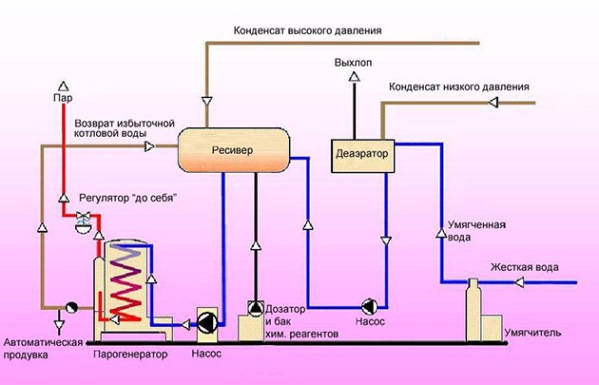

Steam heating scheme

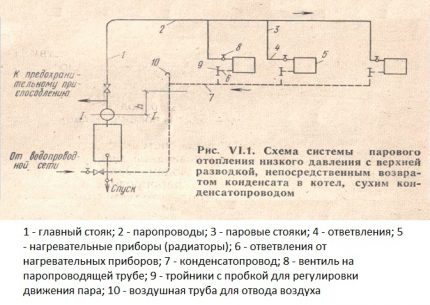

By and large, the schemes of heating systems for steam and water are almost the same. Only in the case of steam, the connection to the boiler becomes more complicated, an additional storage tank for condensate (receiver) and water treatment devices appear, which is shown in the diagram:

Regardless of whether you are going to install heating with your own hands, or hire specialists, we will present 5 arguments why it should not be steam:

- steam heating is traumatic: radiators and pipes heated to 130 ºС are a source of burns for you and your children;

- lack of savings: it is almost impossible to regulate the temperature in rooms heated by steam;

- the purchase and installation of steam boilers, as well as special fittings, is much more expensive than traditional water systems;

- the commissioning of steam generating equipment requires permission from the relevant control authorities;

- steam generation equipment is a source of increased danger. Its scope is industrial production.

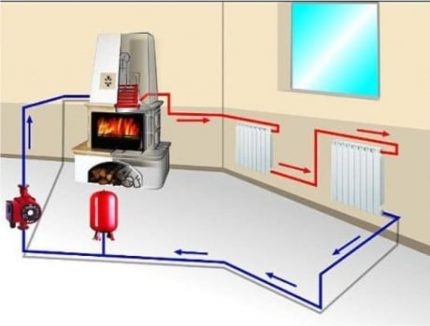

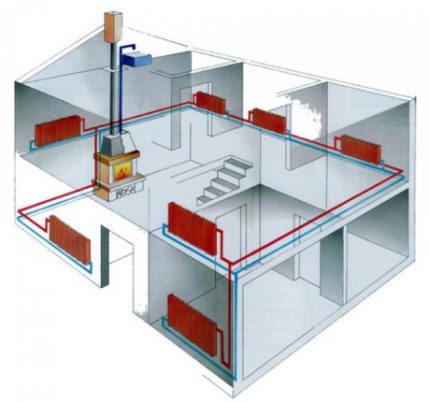

Water heating from the stove

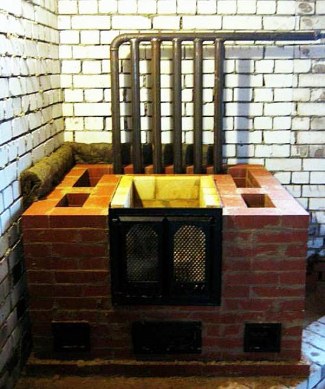

There is such a thing as stove steam heating, introduced by our grandfathers. But there is no steam in the pipelines here, it is a water system with radiators, powered by a heat exchanger installed in the furnace or flue of the furnace. Heat exchangers for these purposes are of two types: in the form of a coil or a container with nozzles. The tank is usually welded from stainless steel, and the coil is made from thick-walled steel pipes.

Advice. When it is planned to make heating in the country or in another building with a periodic heating method, then in order to avoid defrosting of the batteries and the heat exchanger in the stove, it is necessary to fill the system with antifreeze liquid - antifreeze.

