Maintaining a comfortable temperature with a three-way valve for heating

There are two ways to adjust the energy released by the radiator:

- A qualitative change in the properties of the radiator.

- Quantitative regulation of the generated heat.

In both cases, manipulations with the liquid circulating through the pipes are necessary.

Qualitative change in the properties of the radiator

In order to regulate the microclimate in the room, you can transfer the heat generator to another mode of operation - as a result of which the temperature of the water entering the radiators changes.

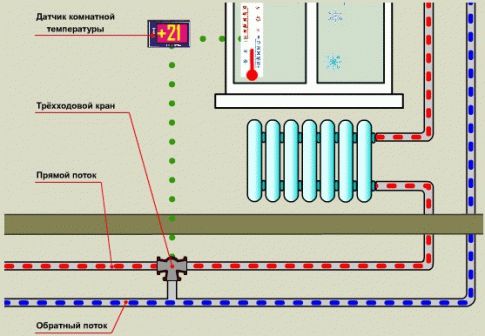

The presence of a three-way valve allows you to adjust the climate in the room with any type of heating

You can switch the mode on the wall-mounted boiler, if we are talking about a country house. However, the situation is much more complicated in the case of a boiler house in an urban microdistrict.

Useful advice! In the case of a city apartment, when you do not have access to the boiler room, it remains to regulate the energy already released by the coolant.

In the case when you cannot influence the temperature of the water entering the radiator, you can adjust its amount. For this, it is necessary to buy three-way valves for heating with a thermostat. These devices allow you to limit the amount of water passing through the radiator, and as a result, with the same area of \u200b\u200bthe battery, more or less heat will enter the room, of course, within the limits of the system's capacity.

Three-way mixing valve device with thermostat

A three-way valve for the heating system and a temperature controller mounted on a radiator can be used separately, however, in autonomous heating systems of modern apartments and private cottages, a combined method is often used to increase efficiency. Thus, it is advisable to purchase a three-way valve for heating with a thermostat.

Heat flux adjustment limit

It is important to take into account that the principle of operation of the three-way mixing valve allows you to increase or decrease the temperature of the radiator only within the established limits. These limits are dictated by the technical characteristics of the thermal device, namely, the value of its maximum heat transfer, and depend on each particular radiator.

Maintaining a comfortable temperature with a three-way valve for heating

There are two ways to adjust the energy released by the radiator:

- A qualitative change in the properties of the radiator.

- Quantitative regulation of the generated heat.

In both cases, manipulations with the liquid circulating through the pipes are necessary.

Qualitative change in the properties of the radiator

In order to regulate the microclimate in the room, you can transfer the heat generator to another mode of operation - as a result of which the temperature of the water entering the radiators changes.

The presence of a three-way valve allows you to adjust the climate in the room with any type of heating

You can switch the mode on the wall-mounted boiler, if we are talking about a country house. However, the situation is much more complicated in the case of a boiler house in an urban microdistrict.

Useful advice! In the case of a city apartment, when you do not have access to the boiler room, it remains to regulate the energy already released by the coolant.

In the case when you cannot influence the temperature of the water entering the radiator, you can adjust its amount. For this, it is necessary to buy three-way valves for heating with a thermostat. These devices allow you to limit the amount of water passing through the radiator, and as a result, with the same area of \u200b\u200bthe battery, more or less heat will enter the room, of course, within the limits of the system's capacity.

Three-way mixing valve device with thermostat

A three-way valve for the heating system and a temperature controller mounted on a radiator can be used separately, however, in autonomous heating systems of modern apartments and private cottages, a combined method is often used to increase efficiency. Thus, it is advisable to purchase a three-way valve for heating with a thermostat.

Heat flux adjustment limit

It is important to take into account that the principle of operation of the three-way mixing valve allows you to increase or decrease the temperature of the radiator only within the established limits. These limits are dictated by the technical characteristics of the thermal device, namely, the value of its maximum heat transfer, and depend on each particular radiator.

The role of the valve in the system

When designing buildings, the power of heating devices is selected based on the area and other factors. But these calculations cannot guarantee that the room will always have a comfortable temperature. It can be increased or decreased by many factors, for example, strong winds, temperature fluctuations in the street. The sun through the windows on the south side of the house can overheat the room from the outside, and household appliances, stove, oven - from the inside. In such situations, a three-way valve with a thermostat saves. Thanks to him, a comfortable temperature is maintained in the room and at the same time the heating system is used sparingly.

How to raise / lower the temperature with a three-way tap

- Adjust the temperature of the water entering the radiator. This is possible only when the house is heated by a separate boiler.

