Insulation of the ceiling with foam plastic from the outside

The best option for insulation in a wooden house is to fix the foam from the outside. In this case, work is carried out at a certain temperature regime - from +5 to +30 degrees. In addition, the technology of installation work depends on whether the attic is heated or not.

If the attic is heated, a crate of wooden bars is arranged between the supporting beams. Folgoizol is lined over the entire floor area. Styrofoam is fixed on top. A vapor barrier layer is laid on top of the foam plastic (the material is overlapped). The joints need to be glued. Finishing layer - screed and flooring.

If the attic is not heated, the temperature in the room can drop to -15 degrees in winter. In this case, between the supporting beams, you need to make a crate from the board. A layer of vapor barrier is laid on top, a layer of expanded clay with a thickness of 10 to 15 cm is laid. Expanded clay prevents fire. A layer of vapor barrier is again laid on top of it, and only then the foam plates are attached. Joints must be treated with mounting foam. After that, boards or reinforced mesh are laid, which are poured with a screed.

Log cabins for baths and saunas are insulated from the outside. To do this, choose a heater with a thickness of 15 to 35 cm.

In a room where the ceiling is insulated with foam, it will always be warm and comfortable. Creating the ideal microclimate in the house is quite simple. The main thing is to follow the technology, follow the recommendations of experts and buy high-quality materials.

Read an overview of materials for ceiling insulation in our separate review.

Styrofoam fixed on the wall qualitatively insulates any structure. Due to good thermal insulation characteristics, high density, small load on the wall, and most importantly, low price, the material is in great demand.

Fixing foam is not difficult, but there are features that every installer must take into account. The features of fixing the foam are described in this article.

Ceiling mount

The main condition for such fastening is the high-quality preparation of the ceiling, which includes cleaning from whitewash and dirt, as well as laying electrical wiring.

The foam is attached in one of the following ways:

The crate or frame for the ceiling is made of wooden bars. In order not to cut the slabs, it is recommended to form the size of the cells of the crate to fit the dimensions of the sheets.

Inside the cells, the foam is attached to the glue or fungi. All gaps are sealed.

A vapor barrier film is applied on top of the insulation, which is held on the crate.

At the final stage, drywall sheets are attached to the ceiling.

This method is much cheaper than discussed earlier. The main thing is to choose and prepare the adhesive composition correctly.

When preparing the surface of the ceiling, in addition to cleaning, it is coated with a disinfectant solution and primer. When it is not possible to completely remove the whitewash, the entire ceiling is covered with adhesive.

Adhesive is applied to the plate with broken lines. Laying of plates is made from the middle of the ceiling with a shift.

Dowels are used for additional fastening.

On top of the laid insulation, a reinforcing mesh is attached, which is then puttied and processed.

Features and characteristics of the material

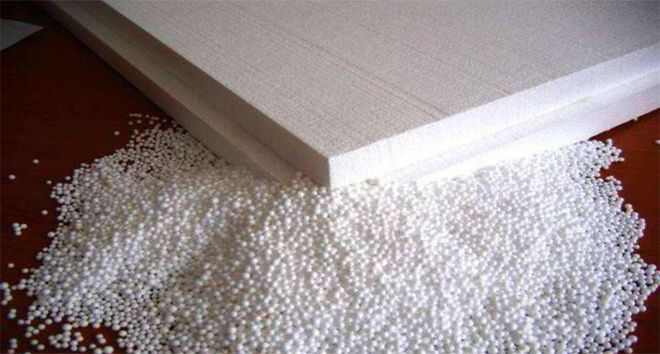

Styrofoam is a building material made from plastics by foaming with the addition of ingredients to give certain performance characteristics. The material has a porous structure and low density, since the main volume is filled with air. Due to this, the foam has good thermal insulation qualities.

