Manufacturing Recommendations

It follows from the previous section that it will not be possible to get rid of an ordinary barrel of 200 liters, unless its capacity is not less than half a cube. This is enough for a house of 30 m2, and then not for long. In order not to waste time and energy in vain, it is necessary to

From the point of view of placement in the boiler room, it is better to make a rectangular container. Dimensions are arbitrary, the main thing is that their product is equal to the calculated volume. The ideal option is a stainless steel tank, but ordinary metal will do.

At the top and bottom, a do-it-yourself heat accumulator must be provided with nozzles for connecting to the system. To prevent the steel walls from bulging outward with water pressure, the structure must be stiffened with ribs or jumpers.

The battery tank must be well insulated, including from below. For this purpose, foam with a density of 15-25 kg / m3 or mineral wool in slabs of at least 105 kg / m3 of density is suitable. The optimal thickness of the heat-insulating layer is 100 mm. The resulting apparatus filled with coolant will have a decent weight, so a foundation will be required for its installation.

Advice. If a container is required for a gravity heating system, then it should be install by hand on a metal stand, not forgetting to insulate the lower part. The goal is to raise the tank above the level of the batteries.

Advantages and disadvantages of TA

TA dimensions are impressive

Let's start with the benefits of using a hot water and heating storage tank:

- temperature stability in the circuit;

- fuel economy;

- reduction in the number of fuel loadings into the boiler;

- the heater fully realizes its power potential;

- the possibility of saving if an electric boiler acts as a heater;

- simultaneous heating of the heat carrier in the heating circuit and hot water.

There is nothing that does not have its shortcomings. Same with heat sinks.

- take up a lot of space;

- are expensive;

- need a more powerful boiler.

Everyone understands that every business must be done well and efficiently, preferably adhering to all the rules. In practice, unfortunately, this is not always possible. Here you need to count the money, because everything always rests on them. The use of buffer tanks really helps to reduce fuel costs and stabilize the temperature in the circuit. At the same time, initially you will need to buy a boiler twice as powerful, which, of course, is more expensive, and buy the heat accumulator itself, which is also not cheap. You can make purchases gradually, first make a circuit without a storage tank, and then buy it over time if the desire does not disappear. In this case, it will be necessary to slightly correct the layout of the heating pipes.

Interesting on the topic:

- High radiators for heating system

- How to make a long burning stove

- Painting heating pipes

- Antifreeze and cooling liquids for heating.

Heat accumulator calculation

A container for the accumulation of thermal energy can be either purchased ready-made or made independently. But a natural question arises: what capacity should the tank be? After all, a small tank will not give the desired effect, and too much will cost a pretty penny. The answer to this question will help to find the calculation of the heat accumulator, but first you need to determine the initial parameters for the calculations:

- heat loss of the house or its quadrature;

- duration of inactivity of the main heat source.

Let us determine the capacity of the storage tank using the example of a standard house with an area of 100 m2, which requires an amount of heat of 10 kW to heat. Assume that the net idle time of the boiler is 6 hours, the average temperature of the heat carrier in the system is 60 °C.Logically, during the period of time while the heating unit is idle, the battery must supply 10 kW to the system every hour, for a total of 10 x 6 = 60 kW. This is the amount of energy that should be accumulated.

Since the temperature in the tank should be as high as possible, for calculations we will take a value of 90 ° C, domestic boilers are still unable to do more. The required capacity of the heat accumulator, expressed in mass of water, is calculated as follows:

- Q is the amount of accumulated thermal energy, in our case it is 60 kW;

- 0.0012 kW / kg ºС is the specific heat capacity of water, in more familiar units of measurement - 4.187 kJ / kg ºС;

- Δt is the difference between the maximum temperature of the coolant in the tank and the heating system, ºС.

