Connection

If the choice fell on heating with underfloor heating, then you will have to make the correct connection to the radiators. A significant investment will be required, which will be directed to piping a solid fuel boiler. In this case, buffer capacity is simply indispensable. The main reason is that it is quite difficult to heat the water floor to the required temperature with the help of firewood, because we are talking about maintaining the temperature inside the system. Such a system needs timely heat release, otherwise the existing water jacket may overheat and even boil.

It is very problematic to heat the coolant to 40°C with solid fuel, since its operating temperature is about 55°C. If the temperature drops, this will lead to the formation of condensation, which over time will make holes in the metal walls. Even if a cast iron boiler is used, this will not help to avoid possible corrosion. In the presence of condensate, a characteristic coating begins to form, which does not allow the fuel to be burned efficiently. To maintain the efficiency of the entire system, the installation of a heat accumulator is necessary.

Types of boilers

All boilers are divided into two types:

- Dual products.

- One piece products.

Double-circuit devices are capable of performing several tasks: heating water and heating. Water heating occurs due to the fact that such a boiler is equipped with a storage boiler. And some models are equipped with a supply heat exchanger instead of a boiler, which also provides water heating.

Single circuit devices. In the heating system, such boilers only heat the coolant, that is, with their help, you can only heat the house. But in order for them to provide water heating, then you need to additionally purchase it: boilers, mixing units and many other devices. Only in this case it will be possible to connect a warm floor.

According to the type of installation, boilers are divided into two categories:

- Suspension-type equipment, the power of which reaches up to thirty-five kilowatts.

- Floor type boilers, their power is up to one hundred and twenty kilowatts.

Among these two types, suspended models are the most popular, because they require much less cost and are easy to install. Wall-mounted boilers are equipped with a circulation pump and other devices that are necessary for a boiler room. In order for such equipment to be put into operation, all that needs to be done is to attach pipes to it through which hot water will pass and connect the heating pipeline. Models that are equipped with a storage boiler are ready-made small boiler rooms from which water for the batteries will be heated.

If you are interested in which boiler is better to choose and how to connect a warm floor, you first need to find out what types of such equipment exist. To install a warm water floor system in the house, which will be heated from the boiler, you can consider the following types of automatic heating devices:

Electric water heating equipment.

- The boiler is single-circuit gas.

- Double-circuit gas equipment.

To heat the water floor, you can choose any of these types, but there is an important condition here - the operation of such equipment must be automated. Most often choose electric or gas 2-circuit equipment

However, if we take into account that the price of energy carriers is constantly increasing, then installing a gas boiler is much more profitable from an economic point of view.However, in order to make a water-heated floor connected to such equipment, it is necessary to foresee a separate room in advance, and also equip a good ventilation system.

In addition, a collector can be installed in a separate boiler room. A gas 2-circuit unit will be able to warm the air well, plus it will provide the house with hot water. However, its installation for a warm water floor must be carried out in compliance with a number of important rules. Such work should be carried out by employees of the gas service, but the independent installation of gas equipment will be considered illegitimate and will not meet accepted standards.

Installing an electric boiler, unlike a gas boiler, is not particularly difficult and can be done independently. Such heating equipment is environmentally friendly, which cannot be said about other types of boilers, moreover, the scheme for connecting a warm floor to such a boiler does not require special knowledge. However, this unit has one big disadvantage - the high price of electricity, which is constantly growing. Electric heaters can be installed both in private houses and in city apartments.

The diesel unit for the "warm floor" system is most suitable for installation in cottages. The installation of such equipment is not very difficult, the scheme of their installation is quite simple. Diesel models are unpretentious in operation, however, in order to maintain their smooth functioning, they need to be constantly monitored.

Solid fuel heating units are also suitable for country houses. For their work, coal briquettes are used. As for the power of solid fuel boilers, it, like the efficiency (efficiency), is very high. In houses with heating radiators, a solid fuel unit is considered the best option.

