Calculation of the barrel volume

The volume of a barrel for a septic tank is calculated in the same way as the volume of any other local treatment plant. It is necessary to take the rate of water consumption per person (according to SNiP - 200 l / day), multiply by the number of residents and additionally multiply by 3 (this is how many days the water in the septic tank should settle). The result is the following formula:

V = (200 xn) x 3.

That is, for a family of 4 people, a 2.4 cubic capacity is required. At the same time, it should be noted that in reality it is very rare for one person to consume 200 liters of water per day. In the case of economical consumption, this figure can be halved and, accordingly, a smaller tank can be used.

The size of the barrel is selected taking into account the peculiarities of the operation of the sewer system

How to make an aeration field

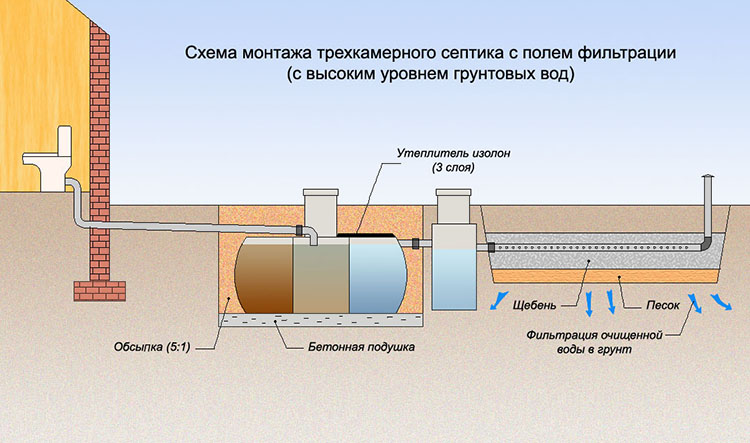

If the groundwater on the site is high, it is necessary to apply a different septic tank scheme: instead of the last chamber - the filtration well - they arrange a filtration field. It is done like this:

- A trench is dug in a suitable place, which at one end rests against the second tank of the treatment plant. The depth of the excavation is 60 - 70 cm, and the width should be such that two drainage pipes with perforated walls can fit in it.

- The inner surface of the trench is covered with geotextiles. The cut should be wide enough, since they will also need to cover the pipes laid in the trench.

- At half the depth, the trench is covered with rubble, which must be leveled and compacted.

- It is necessary to lay perforated pipes on a layer of crushed stone, connecting them at one end to the second barrel. The holes in the barrel should not be cut next to one another, but at some distance, so that the angle between their axes, when viewed from above, would be 45 degrees.

- A 10-centimeter layer of crushed stone is poured over the pipes. Then the entire structure is “wrapped” in geotextile, laying its edges with an overlap of 15–20 cm.

- The filtration field must be covered with soil. Now you can grow a lawn or a flower bed here.

Instead of geotextiles, you can use a banner canvas - a durable waterproof material coated on both sides with a thin layer of PVC.

Use of metal barrels

Having several metal barrels with a capacity of 200 liters available, you can make a good home-made septic tank in the country. The order of manufacture and the scheme remain unchanged. But still, working with metal is different from working with plastic:

- You cut holes in the metal walls with an electric jigsaw, just use a metal file. It is better to weld metal ventilation and overflow pipes. This requires a welding machine and the skills of a welder.

- The advantage of metal barrels is that in order to increase the volume of the septic tank, they do not need to be added to the row. It takes up a lot of space, which is very problematic in a country house with a small plot of land.

- To increase the volume of the chamber, weld the barrels together vertically. At the same time, you leave the lower barrel with the bottom, and in all those welded above, cut off the bottom with a grinder. According to this scheme, you can make a septic tank from two chambers of any capacity. For structural strength, reinforce the welds with jumpers.

- The only drawback of metal is rapid corrosion. Bituminous mastic will help extend the service life. It can be purchased ready-made at the store or made from bitumen melted in a bucket over a fire. For elasticity and better adhesion to metal, add some gasoline to hot bitumen. Finished mastic treat all sides of the barrels before installation.

The metal structure is stronger than the plastic one, so you can not be afraid that the camera will be crushed by the pressure of the soil.The use of such a septic tank is especially important on land plots with moving soil.

