Classification

BRIDGE CRANE is presented in the form of a steel structure with a moving trolley or an electric hoist.

The equipment of such a crane consists of various exciting devices:

- buckets;

- magnetic devices;

- containers lifting mechanisms.

Application: when lifting and transferring goods in factories, warehouses, as well as on any construction sites. One-time use is possible when there is no electricity. In this case, the use of a manual overhead crane is assumed.

GANTRY CRANE moves on rails embedded in a concrete base. This type of crane has a bridge with one or two beams. It is equipped with a trolley and a device for capturing goods. The use of such cranes is carried out in factories, in the production of reinforced concrete products, in loading areas at the railway.

The JIB CRANE differs from others in that the device for capturing the load is located at the end of the boom, which can have several sections.

Cranes with booms are distinguished by types of undercarriages:

- railway type (rails are needed for movement);

- automotive (reinforced chassis required);

- crawler;

- pneumatic wheel (using a chassis with additional support);

- floating (for ships).

Jib cranes can be driven: hydraulic, mechanical, electric and combined.

The use of such

TOWER CRANE includes:

- tower

- working boom with adjustable reach;

- base part;

- running device;

- operator's cabin for control.

How does a tower crane work?

The movement and turns of the tower crane are carried out with the help of certain blocks, winches, chain hoists. The operator, sitting in the cab, gives commands: raise or lower the boom, or change its reach, or move the cargo trolley.

According to the models, three types of tower cranes are distinguished: attachment, self-elevating (trailer), railway crane - it needs rails and a flyover.

Purpose: construction, high-altitude work, loading at the largest storage facilities.

There are tower cranes according to the types of undercarriages:

- caterpillar type;

- on pneumatic wheels;

- rail type;

- on the chassis;

- walking option;

- automotive type.

Due to the extensive classification, tower crane models are indexed into groups with similar assembly units and circuit diagrams, similar modules. This makes it easier to repair it, as well as to choose a tower crane according to certain characteristics.

One of the well-known world manufacturers of these machines is the French company Potain (Potain). Potain cranes can also be purchased on the Russian market, for example, at the Moscow company Capital Crane LLC, whose website provides more detailed information about the types, characteristics and technical data of this construction equipment.

CABLE CRANE

Having two towers, with a rope fixed between them for the movement of the cart, such a crane is a simple and reliable mechanism. It is used for large-scale construction works (bridges, locks, dams) and in the largest warehouses.

PORTAL CRANE

This is a mobile metal structure that can not only ride on rails. Under it, a railway car or other type of transport can pass.

Running device of this type of cranes:

- with the help of rails;

- on pneumatic wheels.

Scope: gateways; hydroelectric power station; dams, large warehouses.

RAILWAY CRANE

Able to move by rail with the performance of work on the lifting of goods next to the tracks. It is used for the repair and laying of the rail track, for the construction of various communications. Such a crane is capable of moving as part of a train.

Advantages and disadvantages of products

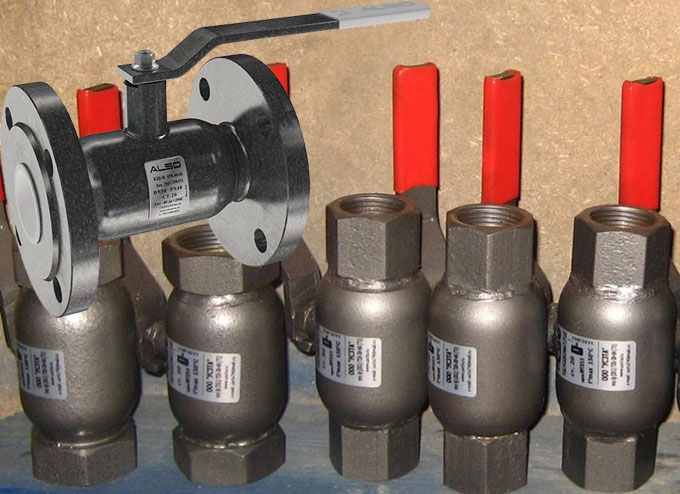

The crane ball has the following advantages:

- a light weight;

- small building length;

- low hydraulic resistance of the working substance;

- possibility of installation in any position in space;

- excellent value for money;

- high quality tightness;

The disadvantages of the products include:

- high amount of torque required to turn the handle;

- the appearance of water hammer in the water supply system when the tap opens quickly;

- the need to open and close the tap regularly (at least once a week) so that the ball does not “stick”;

- poor applicability of the most common products with a PTFE seal at operating temperatures above 150C.