It doesn’t matter which of these boilers you choose, before buying it, you need to calculate its power, you also need to correctly find the place where the underfloor heating will be connected, and purchase additional devices, such as a storage boiler, etc.

How to choose a solid fuel boiler for underfloor heating

Heading to the store for a solid fuel boiler, most people have no idea what exactly to look for. They rely on sellers, who often act in their own interests.

Let's consider the issue of choice more carefully. The main criteria for a solid fuel boiler are parameters such as:

- Power.

- Power regulator.

- Energy dependence.

- Water heating method.

Let's consider each of them in more detail.

When calculating the power, they take into account how well the room is insulated, as well as its area. On each boiler, the manufacturer indicates the volume that can be heated by the boiler, in the absence of heat loss.

Otherwise, they buy a solid fuel boiler with a capacity of 24% more than necessary.

Manufacturers produce boilers with and without a power regulator. It can operate automatically or manually. The first option is more economical.

The use of energy dependence in the device of a solid fuel boiler increases its productivity, but makes the boiler dependent on electricity and reduces the level of autonomy.

Not the last role is played by the method of heating water. When a device is required not only for heating the house, but also for supplying hot water, then a double-circuit boiler is chosen, since it heats water in flow mode. If a drive is needed, a buffer capacity is installed.

Safety requirements

Safety requirements for the operation of gas equipment are almost the same for all types of boilers.

Basic provisions

:

- a separate room is required to accommodate a gas boiler;

- the boiler room must be equipped with a gas analyzer so that when gas accumulates (for example, when the burner spontaneously goes out), it will be notified in time;

- there should be no foreign objects in the boiler room, especially flammable ones - paints, solvents, chemicals, etc.;

- the boiler must be free for air flow, it is forbidden to lean or lean anything against it;

- if you smell gas, immediately shut off the supply, inform the gas service and ventilate the room. When using propane-butane, ventilation may be useless, since it is heavier than air and accumulates below;

- it is forbidden to repair the boiler safety sensors by yourself.

The requirements are simple, but they must be strictly observed in order to avoid dangerous consequences.

Do-it-yourself installation and connection of the boiler

A long-burning solid fuel boiler is sometimes mounted with your own hands, for this it is worth adhering to a certain order:

- Perform preparation. Drawings and diagrams are checked. The future premises are chosen, the concrete platform is poured on which the equipment is mounted.

- Establish communications.

- Perform binding. The most labor-intensive stage of work. All communications are connected. If the model is double-circuit, the return line for water heating is connected. Next, a string is made for additional equipment, for example, a buffer tank. If necessary, a draft regulator is installed.

- Mount a brick chimney or other exhaust combustion element.

- Check the chimney and chimney.

- Carry out final preparatory work.

- Perform system startup.

That's all, the Palych (or any other) solid fuel long-burning boiler is installed with your own hands and ready to go. The first launch is performed on the street. It also undergoes pressure testing. Turn on the water supply, having previously opened all the plugs and valves, raise the system pressure to 1.3 Atm. Checking the boiler for leaks

Particular attention is paid to joints and welding joints.

Choice

First of all, you should choose a water heater for a warm floor of suitable power. Calculating the power of the boiler is a difficult task, the easiest way is to proceed from the average value - 1 kW of power per 10 square meters. m. area.

It is necessary to pay attention to the possibility of adjusting the operating mode of the boiler. It is best if there is the possibility of smooth adjustment .. It is also necessary to determine the required number of circuits, the type of installation and other characteristics of the boiler that will best suit the requirements of the existing room

It is also necessary to determine the required number of circuits, the type of installation and other characteristics of the boiler that will best meet the requirements of the existing room.

How to make a heat accumulator with your own hands

A do-it-yourself heat accumulator for a solid fuel boiler is an energy-efficient and uncomplicated design, representing a container in the middle of which there is a coolant that receives and accumulates energy. After the boiler has completed its work cycle, the space is heated by absorbing the previously collected energy. Thanks to this, the heat accumulator significantly increases its efficiency and significantly saves resources.

