Materials for connecting products

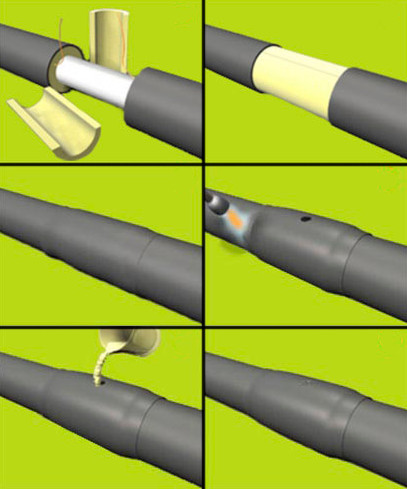

PPU pipe connection diagram.

High-quality sealing of product joints is the most important condition for trouble-free and reliable operation of heat network pipelines.

The use of a heat-shrink sleeve or tape to insulate the joints of PPU pipes makes it possible to protect the thermal insulation of polymeric materials by creating a protective polymer or steel casing, which, in terms of its qualities and characteristics of thermal insulation, will be similar to the shell of the product.

Depending on the method of installation of the pipeline, a heat-shrink sleeve on an adhesive basis (with an applicator) or a galvanized steel casing with a heat-shrink tape complete with polymer locks can be used to insulate the joints.

To isolate joints, there are such connection kits:

1. For products with galvanized sheath:

The sequence of installation of the PPU pipe.

With polyurethane foam components:

- galvanized casing;

- polyurethane foam components;

- sealant.

With polyurethane foam shell:

- galvanized casing;

- polyurethane foam shells.

2. For products with a polyethylene sheath:

With galvanized casing and polyurethane foam components:

- galvanized casing;

- shrink tape;

- polyurethane foam components;

- sealant.

With polyurethane foam shell:

- shrink tape;

- polyurethane foam shells.

The use of materials for sealing joints that do not meet the existing requirements of GOST 30732-2006, as well as non-compliance with the entire technology of insulation of PPU joints, will create the preconditions for a violation of the insulation protection in the most vulnerable places of any pipelines - the junction of the pipe and the fitting. The result of this will be the occurrence of premature external corrosion of the pipe with the subsequent failure of the pipeline or carrying out constant costly repairs.

Laying a pipeline is not possible using only a straight product, as it often becomes necessary to change its direction or branch. For such purposes, manufacturers provide for the manufacture of various shaped products:

- transitions;

- fixed supports;

- tee branches;

- Z-shaped elements;

- various branches, etc.

Straight sections of products, shut-off valves (in most cases ball valves) and fittings are supplied by manufacturers with thermal insulation already applied during the manufacturing process, which has a “pipe in pipe” design.

These products are unlikely to be necessary for you when repairing the plumbing and heating system of your apartment. But in order to conduct hot water or heating to a suburban building or connect to a heating main for heating a large warehouse, this product will be simply irreplaceable.

Sealing joints of pipes covered with polyurethane foam insulation materials and methods

PPU pipes are a highly reliable modern design. Installation of these products should be carried out in accordance with the normative indicators and recommendations of the manufacturer. The technology for laying pipes is quite simple, but must be carried out in accordance with all quality and safety requirements. In case of violation of the norms, a decrease in the service life and other negative consequences are possible. According to the manufacturer's recommendations, the PPU pipe installation technology, and in particular welding and joint sealing, can only be performed under temperature conditions above zero and at normal humidity levels. Given the vagaries of the weather, you will need to purchase a special heated assembly tent that can protect the work area from any bad weather.The pipe welding process is carried out directly at the bottom of the trench. Welding of straight elements is carried out on the edge, upon completion of the work, the pipes are laid in place.

polyurethane foam

This material has many advantages that make it popular. PPU is a shell or insulation that has useful properties: thermal conductivity, as well as the ability not to lose its structure for a long time period.

Such polyurethane foam is created on the basis of two components Izolan-45 and Voratek CD 100.