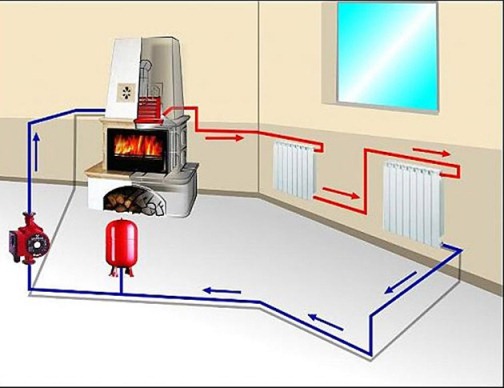

To make steam heating from the stove, you need to perform piping and install radiators. As a rule, the power of the heat exchanger is enough for good heating of 2-4 batteries, and this amount should be guided by. The system can be made gravity-fed, but this will clutter your home with large diameter pipes. If there is no urgent need, then it is better to install a circulation pump and lay lines above the floor.

As with solid fuel boilers, a safety group must be installed on the supply pipe. The combustion process in the firebox is not always possible to control or stop in time, so the presence of a safety valve with a pressure gauge will not hurt. The best option, in which overheating of the furnace tank is almost impossible, is the presence of a heat accumulator.

What it is

When water boils at constant pressure, it keeps its temperature constant. The steam formed as a result of such boiling has a significant amount of thermal energy. At the moment of condensation, i.e. when the vapor turns into a liquid, this energy is released and transferred to the environment.

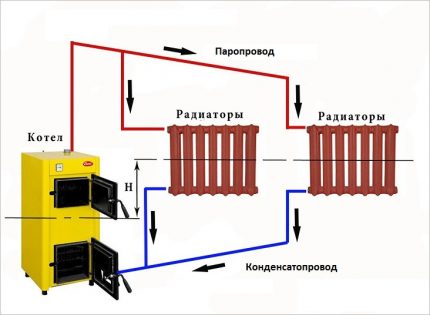

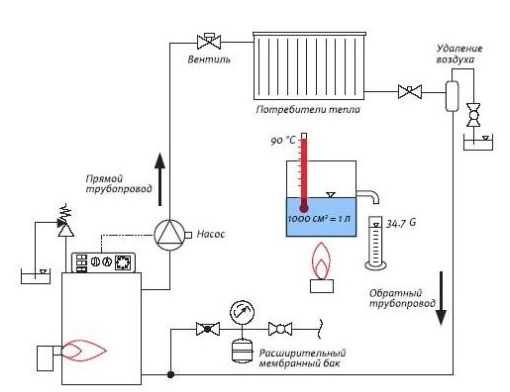

This principle is used in the operation of steam heating systems. Water boils in the boiler, the steam moves through pipes to radiators, where it condenses and breaks up with heat, thereby heating the air in the room. The water obtained during the condensation process continues to move through the pipes and returns to a special storage tank, and then flows to the heater naturally or by force, using a pump.

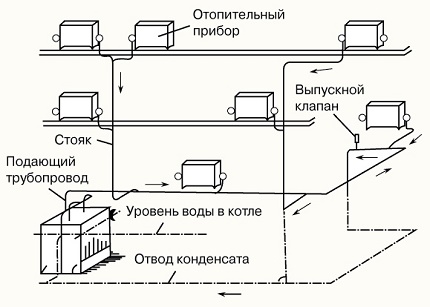

This diagram demonstrates the principles of distributing steam heating. The heater must be located lower than the radiators, the condensate line is given a slope

In such systems, so-called dry saturated steam is usually used, which does not contain suspended water particles. The amount of steam in the system is reflected in its operation.If there is too little steam, this will create problems for the free flow of condensate, and cold air will collect at the bottom of the heater. A sufficient volume of steam improves the outflow of condensate, which is pushed to the walls and flows down them in the form of a thin water film.

Depending on the pressure inside the steam heating system, they are divided into:

- vacuum steam;

- low pressure;

- high pressure.

In the first, the pressure is less than 0.1 MPa, in the second - even lower - up to 0.07 MPa, and in the third - more than 0.07 MPa. Open low pressure systems have access to air from the atmosphere, but they can also be closed, i.e. completely sealed.

In closed systems, water immediately enters the heat exchanger after condensation, but open systems are often used, in which the coolant is first collected in a storage tank and then pumped to a boiler for heating. Condensate can completely fill the pipes through which it moves for heating or only partially. The latter option is preferable, because when the system is turned off, the pipes in it will remain dry.

