The device and operation of drain tanks

All drain tanks have a similar design. The difference is only in the mechanism of starting water.

Structurally, a toilet cistern with a button or two buttons, as well as a flush lever, can be represented as a set of interacting nodes:

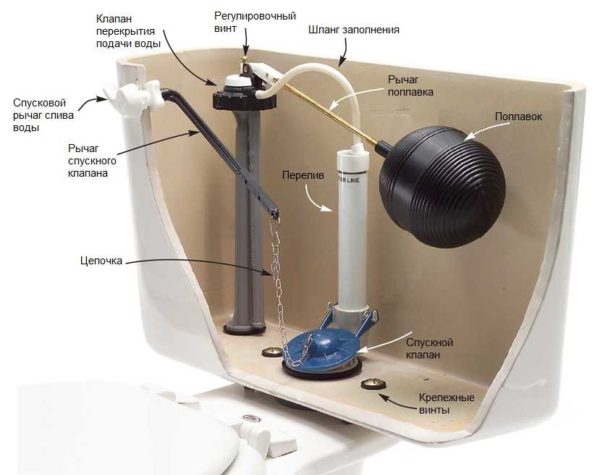

- Fill valve. He is responsible for maintaining the water level at a certain level. The valve is controlled by a hollow float. When the water rises to the desired level, the float closes the water supply channel to the tank;

- Plastic float attached to the filling valve. Works on the principle of a rocker, rising when filling the tank;

- Drain valve with overflow system. Modern tank options involve controlling this valve by pressing a button. With manual control of the old-style drain, it is enough to pull the lever or chain to start water into the toilet;

- Overflow is a mandatory component of the tank. It is adjustable in height, thanks to which the maximum water level is set. When this level is exceeded, water flows through the overflow pipe into the sewer without spilling out through its walls.

A tank with a mechanical drain is very simple to operate. Water enters it through the filling valve when the float is in the lowered position. After reaching a strictly defined level, the float shuts off the water supply. Drainage is controlled manually. If the tank is equipped with buttons, then the water is drained after pressing them. In this case, the drain valve partially or completely opens, passing water into the toilet. The float drops, slightly opening the filling valve.

The structure of the toilet flush tank with two buttons is a bit more complicated, but you can use such a tank more economically. If you press one of the buttons, the water is partially drained. Full drain occurs when the second button is pressed.

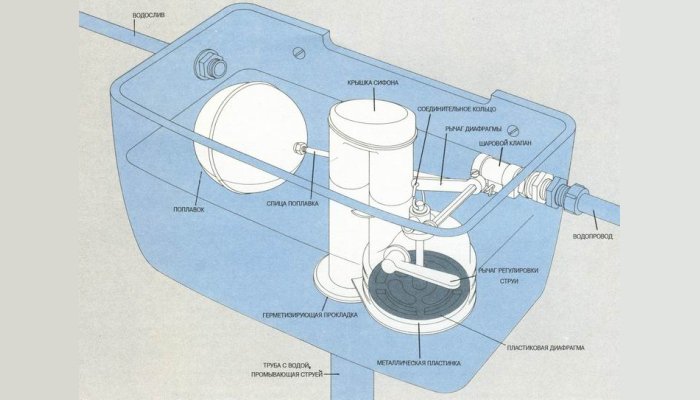

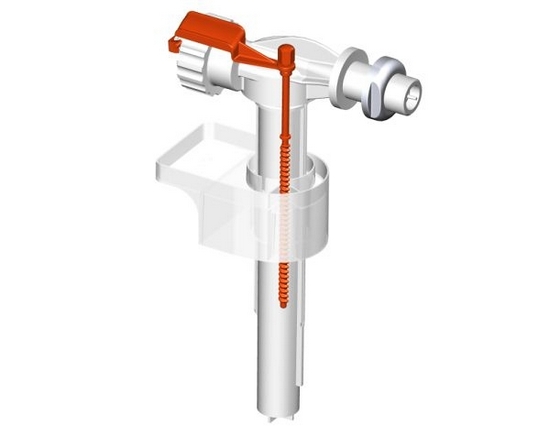

Increasingly, you can find new types of tanks that have a lower connection to the water line. It is advisable to install them if the use of a side connection is not possible due to lack of space. The main difference of such a tank is the presence of a membrane valve. Under the action of water pressure in the pipeline, the valve opens slightly and allows water to enter. When the water rises, the float presses on the piston rod, which gradually closes the diaphragm valve. When the set level is reached, the valve closes completely.