Heating from a solid fuel boiler (installed by oneself) with a heat accumulator consists of many spiral tubes that are located around the entire perimeter of the tank. This arrangement is due to the fastest use of heat. Each of the spiral circuits located in the tank is responsible for one action. For example, the first one receives the generated thermal energy, the second heats the area of the room (building), the third heats water for domestic purposes.

Advantages of using a heat accumulator:

- Accumulation and concentration of thermal energy.

- Possibility of combining two or more heat sources.

- Increase in productivity.

- Availability of hot water.

- Temperature control.

A do-it-yourself solid fuel boiler with a water circuit, installed by yourself, allows you to save money when it is equipped with a heat accumulator.

For self-production of a heat accumulator for a boiler, you will need a large capacity. It is almost impossible to make it yourself. The ideal option is a stainless steel tank or any container with a lid. The thickness of the steel used is 4-9 mm. The preferred shape is a cylinder or a sphere, in extreme cases a cube.

A suitable option is a barrel. For a summer residence or a country villa, the minimum volume of a barrel for a solid fuel boiler starts from 1 ton. On large containers, stiffeners are welded on before use, which will significantly strengthen it.

Having received the necessary capacity, they think over its location, since in the future it will be much heavier. Next, diagrams and drawings will be needed.

Consider the step-by-step manufacture of a heat accumulator for a solid fuel boiler. The order of its manufacture:

- A flange is welded to the size of the cover. In the future, it will be used for bolted connections. To seal the cover, stiffeners are installed.

- The inside surface is treated with phosphoric acid (solution), primed 4 to 6 times and covered with two or three layers of high-temperature paint.

- Welding work is in progress. Coils are welded inside the barrel.

- If possible, powder coating is carried out together with the coil. It allows you to get a high-quality coating, which increases the anti-corrosion properties.

- The main tank and coil are checked for leaks.

- Grinding and painting of the outer side of the barrel is carried out. The preferred color is silver.

- Insulated with a layer of aluminum foil and a thick ball of min. cotton wool.

Safety requirements:

Given that the heat accumulator for a solid fuel boiler is constantly heated, fire safety rules must be observed

What quickly and easily catches fire is moved to a safe distance.

A closed-type system will have a rather high coolant pressure, so special attention should be paid to welds, joints, and connections. Also on the cover it is necessary to install heat-resistant rubber gaskets that can withstand the operating temperature of the coolant.

In the case of using heating elements for additional heating, it is necessary to follow the rules of electrical safety: the tank must have a “ground”, that is, grounding, and the contacts must be insulated.

Their use is beneficial for:

- The need for hot water supply of large facilities (public baths, hospitals, kindergartens, schools).

- Use of fuel materials.

- The use of thermal compressors (makes their work more balanced).

As you can see, do-it-yourself installation of a solid fuel boiler is a rather simple and primitive thing, but at the same time it has a number of features. The element is installed both in an apartment and in a private house. Installation costs are minimal, savings are maximum. The range is varied, everyone will find what suits him. Also, it should be noted that you can make a solid fuel boiler with your own hands for the garage. If you are not confident in your own abilities, call the master, he will do all the necessary work efficiently and on time.

Suitable for underfloor heating

Most of the boilers are designed for traditional heating systems, that is, they produce a coolant with a temperature of 60-95 ° C. The peculiarity of water floor heating is that much lower temperatures are required: about 35-50 ° C. Only under such conditions is it not possible to burn the floor will be, but will be pleasantly warm.

There are two solutions: find an installation that can deliver warm, not hot water, or mix cold water with hot water, and only then dispense it into the pipes. The second solution requires additional equipment - a collector unit, in which mixing takes place. This is not the cheapest technology, since it is required to measure the temperature of hot water and return, mix them until the temperature drops to the desired level. Of course, collector nodes are different, more or less expensive, but they still need to be bought and installed.