Brass ball valves - features

Advantages:

- a wide range of models from different manufacturers;

- affordable cost;

- high speed of delivery;

- performance, optimal for water and gas;

- resistance to mechanical stress.

Flaws:

- a small selection of diameters of ball valves - they are produced, as a rule, with Du 8-100mm;

- unstable operation if the operating temperature exceeds 200C;

- inability to stably use the valve in pipelines with oil products;

- no welded model.

Steel ball valves - features

These valves are made of carbon steel (marked 20 or 25), which are widely used in housing and communal services and industry.

Advantages:

- low cost;

- a wide range of models from different manufacturers;

- high speed of delivery;

- performance, optimal for water and gas;

- wide range of

- resistance to mechanical stress.

Disadvantages of steel cranes:

- difficulties are possible with prolonged use in cold water supply pipelines;

- inability to use products in slightly aggressive environments;

- instability at operating temperature below -40 degrees C;

Crane device

Inside the body of water faucets there is a device that blocks the flow of water. Depending on the type of construction, this role is played by an expanding ring with a seal, a ball, a thermostat or a solenoid valve.

The device consists of the following elements:

- Device body.

- At the base are the supply pipes.

- Coupling.

- Cap nut.

- Pipe branch.

- A flag (cap) is provided to adjust the flow mixing.

- Spout. The element provides water supply. Performed in various forms.

- Seals, gaskets are necessary to prevent leakage at the joints of elements.

- Aerator. The nozzle provides atomization of water, making the jet softer.

Water faucet device.

Locking and regulating devices are mounted in any premises where water supply is provided.

Alloy Steel Products Cold Resistant Faucet

Such valves are made of alloy steel (usually grade 09G2S) and are used at temperatures below -60C. In terms of other characteristics, the products are identical to steel ones.

Stainless steel ball valve

The product is made of stainless steel (grade 12X18H10T and the like) and is widely used in industry.

Key Benefits:

- a wide range of working environments;

- applicability at temperatures below -60C.

Flaws:

- high price;

- limited choice of models - on sale mainly with DN 8-300 mm;

- long-term delivery of most of the products.

Cast iron faucet

A cast iron ball valve is more expensive, since steel is mass-produced. That is why most manufacturers refused to produce cast iron products, and since 2010, only one manufacturer has been producing cast iron cranes in our country.

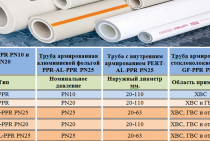

Polypropylene tap

Plastic products are produced, as a rule, from polypropylene and are installed on plastic pipes.

Key advantages of polypropylene taps:

- durability - products serve for a long time like brass;

- affordable cost;

- a light weight.

The key drawback of the products is the possibility of installation only on plastic pipes.

Classification of cable cranes

According to the degree of mobility, there are:

- Fixed - their supporting elements (towers) do not move, as they are installed directly on the foundations. Therefore, all cargo operations are carried out in the working area under the rope.

- Movable - their supporting elements, one or both, move along the paths arranged for them. Their working area expands significantly and depends on the trajectory of movement.

In turn, fixed cable cranes are divided into 4 subtypes:

- Stationary - supports are fixed as rigidly as possible. As a result, the carrier rope constantly maintains its middle position, not shifting anywhere during the movement of the trolley, and the working area is the narrowest.

- With tilting masts - the supports can swing transversely. When the trolley moves, the carrying rope can move at an angle of up to 6 degrees, which expands the working area.

- With lateral guying - the towers are connected to the foundation with the help of hinges, and on both sides they are equipped with winches and chain hoists for hauling. Thanks to this, it is possible, by pulling up and releasing the chain hoists, to shift the rope even more, since the swing angle of the masts reaches 8-12 degrees.

- Boathouses - several cable cranes with a common support, but separate drives and trolleys. They operate independently of each other, provide a wide service area (with proper configuration), and are used mainly in shipbuilding.

Movable cable cranes are classified into 3 subtypes:

- Parallel - both towers move synchronously, along straight paths. Such a trajectory of movement forms a rectangular working area.

- Radial - there is a stationary tower and one (or several) moving - along the ring (or concentric paths). The working area with such trajectories of movement is a sector.

- Circular - both towers move along concentric paths. With this movement, the working area is formed in the form of a torus.

- with a hook (traverse) - a load is suspended on it;

- with a grab - a bucket that collects loose or lumpy material;

- with a bucket - it scoops up the load, and then opens or capsizes.

For maintenance of the working area, there are:

- Stationary cable cranes - are constantly used at one facility.

- Portable - quickly installed and dismantled, easily transported from one working point to another.