And the refinement of the technology for processing polymeric materials makes it possible to create shells for insulating products of different diameters. Installation of polyurethane foam insulation can be carried out both for a new pipeline and for the repair of an old or a certain section of it.

Description of PPU pipes

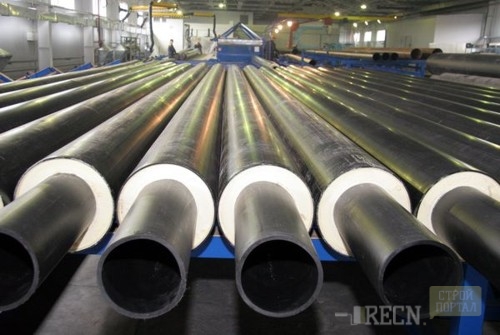

PPU pipes

Such products are used quite widely for laying heating networks in an above-ground and channelless environment.

For above-ground laying, pipes are made with a protective metal sheath. For channelless - with an outer protective sheath of low-pressure polyethylene.

There can be two types of insulation: 1PPU and 2PPU. The latter are used in regions with low temperatures, the first type - in regions with a temperate climate.

About the speed of installation of thermal insulation

Pipelines with insulation

Work on the installation of PPU thermal insulation is carried out quite quickly, especially when compared with other methods. At the same time, this method is easy, effective and inexpensive - an ideal option. If this is necessary, it is possible to form thermal insulation with separate elements. The material is easy to cut and fit to a specific pipe.

You can also reuse the shell, if its quality is not affected in the first use. All this makes PPU material - an excellent method of performing pipe insulation. This can be confirmed by numerous video clips demonstrating the process.

Laying a pipeline using PPU pipes

It is worth remembering that the ends of the stripped insulation during welding must be covered with non-combustible material.

Installation of the PPU product consists of the following main steps:

- at a distance of no more than 300 mm from each edge of the product, thermal insulation is cleaned;

- a welded joint is carried out, which must be checked for strength without fail using a portable flaw detector;

- a heat shrink sleeve is mounted on the pipe;

- the cavity under the heat-shrinkable sleeve is filled with mounting foam, after which the sleeve is deposited in place by heating it, thereby ensuring the tightness of the outer layer of the joints.

When sealing joints, you should be aware that, due to the fact that polyethylene and polyurethane foam are combustible materials, the ends of the stripped insulation must be covered with any non-combustible material for the duration of welding. To protect the outer shell, for example, asbestos cloth can be used.

Often, the installation of pipes that have pre-installed thermal insulation is performed by horizontal drilling. In a large settlement, digging a highway with busy traffic is very problematic. However, how to perform pipe insulation if it has already been dragged through a horizontal puncture in the ground? And this is where a product with a polyethylene sheath comes to the rescue, on which thermal insulation is pre-installed.

What is the insulation of pipe joints

The final stage of pipeline construction, namely the insulation of pipe joints, occurs when an insulating material - polyurethane foam - is placed in the entire open area. PPU is also used to insulate the rest of the length of the structure; insulation is applied in the factory.

There are two technologies for filling the joint:

- Filling joints with liquid polyurethane foam. Installation of polyurethane foam shells or couplings.

Both the first and second methods can be called practical and effective.Among the advantages of the shells are the following qualities:

- many manufacturers produce shells with different thicknesses, which allows you to choose the optimal thermal insulation for a particular climatic zone. Reinforced insulation will be effective even at temperatures below -100 degrees; it is the polyurethane foam type of insulation that is most often used, since this polymer is highly resistant to moisture, pressure and mechanical damage; when using a polyurethane foam shell produced in factory conditions, the risk disappears uneven pouring of liquid polymer. And insulation vulnerabilities lead to premature corrosion of the steel pipe under the polymer layer.

Joints can be isolated by pouring liquid polyurethane

At the same time, the technology of filling with liquid foam remains competitive and provides high adhesion with existing insulation layers.