So, the water accumulator should contain 60 / 0.0012 (90 - 60) = 1667 kg of water, which is approximately 1.7 m3 in volume. But there is one point: the calculation is made at the lowest temperature outside, which happens infrequently, excluding the northern regions. In addition, after 6 hours, the water in the tank will cool down only to 60 ºС, which means that in the absence of cold weather, the battery can be “discharged” further until the temperature drops to 40 ºС. Hence the conclusion: for a house with an area of 100 m2, a storage tank with a volume of 1.5 m3 is enough if the boiler is inactive for 6 hours.

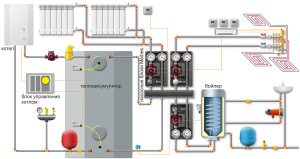

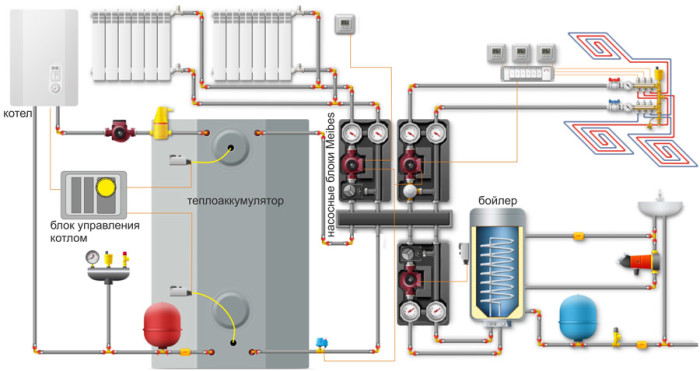

Storage tank installation

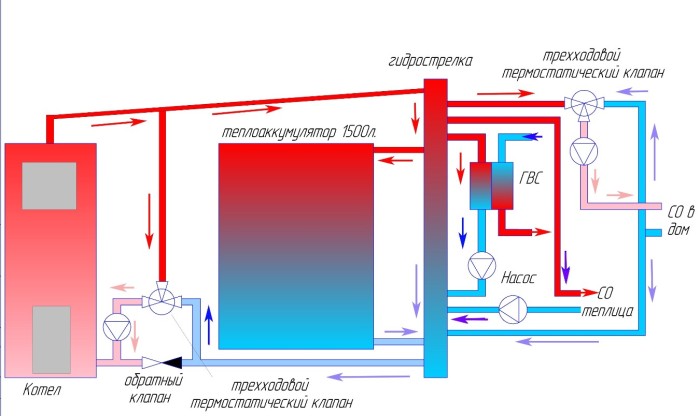

Scheme of connecting a heat accumulator to a heating system

The tank is installed in front of the heating radiators. The best option is to connect the inlet pipe immediately after the boiler. According to this scheme, the heating of water in it will be carried out as quickly as possible.

- Shut-off valves on all branch pipes;

- Manometers and thermometers. Temperature sensors should indicate the degree of heating of water in the tank and the coolant;

- Sets of 2-way valves for mixing heated water and coolant from the return pipe, so you can minimize energy costs.

Maintenance of the storage tank must be done before each heating season. It is best to disassemble it completely to remove scale and check the condition of the structure. If this is not possible, washing with special solutions is done.

The video material describes the advantage of using a storage tank for an autonomous heating system:

Thanks to the author for an interesting article. I myself learned about heat accumulators after buying a solid fuel boiler, I had to buy more and put it into a ready-made system. I took a barrel of the Termiko trademark, made in Ukraine. So far, the impressions are purely positive. Firewood consumption has decreased by 25 percent, the boiler after loading gives heat for another 6 hours. In general, it has become much more convenient to heat the house. In general, I advise you to immediately look in the direction of buffer tanks when buying.

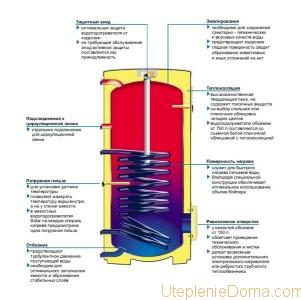

The design of the storage tank for heating

Sectional view of an accumulator tank for heating

Now let's take a closer look at the design of the heat accumulator. If the tank is intended only for the heating circuit, then its design is quite simple:

- sealed housing;

- insulation layer;

- branch pipe in the upper part for supply;

- return pipe at the bottom.