If the steam heating coolant after condensation moves directly to the boiler for subsequent heating, the system is called closed. If the condensate is first collected in a storage tank, from which it is pumped into the boiler by a pump, the system is classified as open-loop.

Design of a steam heating system

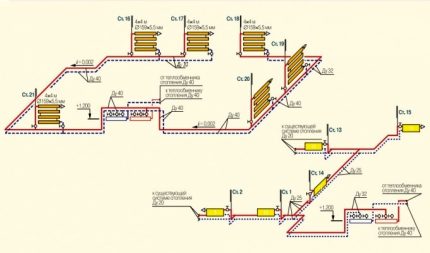

Even for a small room, it is best to draw up a project. A system made on the “maybe” with a high degree of probability will soon require rework, and a diagram drawn up on paper will immediately identify weaknesses and correct them. For example, in order to create a system with natural circulation of the coolant, the heat exchanger, and, accordingly, the heating device, should be located at the lowest point of the house.

The steam pipeline and condensate pipeline of heating systems with a natural type of movement of the coolant are arranged with a slope in the direction of its movement (+)

This means that the stove or boiler must be below all radiators, as well as pipes that are not vertical, but horizontal or at an angle to the vertical. If it is not possible to place the heating device in this way (there is no basement in the house, the basement is used for other purposes, etc.), forced circulation heating should be preferred.

The diagram shows a heating system with forced circulation. for its installation you will need a circulation pump and a storage tank

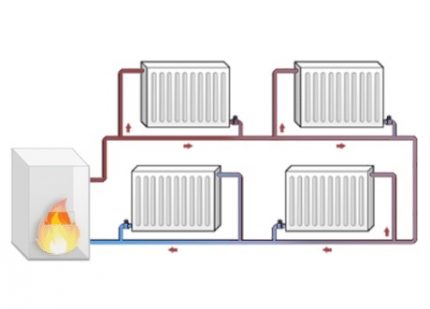

Therefore, it is necessary to include a pump in the circuit, which will pump water into the heat exchanger. An important point in the design of the heating system is the order in which radiators are connected. Serial connection or the so-called one-pipe system involves the connection of all radiators in order.

As a result, the coolant will sequentially move through the system, gradually cooling down. This is an economical connection option, which is easier to install and cheaper. But the uniformity of heating with this method will suffer, since the first radiator will be the hottest, and the last coolant will enter in an already half-cooled state.

One-pipe connection of radiators, as can be seen from this diagram, involves a series installation. The coolant enters the last radiator already cooled down

A one-pipe solution can only be acceptable when connecting steam heating in a country house or in a small house, on an area of \u200b\u200bless than 80 square meters. m. And for a spacious cottage or a two-story building, a two-pipe system is more suitable, in which radiators are connected in parallel. Such a scheme ensures the simultaneous, rather than sequential, flow of coolant into each radiator, and the heating of the premises is carried out more evenly.

But with a two-pipe circuit, two pipes will have to be connected to each radiator: a straight line and a “return”. Such a system is more difficult to implement, and it will cost a little more than when installing a single-pipe system. However, the vast majority of water heating systems are made according to a two-pipe scheme, despite the difficulties, and they function quite successfully.

This diagram shows a two-pipe system for mounting steam heating radiators. Each radiator is connected to a common riser and has a return pipe, which ensures even distribution of the coolant

If a wood-burning stove is supposed to be used as a heat source, then a special heat exchanger should be immediately calculated and designed. It looks like a coil welded from metal pipes. This element is built directly into the design of the furnace, and is not installed separately.

Therefore, the design of a new furnace should also be considered at the design stage. You can also use an existing furnace, but it will have to be partially disassembled in order to mount the heat exchanger inside. To obtain 9 kW of heat, a heat exchanger with a surface area of about one square meter is needed. The larger the area to be heated, the larger the heat exchanger should be.

If it is supposed to heat the room with the help of a boiler, then everything is a little simpler: you need to buy and install it. Usually, for steam heating in a house, it is recommended to take a water-tube boiler model, as the most efficient one. Although fire tube, smoke tube or combined fire tube and fire tube models can also be quite an acceptable option.

