Types and characteristics

1. Heaters Isobel.

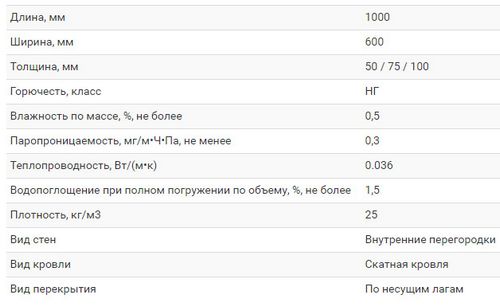

Basalt slabs measuring 600x1000 mm are available in three thicknesses: 50, 75 or 100 mm. They have a density of 25 kg / m3, therefore they can only be used for warming horizontal or inclined unloaded structures (floor on logs, trussed roof, cold attic).

Characteristics of Isobel:

- Thermal conductivity indicators - 0.036 W / m K.

- Volumetric water absorption per day with full immersion - 1.5%.

- Vapor permeability - 0.3 mg / m h Pa.

Also in the manufacturer's lineup there are super-light plates Isobel Light with a density of only 20 kg / m3 for unloaded surfaces.

2. A series of heaters ST.

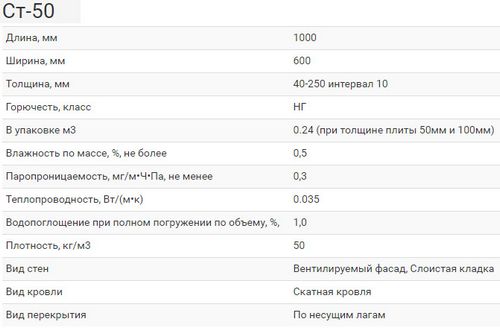

These mats are made from ultra-thin basalt fibers and are available in several densities. The lightest and most effective of them is Izovol ST-50. In addition to it, the series includes plates weighing 60, 75 and 90 kg/m3. The main purpose of these products is the insulation of enclosing wall structures and internal partitions, unloaded floors and ceilings, attics and pitched roofs.

Characteristics of ST plates:

- Efficiency - 0.034-0.035 W / m K.

- Water absorption - up to 1%.

- Fire resistance of thermal insulation - +1100 °С.

- Compression resistance - 10-18 kPa.

- On separation of layers - 5-7 kPa.

The strength characteristics of Izovol in the description are given for slabs ST-75 and ST-90.

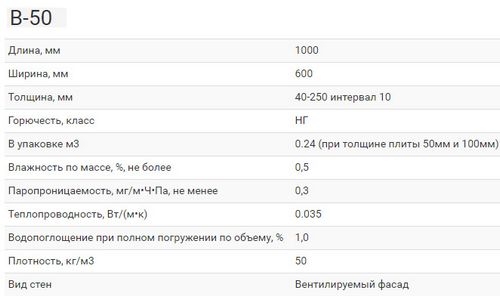

3. Serie B

Fiberglass-laminated insulation is specially designed for ventilated facade systems. An additional layer protects the basalt wool from being blown out and acts as a windscreen on the outside of the building. The density of Izovol-B can be 50, 75 or 90 kg / m3, the compression resistance of the most rigid boards is 10-25 kPa, and for peeling - 5-8 kPa. Other characteristics repeat the ST brand.

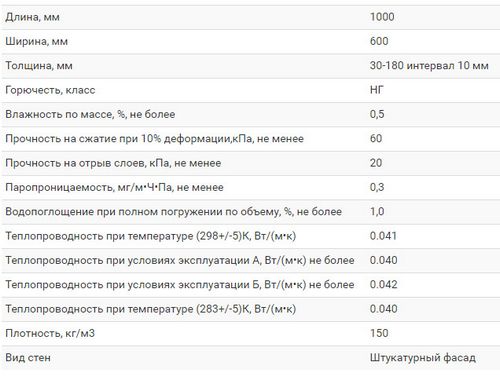

4. Izovol F.

This is also a facade insulation, but already intended for a “wet” ceramic finish. The series includes only three types of plates with a density of 100, 120 and 150 kg / m3 with a thickness of 30-250 mm. Their efficiency is worse (0.036-0.041 W / m ° C), but it is fully compensated by high strength:

- for compression 40-60 kPa;

- for separation 15-20 kPa.