Installation of a septic tank, filtration well and filtration fields

The scheme for performing installation work is as follows:

- Put two plastic barrels in the pit.

- Connect pipes to chambers.

- Backfill the tanks using a mixture of cement (dry powder) and sand. This backfill perfectly protects the structure from destruction during soil movements. The mixture is fed in layers of 0.25–0.3 m, and each layer must be compacted. At the same time as filling, pour water into the containers. Thus, you protect the barrels from deformation.

- Pour a pillow of sand and gravel on the installation site of the third tank (a well for filtering wastewater), put the last barrel on the resulting cake and pour fine gravel into it (about a third).

Your septic tank is ready!

If instead of a filtration well you planned the construction of filtration fields, the arrangement of the latter is carried out as follows:

- For the installation of drainage pipes, dig trenches of the required size. They must have a slope (per meter of pipe products - 2 cm).

- You lay geotextiles on the bottom of the trenches, its sections on the sides are thrown onto the sides of the ditch.

- Fall asleep with crushed stone (height 0.3 m) geotextile material.

- Place pipes for drainage on a layer of rubble. As such, it is allowed to use home-made products (make holes in ordinary steel pipes). But it is better to use factory perforated pipes.

- Fill the trench with a layer of crushed stone and lay geotextiles on top (overlap width - about 0.1 m).

You just have to fill the ditch with earth. Fields for filtering drains are made.

Buying a ready-made sewage treatment plant for autonomous sewage is the right decision from a technical point of view. However, it is not always justified in terms of price. Few dacha owners decide to purchase an expensive deep cleaning station if living in a country house is seasonal and most of the time the sewer system is idle. In this case, it is more expedient to apply a non-standard approach - for example, to make a septic tank from barrels. Such a design will be much cheaper, and its efficiency will be sufficient to meet domestic needs.

Where can a septic tank be installed?

The building and sanitary standards stipulate the minimum distances between the septic tank and the following objects:

- water wells and wells: on soils with good carrying capacity (sands and sandy loams) - 50 m, on all others - 30 m;

- garages and baths - 1 m;

- neighboring plot - 2 m;

- trees (distance to filtration fields) — 4 m;

- roads with busy traffic and car parks: - 4 m.

If you intend to pump out accumulated sludge using a sewage truck, choose a place with the possibility of access for it.

Relative to the house, the septic tank should be installed at a distance of no more than 5 m. If the structure is placed further, it will have to be buried deep to ensure the slope of the pipe coming from the house. In addition, with a significant length, this pipe will often become clogged.

Choice of material metal or plastic

In order to save money, a septic tank in a country house is very often made from barrels that previously performed a different function. For example, they could be used to store grain, sand, cement and other bulk substances. The container can be metal or plastic, the main thing is its tightness.

If, nevertheless, the question arose of buying a barrel, then it is better to give preference to plastic. And that's why:

- wider range on the market;

- resistance to corrosion and aggressive effects of effluents;

- absolute tightness over a long period of operation;

- installation without the involvement of lifting equipment due to low weight.

To be completely objective, it should be clarified that the last point is only partly an advantage. A small mass of plastic makes it necessary to attach the container to a concrete base to level the buoyancy effect of groundwater. In this regard, a septic tank made of iron barrels is considered more preferable, since it does not need anchoring.

Any barrel that meets the tightness requirements can be used for a sewer sump.

Will such a volume of a septic tank be enough

If you use it to the fullest (shower, toilet, sink, etc.), then 200 liters per person per day are accepted for calculation.

If only the toilet, then 25 liters per person per day

The septic tank must be at least 3 daily water consumption.

However (from the photographs), it turns out that the second chamber-barrel "works" only for half the volume (about 100 liters), and the third, in general, for a quarter. In total, the total volume of the septic tank is 200 + 100 + 50 = 350 liters ... It seems to me that this is really not enough for peace of mind).

It turns out about 150 liters * 3 = 450 in one barrel. According to my calculations, it’s enough for three (only the toilet is hooked up).

I have an analogue. Three children and two adults year-round. It has been working for 1 year and 10 months. Has not been pumped out yet. In addition, 10 meters of a leaky pipe in the ground.

Why is it better to make a septic tank from barrels

For the installation of long-term treatment facilities, it is best to purchase a special container.