Nothing else is required, but if it is necessary for the storage tank for heating to also heat water for household needs, then a copper coil and, of course, two branch pipes (inlet / outlet) are built into the tank body. Cold water is connected to the inlet pipe. It passes through the coil and heats up from the coolant that is in the buffer tank. Already heated water comes out of the tank, which is supplied to the bathroom and kitchen faucets. At the same time, it depends on the length of the copper coil how long the water will stay inside the TA and, accordingly, how much it will heat up.

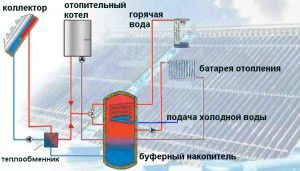

The HE design can have not only several heat transfer circuits, but also several heating sources.So, the heating of the coolant in the tank can be carried out in several ways:

- from the heater;

- from electric heaters.

Electric heaters can be fed directly into the network and turn on when necessary. Also, modern buffer tanks for heating accumulators are equipped with a heating element connected to solar panels, which allows you to use free solar energy.

As always, craftsmen are interested in whether it is possible to make a battery tank for heating with their own hands. Of course, you can if your hands are in place, but it’s impossible to say that it’s very simple.

What you need to pay attention to:

- the top of the tank should not be flat, otherwise it will squeeze out with pressure;

- the supply and return pipes must be in the right planes;

- the whole structure is absolutely sealed;

- metal about 5 mm thick.

Below in the video you can see how one of the craftsmen made a storage tank for heating with his own hands from a barrel.

Battery buffer volume

Let's figure out how much heat storage should be. There are different opinions, which are based on the calculation based on:

- area of the premises;

- boiler power.

Let's take a look at each of them. If you start from the area of \u200b\u200bthe room, then there can be no exact recommendations. Since there are many factors that affect the battery life of the system without a boiler, the main of which is the heat loss of the room. The better the house is insulated, the longer the buffer tank will be able to provide housing with heat.

An approximate calculation, based on the area of \u200b\u200bthe room, is that the volume of the heat accumulator should be four times the number of square meters. For example, a house with an area of 200 square meters is suitable for a TA with a volume of 800 liters.

Of course, the larger the tank, the better, but in order to heat a larger amount of coolant, more heater power is needed. The calculation of the boiler power is made based on the heated area. One kilowatt heats ten meters. You can also put a five-ton tank, only if the boiler does not pull such volumes, there will be no point in installing such a large heat accumulator. So, you need to make adjustments to the calculation of the power of the boiler itself.

It turns out that, perhaps, it is more correct to make a calculation based on the power of the boiler. Let's take for example the same house of 200 sq. m. An approximate calculation of the volume of the buffer tank is as follows - one kilowatt of energy heats up 25 liters of coolant. That is, if there is a heater with a power of 20 W, then the volume of the TA should be about 500 liters, which is clearly not enough for such housing.

Based on the results of the calculations, we can conclude that if you are going to install a heat accumulator, then you need to take this into account when selecting the boiler power and take not one, but two kilowatts per ten meters of heated area. Only then will the system be balanced. The volume of TA also affects the calculation of the capacity of the expander. The expansion tank is an expansion tank that compensates for the thermal expansion of the coolant. To calculate its volume, you need to take the total volume of the coolant in the circuit, including the capacity of the buffer tank, and divide by ten.

Design features of the heat accumulator

The main element of any TA is a thermal storage material with a high heat capacity.

Depending on the type of material used, heat accumulators for a boiler can be:

- solid state;

- liquid;

- steam;

- thermochemical;

- with an additional heating element, etc.

For heating and hot water supply of private houses, hot water storage tanks are used, where it is water with a high specific heat capacity that acts as a thermal storage element.

Instead of water, antifreeze is sometimes used. designed for home heating systems.