According to the method of rope tension, cable-type cranes are:

- with counterweight;

- with a fixed mount;

- with oscillating supports;

- with a descending rope.

As you can see, there are a lot of options, and this indirectly indicates the demand for such lifting equipment. The classification of cable ropes is very extensive, and among their diversity you are sure to find a model with the required load capacity, span height and width of the working area.

Differences between a crane and a valve

Valves and gate valves are characterized by high tightness, both designs are suitable for high pressure pipes.

The gate valve is a locking mechanism that involves blocking the water flow through a partition. Constipation allows not only to block the flow, but also to regulate its intensity. The partition is made in the form of a sheet, board or wedge. Some designs provide for the presence of two or more partitions that move apart to supply water.

The main differences between the two types of structures are:

- The presence of a blocking element at the valve, which moves perpendicular to the flow up or down, or from side to side. At the crane, the main element is the shutter, in which the channel is made. The shutter can rotate around its axis. When the channel is placed at a slight angle or parallel to the flow, the intensity of the liquid supply increases, and when placed perpendicularly, the water flow is blocked.

- Frequent use of the valve leads to rapid wear of the device. The crane differs in higher wear resistance.

- To accommodate the moving part of the partition, there is a need for additional space outside the pipeline section. When installing the crane, space is required only for the adjusting elements.

- The valve is used as a locking element. A tap is used to adjust the intensity.

The water valve is used as a locking mechanism.

Gate valves are not used as elements of household models.

Characteristics and material of manufacture

Aluminum-silicon alloy is often used in the production of die-cast cases.

Various models are made from the following materials:

- bronze;

- brass (often decorated with galvanized coating);

- copper;

- cast iron;

- alloy steel;

- plastic (polypropylene or polyethylene).

The classification of plumbing devices is standardized by GOSTs 19681-94 and 25809-96. Characteristics depend on several parameters:

- throughput. There are 3 groups of mixers with parameters 40-50%, 70-80%, 90-100%.

- Tightness class, admissible pressure. Class 1 provides for a head up to 1 MPa, class 2 - up to 0.63 MPa.

- Noise level. Mixers are divided into 3 groups: up to 20 dB, 20-30 dB and more than 30 dB.

- Temperature regime. Faucets are available for cold and hot water (up to 75°C).

Each product is accompanied by technical documentation, where the parameters are indicated.

General information

Water faucets are divided into two main types

- Faucets. Are established on a sink, a washstand, a bathroom, a shower. I regulate the supply and mixing of water at one point.

- Shut-off valves are mounted on water pipes and perform the function of overlapping in the system.

Valve cocks

Stopcock with valve. In taps with a valve or a lamb, a crane box is installed inside, which shuts off the liquid. When the lamb unwinds, a crane box rises from the outlet and frees the passage. When the faucet is turned on, it lowers and blocks the flow of water; a rubber gasket is installed on it to increase the sealing.

Crane parts

- Lamb (valve)

- Spindle

- Sealing nut

- Frame

- Washer with gasket

- Nest.

The body (it is often called a herringbone) has a spout in the center, and on both sides of the valve with faucet boxes. One lamb controls the supply of hot water, the other cold. In the center, the streams mix and fall into the spout.

Ball valve for installation on pipes.

The overlap of water occurs due to the ball, in which a hole is made in the center. When the lever is turned, the ball unfolds, and a passage for water is formed in the center. When the lever is returned to its original position, the ball turns, with the hole perpendicular to the pipe, and the entire spherical sides of the ball overlap the pipes.

Recommendation. Closing of the tap should occur smoothly, avoiding sudden movements. This will help reduce the risk of damage to the water mains.

Ball valve device

Ball valves are divided into:

- Full bore with equivalent pipe and valve diameters

- Reduced. The fitting diameter is smaller than the pipe section. Cranes of this type minimize the occurrence of water hammer.

Mounting type

- Threaded. The thread can be either internal or external. The fitting is connected by a coupling or screwed into the pipe.

- Combined. There are two types of thread on the fitting. One side is external and the other is internal.

- Welded.The stopcock is welded to the pipeline.

- Flanged. A flange is a separate piece, round or square, with holes around the perimeter, for bolts or studs. The flanges are welded to the pipe and fitting, after which they are connected using a sealed rubber gasket.

Ball Single Lever Mixer

Manufacturers offer two models of the mechanism:

- Ball. Mixing and water supply occurs thanks to three holes in the cartridge.

- Ceramic. The supply and adjustment of water is carried out thanks to polished metal-ceramic plates. The device of the crane is quite complicated. The design is not very popular.