We supply the following materials and systems - click on the one you need

EnergoIzolyatsia supplies rigid polyurethane foam shells designed for thermal insulation of hot water and heating pipelines, oil pipelines, etc. with a diameter of 22 to 1020 mm.

PPU shells are rigid cylinders, half-cylinders or segments 1000 mm long, th..

EnergoIzolyatsia supplies rigid polyurethane foam shells with foil coating, designed for thermal insulation of pipelines for hot water supply and heating, oil pipelines, etc. with a diameter of 22 to 1020 mm.

PPU shell is a rigid cylinders, semi-cylinders or segments of ..

EnergoIzolyatsia supplies rigid PPU shells coated with galvanized steel, designed for thermal insulation of hot water and heating pipelines, oil pipelines, etc. with a diameter of 22 to 1020 mm located on the street.

The PPU shell is a rigid cylinder..

In addition to PPU shells, our company also supplies polyurethane foam bends for thermal insulation of pipes, as well as the PPU shells themselves, they are available in the following versions:

PPU bends without outer coating (without cladding)

PPU foil bends

PPU bends covered with fiberglass

galvanized leather..

Showing 1 to 4 of 4 (pages: 1)

PPU shell

represents tough

cylinders, semi-cylinders or segments, usually 1000 mm long, 30 mm thick, designed for thermal insulation of pipelines with a coolant temperature of up to +120ºС, oil pipelines, gas pipelines, etc. It is possible to manufacture shells with a protective coating of foil, fiberglass, galvanized metal and other coating material.

More expensive options come with longitudinal and transverse locks, cheap ones just come with flat edges without locks. Photos of castles below in the photo

It is necessary to take into account the nuances of installation: Rigid!

this means that you will not succeed as with - to tighten the cylinder somewhere at the welded joint. If the welded joint is thick and hits the middle of the shell, the edge of the shell may protrude by 5-10mm. All irregularities that interfere with the installation will need to be cut out of the shell (cleaned) so as not to interfere with a snug fit.

Before installing the shells on the pipeline, it is necessary to take measures to prepare the surface of the pipe, it must be cleaned of dirt, scale and rust, degreased and primed.

Shell installation methods:

One of the undoubted competitive advantages of the PPU shell is the ease of its installation. However, with all the simplicity of the pipeline insulation process, it is recommended to consider the following recommendations:

1) Installation of PPU shells can be carried out at any time of the year, provided there is no precipitation;

The pipe must be dry!

- If moisture gets under the PPU shell, it will cause multiple corrosions like in a greenhouse - an example in the photo:

2) Before installing the PPU shells, it is necessary to treat the surface of the insulated pipe with an anti-corrosion primer. The soil must be dry!

3) When joining the semi-cylinders and the shells themselves, it is necessary to coat the joints with one-component polyurethane adhesive to ensure the best waterproofing. Glue is applied to one of the surfaces, then the adhesive surface is treated with sprayed water. After that, the shells are mounted with technological fixation, within one day, using bandages. Glue consumption is not more than 300 g/m². The shell is securely fastened, the connection is seamless, not detachable;

4)Quick installation

by fastening the shells on the pipe with plastic ties, metal bands, knitting wire. Access to damaged pipes, fistulas and cracks, reusable. Cylinders can be tightened either with ordinary plastic clamps manually or with a special polypropylene tape (12 and 19 mm) using plastic or metal locks. In the latter case, a special device is needed - a tensioner.

5) For foil shells, after installation is completed, it is recommended to glue the joints of the longitudinal and transverse locks with foil tape

Important! Foil shells can be used without an additional cover layer only indoors. According to SP 61.13330.2012, it is ALWAYS necessary to make a protective cover layer on the street - either or

PPU insulation technology

What is PPU pipe insulation? The name is intricate, and the process is simple - like all ingenious. The design is, in fact, an ordinary pipe, but coated with a special layer that reduces wear on parts and reduces heat transfer losses in the network. The coating material is called polyurethane foam, hence the name of the product - PPU.