An example of a water heater with an additional electric heating element for a hot water supply system is a modern storage water heater.

A conventional thermal energy accumulator is a sealed metal tank of various volumes (from 200 to 5000 liters or more), as a rule, of a cylindrical shape, enclosed in an outer shell (case).

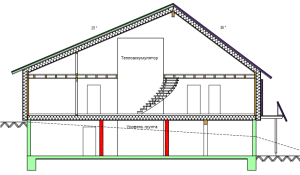

Between the tank and the outer shell there is an insulating layer of heat-insulating material.

In the upper and lower parts of the tank there are two branch pipes for connecting to the heating boiler and to the heating system itself.

At the bottom there is usually a drain valve for draining the liquid, and at the top there is a safety valve for automatic bleeding of air when the pressure inside the buffer tank rises. There may also be flanges for connecting pressure and temperature sensors (thermometer).

Sometimes one or more additional heaters of various types can be installed inside the buffer tank:

- electric heater (TEN);

- and / or a heat exchanger (coil) connected to additional heat sources (solar collectors, heat pumps, etc.).

The main task of these heaters is to maintain the required heating temperature of the working fluid inside the HE.

Also, a DHW heat exchanger can be located inside the tank, which provides hot water by heating it with the working fluid of the heating system.

The principle of operation of the storage tank

Heating circuit with a heat accumulator

The principle of operation of TA for a solid fuel boiler is based on the high specific capacity of the working fluid (water or antifreeze). By connecting the tank, the volume of liquid increases several times, as a result of which the inertia of the system increases.

At the same time, the coolant heated to the maximum by the boiler retains its temperature in the HE for a long time, flowing as necessary to the heating devices.

This ensures continuous operation of the heating system even when the combustion of fuel in the boiler stops.

Consider the operation of a system with a solid fuel boiler and forced supply of coolant.

To start the system, the circulation pump installed in the pipeline between the boiler and the heat accumulator is turned on.

The cold working fluid from the lower part of the HE is fed into the boiler, heated in it, and enters its upper part.

Due to the fact that the specific gravity of hot water is less, it practically does not mix with cold water and remains in the upper part of the buffer tank, gradually filling its internal space due to cold water being pumped into the boiler.

When the circulation pump installed in the return line of the system between the heating devices and the storage tank is turned on, the cold coolant begins to flow into the lower part of the HE, displacing hot water from its upper part into the supply line.

In this case, the hot working fluid flows to all heating devices.

The required amount of heat for space heating can be automatically regulated by a room temperature sensor that controls the operation of a three-way valve installed at the TA outlet in the supply line. When the set temperature in the room is reached, the sensor sends a control signal to the valve, which is triggered and limits the supply of hot coolant to the system, redirecting it back to the heat exchanger.

After the combustion of fuel in the boiler, the hot coolant from the storage tank continues to flow into the system as needed until the cooled working fluid from the return line completely fills its internal volume.

DHW scheme with storage tank

The operating time of the TA when the boiler is not working can be quite a long time.It depends on the outdoor temperature, the volume of the buffer tank and the number of heaters in the heating system.

To preserve heat inside the heat accumulator, the tank is thermally insulated.

Also, additional heat sources can be used for this in the form of built-in electric heaters (heaters) and / or heat carriers (coils) connected to other heat sources (electric and gas boilers, solar collector, etc.).

The DHW coolant built into the tank provides heating of cold water supplied through it from the plumbing system. Thus, it plays the role of a flowing water heater, providing the needs of the owners of the house for hot water.

When you need a heat accumulator

This simple element of the heating system in the form of an insulated water tank is recommended to be installed in such cases:

- for the most efficient operation of a solid fuel boiler;

- together with an electric heat generator operating at a reduced night rate.

For reference. There are also water heat accumulators for greenhouses, used to store solar energy received during the day.