However, such an installation is expensive and it is not always advisable to spend such funds. Especially if there is no year-round residence in the house or a temporary structure is required. There are two main advantages of do-it-yourself septic tanks:

For the manufacture of a septic tank, you need a barrel with a volume of 200 liters or more.

- low cost;

- ease of installation;

- ease of dismantling.

Today you can find plastic barrels with a capacity of 200 to 250 liters relatively inexpensively. Of course, they have already been in use, but for our purposes they are quite suitable. Moreover, there are no difficulties in arranging the structure; anyone can do it.

However, we can not say about the minuses. Such a septic tank, despite the volume of barrels, is still considered small. There are sanitary standards, according to which the volume of the septic tank must contain such an amount of waste that is formed in 3 days. When using treatment facilities from barrels, this point must be taken into account. That is, the number of drains should be the smallest.

Materials and installation of barrels

To start work on the installation of a treatment plant, it is necessary to prepare the following materials:

- 3 barrels, the volume of which is not less than 200-250 liters;

- crushed stone, fraction from 1.8 to 3.5 cm;

- plastic pipes for sewerage with a diameter of 110 cm;

- drainage pipes;

- connecting elements for pipes;

- geotextile.

Before installation, you need to prepare the barrels. There are holes for connecting and output pipes. In the first barrel, the outlet hole must be made at a distance from the lid 20 cm below. And the outlet is made even lower, 10 centimeters from the inlet, and placed on the opposite side.

Usually plastic barrels have screw caps. No need to bury and insulate the lid, especially in the first barrel. Indeed, over time, ventilation will be required, through the hole it will be convenient to clean the structure itself.

The holes in the second barrel completely repeat the previous ones. In addition, additional holes are often made, to which drainage pipes are then brought. They are positioned in such a way that they are in relation to each other at an angle. The angle can be around 45 degrees.

Each connection of pipes and barrels must be made with a waterproofing material. The use of silicone sealants is not recommended.

Next, a pit must be dug.Its dimensions exceed the dimensions of the barrels, approximately 25 cm on each side. The bottom of the pit must be sealed. Before laying the barrel, a drainage layer is created. As already mentioned, for each barrel, the drainage layer meets its own standards.

It will be great if the bottom of the pit is poured with concrete, having previously installed hinges there. Barrels are then tied to these loops with straps. All this is done with one single goal: so that during the melting of snow in the spring, the entire structure of the treatment plant does not float and collapse. Of course, if the installation is temporary, then it is not advisable to do this.

When the pit is ready, barrels are installed there. At this stage, you need to monitor the pipe connections. Everything must be sealed. After that, everything is covered with soil.

Before filling the created septic tank, the soil is mixed with cement. An important detail: the cement is mixed with the soil when it is in the form of a dry powder. In the future, it will allow you to fix the layer, and in the rainy season and snowmelt, the soil will not be so mobile.

Backfilling is done in several stages. Each layer must be compacted, especially near the barrels. Be sure to ensure that the details of the structure are not damaged.

Septic tank device

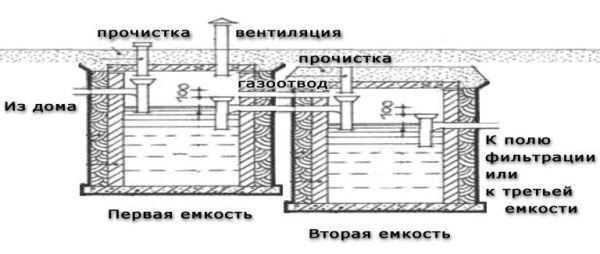

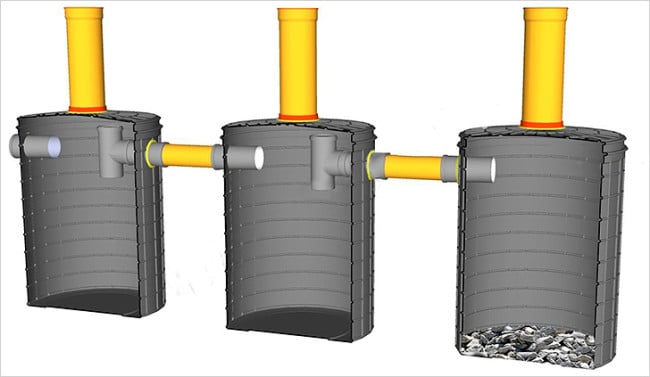

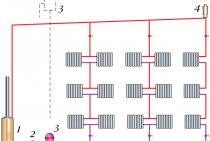

Consider how to make a septic tank from a barrel. To install a septic tank, you will need three barrels, which will be connected in series with pipes. The first two barrels will have bottoms, and the last one will need to be cut off - the purified water should go into the ground. With a high level of groundwater in the area, a special structure will be needed to organize the flow of treated water - a filtration field, also called an aeration field. We will describe below what it is.

