Insertion depending on the type of pipes

Previously, water pipes were laid from cast-iron and steel pipes. Today, plastic is predominantly used. Depending on the material, there are differences in the inset.

Working with polymer reinforcement

They cut into a plastic pipe under pressure using an electric-welded saddle clamp. Outwardly, the product resembles a tee of 2 halves, on the vertical branch pipe there is a tap thread. A nozzle is inserted through it to drill a hole in the line. Clamp - made of plastic, with a built-in spiral for connecting the welding unit.

The connection made by the method of electrodiffusion welding is not only hermetic, but also durable - it can withstand pressure up to 16 atm. Products resistant to corrosion, serve up to 50 years. Electrowelded models of saddles have a built-in cutter, which makes a hole. It is rotated by the shank with a key. The parameters for the operation of the welding machine are indicated on the body.

Connection to the water supply is carried out in the following sequence:

- Clean the pipe, removing dirt. The dismantled clamp is mounted at the plunging point.

- Connect the device, weld. Leave for 1 hour to cool.

- Screw on the valve. A drill is inserted through its cavity, a hole is made.

When the jet hits, quickly pull out the tool and shut off the water. A pipe leading to the house is connected through the coupling.

Foundation reinforcement

Connecting cast iron pipes

When working with cast iron, the features of this metal are taken into account: it is fragile, and if handled carelessly, it can burst. The connection is made without welding, by installing a saddle clamp with rubber seals

The hole is made with a special drill with straight flutes, sharpened at 116-118 °. The device will have to be changed several times - it quickly becomes dull. It is easier to make a hole with a special bimetallic crown. Tools are constantly cooled with oil or water. Do not press hard, the speed is small.

The whole process of inserting into a cast-iron water pipe looks like this:

- The pipe is cleaned of anti-corrosion grease, rust. At the site of the breakdown, the upper hardened layer of metal is removed with a grinder.

- Install the saddle, not forgetting the rubber seal. It will ensure the tightness of the connection.

- A valve is mounted on the pipe. A crown is inserted through it and drilled.

A drill is removed from the hole made, the tap is turned off. Connect a branch of the home highway.

Features of working with steel pipes

Pipeline welding.

The rigidity of steel is similar to cast iron, but the material is more ductile. The insert is made using a welding machine in the following sequence:

- Remove rust from surface. Install the saddle clamp by tightening the halves with bolts.

- Weld the seams, make sure the tightness.

- Screw on the stopcock.

- A pipe is drilled through it, but not completely. A little of the body is left and go through with the help of a hand drill.

You can use a steel threaded pipe. The segment is welded to the line, a valve is connected, a hole is made.

To make sure the quality of the welds, a simple trick is used. The inner surface of the clamp is coated with kerosene. Chalk is applied outside - with flaws in the seam, greasy spots will appear on it.

Features of tapping into a water pipe

According to the rules, for the tie-in, you should take a permit signed by the management of the local water utility and a plan of the site where the work will be carried out.In addition, technical conditions will be required, for which you will have to visit the central department of the water utility. Specifications usually contain information about the connection point, data for the tie-in, as well as the diameter of the pipeline of the underlying pipeline.

In addition to the employees of the water utility, other companies specializing in such work with the appropriate license can develop design estimates. The price for services related to the preparation of documentation for tapping into a pressure water supply may be slightly lower for such organizations.

However, in the future there is a possibility of a conflict situation with representatives of the water utility, who do not always give approval to such design developments.

Having received the necessary papers, you should contact the SES department, where to register the project. Here you will also need to write an application to obtain the necessary permission to connect to the water supply system.

In accordance with generally accepted standards, only specialists with the appropriate approval can perform work on tapping into a water pipe. The person who ordered the implementation of this service can save money only on digging and filling the trench with his own hands, as well as on auxiliary work that does not require permits.

There are some situations in which inserting a pipe into a water supply system is prohibited:

- connection to the highway without installing a meter;

- lack of connection to a centralized sewerage system;

- a larger diameter branch branch than that of the main pipeline.

Laser cutting of metal - more details on the website.

Manhole construction

Such a well will be enough to place shut-off valves in it and perform the necessary manipulations for connecting to the water supply. Such a structure will make it easier in the future to carry out possible repairs to the home system.

To make a well, they dig a pit of the required parameters, the bottom of which is covered with a ten-centimeter layer of gravel. To form a reliable foundation, the resulting “pillow” is covered with a sheet of roofing material. A concrete screed is poured on top.

After at least three weeks, the walls of the shaft are laid out above the hardened slab. For this purpose, brick, reinforced concrete rings or cement blocks can be used. The mouth of the pit is raised flush with the surface.