Sometimes a home-made boiler is used to organize steam heating, in which used engine oil is burned. But this option is considered suitable for use in utility rooms, for example, in a garage. For a residential building, this option is not very good.

Performing preparation work

When the decision is made to do any installation work, to connect the boiler to supply water, it should not be thought that it is easy. First of all, what is required is to prepare for the installation work. First, consider what such a system looks like. Such space heating is carried out by means of thermal regulation of the heat carrier. The flow inside the system will not move due to the water pump, but under the action of increased pressure inside the water masses. The boiler is distinguished by the ability to immediately work with various thermal masses. The pressure itself is located in the heat carrier located on the racks, which can cool each water flow. It should be noted that thanks to this process, the heating radiators can certainly receive water in a chilled state, which will return inside the boiler and push out hot water again.

Next, you can design a water supply system. First of all, what needs to be done so that the heating inside the house can provide convenience, it is necessary to make a calculation of the volume of water that is needed in order to heat the room. Then you can calculate the power for the pump. Only after all this can the choice of a water boiler and all components be made so that the boiler works without interruption.

During the installation of the heating system, boilers are selected in accordance with the power, relying on the area of \u200b\u200bthe room to be heated. This can be estimated using the formula: the dimensions of the area, measured in square meters, are multiplied by 1.2 kilowatts and divided by ten. The value of the boiler power that is obtained is used for the climate zone in the central region of Russia.

Forced circulation of the heat carrier inside heating systems on water is used with the help of an electric water pump.When using this scheme, uniform heating of the system as a whole is ensured, the temperature value of the batteries, which are located at a remote distance, must be high. During the operation of the circulation pump, it is possible to refuse to use steel pipes with a large diameter for pipelines of the heating system.

The use of polypropylene pipes when installing a heating system is more profitable than metal plastic pipes, both technically and economically. First of all, they in a separate form have a lower price. Further, during the installation of pipelines from metal plastic pipes, expensive elements are used for connection.

In addition, when using the monolithic method, there are no threaded connections that can crack after some time (for example, rubber gaskets for sealing lose their elasticity). Polypropylene pipes, which are connected in a monolithic way, have significant mechanical strength, respectively, are more reliable. Finally, when using such pipes, freezing can be allowed (they have the property of elasticity).

Assessment of advantages and disadvantages

What are the benefits of a steam heating system? It is relatively easy to make even on the basis of a conventional wood-burning stove. This is especially true in areas where there is no centralized gas supply, and firewood or other solid fuels are readily available. Steam as a heat carrier is significantly ahead of water. Its heating rate is three times higher.

In addition, the steam heating system is unlikely to fail during the winter cold due to lack of heating. If the firebox burns out, the water from the system will collect in the storage tank or in the heat exchanger, and the pipes and radiators will remain empty. With water heating, freezing of the coolant with which the entire circuit is filled, as you know, leads to rupture of pipes.

Finally, the dimensions of steam heating radiators must be significantly smaller than for water systems, since the amount of thermal energy obtained as a result increases several times. This will slightly reduce the cost of installing a heating system at home.

Decorative grilles for steam heating radiators are not only an element of interior design, but also a means of protection against burns.

This concludes the list of advantages of the steam system, and we can move on to its disadvantages, which are quite significant:

- high risk of burns;

- increased noise level during operation;

- Difficulties with adjusting the operation of the system;

- the need to purchase expensive pipes, etc.

Steam heating is not recommended for residential premises by safety standards, since it poses a high danger to the health and life of people living in the house. So, the operating temperature of the radiators will be very high, if you touch them, you can get a serious burn. Therefore, all radiators will have to be closed with reliable decorative grilles.

Ordinary PVC pipes are not suitable for such a system, since they must withstand high pressure and temperatures of more than 100 degrees. The same requirements apply to other elements of the system. Steam heating pipes should be copper or galvanized steel.

Copper pipes are an ideal, but not at all cheap communication option for steam heating systems. To connect these pipes you will need a welding machine

In any case, this moment cannot be called budgetary.

Security issues must be given the utmost attention. All installation work, for example, welding of copper pipes, will require the highest quality workmanship.

If the connection breaks and a jet of steam escapes into the hole, one of the residents of the house risks serious burns.

