Production of reverse osmosis membranes

FilmTec Corporation, a structural subdivision of DOW Chemical Corporation (USA), is the world leader in the production of membrane elements. Membrane elements are manufactured directly in the USA.

The company's membranes are certified worldwide for water treatment both for drinking purposes and in industry.

DOW FilmTec membranes with a diameter of 2.5” - 4” - 8” are presented in several series for the main types of water:

- XLE - for fresh;

- BW - for salty;

- SW - for sea and with a high level of salinity.

Since 1995, Ecosoft has been the official importer of DOW FilmTec membranes in Ukraine.

And since 1017, the company began producing its own membrane elements from American linen, which made it possible to reduce the cost of reverse osmosis technology.

Requirements for water supplied to the reverse osmosis membrane

The membrane sheet is made of a rather sensitive material, so the quality of the water supplied for treatment must strictly comply with the permissible values:

- less than 0.56 mg/l of suspended solids;

- oxidizability - less than 4 mgO2 / l;

- free chlorine less than 0.1 mg/l;

- supply water temperature - 4 - 30 ° С;

- iron - up to 0.1 mg / l;

- manganese - up to 0.05 mg/l;

- hardness - up to 3 mg-eq / l.

Some of the parameters (iron, manganese, silicates) may be higher than the declared norms in the case of using antiscalants (special substances that prevent the deposition of sediment on the membrane surface).

The remaining parameters are achieved through pre-treatment, which may include mechanical filtration, softening, iron removal or adsorption, depending on the parameters of the source water.

Strengths and weaknesses of the reverse osmosis system

Among the advantages of the osmosis water purification system are the following:

- High level of cleaning. This characteristic is the hallmark of the reverse osmosis system. As examinations have shown, purified water contains 10 times less impurities than indicated in the relevant standards. The membrane block is assembled in such a way that impurities cannot accidentally enter the purified liquid.

- Possibility to prepare water for different purposes. The liquid that has got into the storage tank can be used without restrictions for drinking and cooking. It does not need to be boiled before use. From a medical point of view, such water is much healthier than boiled water from a city pipe. If the house has an aquarium, it can be replenished from the storage tank without prior settling.

- Ease of installation. Although the design of the system is an order of magnitude more complicated than conventional household filters, it does not require special skills to install. As a rule, the complete set of the device includes all the elements necessary for installation. In addition, each of the component nodes can be replaced at any time.

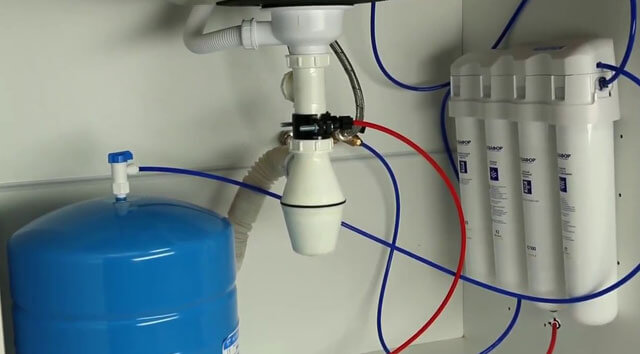

- compactness. The system cannot be classified as too bulky. As a rule, it consists of a container and several filters with a membrane. To accommodate the complex, the space under the sink is usually used. The compact faucet is conveniently displayed and placed on the sink surface. Modern design allows it to fit well into any kitchen interior.

The weaknesses of reverse osmosis are also commonly attributed to the low rate of water filtration. The liquid moves through the membrane very slowly. On average, a standard membrane is able to purify 150-300 l/day. It should also be borne in mind that 2/3 of the volume of water, along with pollution, is discharged into the sewer, which slightly increases utility bills.To avoid discomfort during the operation of the system, it is necessary to choose the right volume of storage capacity. In this case, the deficit may occur only immediately after the introduction of the system into operation.

Water concentration tank

The filtered water is collected inside a special container with a volume of 4-12 liters: the exact indicator is affected by the level of system performance. High-quality steel is most often used as the material for the manufacture of containers. From the outside, the vessel is finished with durable enamel. Inside the tank there are two compartments - for water and air. In the middle, the chambers are separated from each other by a silicone gasket. To adjust the air volume, the container is equipped with a nipple, the reverse end of which goes outside the tank. For inflating, a car pump is usually used.

Thanks to the air chamber inside the container, a certain pressure is created, which allows transporting water to the faucet with some pressure. To supply water to the consumer, the container is equipped with a reliable hose with a nozzle. As a rule, a separate faucet is used to install reverse osmosis, placed on the sink next to the main mixer. This makes it possible, in the event of a water supply interruption through the water supply system, to use the supply that is available inside the storage tank. In order to supply liquid under a stable pressure, it is sometimes necessary to force air through the nipple outlet.