Repair of a two-button tank

Economical water consumption adds popularity to such a plumbing fixture. And how to repair a toilet flush tank with two buttons? The principle of disassembling such a tank remains the same as that of the one-button version.

Typical breakdowns of a two-button tank:

- Button drop. To install the buttons in place, remove the cover by unscrewing the retaining ring near the button. Sometimes the buttons fall into place if you press them again.

- If the water does not drain, check the integrity of the connecting fittings. Replace it or replace it with a piece of copper wire.

- The flow of water through the drain valve indicates the wrong position of the valve relative to the drain hole. If water overflows through the overflow, adjust the water level by changing the position of the float or the height of the overflow.

And if you are interested in how to install a shower cabin with your own hands, then we also have material on this topic.

Before buying a water filter, we recommend that you familiarize yourself with our tips for choosing them.

How the drain mechanism works

By pressing the shutter button, the tank system starts to work. Such a device for draining equipment is in connection with its "stuffing" located in the container itself. Until the button is pressed, the tank is waiting. It already has water that runs up to the set level. With the help of a special pear, the liquid is held in the tank. It is made of rubber material, therefore it always fits tightly enough to the saddle. By pressing the button, a pull is produced, which in turn pushes the bulb to open the drain. As a result, the saddle will not clog, liquid will enter the opening of the tank and flow out into the toilet.

Toilet bowl with a button on the cistern lid

After the operation of releasing the button located on the tank lid, the pear does not immediately return to its original position. Otherwise, this would have affected the fact that the drain was short-lived. In the right device, this is the process of slowly lowering the pear, completely hollow inside. There is only air in her, pushing her out of the saddle.

The lifting force of this component of the system becomes less by the degree of water intake into the tank. At the end, the pear is completely sucked to the saddle. Installation would not have brought a positive result without a special guide tube. The secret here is that various forces act on the rubber shutter, leading it in the direction of minimum resistance. If there was no pipe in the design, then this rubber element could not return again to the seat located in the center of the tank.

Internal organization

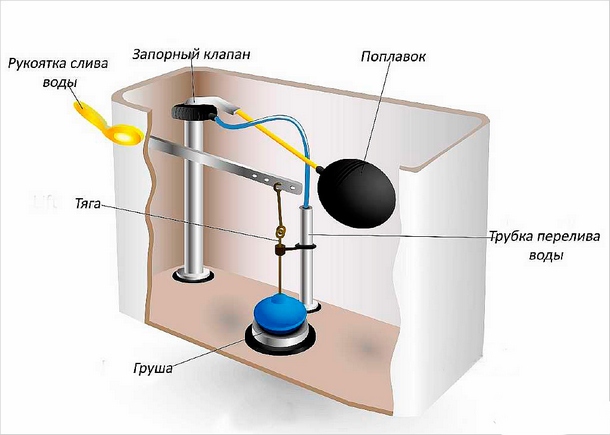

The toilet cistern consists of two simple systems: a set of water and its discharge. To troubleshoot possible problems, you need to understand how everything works and works. First, consider what parts the old-style toilet bowl consists of. Their system is more understandable and visual, and the operation of more modern devices will be clear by analogy.

The internal fittings of a tank of this type are very simple. The water supply system is an inlet valve with a float mechanism, the drain system is a lever and a pear with a drain valve inside. There is also an overflow pipe - through it excess water leaves the tank, bypassing the drain hole.

The device of the drain tank of the old design

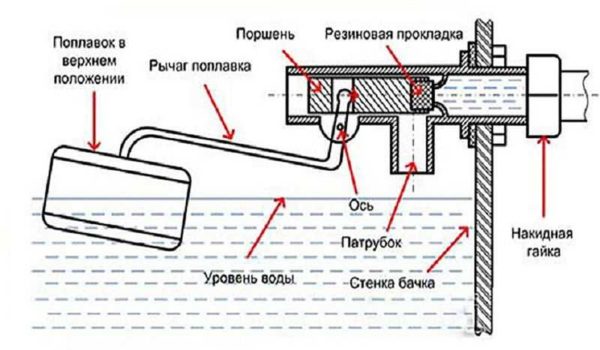

The main thing in this design is the correct operation of the water supply system. A more detailed diagram of its device is in the figure below. The inlet valve is connected to the float using a curved lever. This lever presses on the piston, which opens / closes the water supply.