Advantages

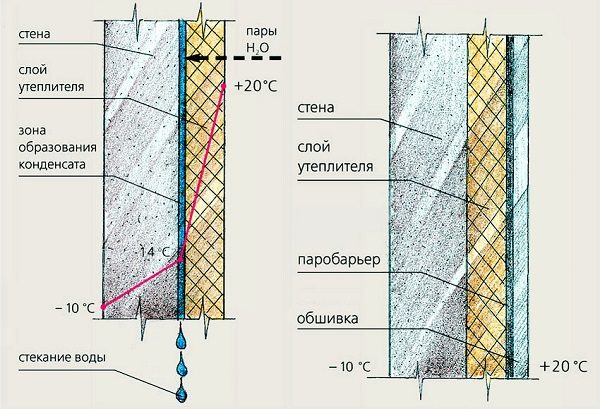

- Minimal hygroscopicity (the material practically does not absorb moisture).The use of foam does not require additional waterproofing and vapor barrier. However, it should be borne in mind that vapor barrier is desirable in wooden houses (instead of a vapor barrier layer, joints between the plates can be treated with sealant or construction foam).

- Styrofoam retains its shape and does not deform, unlike mineral wool. This eliminates the appearance of cold bridges, thermal insulation properties are preserved throughout the entire period of operation.

- To insulate the ceiling, a layer of foam plastic 5 cm thick is sufficient, which is much less than the thickness of mineral wool.

- The material is resistant to temperature changes, chemicals. Insects, fungus and mold will never appear in the foam.

- It has excellent soundproofing qualities.

- Styrofoam is easy to install, lightweight, easy to cut.

Flaws

- Relatively short service life. The maximum service life declared by the manufacturers is only 20 years. If the installation is carried out in violation of technology, the insulation will have to be changed after 10 years.

- Styrofoam is dangerous in a room with a poor ventilation system. Since the material does not allow moisture to pass through, it begins to accumulate indoors in the form of condensate. This leads to the appearance of fungus and mold, which negatively affects people's health (first of all, children, people with allergic reactions and asthma are at risk). The solution to the problem is the organization of supply and exhaust ventilation.

- In the process of burning, the foam releases toxic substances. The material emits black smoke, which contains toxic substances that can cause paralysis of the respiratory tract.

Styrofoam features

- Polyfoam is a fairly dense material, as a rule, installation is carried out quickly and without problems. The only caveat - you can not allow a strong deformation of the material.

- If it is impossible to lay the material without gaps, the slots and joints are treated with special fillers (sealant, mounting foam) and glued with mounting tape.

- Many do not use polystyrene foam in repair and construction work, as they consider this material unhealthy. This opinion is erroneous. Styrofoam, created in accordance with the prescribed technology, does not pose any health hazard.

- Styrofoam is a combustible material, and given that it emits toxic smoke during combustion, this is a serious argument against it.

- It should be noted that small rodents often equip housing in polystyrene. As a result, the material loses its thermal insulation qualities.

What is foam

For the first time, the production of foamed organic matter of styrene was established by the American concern BASF in 1951. The material called "styrofoam" consisted of 98% air filling the cells of the foam base, which gave it low thermal conductivity, water absorption and vapor permeability.

The technology was improved, and extruded polystyrene foam appeared - self-extinguishing foam. Also, the current insulation material contains antifungal additives.

The quality and technical characteristics of foam plastics in Russia are declared by GOST 15588–2014 “Polystyrene foam heat-insulating plates. Specifications". Instead of the usual PSB markings and corresponding markings, PPS markings now operate in the Russian Federation, and the expanded polystyrene itself is divided into cut (R), cut graphite-containing (RG) and thermoformed (T). Plates intended for use in facade insulation using plasters are additionally marked with the letter F.

According to this document, the technical characteristics of slabs for facade work are as follows:

| Name of indicator | The value of the indicator for slabs of the brand | ||

| PPS16F R | PPS15F RG | PPS20 F RG | |

| Density, kg/mcub., not less than | 16 | 15 | 20 |

| Strength for compression kPa | 100 | 70 | 100 |

| Bending strength, kPa, not less than | 180 | 140 | 250 |

| Tensile strength kPa, not less than | 100 | 100 | 150 |

| Thermal conductivity in a dry state, condition A, °C (283 K), W/(m×K), no more | 0,036 | 0,032 | 0,031 |

| Thermal conductivity in dry state, condition B, °C (298 K), W/(m×K), no more | 0,038 | 0,034 | 0,033 |

| Humidity,% no more | 2,0 | 2 | 2 |

| Water absorption for 24 hours,% of the volume, no more | 1,0 | 4 | 3 |

| Self-burning time, s, no more | 1 | 1 | 1 |

Do-it-yourself foam insulation technology for external walls

It is within the power of a master who is familiar with the basics of finishing work to insulate the walls.