A septic tank built according to this scheme is called a three-chamber. The effluents coming from the house in the first chamber (barrel) are settled and at the same time decomposed by special bacteria into simple non-toxic substances that will settle to the bottom.

Arrangement and installation of a three-chamber septic tank with a filtration field

As the chamber fills, the clarified water that appears on top will flow through the pipe into the next container, where it will pass the second stage of purification with the participation of bacteria of a different species. After that, again through the overflow pipe, the liquid enters the filtration well (barrel without a bottom) or into the aeration field. After such purification, no more than 5% of contaminants remain in the water, which makes it possible to use it even for watering a garden or vegetable garden.

If the second stage of cleaning is not provided and the septic tank consists of only two barrels, it is called a two-chamber. It will be less effective, but easier to install.

Material options for a septic tank in the country

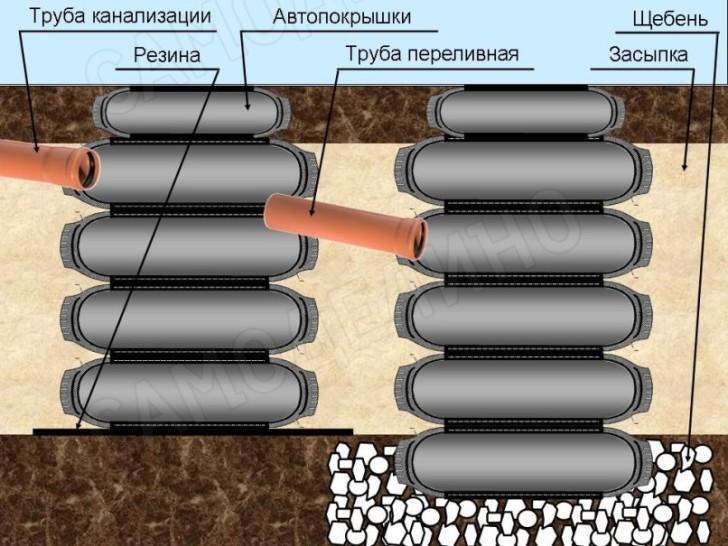

Depending on financial capabilities, a septic tank in the country is made from a variety of materials. With virtually no material costs, you can get decommissioned large-diameter tires at the nearest tire fitting workshop or at a car company.

Tires from the Kirovets tractor are well suited. They are stacked on top of each other in a dug pit. A septic tank made of ready-made concrete rings is equipped even faster and more reliably. The sewage receiver can be laid out with brickwork. Also used are barrels of large volume and the so-called eurocubes, which are sealed plastic containers.

When installed, they are concreted on the sides, as they are light in weight and can move when the groundwater level rises.

How it all works

The left barrel is the last one! All water from it is pumped out by a drainage pump into a pit on the street (or a filtration well / filtration field - according to the circumstances). And the first barrel on the right goes there from the toilet bowl, everything in it floats that does not sink, and sinks what turned into silt.

To speed up biological processing in the first barrel, constant aeration is carried out with an aquarium compressor (you can use something more productive - then the design will begin to strongly resemble a full-fledged automatic cleaning station, such as Unilos Astra). It will also be useful to periodically add bacterial cultures through the toilet (there are a large selection in stores).

When summer comes, I will insert the pump into the first barrel and throw the end of the hose into the garden, clean the bottom of the silt and then return everything to its place.

you need a pump or a drainage pump with a float (price 1,500-2,500) or make a float for the baby so as not to run around with the pump all the time!

Arrangement of a septic tank from barrels with your own hands

To ensure normal wastewater treatment, it is desirable to use two chambers in the septic tank: in the first, heavy substances settle to the bottom, and in the second, clarified water settles before being discharged into the ground.