When filling the tank, the float is in the lower position. Its lever does not put pressure on the piston and it is squeezed out by water pressure, opening the outlet to the pipe. Water is gradually drawn in. As the water level rises, the float rises. Gradually, he presses the piston, blocking the water supply.

The device of the float mechanism in the toilet bowl

The system is simple and quite effective, the filling level of the tank can be changed by bending the lever a little. The disadvantage of this system is a noticeable noise when filling.

Now let's look at how the drain of water in the tank works. In this embodiment, the drain hole is blocked by a pear of the drain valve. A chain is attached to the pear, which is connected to the drain lever. By pressing the lever, we raise the pear, the water drains into the hole. When the level drops, the float goes down, opening the water supply. This is how this type of cistern works.

Modern models with lever drain

They make less noise when filling the cistern for toilet bowls with a lower water supply. This is a more modern version of the device described above. Here the tap / inlet valve is hidden inside the tank - in a tube (in the photo - a gray tube to which the float is connected).

Drain tank with water supply from below

The mechanism of operation is the same - the float is lowered - the valve is open, water flows. The tank was filled, the float rose, the valve turned off the water. The drain system remained almost unchanged in this version - the same valve that rises when the lever is pressed. The water overflow system has hardly changed either - this is also a tube, but it is brought out into the same drain.

You can clearly see the operation of the drain tank of such a system in the video.

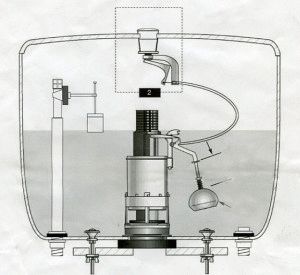

Models of toilet bowls with a button have similar water inlet fittings (some with side water supply, some with bottom) and drain fittings of a different type.

Tank device with push-button drain

The system shown in the photo is most often found in toilet bowls of domestic production. It is inexpensive and quite reliable. The device of imported units is different. They mainly have a bottom water supply and another drain-overflow device (pictured below).

Imported cistern fittings

There are different types of systems:

- with one button, water is drained as long as the button is pressed;

- with one button, draining starts when pressed, stops when pressed again;

- with two buttons that release different amounts of water.

The mechanism of operation here is slightly different, although the principle remains the same. In this fitting, when the button is pressed, a glass is raised that blocks the drain, while the stand remains motionless. In short, this is the difference. The drain is adjusted using a swivel nut or a special lever.

Toilet bowl design

Today, the building products market includes a variety of drain tanks, their difference lies in the source material, the working device of the parts, price and quality.

The principle of operation of all such structures is approximately the same, only the mechanism is different, which happens:

Toilet steer with one flush button

- with one flush button;

- with a pair of flush buttons;

- with a device that has two modes.

Relatively recently, a mechanism appeared on sale in which two buttons are included. This system can reduce water consumption. Using one button - all the liquid from the drain tank flows out, using the other button - only a part will merge. The flush procedure itself also looks different:

- Water enters the toilet bowl directly from the cistern, here the water moves in one direction.

- During flushing, water flows all the time in different directions. This drain is more efficient, but it produces a lot of noise.

In order not to make a mistake in choosing such a device, and in the future it is easy to assemble and repair, it is worth knowing its design. The mechanism of functioning of drain tanks is simple: its work begins with the collection of the required amount of water and its descent into the sewer through the toilet.

To some extent, the design resembles a conventional water seal, which includes a seal, levers and a float. By independently pressing a lever or a button on the lid, water flows out, while performing the most important tasks - eliminating waste products into the sewer.

Toilet bowl design

There are visible structural elements, these are:

The invisible part of the design includes:

- plug;

- float valve;

- drain valve.

Equipment installation

It is not difficult to buy stop valves in any plumbing store, but it would be better to install the branded components included in the kit. Thus, there is a greater likelihood of matching all components.

To install the drain tank with your own hands, you need the following tools:

- wrenches: adjustable and open-ended;

- bendable hose;

- screwdriver;

- plumbing system;

- gaskets of the right size;

- fuma made of rubber.