- Change the amount of water entering the batteries. The method is suitable for both owners of autonomous boilers and owners of apartments that are heated by city boilers. Of course, in the case of centralized heating, it is possible to increase the flow of water only within the limits provided by the system.

What is the three-way valve for heating with a thermostat responsible for?

The thermostatic valve guarantees the practicality and efficiency of the system. Three-way valves for heating are designed to regulate the heat flow, which ensures indoor comfort and economy of use.

The three-way valve ensures the efficiency and economy of the heating system by regulating the heat flow

Why regulate heat flow?

Before proceeding with the design of the heating system, a thermal calculation is made. Based on its results, a suitable power and type of heating devices are selected that can maintain the optimum temperature in the room.

The area of \u200b\u200bthe room is taken into account, after which possible heat losses are analyzed. Based on this, the performance of the heating system is calculated, which is necessary to create a comfortable microclimate in the rooms. After that, a heat balance is compiled for all rooms.

However, these calculations are made under specific conditions, which may change during operation. Factors affecting the operation of the radiator are different:

- temperature fluctuations in the street;

- solar Activity;

- wind power;

- the presence of household appliances that generate heat.

Heating scheme with a three-way valve

As a result, the calculated temperature balance is disturbed, and the room becomes hot. However, it is impossible to remove parts of the radiator from the room or dampen the heat radiation. Thus, it becomes necessary to control the energy generated by thermal appliances in order to maintain a comfortable microclimate in the room.

Three-way valve device for heating

To understand how three-way valves work in a heating system, it is important to understand its structure. The design of the three-way valve for heating

The design of the three-way valve for heating

Visually, this device looks like an ordinary metal tee. Brass is usually used as the material for the manufacture of the valve, sometimes cast iron or steel is taken. There are three nozzles in the body of the device.

However, inside the tee there is a mechanism on which the principle of operation of three-way valves is based. It automatically regulates heat flows, allowing you to maintain a comfortable microclimate in the room.

1 Device description and design

A three-way faucet for heating often looks like a tee made of bronze or brass, on the top of which there is a washer for adjustment. Under the washer, you can see a temperature-sensing device, the purpose of which is to activate the working rod that comes out of the body.

A cone-shaped element is installed on the inside of the stem, which is securely and hermetically installed in the so-called seat. Below are the main components that make up the valve-thermostat system:

- the body itself;

- thermostat insert;

- tapered component;

- stock;

- the so-called saddle;

- the main element is the pressure relief chamber;

- sealing component.

1.1 Functional principle

The principle of operation of the valve with an electric drive or for a pressure gauge is as follows. The liquid passes through the front and right hoses of the system until the temperature regime increases to the required level.

Scheme of including a three-way valve in the heating system

The essence of functioning is to maintain the required temperature at the outlet of the boiler within the required limits.

In the event that the media parameters go beyond the required limits, the external element will press on the stem. At this point, when the stem moves, the cone will come out of the seat, resulting in open communication between all channels. This procedure will be carried out until the front pipe is completely closed, if the temperature of the liquid does not begin to change.

On sale you can also find a thermostat for boilers or a pressure gauge with a different type of valve mechanism, which is similar in structure to a ball valve. In such a device, instead of a seat with a cone-shaped element, there is a spherical part with a special sample.

In this case, when redistributing water flows, the actuator of the thermostatic system does not press, but rotates the rod with the ball mounted on top.

To date, a thermostat with a spherical component does not have a large throughput, so they are used in domestic heating systems. There is another type of device: instead of a ball, a sector is mounted on the stem. The working element of the sector can completely block one or partially two water flows.

Special taps for heating varieties and operation

If in old central heating systems it was possible to meet a tap on the radiator only for airing, today this device is considered an integral element. The valve for the heating battery is a ball-type shut-off valve.

With the help of the device, not only pipes are connected to radiators, but also control over the flow of coolant is provided. After installation, the valves must be in the closed or open state, otherwise their performance will be impaired.

Three-way valve for heating with thermostat for heating system

Below we will find out which taps are best for heating and why. You will find out why exactly they are needed, where and how they are mounted.

Three-way valve for heating

A three-way heating valve is a tee in which, with the help of a locking mechanism, the heat carrier is redistributed in the heating system.A three-way valve is used where it is necessary to regulate the heat supply by reducing or increasing the temperature of the coolant.

A simple example: the coolant, when moving through an extended heating system, at the beginning of the “path” has a higher temperature, which leads to more intense heating of the radiators, and, as a result, overheating of the premises, to eliminate which a three-way valve is used.