Fabrication of structures

What methods of implementing PPU pipe insulation do manufacturers practice? The coating is applied in two ways:

- With the help of making a "shell".

- Through filling. This technology is also called "pipe in pipe".

In simple terms, PPU thermal insulation for pipes is a kind of “fur coat” worn on the base shell. So, what is included in such a structure?

- the deepest layer is the steel base;

- middle thermal insulation layer - polyurethane foam;

- protective shell.

Everything is clear with the first two positions, but what is used as protection for products? It all depends on where and under what conditions you lay communications. If the network passes above the ground (air laying), then galvanized steel is chosen as protection, when the installation of the system in the ground implies the use of a polyethylene sheath.

It's important to know! Products covered with polyurethane foam during transportation to the place of installation and storage in the open air must be protected from getting wet at the ends, otherwise a short circuit of the wires may occur during installation. If the insides of the elements are already wet, then dry everything well before use.

Benefits of PU coating

Pipes with polyurethane foam insulation have long been popular, but for us, such products are still a curiosity. Get acquainted with the advantages of the design and modernize your farm.

So, the advantages of networks with polyurethane foam coating:

- increase in service life (with proper installation, the life of the system can be extended several times - up to 30 years);

- reduction of heat losses during its transmission (approximately - up to 40%);

- ease of installation (you do not need sophisticated equipment for insulating PPU pipes, since such technology products can be laid directly in a trench - without the use of traditional concrete rings or the construction of a well);

- design features allow you to quickly determine on which section of the water supply route an accident occurred;

- the absence of toxic materials in the composition of the product, which makes them the favorites of users who adhere to naturalness in everything;

- reducing the cost of repairing the track;

- elimination of the risk of system humidification due to moisture condensation;

- high temperature resistance of products, so that they can be mounted even in regions with a harsh climate;

- the possibility of using a remote monitoring system for the humidification of network elements.

Features and benefits of PU foam insulation

Increased requirements are put forward for materials, design and laying of networks, which is due to the significant working pressure and temperature of the coolant. And the insulation characteristics determine the level of heat loss on the route. We propose to use PPU - polyurethane foam, which is characterized by high insulating performance. Compared to traditional materials used in the construction of such lines, it provides the following basic advantages:

- reduction of heat losses up to 40%;

- increase in service life - for PPU it is about 30 years instead of the usual 10-15;

- reduction of repair costs (3 times).

What are the advantages and disadvantages of pipes

Despite good thermal conductivity and durability, PPU pipes have both advantages and disadvantages. Let us consider in more detail what are the pros and cons of PPU pipes.

Advantages:

- PPU insulation has a low coefficient of heat conductivity.

- The operating temperature can range from minus seventy degrees to plus one hundred and thirty degrees Celsius.

- A moderate ability to absorb liquids was noted.

- The density of the material is fixed at the highest mark.

- The service life without major repairs is from twenty-five to thirty years.

- Heat loss can be as low as one or two percent.

- The monitoring system monitors the likelihood of a leak.

- Saving money.

- The pipe kit includes everything you need for quick installation - bends, tees, fittings and compensators.

- When compared with other types of thermal insulation materials, PPU pipes will be lighter than similar structures with PPM or APB insulation.

- When using pipes, no additional anti-corrosion measures are required.