Stainless steel pipes are able to withstand such loads typical for steam heating systems as high temperature and high pressure in the system

Another disadvantage of steam heating is the increased noise level. To fix this problem, you must correctly install the radiators. They are hung on special anti-noise brackets. The boiler or stove is best placed in a separate room. In addition, copper pipes can be placed in the thickness of the walls, which will also reduce the noise level.

Finally, it is a little difficult to regulate the heating temperature in rooms with steam heating. You can not install a thermostat and simply reduce the amount of steam. You will have to reduce the amount of fuel, which is not always easy, or ventilate the premises. Before starting work on the installation of a steam heating system, all these points should be taken into account.

Features of low pressure systems

A common variant of such a system is a closed one, using a gravity return of condensate to the boiler, which does not completely fill the pipes, while using the upper piping. First, the system is filled with water to the required level, after which heating begins. The condensate flows down the common riser and, when a predetermined level is reached, is forced out into the boiler.

In the same system with bottom wiring, it is recommended to install pipes with a slight slope in the direction of steam movement in order to reduce noise effects. A loop-shaped water seal is installed at the place where the condensate is drained, preventing the steam from moving to the condensation line.

The steam velocity in such systems should be moderate, not more than 0.14 m/s. Otherwise, the steam will also capture particles of moisture accumulated on the walls. As a result, the system operates with a lot of noise, and the risk of water hammer increases.

Combined wiring, i.e. a combination of upper and lower wiring is used if pipes are laid under the floor of the upper or middle floor of the house. The lumen of the pipes through which water returns to the boiler, in this case, will be closed by condensate.

If the pressure in the system exceeds 0.02 MPa, it should be made open. The air is removed through the condensate tank, and so that the steam does not leave the system, a steam trap or water seal is installed. Water from the accumulator is pumped to the heat exchanger, which allows the accumulator to be installed below the level at which the heat exchanger is located.

The heat carrier for heating a private house with a boiler room is heated in a heat exchanger located in the boiler room. Upon reaching the operating temperature, the steam moves to the collector, dividing the flow into two circuits: for the main rooms and for the boiler room (+)

Steam heating boiler in a private house

A steam boiler is an alternative type of heating for private houses and cottages. Water heating of buildings is incorrectly called “steam” - such a confusion in the names is associated with the principle of heating apartment buildings, where an external coolant under pressure flows from a CHP to individual houses and transfers its heat to an internal carrier (water), which circulates in a closed system.

Steam heating in a private house is used much less frequently than other methods of space heating. It is economically justified to use the boiler in a country house or a country house, when year-round living is not provided, and the main role in heating is played by the speed of heating the premises and the ease of preparing the system for conservation.

The possibility of installing such equipment in addition to the existing one, for example, a furnace, is another advantage of using steam as a heat carrier.

As a result of water boiling in the boiler unit (steam generator), steam is formed, which is supplied to the system of pipelines and radiators.In the process of condensation, it gives off heat, providing rapid heating of the air in the room, and then returns in a liquid state in a vicious circle to the boiler. In a private house, this type of heating can be implemented in the form of a single- or double-circuit scheme (heating and hot water for domestic needs).

According to the wiring method, the system can be single-pipe (serial connection of all radiators, the pipeline runs horizontally and vertically) or two-pipe (parallel connection of radiators). Condensate can be returned to the steam generator by gravity (closed circuit) or forcibly by means of a circulation pump (open circuit).

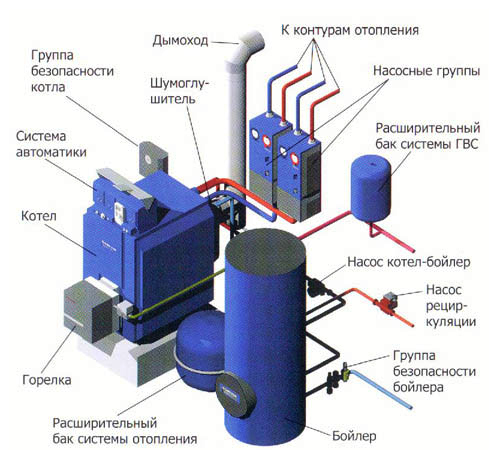

The scheme of steam heating of the house includes:

- boiler;

- boiler (for a two-circuit system);

- radiators;

- pump;

- expansion tank;

- shut-off and safety fittings.