Touchless faucets

These faucets do not have a lever or valves. They work from the sensor. The sensor is triggered by the movement of the object. Models are divided into - standard and high-tech. Standard faucets have only water supply from the sensor. The parameters are set using levers mounted on the case.

High-tech can be adjusted by gesture. Or have a touch panel on which the required parameters are set. Models are available with a remote control and many other additional features.

The disadvantage of such mixers is their volatility, high cost, and in the event of a breakdown, most likely, you will have to buy a new device.

Principle of operation

The faucet mechanism is based on the following:

- A valve is mounted on a spindle located vertically.

- The lower part of the shaft moves inside the nut. At the end of the spindle is a spool, which consists of a disc and a gasket, which is fastened with a button or nut. The outer part is screwed into the body with a nut.

- When the valve is closed, the spindle is screwed in. The gasket sinks onto the seat, blocking the fluid.

- Another barrier to water flow is the sleeve at the top of the spindle. It has rubber seals for waterproofing.

Crane boxes made of ceramics have a semi-turn mechanism. Ceramic plates with holes are tightly pressed, one of them is motionless. When opened, one of the plates begins to rotate, the liquid enters at the moment when the holes coincide. This technology is considered more reliable.

Set of mixers for water.

The device of the tower crane and the principle of its operation

Any modern model has five key components:

- The tower is a top- or bottom-turning telescopic or lattice tubular structure. In modern models, it can be of a built-up or growing type, folded (dismantling is done right at the facility) or not disassembled.

- Working boom - a structure of a lifting, beam or articulated type, equipped with a cargo trolley, made of pipes, or angles, or profiles. There are two types of it - hammer-shaped and suspended.

- The supporting part bears all vertical and overturning loads, therefore, increased requirements are placed on its reliability.

- Running gear - a mechanism that provides movement and rotation of the tower crane. In practice, this is a rail or, less commonly, a walking structure.

- The control cabin is a workspace for the operator giving commands.

With the help of 3 types of mechanisms - blocks, winches, chain hoists can be distinguished - the main operations are performed: in the general case, they come down to moving and turning the tower crane, to vertical work, that is, to raising and lowering the boom, as well as to horizontal - changing its reach , or moving the cargo trolley. The operator from the cab gives the appropriate commands.

So, to rotate the SLE (turntable) transfers certain vertical and overturning loads to the chassis frame (fixed part).The load is captured by a hook clip fixed on a rope, and with the help of a winch it is moved up and down to the working height. The reach of the boom is also simply adjustable - by lowering and raising it, as well as moving the cargo trolley along it.

Tower crane classification

All the variety of modern models is divided into 3 groups.

By appointment:

- General purpose - for solving civil and general industrial problems, most often construction;

- Special - for efficient work of increased complexity;

- High-rise (self-elevating, creeping, attached) - for tasks solved at high altitude;

- Loaders - in demand for high-performance work, usually relevant in large warehouses.

When possible to move:

- Stationary - can be universal or attached;

- Mobile - can be trailed or self-propelled;

- Self-elevating - mounted directly on top of the object under construction.

By type of running gear:

- On tracks

- On pneumatic wheels

- On rails

- on chassis

- Walkers

- Automotive

It should also be noted that, according to their design features, the lines of tower cranes that are relevant today can be classic, headless and quick-mounted.

The classification is quite extensive, so indexation is carried out for all models. Tower cranes, depending on their role and performance, are marked in groups. Moreover, in such a way that inside each there are similar assembly units, general circuit diagrams, unified or even similar block modules. Thus, almost every characteristic of a tower crane, regardless of its manufacturer, is predetermined, which facilitates its selection, operation and repair.

Appointment of cranes

In autonomous, local or central water supply networks, equipment is used that performs certain functions. It can serve as a control or shut-off valve. The most commonly used element for such purposes are water taps. These types of products are designed to perform various tasks. They regulate the pressure and its throughput by changing the flow area of the pipe.

There are types of water taps that, using a ball mechanism, only open or close the flow. Other devices allow adjustment. They gradually reduce the pressure. These types of faucets are more commonly used for the home.

Advantages and disadvantages

The advantages of the products are simplicity, reliability, ease of repair and compatibility with domestic water supply systems. More expensive models allow you to save consumption, have the function of blocking the flow when the maximum temperature is exceeded. A number of models for the purpose of hygiene are convenient to install in public places thanks to the built-in sensor.

Different types of mixer designs have disadvantages. Among them: gasket wear, sensitivity of ceramic parts to a dirty environment, the need to install a filter. Touch models are less reliable.