Let us consider in detail the method of insulation, called the "wet facade".

Tools

- level, plumb line, hammer, tape measure, pencil, hacksaw (knife), trowel and spatula;

- a bucket for mixing glue and plaster;

- hammer drill or impact drill with bits or drills for concrete;

- whisk nozzles on a drill for preparing solutions.

From consumables get:

- glue for polystyrene on a cement or synthetic basis;

- dowels with a rod length of 4-5 cm more than the thickness of the foam;

- mounting foam or adhesive foam;

- foam gun.

Work progress step by step

Wall insulation begins with preparatory work:

calculation of the amount of insulation and its purchase;

- preparing and testing instruments;

- purchase of consumables;

- installation of scaffolding (if necessary).

- The surface of the walls is being prepared, which is cleaned of dust and dirt.

- The voids in the seams (if any) are sealed with cement mortar or foam.

- The surface is leveled with plaster so that the irregularities do not exceed 1.5 - 2 cm. This will facilitate the fitting of the sheets, reduce the amount of expensive glue during further finishing.

- At a level of 50 cm from the ground, a support bar is fixed strictly horizontally, if the foam is not placed to the ground, and finishing with other material is provided.

- With the help of a level and a plumb line, markup is made.

- A sheet is applied according to the marking and through it (so that there are no mistakes) a hole is drilled in the wall for the dowel.

- Starting from the central hole, fix the sheet on the wall.

- The second and subsequent sheets are placed with an offset (staggered).

- The seams are sealed with mounting foam. Remove excess sealant after complete curing, usually after 12 hours and up to a day.

- With a special toothed roller or other improvised means, punctures are made up to 0.5 - 1 cm deep on the foam surface for better adhesion to the layer of glue-plaster.

- A 1-2 mm layer of specialized glue for expanded polystyrene is applied to the foam plastic, which is leveled with a spatula.

- A fiberglass mesh is applied to the glue and “heated”. The joints are overlapped, overlapping by 10 cm. The seams between the sheets and the edges of the grids should not match.

- Smooth out the adhesive with a spatula. By adding portions of glue in the right places, the final leveling of the surface is carried out, working as when using putty.

Finishing

After the composition has dried, the surface is primed with means for outdoor work.

After the composition has dried, the surface is primed with means for outdoor work.

The final finishing is carried out with facade paint or bark beetle plaster is used. The latter option is preferable, as it hides inaccuracies and irregularities, which are especially clearly visible in side lighting.

With frame insulation, there are no tricks. The foam is fixed with dowels with wide caps between the frame rails. The remaining voids are filled with mounting foam or glue-foam. Then, without fail, a waterproofing membrane is nailed to the frame. It is convenient to do this with bars of a counter-lattice, the thickness of which is 1-1.5 cm. After installing the siding or other material, there will be a gap between it and the foam, which will reduce the likelihood of materials dampening - the facade will become “ventilated”.

Fixing to concrete and brick wall

Often, a special crate is made to insulate concrete and brick walls, which holds the foam plates. Unfortunately, it is not always possible to install it, and in addition, there are additional costs.In practice, other methods of fastening are in demand.

- With the help of an adhesive.

This method has some peculiarities. Firstly, the individual components of the adhesive can destroy the foam, and secondly, not every stickiness of the adhesive will bind the foam to concrete and brick.

The fastening of the insulation plates is carried out in a certain sequence:

the surface is leveled, then mud and oil deposits are removed from it;

glue components are connected according to the instructions. The resulting composition should not contain water, then it will not peel off for a long time;

the adhesive composition is laid on the plate in separate sections so that there is space for air to escape;

the heater is pressed and held.

- With the help of dowels.

For fixing the plate, its center and corners are selected. Joints for better thermal insulation are treated with sealants.

The plates in the bottom row are attached first. Deformation gaps are left between all plates, which ensure the stability of the coating during temperature changes in the environment.

- With the help of the adhesive "liquid nails".

The composition is characterized by high heat resistance and moisture resistance. It has features of use:

to protect against the toxic component of the adhesive, it is necessary to use special gloves;

the adhesive composition is applied only at certain points;

hardening time no more than 30 minutes.

- With adhesive foam.