Description of steam heating boiler

The key element of space heating is the steam generator, the design of which includes:

- furnace (fuel combustion chamber);

- evaporator pipes;

- economizer (heat exchanger for heating water due to exhaust gases);

- drum (separator for separating the steam-water mixture).

Boilers can operate on various types of fuel, but it is better for private houses to use a household steam boiler with the ability to switch from one type to another (combined).

The efficiency and safety of such space heating depends on a competent approach to choosing a steam generator. The power of the boiler unit must be commensurate with its tasks. For example, to create an optimal microclimate in a house with an area of 60-200m 2, you need to buy a boiler with a capacity of 25 kW or more. For domestic purposes, it is effective to use water-tube units, which are more modern and reliable.

Self-installation of equipment

Work is carried out in stages, in a certain order:

1. Drawing up a project taking into account all the details and technical solutions (length and number of pipes, type of steam generator and its installation location, location of radiators, expansion tank and shutoff valves). This document must be agreed with the state control authorities.

2. Installation of the boiler (made below the level of the radiators to ensure steam advances upwards).

3. Piping and installation of radiators. When laying, a slope of about 5 mm should be set for each meter. Installation of radiators is carried out using a threaded connection or welding. In reviews of a steam heating system, experienced users recommend installing taps to eliminate problems when air locks occur and facilitate subsequent operation.

4. Installation of the expansion tank is carried out 3 meters above the level of the steam generator.

5. The piping of the boiler unit must be carried out only with metal pipes of the same diameter with outlets from the boiler (adapters must not be used). The heating circuit is closed in the unit, it is desirable to install a filter and a circulation pump. A drain unit must be installed at the lowest point of the system so that the pipeline can be easily emptied for repair work or conservation of the structure. Necessary sensors that control the process and ensure safety are necessarily mounted on the boiler unit.

6. Testing a steam heating system is best done in the presence of specialists who can not only perform all procedures in accordance with applicable norms and standards, but also eliminate any shortcomings and inaccuracies in the installation scheme with their own hands.

Tricky meter that saves electricity. It pays off in 2 months! Everyone needs to know this in order to save money!

Advantages of solid fuel boilers

In homes where gas is not available or prohibitively expensive, solid fuel boilers are used. Such heating is also preferred by those who want to save on heating their homes.It will cost 2 times cheaper than gas and 3 times cheaper than electric.

Solid fuel heating boilers have many advantages:

- Autonomy. Since the operation of the equipment does not depend on external power sources, it will be enough to have a supply of firewood or pellets to ensure trouble-free operation.

- Variability. Depending on the availability of raw materials, peat, coal, briquettes, firewood, pellets can be used.

- Environmental friendliness. When a renewable raw material, wood, is used, it does not harm the environment.

- Practicality. The device is simply arranged, so it is easy to maintain, and it lasts a very long time.

Long-burning solid fuel boiler - features of work and operation

The main feature of equipment designed for long burning is the increased heat resistance of structural elements. The air supply system is also different. The main fuel for such boilers is coal, coke, oil products, peat.

When solid fuel long-burning boilers are used for the home, after loading with coal they can work up to 5 days, and with firewood - up to 2 days.

The indisputable advantages of this equipment are savings on inexpensive fuel and the ability to not think about its operation for several days. But it must be borne in mind that the functioning cycle:

Range

The proposed range of products includes equipment of German, Italian, Slovak, Russian production.

The Bosch brand is well known to the Russian buyer for the high-quality household and industrial appliances and equipment that it supplies to the market.

If you are looking for the best solid fuel boiler, you should pay attention to German products. It is manufactured to the highest standards, impeccable quality.

A good choice is the Slovak brand Protherm. The model range includes solid fuel boilers used for a private house of various heated areas. The material from which the equipment is made is low-temperature cast iron, which minimizes heat loss. The technique is complemented by special sensors that help owners easily adjust the power.

If you are looking for solid fuel boilers, the price of which includes only the cost of production with a reasonable margin, this is a domestic technique from Zota. The products of the Krasnoyarsk plant, which has been operating since 1992, have earned high marks from customers as reliable and easy to use.