What are the disadvantages of PPU pipes:

- despite the long service life and the availability of operational remote control, PPU pipes are also subject to corrosion. Due to the fact that the metal pipe is in a protective sheath, the corrosion process becomes less noticeable;

- the heat resistance of the insulating material does not exceed one hundred and thirty degrees, which does not allow the use of pipes in heating networks operating according to different temperature schedules: one hundred and forty to seventy and one hundred and fifty to seventy degrees. Pipes can withstand such temperature fluctuations, provided that an additional heat-insulating layer is laid (for example, Vector coating or polymer concrete);

- polyurethane foam is not particularly durable and is not resistant to mechanical stress;

- if moisture gets on the heat-insulating layer, a rapid corrosion of the pipe is possible. As a result of this factor, it is impossible to exclude the use of an additional hydroshell (polyethylene durable layer);

- if a certain section of insulation is damaged or moistened, then it becomes necessary to completely replace the section of the heating network. PPU insulation cannot be repaired separately;

- PPU insulation - flammable material;

- each pipeline or heating network must be equipped with OEC systems for measuring the moisture content of the insulating layer.

Galvanized Pipe Insulation Variety

In the production of PPU pipes, the following technology is used:

- The steel carrier pipe is dried and cleaned of dirt, scale and rusty deposits, and plastic ring supports are put on it.

- A copper conductor is threaded through the holes of the supports along the entire length of the workpiece.

- Push the pipe on the centralizers into the zinc sheath.

- Plugs are inserted into the ends, the surface is heated and liquid PPU is poured into the annulus.

- After technical quality control and marking, the pipe is sent to a warehouse for storage.

Pipes with PPU thermal insulation are produced with a diameter of 32 to 1420 mm (GOST 30732-2006), their length for a pipe diameter of up to 219 mm lies in the range of 8 - 12 m, with diameters of more than 273 mm, the length is 10 - 12 m.

To increase the service life of products, galvanized pipe insulation is additionally coated on the outside with paint, varnish, polymer and waterproofing compounds (bitumen primer), renewable during operation.

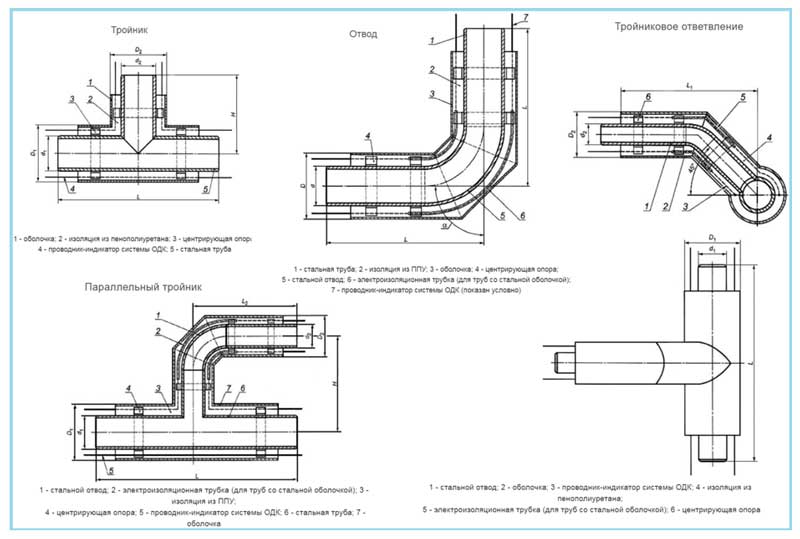

Rice. 7 Shaped connectors according to GOST 30732-2006

The length of the pipe coating should be equal to the polyurethane layer with a margin of 50 mm at the edges, the polyurethane ends of pipes and fittings are covered with bitumen-rubber or other waterproofing. When supplying pipes up to 426 mm in size, they must have two diagonally located SODK copper wires with a cross section of 1.52 mm, if the diameter exceeds 530 mm, three wires are used for 3, 9 and 12 hours.

To connect sections of the highway, change its direction and device branches, a wide range of fittings is used in the form of bends, transitions, tees with straight and parallel outlets, S-shaped fittings, plugs and end elements. Fittings can have built-in shut-off valves and gate valves, their service life is at least 30 years.