The instruction for the device of such equipment includes several stages. Initially, it is necessary to install the lower part of the drain assembly in the tank, the main thing is to make it a snug fit to the outlet opening. Install a rubber gasket between the bottom of the container and the base.Then install the tank on the toilet. A tight rubberized ring should be laid between them. This will prevent surfaces from touching. With the help of bolts, the construction of the set and descent should be screwed to the toilet.

If this is a drain tank device with a button with a lower water supply, then before the installation of the structure, it is necessary to correctly install the elements that will supply the liquid. In this system, rubber gaskets should be firmly fixed. They will help prevent leakage. In a structure placed on top, these elements will not be needed, since they are above the water level. After fixing the tank, you can install such nodes. The same method is used for these types of mounting. A tube is threaded into the opening of the tank and fastened on both sides with nuts.

The next step is to attach a bendable hose to the riser fitting, attaching a water tap, which allows, if necessary, to make repairs and shut off the water supply. Typically, hoses have nut and gasket elements in their design, which provide fastening strength. However, craftsmen most often build in a fuma for greater reliability. After the operation of connecting the tank to the water supply system, the float should be adjusted. The liquid level should be 15 cm below the edge of the tank.

At the last stage of installation, you will need to install the mechanism. The top reinforcement should be placed in the opening of the lid and attached with decorative elements covering the opening.

Main systems

The action of any tank is based on the functioning of the systems for collecting and draining water. The set is due to the operation of the intake system, which regulates the progressive filling. The inlet fitting, regardless of the type of drain equipment, is of the same type and consists of a float that allows you to adjust the intensity of filling the system with water.

In the process of draining water, another valve is involved, which allows you to control this process. This design is varied. Certain positions of the outlet fittings make it possible to use a dual-mode and emergency drain.

One button

You can see a diagram of a toilet cistern with a button in this illustration:

A plastic or metal float controls the opening of the ball valve. which allows water to enter the tank. The volume of incoming water is controlled by a diaphragm, which is equipped with a special lever device that regulates the pressure of the water jet.

The drain is regulated by means of a siphon. the location of which is the central part. To fix the siphon to the outlet system, a special gasket is used - the “saddle”. A drain button is fixed on top of the entire structure.

The standard siphon can be provided with a detachable design, which allows you to perform the cleaning process only on the upper part. and the lower part is simply washed.

With two buttons

The device of a drain tank with two buttons differs in the high level of profitability. Water consumption is reduced due to the possibility to provide a minimum drain or completely empty the volume.

An illiterate installation provokes the operation of two buttons as one, with the same volume of drain. A properly installed mechanism is characterized by a small drain at the level of 2-4 liters, and about 6-8 liters of water are spent on a large drain.

The difference from the design of the toilet cistern with one button lies solely in the design of the outlet valve.

It is impractical to install such fittings on small devices. If replacement is necessary, any hydraulic system of a suitable size can be used.

The principle of operation of the drain mechanism

The operation of this mechanism begins with pressing a button that is associated with the internal elements of the drain system. Up to this point, the tank is already filled with water to a regulated level and the entire volume is held by a rubber bulb. Such material contributes to a fairly tight fit to the saddle. Pressing the button causes a pull that repels the bag. from which the drain hole opens.

After returning the button to its original position, the hollow and air-filled pear does not immediately return to its place. As it fills with water, the pear becomes heavier, lowers and fits snugly on the saddle. However, for the full functioning of the pear, a special pipe is important, which regulates the action of various forces on this rubber element.

After choosing and installing a toilet, certain questions may arise, such as why water does not enter the toilet bowl or how to fix a leak in the toilet bowl. Read the answers to these questions in the following articles.

How to fix a toilet flush tank with a button, learn from this material.

What is the result

As you can see, in the design of a modern car, increased requirements are put forward for the engine cooling system and its correct operation. For this reason, a special tank is additionally used in the design for effective functioning.

You also need to know if the specified expansion tank of the engine cooling system is involved in the circuit, that it is highly desirable to fill the system with only antifreeze or antifreeze, and not water

As for breakdowns, if pressure builds up in the cooling system or air pockets form, special attention must be paid to the cover of the expansion tank . ), the engine may overheat, etc.

Violation of the valves in the cover often leads to the fact that the pipes are damaged, the thermostat fails faster, the cooling system pump (pump) suffers, the engine may overheat, etc.