When building a well in a site with frequently rising groundwater, it should be watertight. It is most convenient in this regard to use a ready-made plastic container, which is attached to a concrete base. The upper part is covered with a plate with a hole for installing a hatch.

Water pipes are made of several types of materials: plastic, cast iron or steel.

It is worth paying attention to each of them.

Work Permit

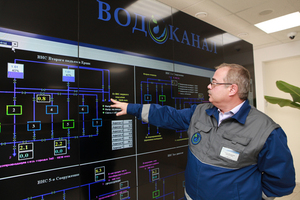

Permission to crash into a pipe is required. Without it, unauthorized connection is considered illegal, entails an administrative penalty - the violator is fined. First, documents are submitted to Vodokanal for ownership of land and a house. Together with them, they provide a site plan, a copy of which is issued and certified by the center that registered private ownership. It is necessary to check whether underground communications pass through the territory.

When permission is obtained, contact the sanitary and epidemiological station. There, the document is registered and checked whether the connection violates sanitary standards. After a positive decision, you can order a project. The work will be performed by any design organization, but it will have to be certified by Vodokanal, so it is better to contact its specialists immediately.

The tie-in is allowed to be performed only by licensed workers, it is forbidden to do it yourself.Some site owners, having permission, ignore the ban and connect themselves. The fine does not scare them - the fee for Vodokanal services is much higher.

Working with cast iron pipes

When connecting a solid cast-iron pipe to a water supply system, a certain sequence is observed:

- in the area where the hole will be made, the surface is cleaned of a layer of hardened cast iron and rust;

- a rubber seal is applied on top and the saddle is mounted;

- a shut-off valve is connected to the flange outlet, through which the crown will be inserted;

- stage-by-stage drilling of the pipe body is carried out with periodic cooling of the cut point. Initially, a small diameter drill is used with its subsequent increase;

- after removing the crown, the valve is closed;

- the last step is to apply an anti-corrosion layer and insulation.

Working with cast iron pipes requires the use of several crowns for drilling. Carbide cutting inserts must be built into them.

It is important to prevent possible overheating of the equipment, which can be avoided by wetting the cutting parts with water.

Cast iron is a fairly brittle material, so drilling should be done at low RPM and with minimal pressure on the equipment. When the power tool is pulled out of the hole, it may be hit by a jet of water. Therefore, a protective rubber screen should be installed between it and the cartridge.

If it became necessary to use a saddle clamp, for a snug fit to the pipeline, it is necessary to use a rubber seal. It can also be equipped with a special machine, consisting of a blocking bolt, a flushing cock, a ratchet handle and a shaft with a drill. The design is framed by a metal housing with a guide sleeve, necessary to facilitate the drilling process.

Construction of a well for arranging a node

How to make a well.

The rules for the installation of a central water supply system provide wells for inspecting the pipe and connecting new consumers. If they are far from home, it is advisable to arrange them with your own hands at the place of the tie-in. Such a construction will subsequently facilitate the operation of the home water supply system. A shut-off valve is installed in the well, if necessary, the water supply to the house can be stopped.

The pit dug at the connection point is deepened by 0.5 m, covered with rubble. Roofing material is laid on top, 10 cm of brand 200 concrete is poured. To give strength, it is reinforced with reinforcement. A few days later, when the concrete cushion grabs, a shaft is erected over it. The manhole is given a round or rectangular shape, taking into account that there is 70 cm of free space inside. This is enough to fit a person to control the valve.

For the construction of a well, bricks, blocks are used or well rings are installed. If there is a threat of seasonal flooding, the structure is sealed. To do this, the hole is immediately dug wider so that there is access to the outer walls. They are treated with bituminous mastic, wrapped with roofing material, then covered with excavated earth. You can install a plastic container of a suitable size, seal the pipe entry points well. From above the well is covered with a lid with a hatch.

Connection with plastic plumbing

A saddle clamp with terminals is bolted to the cleaned area in order to be able to connect the welding machine. If an electric-welded collapsible clamp is installed on a plastic pipe, the vertical and direct-flow pipes are initially disconnected.

Further, a clamp with a flange is fixed to the pipeline, with the help of which the valve with a sleeve is connected.On the other side of the lining, a valve is mounted, located on a vertical branch pipe.

At the point of its connection to the highway, a hole is drilled using special equipment. The drill is inserted exclusively at this point to further block the water flow with a shut-off valve.

To ensure the tightness of the joint, an overlay is used during the drilling process. If the insert is made by a welding machine, the hole is made when the surface has completely cooled.

A new pipe is attached to the flange located on the valve. A clamp is mounted over the junction, which is soldered by the welding machine to the line. A tap can be screwed to the hole of the clamp.

This manipulation is not necessary, but it improves the functionality of the new pipeline branch. In the future, if it becomes necessary to stop the flow of water, it will be enough just to turn off the tap.