Rice. 8 Fittings for joining when laying pipelines

Types of insulation for butt joints of PPU pipes

Insulation of PPU pipe joints is carried out by filling the entire volume of the joint with liquid polyurethane foam or by installing polyurethane foam couplings or shells. The material used to insulate the joints of PPU pipes is polyurethane foam. It has a small thickness and excellent thermal conductivity. Previously, during the operation of pipelines, significant heat losses occurred due to the constant wetting of materials. At present, this issue has been resolved thanks to the use of polyurethane foam shells for insulating pipe joints.

Advantages of the shell from PPU:

- PPU shell can be used in regions with frosty winters. It can withstand temperatures up to 130 degrees below zero.

- This type of thermal insulation has high moisture resistance.

- The shell has excellent characteristics of resistance to mechanical damage.

In the construction of pipelines, one of the main tasks is the selection of high-quality joint insulation kits. Durability of a design is provided with reliable sealing of fastenings. One of the best ways to insulate fasteners is to use a heat shrink sleeve. It provides uniformity and the same physical and mechanical properties of thermal insulation.

DIRECTORY

By placing an order for the supply of a PPU heat pipe in our company, each Customer is guaranteed an individual approach, efficiency, accuracy and clarity in the fulfillment of contractual obligations. Since the stages of pipeline construction are strictly interconnected with the current configuration, our client must receive his order with a guarantee in terms of quality, sequence, quantity and just in time. The names of the product range, marking and other symbols for different design organizations and manufacturers may differ, which may require additional clarification and coordination of the content of the order specification between the consumer and the sales office. We offer brief requirements for the symbols of the product range used at our enterprise.

If it is necessary to adjust the pipes at the construction site, the polyethylene sheath is cut first in the transverse direction, then to remove the sheath of the removed insulation fragment, cutting is performed in the longitudinal direction

Particular attention must be paid to ensuring that, at the same time, sawing of the shell further than the cut-out part, see. Recently, polyurethane foam thermal insulation for pipes has become increasingly popular with domestic consumers.

If it is necessary to adjust the pipes at the construction site, the polyethylene sheath is cut first in the transverse direction, then to remove the sheath of the removed insulation fragment, cutting is performed in the longitudinal direction

Particular attention must be paid to avoid sawing the shell further than the cut out part, see. The purpose of laying any type of communications is long-term and reliable operation.

To achieve the best result, it is necessary to comply with the conditions - the use of modern high-quality materials and compliance with the installation technology. This is the only way to guarantee the long-term operation of the pipeline, without violating its integrity and the need for repair. One of the best offers on the building materials market today is pipes in polyurethane foam insulation. Installation of pipes with PU foam insulation is not difficult, regardless of the method of applying the heat-insulating layer

The purpose of laying any type of communications is long-term and reliable operation. To achieve the best result, it is necessary to comply with the conditions - the use of modern high-quality materials and compliance with the installation technology. This is the only way to guarantee the long-term operation of the pipeline, without violating its integrity and the need for repair. One of the best offers on the building materials market today is pipes in polyurethane foam insulation. The installation of pipes with polyurethane foam insulation is not difficult, regardless of the method of applying the heat-insulating layer.

One of the main tasks that determine the quality of a pipeline made of pipes with polyurethane foam insulation is the correct installation of joints. Such products go on sale with non-insulated segments on both sides, which is necessary for ease of connection. If all work is carried out correctly, the pipeline will be reliably protected from aggressive environmental influences and will demonstrate the maximum service life. The operation of the entire pipeline depends on the quality of sealing pipe joints in PPU. The final stage of pipeline construction, namely the insulation of pipe joints, occurs when an insulating material - polyurethane foam - is placed in the entire open area. PPU is also used to insulate the rest of the length of the structure; insulation is applied in the factory. Both the first and second methods can be called practical and effective.

Open sections of heating mains remaining at the joints of pipeline parts in polyurethane foam insulation, we propose to isolate using one of three options for sealing GLC joints:. In the first case, a cavity is first formed using thin sheet steel rolled around the pipe shells, through the hole in which a mixture of components is poured. Subsequently, the steel sheet is removed and glued with thermal insulation tape overlapping the shells. At the request of the customer, only individual elements can be included in the joint insulation kit, for example, if the heating main does not have a UEC system.