This method is distinguished by simple installation, good adhesion to concrete and brick, and low cost.

When using foam, the surface can not be primed. It is enough to cleanse and moisturize it.

The adhesive is processed foam or wall. After a short exposure, the slabs are laid in a checkerboard pattern.

Best Answers

La Nochka:

Are there bars for foam plastic? Bars (or guides) fasten to the ceiling, insulation between them (at least glue the foam), sew up with drywall (according to fire standards, 2 layers are needed). Because in the corridor "+", then vapor barrier is not needed.

Robert Witsup:

All the same, you will have to put an electric warm floor on the floor of the kitchen and bathroom. The floor will not be warm without a heat source. Styrofoam will reduce heat loss from the apartment. GVL is probably not worth it. it is heavy and can fall off. glue over the insulation with a mesh on a cement mixture. peel and paint. so it will be faster. Styrofoam and polystyrene are the same for me. In polystyrene, the price is three times less (probably) and the thermal conductivity is, well, not three times worse than that of polystyrene.

Wind:

answer.mail /question/172676484

Alexander Ulitkin:

Your choice is quite correct. If the polystyrene is 50mm, then this will be enough for insulation.

Types of foam for home insulation

To understand what polystyrene foam is needed for specific types of work, you should carefully study the varieties of material. The classification of heat insulators for walls and floors of the house is carried out according to the following criteria:

- raw materials for manufacturing;

- density;

- dimensions.

Depending on the raw materials used, such types of foam are distinguished as polyurethane, polyvinyl chloride (PVC) and polyethylene. The first one has high elasticity and is a foam rubber that is actively used in the furniture industry. In construction, polyurethane foam is made from such foam.

Polyethylene foam is produced in the form of sheets and is used for packaging fragile items. The usual construction foam is PVC. Expanded polystyrene of this type is suitable as a house insulation from the inside and outside.

The density of the foam is an important indicator. It is on it that the area of \u200b\u200buse of the material depends (whether it can be used in the construction of walls, floors, foundations, etc.). Before buying a foam insulation for the house, it is better to familiarize yourself with what it is, depending on the feature in question:

- PSB 50 is a high density material. In construction, it is rarely found due to the desire of customers to reduce financial costs.Such material is suitable as insulation from the outside and from the inside. Such material is allowed to be laid as part of the floor of premises with a permanent stay of people, the location of furniture and equipment.

- PSB 35 is suitable for insulating the walls of the house from the outside and from the inside. This type of insulation can also be laid in the attic floor cake, provided that there is a strong concrete screed. Styrofoam density 35 is the most common.

- PSB 25. The density of the material allows it to be used as wall insulation from the side of the room. When laying, it is necessary to provide a gap between the heat insulator and the finishing material. It is strongly not recommended to use for floor and external insulation.

- PSB 15 is the minimum density used in construction. This type is best suited for thermal insulation of temporary structures (for example, change houses), containers and wagons.

Characteristics of foam with different densities

Characteristics of foam with different densities

The dimensions of foam sheets are typical. If necessary, it is easy to cut the required shape from the material. Dimensions are assigned depending on the area of the insulated surface, its length and height.

The following sizes are sold on the construction market:

- 2000x1000 mm.

- 1000x1000 mm;

- 1000x500 mm.

Warming technology

After it has been decided what material is required to perform the work, it is important to familiarize yourself with the nuances of the work technology. When fastening, it is necessary to take into account such features of thermal insulation as:

- low strength;

- destruction when exposed to moisture and cold (high-quality waterproofing and vapor barrier will be required);

- instability to fire;

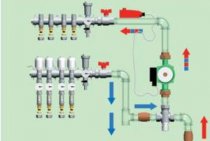

- low vapor permeability, creating a greenhouse effect in the house (a forced ventilation device is required).