Below we consider an example of arranging a septic tank from two plastic barrels with our own hands. This instruction can be considered universal, since most of the points are applicable to the installation of metal containers.

Mounting diagram

The design of such a treatment plant is not particularly complex. The barrels are sequentially connected to each other by means of an overflow pipe, while the second container is located 10-20 cm deeper than the first. Holes are cut in each tank for connecting sewer pipes and a ventilation outlet

It is important to observe the correct position of the inlet and outlet relative to each other: the inlet must be placed 10 cm above the outlet

Wiring diagram of a septic tank of two barrels

Clarified water can be drained into a filter well or a filtration field can be used. The well is used at a low level of groundwater and good permeability of the soil. For its installation, a bottomless barrel is used, in the lower part of which a 30-cm gravel pad is made.

The filtration field has a larger capture area, due to which water is drained even in conditions of low soil throughput. In this case, water is discharged from the second chamber of the septic tank into a drainage pipe, which is located in a layer of gravel or crushed stone.

The number of drainage pipes in the filtration field directly depends on the volume of wastewater

List of materials

To complete the work, you will need the following materials:

- two barrels with a volume of 250-1000 liters (depending on the number of drains);

- sewer pipes with a diameter of 110 mm for outdoor installation (orange color);

- corners and tees for connecting pipes;

- glue and sealant for PVC;

- crushed stone of fine fraction (2-3.5 cm);

- cement;

- sand.

A set of tools for mounting a septic tank from plastic barrels is standard: a shovel, a rake, a level, a jigsaw and a container for mixing the solution.

Stages of work

- In barrels, using a jigsaw, holes are cut for sewer pipes and a ventilation riser. For the inlet, 20 cm recede from the upper edge, and for the outlet 30 cm. The gaps formed between the holes and pipes are filled with sealant.

Connections of elements of a homemade septic tank from plastic barrels

- The size of the pit is calculated in such a way that 20-30 cm remain between the soil and the wall of the tank. The walls of the pit are leveled, and the bottom is rammed.

- Before installing the barrels, the bottom of the pit is poured with a layer of concrete, in which several lugs or pins should be provided for anchoring the septic tank.

The tank is fixed with a strong cable or straps.

- In order for the walls of the septic tank to be protected from seasonal soil movements, the gap between the barrels and the soil is filled with a sand-cement mixture. To prevent deformation of the drums as a result of the pressure created by the backfill, they are pre-filled with water.

- In the immediate vicinity of the septic tank, a pit is dug for a filter well or a filtration field is made to drain purified water into the ground.

- When all installation work is completed, the barrels are covered with a layer of soil. If desired, this place can be hidden from others with the help of grass and other vegetation, leaving only inspection hatches and ventilation on the surface.

Septic tank as an element of landscape design

After completing all the points in this instruction, you can equip a simple septic tank from plastic or metal barrels with your own hands.For the installation of more complex treatment facilities, it is better to use the services of professionals.

How to seal connections

And something seems to me that the places where the pipes enter the barrels are a weak point.

I think a regular rubber seal for the cast-iron-plastic transition will do.

To seal the joints, I used a special glue for plastic (comes in a tube) and then a moisture-resistant ship sealant. Wait a day and you're done.

Glued with a hot glue gun.

Not certainly in that way. It is glued with a special nozzle on a building hair dryer with a rod.

The main material of the rod. There are also polypropylene and polyethylene.

Is it possible to connect a barrel with a cube with a corrugation? In which case, the walking of the soil compensates.

It happens that for a country life no serious sewerage, treatment facilities are required, and therefore every summer resident is quite capable of making a septic tank with his own hands from barrels. Barrels can now be found in abundance. It must be said right away that such a structure should be considered as temporary. In the future, it will be possible to change it to a factory-made septic tank. But if the load on it is small, then it will provide comfort for many years.

You can arrange a septic tank both from metal barrels and from plastic ones. There are many reasons that encourage the creation of temporary septic tanks. For example, a new house is being built in the country. This process is lengthy and a temporary treatment plant can be made to provide comfort. For work, you need to prepare large containers. Experts recommend giving preference to plastic barrels. Metal ones are not suitable for this purpose, and they are not recommended to be used. Such barrels are susceptible to rotting and corrosion from runoff and will quickly fail. Containers must be chosen without leakage and large.