The operation of solid fuel boilers has its own characteristics. The heat generator operates with high efficiency only when operating at maximum modes, if you shut off the air to lower the temperature in the furnace, then the efficiency also decreases. The homeowner also has a lot of worries about the frequency of burning, the firewood has burned out - it is necessary to load new ones, it is extremely inconvenient to do this in the middle of the night. The solution is simple: you need a storage tank that accumulates the heat generated earlier to use it after the firewood burns out in the firebox.

The opposite situation occurs with an electric boiler connected to the network through a multi-tariff meter. To save money, you need to get maximum heat at night, when the tariff is low, and do not use electricity during the day. And here the heat accumulator in the heating system will allow you to organize the optimal schedule for the operation of the heat source, giving out hot water to the system while the heat generator is idle.

Important. To work together with a heat accumulator, the boiler must have at least one and a half reserves in terms of thermal power

Otherwise, he will not be able to simultaneously heat the water in the heating system and the storage tank.

A similar situation with excess heat occurs in greenhouses, in the daytime they are even ventilated. In order to accumulate solar energy for use at night, you can use the simplest heat accumulator of Lezhebok to heat the ground. This is a black polymer sleeve filled with water and laid directly on the bed, it does not allow the soil to cool at night. To absorb more heat, black-colored water barrels are placed inside the greenhouse.

How does the heat accumulator work in the system

Connection scheme: the pipe leading from the boiler is connected to the nozzle in the upper part of the tank, and the return pipe with the circulation pump is connected to the lower inlet.

After the boiler is ignited, the pump selects a cold coolant from the bottom of the tank and delivers it to the boiler. The heated water from the boiler moves to the top of the tank. The process lasts until the entire volume of water is completely heated, only hot water enters the system.

As soon as the temperature exceeds the set parameters, the pump turns off. After the boiler is turned off, when the air or water temperature drops, the automatic control turns on the pump, which supplies the hot coolant from the accumulator along the circuit.

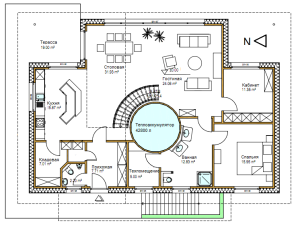

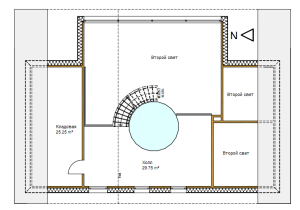

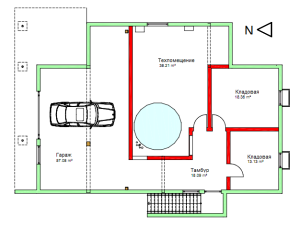

Usually, the entire heating system is located in the basement of the house.

Shutdown, switching on continues until the temperature inside the tank exceeds the temperature inside the circuit.

Tying a solid fuel boiler with a heat accumulator by the method of collector connection to the input, output of the drive has advantages: you can turn on each device for heating separately.

Advantages and disadvantages of buffer capacity

Boiler buffer tank

The main advantages of a heating system with a heat accumulator include:

- the maximum possible increase in the efficiency of a solid fuel boiler and the entire system while saving energy resources;

- ensuring protection of the boiler and other equipment from overheating;

- ease of use of the boiler, allowing it to be loaded at any time;

- automation of the boiler operation through the use of temperature sensors;

- the ability to connect several different heat sources to the HE (for example, two boilers of various types), ensuring their integration into one heating system circuit;

- ensuring a stable temperature in all rooms of the house;

- the possibility of providing domestic hot water without the use of additional water heating devices.

The disadvantages of heat accumulators for the heating system include:

- increased inertia of the system (much more time passes from the moment the boiler is ignited until the system enters the operating mode);

- the need to install TA near the heating boiler, for which a separate room of the required area is required in the house;

- large dimensions and weight, causing the complexity of its transportation and installation;

- a rather high cost of industrially produced HE (in some cases, its price, depending on the parameters, may exceed the cost of the boiler itself).

An interesting solution: a heat accumulator in the interior of the house.