Let's start with boilers for a water floor, which can themselves produce a coolant of the desired temperature. Here in the first place - electric thermal units. You yourself can set the temperature from 25 ° C and above. That is, no additional costs and comfortable work with warm floors. In addition, induction and electrode (ionic) boilers have very small dimensions, which facilitates their installation. If you have one circuit, you can connect it directly to the output. If there are several circuits, a warm floor comb will be needed, but the simplest one, without mixing and temperature controllers. In principle, you can do it yourself from pipes and fittings. From other equipment, you may need (or not, depending on the configuration) an expansion tank, a drain valve and a circulation pump.

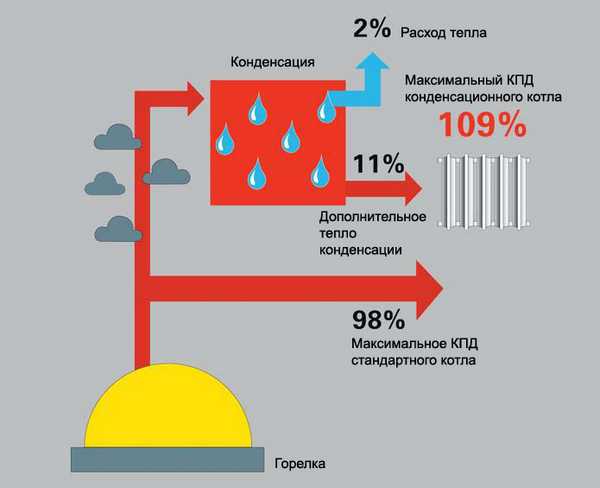

There is another option that shows simply excellent efficiency when working with low-temperature networks - this is. They are most effective at a coolant temperature in the return pipe not higher than 35 ° C. That is, this is an excellent option for a water floor.

The best choice is a condensing gas boiler for underfloor heating

Gas boilers using traditional heat extraction technology require the installation of a mixing unit with control elements. If you decide to use such equipment, try to choose a model that can simultaneously work with two or more circuits. Usually one of them is high-temperature for radiators, and the rest are for low-temperature systems such as underfloor heating. In this case, automatics are engaged in monitoring the temperature and mixing the coolant, and everything happens inside the installation. So if your underfloor heating works simultaneously with radiator heating, such equipment is an excellent solution.

The situation is more complicated with pellet and liquid fuel boilers: for them, a collector (mixing) unit is required. And with all the stuffing: thermometers, controllers and thermal heads.

Tying high-temperature boilers for underfloor heating is not an easy task

Degree of autonomy

The requirements for the comfort of heating equipment are not the whims of spoiled consumers: not everyone has the opportunity to constantly monitor the operation of the heating system and throw up fuel. Therefore, we consider this parameter first.

The highest degree of autonomy in . There is electricity - they work without human intervention. Moreover, after a power failure, they are included in the work on their own, many of them have a "memory" and save the settings. But electric cola is as many as three varieties:

- on heating elements;

- electrode;

- induction.

An electric boiler for underfloor heating on heating elements is a traditional solution. They just have one “disease” - heaters burn, and quite often. But their cost is average, and the technologies have been tested and worked out, even a person who is not very good at communicating with technology can replace a burnt-out heating element. In general, a good (but not the best) option.

The most “non-independent” are solid fuel installations. You need to throw fuel in them often, regularly rake out ash and slag, and regulate the intensity of combustion. Of course I have, . The best models on one tab of coal can work for several days (up to 7 days for some models of the company).But there are also difficulties here: they are demanding on fuel (you need dry firewood or coal of a certain standard), and the price can also scare you away.