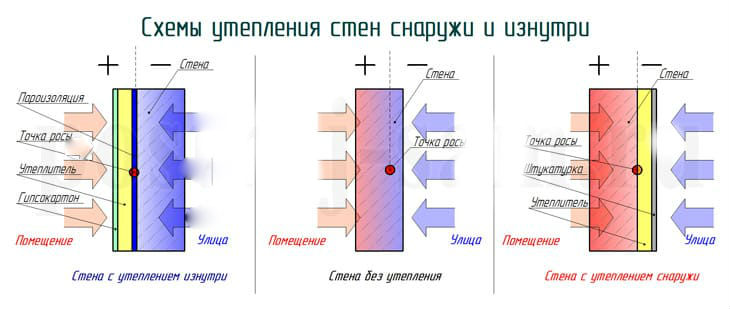

The material can be fastened from the cold air side or from the inside. Styrofoam insulation from the outside will be more competent. Insulation of walls with foam plastic from the inside can be performed only if there are justifications (it is not possible to disassemble the decoration of the house, the insulation of one apartment in an apartment building).

We also recommend that you read the instructions for floor insulation with foam plastic. Insulation of ceilings with this material also has its own nuances. To ensure reliable protection from the cold, it is better to place the heat insulator on the cold air side.

Fastening to the wall is carried out with glue, and after the solution has dried, the material is additionally fixed with dowels-fungi. Before proceeding with fixing with dowels, it is better to wait about 3 days. If the heat engineering calculation was performed correctly, and the technology was not violated during installation, the foam will be durable and reliable.

Wood mount

Styrofoam is attached to a tree in different ways.

- It has long been known that wood must "breathe", otherwise rot will appear. Only thanks to the influx of air, the tree retains its characteristics for many years.

To protect the wooden wall from decay, the foam is laid with a ventilation gap. For insulation, a crate is made of wooden bars. Plates are inserted between the bars. A vapor barrier layer of foil film protects the insulation from condensation.

- Special metal nails are able to securely hold the plates on wooden surfaces. Unfortunately, cold bridges appear at the attachment points, so high-quality putty is required. When plastic fungi are used instead of metal nails, the thermal insulation of the boards is improved.

- Fastening with adhesives is simple and reliable. The main thing is to choose the right glue that is resistant to changes in ambient humidity and temperature. A solution containing cement and glue has proven itself well.

Advantages of foam plastic as a heat-insulating material

The method of insulating the ceiling in a private house depends on the type of roof. If the attic is used as a living space, the foam is placed between the rafters. When the attic is non-residential, it is better to insulate the floor.

Is it possible to insulate the ceiling with polystyrene foam in a city apartment? Undoubtedly. But in this case, the installation of insulation is possible only indoors, and the heat-insulating layer will “steal” 13-15 centimeters in height. As already mentioned, the foam is hygroscopic, so there is no need to lay vapor and waterproofing materials. However, if you insulate, for example, the ceiling in a wooden house, then it is still advisable to lay a vapor barrier film, or carefully process all the joints and cracks between the foam plates using mounting foam or sealant.

Mineral wool shrinks over time, which can lead to the appearance of so-called "cold bridges". Polyfoam is devoid of this drawback, and throughout the entire period of operation does not lose its properties. To insulate the ceiling, it is enough to use foam plates with a thickness of no more than 5-6 centimeters. This is especially true for apartments with low ceiling heights.

Fastening to metal

In the course of insulation work, it may be necessary to fasten to metal surfaces. There are several convenient ways.

- The familiar PVA glue is a good adhesive for metal and foam.

- Mounting foam has good adhesive properties. The adhesion to metal is not very strong, but it lasts a long time.

The foam is packaged in cans, so it is applied to the stove with a special gun. An experienced specialist should work with foam, as it dries quickly, which means that the actions of the installer must be confident.

- Polyurethane glue, which is packaged in convenient cans, is well suited for connecting foam plastic with metal. They are used in a certain technology:

the adhesive composition is applied to the surface of the plate in strips or pointwise;

after the composition is slightly dry, the plate is pressed against the metal;

to make the slab stick better, a wooden spacer is installed, which is removed after 20 minutes.

- The use of the adhesive "liquid nails" allows you to increase the speed of work. This composition instantly connects the plates and metal, but the adhesion strength is worse than with polyurethane adhesive. To achieve a good and fast bond, it is recommended to use these two adhesives at the same time.

- For small jobs, double sided tape is fine. The connection is fast, but does not withstand a large load. In addition, this method is more expensive than the use of other adhesive materials.