In the interior

The use of a heat accumulator is economically beneficial not only for solid fuel boilers, but also for electric or gas heating systems.

In the case of an electric boiler. TA turns on at full capacity at night, when electricity tariffs are much lower. During the day, when the boiler is turned off, the space is heated using the heat accumulated during the night.

For gas boilers, savings are achieved through the alternate use of the boiler itself and TA. At the same time, the gas burner turns on much less frequently, which ensures less gas consumption.

It is undesirable to install a heat accumulator in heating systems where fast and or short-term heating of the room is required, since this will be hampered by the increased inertia of the system.

3 comments

Instead of the heat accumulators indicated in the article, it is possible to successfully use storage water heaters with a capacity of 200 liters or more, connected in parallel. Heat accumulators are connected to the heating boiler after regular heating of the house and (or) the threat of overheating of the boiler. It is much cheaper than the options offered. In addition, heating elements of water heaters can be used during a break in the operation of the boiler, for example, at night. This is beneficial with a multi-tariff meter. The only thing is that when using ethylene or propylene-glycol as a coolant, the magnesium rod installed to soften the water must be removed from the water heaters. Such a system has been working for me for four years, allowing even in winter to heat a solid fuel boiler once a day. In severe frosts (from -27) twice a day. Three storage water heaters with a capacity of 200 liters each serve as a heat accumulator. Each water heater cost me 9700.

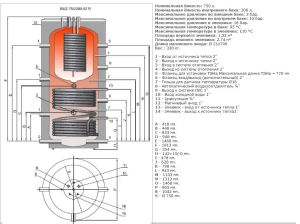

How to choose the right model

Without a buffer tank, the coolant temperature drops immediately after the boiler is switched off. The main criterion for selecting a model is the calculation of a heat accumulator. The formula applied is:

m is the mass of the coolant,

Cp is the heat capacity of the coolant,

T2 is the average end temperature of the water in the tank,

T1 is the average initial temperature.

The specialists of the water and heat supply company will help to accurately calculate the volume and other parameters, or you need to independently set the outgoing indicators on the online calculator, get the recommended data

Take into account the power of the boiler.pressure inside the system, number of radiators, cross-section and diameter of pipes, type and volume of coolant

The accumulating capacity is selected taking into account the following factors: construction material, volume, device power, coolant pressure in the system, functionality. Manufacturers offer heat accumulators, the walls of which are made of black, carbon steel, or stainless steel. They are resistant to corrosion, pollution, require less cleaning, and work for a long time.

- The heat accumulator of the EAB series made of black carbon steel with an internal food-grade stainless steel boiler is designed for a system operating at a pressure exceeding 0.3 MPa. Included are heat exchangers of a simple or block type. It has a magnesium anode that protects against scale. Suitable for additional connection of solar collectors. Used for continuous heating.

- Heat accumulator for heating EA - a device with and without heat exchangers. Material - steel, painted on the outside, thermal insulation is made of artificial blue or red leather. Additionally, you can connect the drive to the solar battery. Models are designed for heating running water, as well as circulating the coolant through the system from the tank.

- A heat accumulator for heating of the EAI type is used when connecting two or more heat sources, with a capacity of 350 - 3500 liters.

The modern heat accumulator has antibacterial protection, is designed for retrofitting Tenami, connecting block heat exchangers.

For a system with a pressure inside of which is more than 4 bar, choose a tank with thicker walls and toroidal tight lids.

