated pipes are used in many construction areas: for the construction of pipelines, for the installation of gas pipelines and ventilation, for the creation of casings that protect electrical wiring, etc.

- Durability. The service life is about half a century.

- Availability. The low price of products allows the use of corrugated pipes in the arrangement of an autonomous sewage system, even in a limited budget.

The polymers used in the manufacture of corrugated pipes are dielectrics, so finished products do not need to be grounded

Forming the surface with rollers of different diameters and widths increases the flexibility of the products. This operational design parameter simplifies the installation process, allowing you to make a bend line without using additional fittings.

The only drawback of corrugated polymer pipes is their vulnerability to high temperatures. But in the sewer, the temperature of the working environment rarely reaches high levels.