Device package

The most valuable component of a reverse osmosis system is the membrane. This element is made of high quality microporous material. It is laid in one or more layers around a perforated plastic rod. On the upper part of the membrane there is a plastic protective casing, for fixing which reliable seals are used.

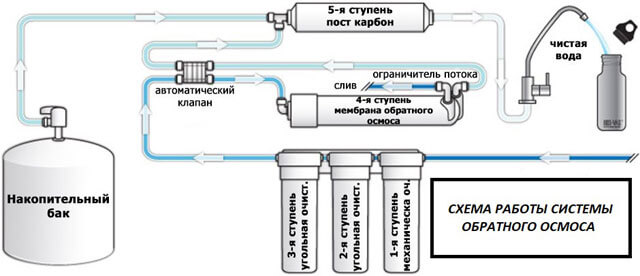

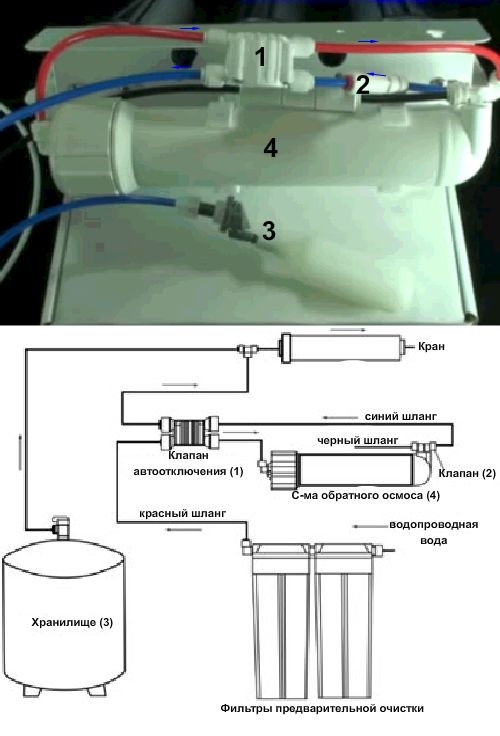

The membrane module works like this:

- After water is supplied inside the housing, it is passed through the porous material. Sometimes an electric pump is used to increase the pressure.

- The molecules of pure water that have passed through the membrane follow inside the storage tank, and the concentrate, weighed down by impurities, is retained by the membrane barrier.

- Further, this solution is discharged outside the membrane device into the sewer pipe.

As already mentioned, direct contact of a membrane filter with plain water from a city pipe is fraught with the most unfortunate consequences. It's all about the microscopic dimensions of its pores (0.0001 microns). The membrane cannot be cleaned or washed like mechanical filters: it can only be replaced. The recommended replacement frequency for this expensive element is once every two to three years.

The exact replacement time is affected by the operating conditions of the product - the level of pressure in the water supply, the concentration and chemical composition of impurities, water temperature, etc. It happens that the membrane regularly serves 5 or more years. Sometimes replacement has to be made after the first year of use. In order to protect the pores of the membrane from premature clogging, pre-filters for water with reverse osmosis are introduced into the system.

As a standard, we are talking about two mechanical and one coal device:

- The role of the first mechanical filter is to retain impurities that are unable to dissolve in water. As a rule, the size of these particles is more than 0.5 microns. These usually include sand, pieces of corrosion, scale, etc.

- After that, water flows through the coal module, which selects chemical contaminants - chlorine molecules, heavy metals, fertilizers from the soil, dissolved iron and various organics.

- Next is one mechanical filter capable of trapping smaller particles. It is the final link in the pre-cleaner module.

Theory

Osmosis is understood as a technological operation, the essence of which is the tendency of water to equalize the degree of concentration of additives in solutions separated by a membrane. These partitions are equipped with such microscopic holes that only water molecules can seep through them.

With an increase in the percentage of impurities in any compartment of such a vessel, the process of water flowing into it will begin, until the density of the liquid in both compartments is completely equalized. Reverse osmosis leads to the opposite effect: here the membrane does not equalize the density of water, but divides it into two portions - clean and dirty. For this reason, the process received the prefix "reverse".

Additional block

Osmosis water filters bring the liquid to a state close to distilled water. Membrane pores do not retain dissolved oxygen molecules, which makes purified water of very high quality. To improve the taste of the liquid, an additional mineralizer and other blocks are used. However, water can also be used immediately after leaving the membrane: it does not even need to be boiled beforehand.

As for the additional block, it usually includes a mineralizer and a bioceramic cartridge. The water passing through them is enriched with calcium, sodium, magnesium, etc. These elements have a very positive effect on the human nervous and cardiovascular system, which helps to avoid many dangerous diseases. As a result, mineral-rich water becomes not only drinkable, but also healing.