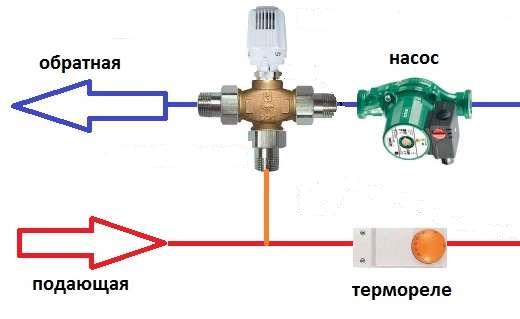

Three-way crane - principle of operation

To do this, hot and cold water are connected to the tap at the same time. As a rule, the connection diagram in the form of arrows indicating the direction of movement is located on the crane itself.

In this case, hot water is the heat carrier coming from the boiler, also called the supply, and cold water is the already cooled heat carrier, also called the return. When the valve is fully open, the supply and return flows into it simultaneously and mix. As a result, the temperature of the water at the outlet of the tap has a certain average value.

If the valve is fully open, then the heat carrier flows directly from the boiler to the heating devices and provides maximum heating of the radiators. When the tap is closed, on the contrary, only the return flow comes to the heating devices.

When the tap is not fully open, the return and supply are mixed and the coolant is obtained with an average temperature.

Types of three-way valves in heating systems

Depending on the design features, there are 2 types of three-way valves: shut-off and adjusting. There is no fundamental difference between them: both can be used to completely shut off the movement of the supply and to control the temperature of the coolant. However, with stopcocks, this is much more difficult. Their design is more suitable for switching the movement of water flow from one pipe to another and does not provide for a smooth change in flow. In most cases, shut-off valves are equipped with a ball mechanism.

For regulation, three-way valves are used, in the design of which there is a stem, the movement of which can be controlled manually or automatically.

From 3-way cock to 3-way valve

The three-way heating tap allows you to manually adjust the temperature of the coolant in heating systems. A three-way heating valve is designed for automatic control, in which an electromechanical device is additionally installed that changes the position of the stem. It is connected to a thermostat, with which the desired temperature in the room is selected.

The installation of three-way valves in the heating system allows you to effectively control the operation of a warm floor, regulate the distribution of heat across rooms and floors, as well as between individual buildings, when it comes to heating several separate objects, for example, a greenhouse and a residential building.

Depending on the principle of operation, there are 2 types of three-way heating valves:

Mixing three-way valve with two inlets and one outlet. Its principle of operation is the same as that of a three-way heating tap. The main purpose of this type of mixing valve is to mix supply and return to obtain a coolant of the required temperature, which is achieved by changing the ratio of hot and cold water.

Dividing three-way valve, in which one inlet and two outlets. During its operation, the heat carrier flow is distributed into two channels, which is necessary when boilers, convectors, etc. are included in the heating system

Regardless of the type of three-way valve (mixing or separating), its installation and use ensures a constant heat flow in the heating system and does not block the movement of the coolant, which is especially important at low temperatures. Only the temperature in the network can change.This is the main difference between a three-way heating valve and a two-way heating valve.

In other words, a heating system with a three-way valve will never defrost.

Three-way valve in the heating system

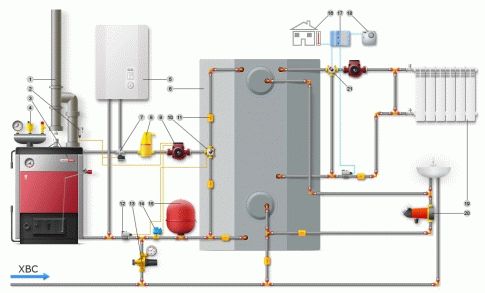

Installation of a three-way valve on a warm floor

When connecting a warm water floor, you can not do without a three-way mixing valve. Hot water from the radiator passes through such a valve, the temperature decreases. As a result, a coolant of the required temperature enters the pipeline of the water floor. The three-way valve is connected to the floor heating circuit according to the diagram. The most productive is considered a sequential circuit.

On the way of the hot coolant to the collector there is a three-way valve with a thermostat. If the temperature of the inlet stream exceeds the allowable for the warm floor, then the valve is activated. The cold return is mixed with the hot. When the temperature reaches the desired value, the thermostat causes the valve to work again.

Installing a three-way valve on a solid fuel boiler

If the house is heated by a solid fuel boiler, then it is difficult to achieve a constant coolant temperature. Direct connection of the boiler to the system is a mistake. When it is not heated, and cold water enters the incoming pipeline, condensation forms. A mixture of ash and condensate forms carbon deposits on the walls of the furnace - growths that are very difficult to remove. Due to soot, heat transfer worsens, the efficiency of the boiler decreases.