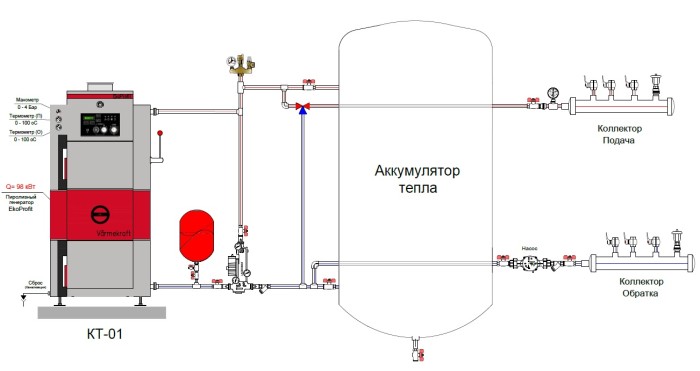

Tank Volume Calculation

How to calculate the volume of a heat accumulator

The main parameter when buying a buffer tank for a solid fuel boiler, as well as for self-manufacturing the device, is the capacity of the heat accumulator, which directly depends on the power of the heating boiler.

There are various calculation methods based on determining the ability of a solid fuel boiler to heat the required volume of working fluid to a temperature of at least 40 ° C during the combustion of one full load of fuel (approximately 2-3.5 hours).

Compliance with this condition allows you to get the maximum efficiency of the boiler with maximum fuel economy.

The simplest calculation method provides that one kilowatt of boiler power must correspond to at least 25 liters of the volume of the buffer tank connected to it.

Thus, with a boiler power of 15 kW, the capacity of the storage tank must be at least: 15 * 25 \u003d 375 liters. At the same time, it is better to choose a container with a margin, in this case - 400-500l.

There is also such a version: the larger the tank capacity, the more efficient the heating system will work and the more fuel will be saved. However, this version imposes limitations: the search for free space in the house for the installation of a large heat accumulator, as well as the technical capabilities of the heating boiler itself.

The volumes of the coolant tank have an upper limit: no more than 50 liters per 1 kW. Thus, the maximum volume of the storage tank with a boiler power of 15 kW should not exceed: 15 * 50 \u003d 750 liters.

It is obvious that the use of 1000 liters or more TA for a 10 kW boiler will cause additional fuel consumption to heat such a volume of working fluid to the desired temperature.

This will lead to a significant increase in the inertia of the entire heating system.

To provide a home boiler room with environmentally friendly fuel, we recommend learning how to make fuel briquettes with your own hands.

Solid fuel boilers are more difficult to switch to automatic operation. Such "smart" electrical devices as the GSM module help to make the heating system more or less self-regulating. Go to description .

Creation and connection

You can easily make such a device with your own hands - for this it is enough to have a welding machine at hand and be able to use it. All operations must be performed in a certain sequence:

- calculate the volume of the container;

- make a well-insulated tank - for this you can use either sheet metal or ordinary pipes of large diameter; the resulting container must be completely sealed;

- at the top and at the bottom of the tank, two pipes should be cut in - these will be the supply and return pipelines;

- at the top of the heat accumulator tank, at least two couplings with a diameter of 1.5 inches are welded;

- they mount a thermometer, as well as an explosive valve, in the couplings with their own hands;

- with a stationary pipeline, the explosion valve is connected to the drainage channel;

- the tank must be thermally insulated - for this, construction foam is used.

In this case, the calculation of the volume of the container and its thickness should be carried out before the start of all work on the manufacture of the device.

Connection methods

The technology for installing a heat accumulator at home depends on the type of water circulation in the system. With the gravitational method, the equipment is mounted in the system as close as possible to the boiler. In the case of forced circulation using a pump, the tank is also placed at the maximum distance from the boiler.

At the same time, for work, you will need a well-thought-out, drawn scheme and maintaining the temperature in the room to install the container within 10-35 ° C. In addition, free access to the nozzles should be provided so that repairs and preventive work can then be carried out.

The heat accumulator, designed for insertion into the boiler, is installed directly in the boiler room - it should not be higher than the boiler itself.

Special care must be taken when a homemade heat accumulator is mounted - it can be poorly treated with mounting foam

Nuances of use

The question is natural - why do we need a thermal accumulator, if the heating system is already doing a good job with the task? That is why it is worthwhile to carefully analyze all cases where the use of such a device is justified.