The action of the bioceramic cartridge is somewhat different. Inside it there are granules, for the manufacture of which baked clay and fragments of tourmaline are used. These materials have a very beneficial effect on water, correcting its structure. Drinking such water can significantly strengthen the endocrine and immune systems.

The installation of a reverse osmosis filter can be divided into several stages

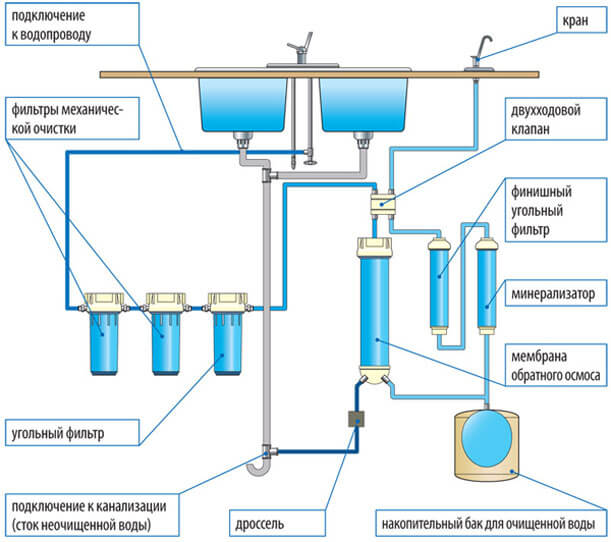

1. The filter is attached to the faucet. Most OO systems come with a diverter that can be attached to any sink in any home. To start working with the filter, turn on cold water and switch the small lever on the divertor. Thus, water will begin to flow into the system. To stop working, simply turn off the water supply. There are several options for connecting the tap water supply to the filter. For example, a hose fitting or seat valve may be used;

2. Place the drain hose on the drain in the sink. So all impurities will go into the sewer. Waste water supply can be arranged with a saddle valve in the drain line;

3. Place the water outlet hose into the barrel or storage container. When using a valve for automatic shutdown, a float is installed. It is worth noting that the automatic shut-off valve is usually not included in the standard delivery of reverse osmosis filters, but they can be purchased as an accessory.

After connecting all the hoses, turn on the cold water supply. The system is now operational. Efficiency depends on temperature and flow pressure.Reverse osmosis systems should only use cold water.

Reverse osmosis filters are characterized by the output of gallons per day (24 hour period). During operation, water does not actively pour out, but forms a slow and steady flow of drops. Pressure is usually not a problem in urban areas, but in some cases it is necessary to install a simple device to increase it.

What is a membrane

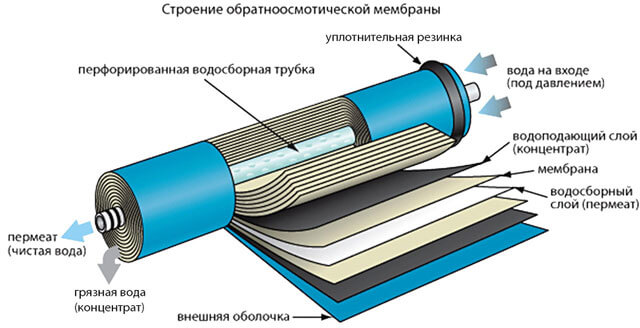

There are three types of reverse osmosis membranes: roll, hollow fiber and flat.

The "roll" membrane consists of a body and the actual filter element.

Inside the roll there is a perforated tube, which serves to create the strength of the element, to collect purified water and as a base for winding the membrane during the production process. A thick layer of semi-permeable polyamide membrane web is wound around it.

During the filtration process, water enters the thickness of the web and collects in the tube.

Thanks to this design, these membranes have the highest performance, minimum material consumption and take up the least amount of space. Therefore, rolled membranes are the most common in the world and occupy 95% of the industrial market.

5% is occupied by devices with flat membrane elements and devices for water treatment based on hollow fibers.

Comparison of filtration technologies

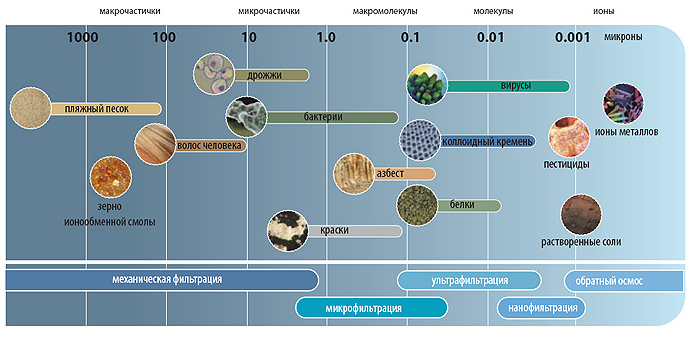

If we compare reverse osmosis with other membrane processes, we can say that it is the most effective water purification technology.