Expert answers

nikita:

It is better to attach polystyrene foam to fungi and, in addition, to glue it, it is best to glue it on mounting foam. And with plywood you are tormented, it will gain moisture, dry and play in size, as a result, the ceiling tile will gradually fall. Yes, and at such a distance as yours without additional guides, it will sag over time, if not immediately. It is better to fill additional bars and how to attach all the plaster

Andrey Firsanov:

Penoplex 30 mm is enough for finishing, do not be afraid to use drywall, do not fall down, if you want to remove it, it's up to you

Vladimir Petrov:

The ceiling must be insulated well. Styrofoam is good, but mice love it. So take penoplex and fasten screws with large caps to the ceiling. A ceiling of 100 mm will be just right. Fasten in a run so that the seams do not connect. Then penofol on it, then slats and attach whatever you want to the slats. It's just that there must be a ventilation gap between the penofol and the casing, otherwise the penofol will not work as it should. Of course, it would be nice to insulate the ceiling from the attic.

costiann:

what kind of uterus, Lenochka? I'm at a loss))) where does the terminology come from? ))) do not listen to anyone, in a private house the ceiling is insulated from above (she laid the same ursa in the attic - and insulated) there is no vapor barrier? - bed film and hem from the room - .the cheaper and more convenient plastic, gypsum - do not care. there would be skills and desire, at least fiberboard)))

Grandfather Au:

there is basalt wool. hem drywall normally along wooden bars, BUT hidden electrical wiring must be laid in STEEL pipes with a VVGng cable ..

Vasya Wow:

For foam there is a special glue Titanium (already liquid, transparent, similar to silicate glue for paper), Sold in any system.market, or Atlas, Aegis (these seem to need to be cooked). I pasted over the ceiling on the loggia with Titanium (polystyrene 40 mm) quickly sticks to concrete, no need to keep it. apply glue in the corners and center of the foam plate, 2 x bottles are enough for the garage (approximately 400-500 ml) And adhesives such as Moment dissolve the foam instantly.

Actually, styrofoam burns too well. It is better to take a non-combustible coating

Unknown:

mounting foam.

Nikolay Denisenko.:

Liquid nails or silicone, foam will not corrode the penis.

wolga:

putty! or plaster. very fast

Alexander Znaika:

Many adhesives, even foam, can corrode foam. Glue a few pieces of Velcro or tape on both sides. It will hold quite securely. Cheap and simple.

Konstantin Okhotnik:

Ceresit SM-11 - an adhesive mixture for laying ceramic tiles, or any other - glued almost all the walls in the apartment with foam plastic 20 mm thick.

Ninadze:

nails))

Alexey Agafonov:

Ceiling tile adhesive might work.

Insulation of the ceiling with foam from the inside

When planning internal insulation, it should be borne in mind that the height of the room will decrease by an average of 5 cm. The plates are fixed to the profile. Foam insulation is carried out according to a certain technology.

- Clean the surface from the old layer of paint, whitewash. Remove dust and dirt.

- Inspect the ceiling for cracks, seal them with putty, level the entire surface.

- When the putty dries, treat with an antiseptic and a primer.

- Secure wiring and securely insulate all exposed wires.

- To make a crate, for this they use different materials - plastic, aluminum or wooden bars. Insulation sheets will be attached to the crate. The bars are fixed at a distance of 0.5 m from each other.

In accordance with the size of the cells of the crate, prepare sheets of insulation.

The foam is fixed with glue or screws. The main condition is that the sheets should fit as tightly as possible to each other. If glue is used, it is applied along the entire perimeter of the foam in a continuous strip and 7-8 glue dots in the center.

Joints and cracks must be sealed with sealant to prevent the loss of warm air.

The finished layer of insulation is treated with plaster, under which a reinforced mesh is laid.

Finishing layer - paint, drywall or decorative plaster.

Best Answers

VOV@YCH A.:

Fix the dowel-mushroom (preferably polystyrene foam). If the guys are pro installers, then they won’t fuse.

Chairman:

Your fears are not unfounded: the heat gun fries at a VERY high temperature, and the foam melts easily. And yes, it is a noise insulator. The most effective means of protecting against noise - tested by professionals, is pasting with cells from under chicken eggs.

costiann:

or ursa... on clips for ventilated facades, foam plastic is a heater, not a sound insulator. change your mind quickly

Scarifier:

Recently, the guys were stretching the ceiling and there was ordinary foam, everything went smoothly. During installation, the web itself is heated, not the foam.