Another problem is a sudden power outage. In this case, the pump is turned off and a temperature jump occurs again. Boilers, especially cast iron ones, are very sensitive to such changes. Therefore, connecting the boiler to the system requires the use of a three-way mixing valve. It forces the water to pass in a small circle until it reaches the desired temperature.

Functions of the three-way valve on a solid fuel boiler

- Distribution. The valve distributes the inlet flow to two heating circuits that operate at the same temperature. In this case, the valve has one inlet and two outlet pipes.

- Mixing. The valve makes it possible to connect a floor heating system to the boiler. The coolant for underfloor heating and for radiators must have a different temperature. Therefore, the three-way valve for underfloor heating has two pipes for the inlet of hot and cold water and one pipe for the outlet.

The three-way thermostatic mixing valve is indispensable in a hot water heating system. It allows you to adjust the temperature. When installing a warm floor, it is necessary to connect a three-way valve in series. It maintains different temperatures in the radiators and in the pipeline of the water floor. Without a three-way thermostatic valve, the normal operation of a solid fuel boiler is impossible.

Three-way valve working principle

Three-way valves with a thermostat differ in the type of actuator. They are divided into saddle, ball and sector.

1) Saddle mechanism.

The valve has a stem that extends beyond the body. At the end of the rod, a cone is fixed, which is included in the saddle. Hence the name of the mechanism - saddle. Water flows through the pipes - front and right - and in order to change the temperature, a cooled or hot coolant is mixed with it from the left. When the target is reached, an external actuator presses on the stem. The cone leaves the seat, making room between the three pipes. As long as the front pipe is open, the process continues.

2) Ball mechanism.

The valve operates according to an identical scheme, only instead of a seat and a cone - a ball with an opening. The drive rotates the rod with the ball fixed on it. It is the ball that opens and blocks the movement of water between the nozzles.

3) Sector mechanism.

It works on a similar principle as a ball valve, only there is a sector at the end of the rod. It half or completely blocks one or two coolant flows.

Types of three-way valves

- Mixing. Chilled water is added to the flow of hot water to lower the temperature. They have two inlets and one outlet. Used in the system of water floors.

- Dividing. The coolant flow is divided into two, without changing their temperature. They have one inlet and two outlets. They are used when it is necessary to divide water into two heating circuits.

Three way valve actuators

The actuator drives the stem and the entire mixing valve.

- Thermostatic drive. The temperature-sensitive element, closed in a special container, expands with increasing temperature. It presses on the rod and sets the whole mechanism in motion. Household three-way taps, small in diameter, are equipped with just such a drive. But it is not difficult to remove it and replace it with another type of device.

- Thermostatic head. It has its own temperature sensitive element. To regulate the operation of the valve depending on the water temperature, the thermal head has a temperature sensor. It is connected to the actuator by means of a capillary tube and is located in the pipeline. Adjustment with a thermostatic head is considered more accurate.

- Electric drive controlled by a controller. It is equipped with sensors that constantly check the temperature of the coolant. If it is increased, the sensors signal this to the controller. Adjustment with the help of such a drive is the most accurate.

- Servo. The controller is missing. Instead, the actuator, having received information from the temperature sensor, controls the valve directly. It mainly comes with sector and ball valves.

What is the three-way valve for heating with a thermostat responsible for?

The thermostatic valve guarantees the practicality and efficiency of the system. Three-way valves for heating are designed to regulate the heat flow, which ensures indoor comfort and economy of use.

The three-way valve ensures the efficiency and economy of the heating system by regulating the heat flow

Why regulate heat flow?

Before proceeding with the design of the heating system, a thermal calculation is made. Based on its results, a suitable power and type of heating devices are selected that can maintain the optimum temperature in the room.

The area of \u200b\u200bthe room is taken into account, after which possible heat losses are analyzed.Based on this, the performance of the heating system is calculated, which is necessary to create a comfortable microclimate in the rooms. After that, a heat balance is compiled for all rooms.

However, these calculations are made under specific conditions, which may change during operation. Factors affecting the operation of the radiator are different:

- temperature fluctuations in the street;

- solar Activity;

- wind power;

- the presence of household appliances that generate heat.

Heating scheme with a three-way valve

As a result, the calculated temperature balance is disturbed, and the room becomes hot. However, it is impossible to remove parts of the radiator from the room or dampen the heat radiation. Thus, it becomes necessary to control the energy generated by thermal appliances in order to maintain a comfortable microclimate in the room.