A solid fuel boiler for a water-heated floor requires the constant presence of a person. Pyrolysis units and long-burning plants require two to three times less “refueling”

You can use a conventional solid fuel boiler for a water-heated floor, but you will have to spend a lot of time near the stove. Although there are already solid fuel units with automated feeding. They make pellet-type bunkers and auger feed. Only the requirements for the size and quality of fuel in them are no less stringent than those that work on pellets. But you can leave your house for a few days and not be afraid that the system will freeze.

Fifth place behind liquid fuel - it is not cheap. Operating costs should also include the need to heat the fuel tank, or install the tank in a heated room. In addition, solar installations require a boiler room. Moreover, it is better to build a boiler room at a decent distance from the house: the noise during the operation of the burner is decent, and the smell is strong, and it penetrates everywhere.

It is generally accepted that the most expensive heating is electricity. But when using automated modern devices, you have to pay only a little more than when using coal or firewood. So do not discount electric boilers for underfloor heating. Just for more economical heating, it is advisable for you to take a thermal unit with the ability to adjust the power. In some traditional electric boilers, heating elements are assembled in groups, and automation, turning groups on / off, regulates the power of work and saves electricity. For a warm floor, it is advisable to take a three-stage, or, in extreme cases, a two-stage unit. Induction and electrode boilers themselves are economical (if controlled by electronics) and have low inertia, that is, they do not waste energy carriers.

Advantages of underfloor heating

Warm floors in comparison with other methods of heating a house provide the most even distribution of the heat given off over the area of the room they heat. Warm air rises vertically from the floor, displacing cooler air from the ceiling. As a result, constant natural convection currents are formed in the room. Convection provides efficient heating of the entire room - at a minimum temperature of the coolant, the room receives maximum heat.

The temperature of the heat carrier in water heated floors should be maintained at the level of 35-40 0 C. For radiator heating, the system should have a coolant supply with a temperature of 55-65 degrees. Thus, less thermal energy is required to heat the underfloor heating system, and, consequently, the cost of heat production is lower. It is by reducing the cost of heat production that savings are achieved without loss of heating quality. In addition, the entire pie of the warm floor accumulates the released heat and, when the circulation stops, will give off heat energy to the room for some time.

Types by type of fuel

Heating boilers are a fairly large group of devices that have a different principle of operation. According to the type of fuel (energy source), boilers are

:

-

Gas

. The most efficient and economical boilers. They have the lowest cost of 1 kW of energy, and the highest efficiency. - . Water heating is carried out using heating elements, electrodes or by induction. The easiest to maintain and the most expensive source of heating the coolant.

-

Solid fuel

. Boilers that use almost everything that burns as fuel - firewood, coal, briquettes, pallets, etc. The availability of fuel makes such a boiler most suitable for autonomous heating of a house, but you have to constantly fill the combustion chamber.Modern models, however, are capable of long-term burning without human intervention. -

Diesel

. The source of thermal energy is a burning diesel fuel. A diesel fuel boiler can operate independently for a long time - up to several months. This type of boiler may even be more profitable than a gas one, if it is not connected to the mains, but uses imported gas. -

Combined

. Boilers that have the ability, if necessary, to switch to another type of fuel. The design of such a boiler can have two furnaces, or one universal for different types of fuel, you just need to replace the burner. At the same time, there are universal boilers with the option of switching firewood - electricity, when a second firebox is not needed. The ability to have an alternative heating option is a valuable quality for a country house when fuel shortages are possible.

Results

So, what to choose? The best option is a gas boiler for underfloor heating with condensing heat extraction technology. On all three parameters, he occupies a good position. The situation is a little worse if you put a gas installation with the “warm floor” function. But, unfortunately, not everyone has the opportunity to connect the main gas. And then the easiest way to implement a water-heated floor with an electric boiler. A small electric boiler can be installed to heat underfloor heating in utility rooms, for example, in a garage or in a country house: it is very easy to install. The next in terms of “quality” is a pellet unit, followed by liquid fuel. The most difficult task and high costs await when using solid fuel boilers for water floor heating.