Why?

The figure below shows a comparison of reverse osmosis with other filtration methods.

First, let's look at other methods of media separation, or filtering.

Conventional filtration - involves the removal of large particles of pollution (conditionally those that we can feel and see with the naked eye) - sand, rust, silt.

The size of these particles is from 1000 µm (1 mm) to 1 µm.

The processes of separating such particles from the liquid phase take place on bulk, cartridge, disk, bag, washing and other types of filters. Such processes are commonly used during pre-treatment of water.

The advantage of simple mechanical filtration is that it can take place at low pressure, for example, filtration on charge filters often takes place without pressurization, and cartridge filters in households operate at pressure created by the pipeline.

Microfiltration is a process of removing particles from 1 to 0.1 microns in size from water. They include bacteria, large dye molecules, pesticides, gelatin, latex emulsion.

Microfiltration processes are not widely used in drinking water treatment technology, but are widely used for wastewater treatment and process water for industrial processes.

Ultrafiltration allows you to remove small particles ranging in size from 0.005 to 0.1 microns (viruses, particles of some proteins, particles of medicines, etc.). The processes are widely used for drinking water treatment in European countries. Ultrafiltration can be considered the best method for preparing relatively pure drinking water. Also, these processes are widely used in the pharmaceutical and food industries.

The use of ultrafiltration in everyday life is limited due to the fact that this process does not remove ionic impurities (hardness salts, heavy metals, nitrates), and they pose a considerable danger to humans, as well as high applied pressure.

Reverse osmosis is capable of removing particles smaller than 0.001 microns, which ensures the removal of even ion-sized contaminants (hardness ions, heavy metals, nitrates, sulfates, etc.).

Reverse osmosis technologies are often used in the preparation of drinking water, in the preparation of distillate for steam boilers, in the food industry.

Now let's take a look at the types of reverse osmosis plants and their applications, from home appliances to large industrial processes.

Selection Guide

When choosing a filtration complex for your home, you need to take into account the following points:

The complete set of reverse osmosis water purification systems is manufactured according to a certain standard, which makes it possible to easily find a replacement for a worn-out unit. However, not all equipment manufacturers follow this principle. This point must be kept in mind, giving preference to complexes with standard parameters. Among them are many devices of domestic production of fairly good quality. The cost of Russian systems, as a rule, is lower than foreign analogues.

It is most profitable to purchase a filter directly from the manufacturer, a verified dealer or in a company store. An indicator of the good quality of a reverse osmosis system is the availability of technical documentation, an official guarantee, and clear instructions for installation and use. When buying, you must definitely require a certificate of quality. It is also better to know how to change the water filter yourself, so as not to overpay for this service.

When choosing the volume of the storage tank, it is necessary to calculate the average monthly rate of water consumption in the apartment. To save the resource of the osmosis filter, it is not necessary to pass all the kitchen water through it. The portion intended for washing dishes, hands and household appliances can be taken directly from the water supply. According to the norms, one person consumes about 3 liters of water per day. Multiplying this figure by the number of family members, they get the daily rate for the entire apartment.

Of great importance are the dimensions of the internal space of the sink. It makes sense to order a tank of significant dimensions for a large family with a spacious kitchen and overall furniture. The most popular are containers with a capacity of 8-10 liters. These models are compact enough to fit inside a standard sink.

Of great importance is the level of working pressure inside the water supply. Reverse osmosis technology is designed for an indicator of 2.8 bar. If the measurements showed that the water pressure is less, then you should purchase a special complex with an internal pump. It will provide the necessary pressure for the passage of liquid through the membrane filter. Water pipes with too high operating pressure are equipped with a pressure reducer. If this is not done, the membrane will quickly fail.

Given the special role that the membrane plays in a reverse osmosis system, it must be carefully checked before purchase.

It is important that high-quality materials are used for the manufacture of this element. The store must require a separate quality certificate for the membrane

As for its performance, a filtration rate of 7 l / h is enough for an average family. If more than 4 family members live in the house, it is necessary to buy a more efficient membrane or acquire a large capacity.

It should be taken into account that as the performance of the membrane increases, so does its cost. Therefore, taking home too powerful appliances is not practical. For example, a system with a capacity of 15 l / h is able to meet the clean water needs of a small canteen or cafe.

An important point when buying is to check the configuration of the system. The complete set includes five basic purification stages as standard: three pre-filters, a membrane and an additional module. The material of manufacture and the function of the last stage in different models may differ.In addition to the previously mentioned mineralizer and bioceramic cartridge, blocks filled with coconut shell, activated carbon and silver ions are very popular. Materials of this type have an antiseptic effect and increase the taste of water.