Purpose and main advantages of products

PPU pipes are ordinary steel products for plumbing or heating, which are covered with a layer of insulation from polyurethane foam (polyurethane foam) during production.

In order to install the pipeline in the ground, it would be ideal to choose a PPU pipe in which the thermal insulation is protected by a polyethylene protective layer (the product is called PPU PE), for air laying - the thermal insulation is protected by a layer of good old galvanization. These products in the price lists are marked "OTs".

However, it is quite difficult to dismantle the outer layer, made in the form of an endless tape, which is wound around the product. Based on this, you can not be afraid of vandalism.

The main advantages of the PPU pipe over traditional heat-insulated products include:

- significant reduction in operating costs (at least 9 times);

- a significant reduction in the cost of repairs (at least 3 times);

- a significant reduction in capital expenditures during construction (at least 1.3-1.5 times);

- increased service life (from 10-15 to more than 30 years);

- reduction of heat loss (from 25-30% to 3%);

- a significant reduction in the pipeline construction period;

- the possibility of realizing operational remote control (SODK system) for moisturizing the polyurethane foam insulation of the PPU pipe.

Technology of installation of a heat-shrinkable sleeve

Materials and tools:

- polyurethane foam sleeve;

- pipeline;

- butt joints of PPU pipes;

- gas-burner;

- soap solution;

- liquid PPU;

- Cork.

First, a sleeve is put on one of the pipes, which, after fastening the pipes, is shifted to the middle of the fastening. After that, the protective shell is removed from it. Then, using a gas burner, it is heated until it shrinks completely. At the same time, it takes the form of a barrel. Then check the tightness inside the coupling. To do this, a plug is placed in its hole and air is injected under a pressure of 0.5 atmospheres. We need to check the pressure in five minutes. It must remain unchanged. If the pressure has decreased, then you need to check the quality of the fit of the edges of the coupling. The test is carried out with a soapy solution.

For the installation of insulation, it is necessary to use only high-quality materials, this will increase the service life and ensure the efficient operation of the pipeline.

If the quality of shrinkage is not enough, it is necessary to perform a more dense installation. If the pressure has not changed, then it is installed correctly. After that, you need to pull out the cork and pour liquid polyurethane foam. Then the polyurethane foam should foam and harden. After that, the internal holes are closed with polyethylene plugs. They are welded to the clutch. This ensures reliable waterproofing and thermal insulation of pipeline joints. The method of insulation with the help of couplings reliably protects the fastenings of communications from aggressive external influences, wind, rain, snow, frost, as well as from mechanical damage and other influences.

Liquid polyurethane foam is made from a special foam pack containing polyol and polyisocyanate. When mixed, they form a liquid mass, which foams, increases in volume, and then hardens. To isolate joints by pouring polyurethane foam, foam packs are used. They relieve builders of the need to prepare the solution and pour it with the help of funnels into various containers. Thanks to this, work is carried out quickly, the quality of work and safety for human health improves.

If the fasteners cannot be isolated by pouring, then polyurethane foam shells are used. The use of shells is also possible when repairing the waterproofing of fasteners. Polyurethane foam shells have a long service life, their strength and rigidity do not allow thermal insulation shifts.

Pipe insulation

It is no secret that most of our residential buildings have centralized heating, as well as water supply. But for this it is not enough to heat the water to the desired temperature, it still needs to be delivered with minimal heat loss.

Previously, glass wool was used for these purposes. The pipe was wrapped in a layer of thermal insulation. The layer was fixed with steel wire. Further on, the pipe was covered with a sheet of galvanized steel from above. Over time, instead of galvanizing, ordinary cement mortar was used. But this approach was accompanied by large heat losses.

And only recently have pipes in polyurethane foam (PPU) been widely used. And then pipe shells were invented as thermal insulation.