Connection

It does not matter whether the solid fuel boiler is equipped with a water circuit or not, in the optimal mode, the fuel burns out, forming as few residues as possible, not only ash, but also acids with tar. The power in such systems is regulated by limiting the access of oxygen to the furnace.

However, it is not possible to use up all the heat released during the combustion of solid fuel - otherwise the radiators will get very hot, and the pipes will wear out quickly.

At the same time, the use of a heat accumulator for the operation of a solid fuel boiler provides the following opportunities: sending the heat generated by the boiler to the heat accumulator tank and circulating warm water in the system after complete combustion of the fuel in the boiler.

Application in electric boilers

When an electric boiler is installed at home, the installation of a heat accumulator to it is effective in reducing the tariff for electricity consumption (two-tariff meter) at night. It is necessary to program the boiler timer to turn on at night, and it will heat the additional battery capacity, and during the day the received thermal energy will heat the house.

Such a simple scheme for using a heat accumulator and an electric boiler in combination can significantly reduce energy costs.

What is distilled water

Distillate or distilled water is a liquid without impurities. Such a substance is pure water, which does not contain salt, minerals and impurities. Due to this, such a liquid is not capable of conducting electric current and is a dielectric.

Distilled water is added to the battery because it is initially contained there along with some sulfuric acid.Acid acts as a conductor, and water simply dilutes it to the required concentration. Collectively, these fluids constitute an electrolyte.

But water during the operation of the battery tends to evaporate and its percentage in relation to the acid decreases. As a result, the density of the electrolyte increases. That is why motorists quite often independently replenish the level of distillate content in the battery.

Buffer tank for heating

Buffer tank in the heating system

It is a barrel, inside of which there is a coil - it is connected to the heating main. Its material is copper or steel. Energy from the coolant through the surface of the coil is transferred to the water in the tank.

Design specifics

At first glance, the storage tank for heating does not have any particular advantages. However, with a deep analysis, it turns out that the relevance of its installation in an autonomous network is an indisputable factor. What is the function of this structure?

- Transfer of thermal energy to water, which can be used for hot water supply;

- Increasing the duration of heating operation even when the boiler is turned off. To do this, one of the pairs of pipes is connected to the system through two or three-way valves. In this case, the buffer tank of the heating system will mix the cooled coolant with hot water stored in it;

- The use of heated water for low-temperature heating circuits - a water heated floor.

Such possibilities are explained by the design features. All factory buffer tanks for heating have additional insulation circuits. That minimizes the heat transfer of heated water. Also, the pipes have different diameters for switching with heating circuits.

When choosing a factory model of the heating system capacity (buffer, storage or storage), you need to pay attention to the number of nozzles - from 2 to several tens. Their optimal number depends on the circuits in the system.

Buffer capacity calculation

Sectional storage tank

Any capacity of the heating system, first of all, is characterized by volume. To calculate it, it is recommended to use special programs. If this is not possible, you can make approximate calculations yourself. The heat capacity of water is 4.187 kJ/kg*C. If the heating system has a rated output of 24 kWh, then the heating storage tank must keep the system running for 4-8 hours after the boiler is turned off. It is necessary to calculate the volume for the hourly heating operation. In this case, the temperature difference should be 70-45=25°C. Knowing that 1 kWh is 3600 kJ, we can calculate the capacity:

(24*3600)/(4.187*25)=825 kg or 0.825 m³

This is only an approximate calculation scheme, since each capacity of a heating radiator has a number of additional characteristics - heat loss, temperature and humidity in the room, type of heating (gravitational or forced circulation).

What should be considered when choosing a buffer tank for a heating system?

- Its useful volume;

- The area of the heat exchange element;

- Type of heat exchanger - coil or tank in tank. The latter is preferable, since such a design increases the area of \u200b\u200bheating water in the tank.

The price of a storage tank for heating is high - the simplest model for 800 costs from 35 thousand rubles. so they often try to do it themselves.

For heating a small private house, installing a tank of less than 500 liters is unprofitable. It will not be able to accumulate the required amount of thermal energy.