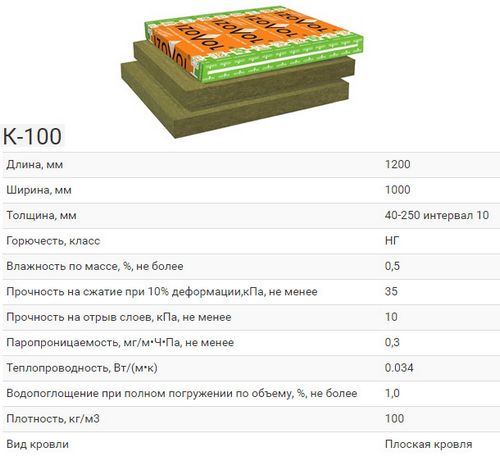

5. Izovol K.

This heat-insulating material Izovol has a non-standard "double" size of 1200x1000 mm, which allows you to cover a large roof area with one sheet. In addition, K series mineral wool has excellent performance characteristics:

- Density - 100-175 kg / m3.

- Thermal conductivity - 0.034-0.039 W / m K.

- Compressive strength - 35-70 kPa, tear strength - from 10 to 16 kPa.

- Water absorption ≤0.5%.

6. Izovol P.

It is intended for laying under a concrete coupler of floors and flat roofs. It can also be used to insulate basements and other areas with high humidity. With a density of 175 kg/m3, Izovol-P withstands a load of up to 65 kPa without layer deformation, while maintaining an efficiency of 0.037 W/m K. The lighter thermal insulation weighing 100 kg/m3 is rated at 35 kPa.

7. Special types of mineral wool.

The Izovol product range is not limited to board materials. There is also rolled insulation, cylinders designed to protect utilities, fillers for sandwich panels. Izovol Acoustic brand insulation also belongs to special types of mineral wool, although it is available in the form of standard plates.

Separately, it is worth mentioning Izovol hydrophobic mats with a reflective layer of aluminum foil. They increase the effectiveness of basalt wool at temperatures up to +570 ° C and provide the insulation with additional protection from getting wet. The choice of density in rolls is possible in the range from 40 to 80 kg / m3, for Izovol-C pipe casings, the indicators are much higher and more diverse - 50-120 kg / m3. The thickness varies from 40 to 100 mm.

Reviews

took Rockwool

Oleg, Belgorod.

Kirill, Moscow.

Yuri, Krasnodar.

there were slopes

Igor Sergeevich, Rostov-on-Don.

The cost of heaters

| Brand | Thickness, mm | Plates in a pack, pcs. | Insulation area, m2 | Cost, rub/pack |

| Isobel Light | 75 | 6 | 3,6 | 290 |

| L-35 | 100 | 4 | 2,4 | 325 |

| ST-50 | 50 | 8 | 4,8 | 420 |

| B-90 | 100 | 4 | 2,4 | 950 |

| F-150 | 100 | 2 | 1,2 | 640 |

| K-120 | 100 | 2 | 2,4 | 1150 |

| P-100 | 50 | 4 | 2,4 | 940 |

| Acoustic | 100 | 4 | 2,4 | 450 |

Features of the national product

Izovol insulation is produced at the Belgorod Non-Standard Equipment Plant (CFD) from gabbro-basalt fibers. But unlike foreign analogues, the melt of rocks for the formation of thin threads is carried out in gas furnaces. This allows you to reduce energy costs for production, and hence the cost of the product itself. The technology is called Ecosafe, since the presence of coke or blast-furnace slag in the fibers of thermal insulation is completely excluded here. As a result, it was possible to achieve constant properties of stone threads, a stable acidity module (2.0-2.2) and record-breaking efficiency indicators for mineral wool.

The scope of Izovol insulation is the same as for other stone wools, and also depends on the density of the material. Basically, Izovol insulation is used in construction to protect:

- Internal premises (walls, lag floor).

- Roofs and attics.

- Unloaded floors.

- Facades for cladding or subsequent plastering.

- Flammable objects, such as steam rooms in saunas and baths.

So far, the Belgorod mineral wool Izovol is not very well known to a wide range of buyers. However, the relatively low cost of a heater with decent characteristics arouses interest in it. So some have already tried the new material in their work and shared their impressions in their reviews. The only thing that is too early to talk about is the actual service life of mineral insulation. She entered the market only 10 years ago, but the manufacturer promises her a "life expectancy" of 50 to 80.

Technical characteristics of the insulation:

- Density 20-175 kg / m3 (depending on the Izovol series), respectively, the compressive strength varies within 35-80 kPa.

- Thermal conductivity - 0.033-0.041 W / m K.

- Fire resistance – +800..+1100 °С. In fact, stone wool does not burn, however, when it reaches this temperature, it begins to deform.

- Vapor permeability - 0.03-0.035 mg / m h Pa.

- The maximum length of the insulation fibers is 50 mm, the thickness is 5-15 microns.

- High resistance to aggressive environments, fuels and lubricants, alcohols.

Judging by customer reviews, there were also some shortcomings, but they turned out to be uncritical. Most of all complaints are about bulky packaging and a thin film that makes it difficult to transport mineral wool.