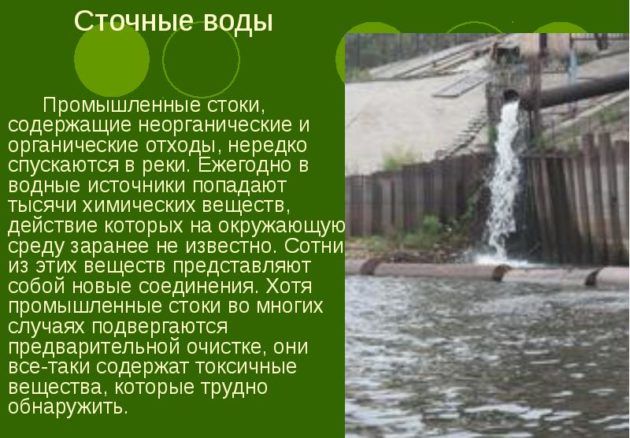

What is wastewater

To understand what kind of threat wastewater can pose to health and the environment, it is necessary to give a clear definition of the concept. Effluent refers to all types of water that have passed a full or incomplete cycle of domestic, industrial use.

Types of pollution

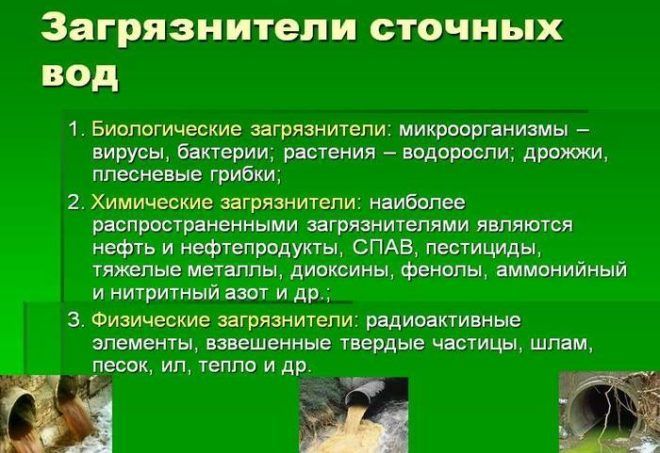

Among the main types of pollution, the following options are distinguished:

- Human and domestic animal faeces.

- Other masses of biological origin.

- Various chemicals, including alkaline ones.

The category of waste liquid also includes waste that enters the storm sewer as a result of precipitation of any type (rain, melted snow). Since they contain a large number of reagents and other chemical inclusions used by city utilities. As well as impurities from settled exhaust gases, from cars, etc.

Based on the types of pollution, there are 3 main types of wastewater.

Wastewater containing a large amount of impurities of inorganic origin is called mineral. Most often, such water came into contact with soil particles, salts and other substances of inorganic groups.

If there are impurities of organic origin, wastewater falls into the category of the same name. In such water there is a large number of products, the result of the vital activity of the plant and animal world as a whole.

There are also biological wastewater. Impurities in such water are associated with other elements, they feed and multiply in a humid environment.

Craft edit edit code

| Ingredients | crafting recipes |

|---|

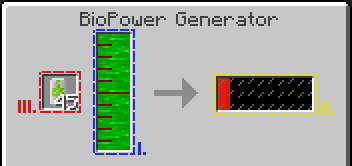

Interface

- I. Tank for storing fuel with a volume of 10 buckets.

- II. Internal battery. Stores up to 30,000 EU of generated energy.

- III. This slot accepts capsules or buckets of biomass and biofuel.

Fuel types

| Fuel | Energy | Power | So you | Time |

|---|---|---|---|---|

| 1 bucket of biomass | 4000 EU | 8 EU/tact | 1000 | 50 s |

| 1 bucket of biofuel | 64 000 EU | 16 EU/tact | 2000 | 1 min 40 s |

The use of biofuels is much more profitable than biomass. This can be verified by making simple calculations (1.7.10):

It takes exactly 336,000 RF (21 coals in a Stirling engine) to produce 1000 mV of biomass in a fermenter. Therefore, from 3000 mV of biomass in the biogenerator, we will get 12,000 EU, since 1000 mV of biomass is 4000 EU, and we will spend 336,000 × 3 = 1,008,000 RF for this.

In the distiller, 1000 mV of biomass is processed into 300 mV of biofuel, and 80,000 RF are spent on this. 10 buckets of biomass equals 3 buckets of biofuel at a cost of 800,000 RF. Therefore, to create 10 buckets of biomass, we have to spend 336,000 × 10 = 3,360,000 RF, as well as another 800,000 RF for processing into biofuel. As a result, to create 3000 mV of biofuel, we will spend 4,160,000 RF and get 64,000 × 3 = 192,000 EU in the biogenerator

And now attention:

3000 mV biomass - 1,008,000 RF - 12,000 EU

3000 mV biofuel - 4,160,000 RF - 192,000 EU.

Biofuels are more profitable than biomass, although earlier at other EU prices it was the other way around.

| This article is about the Bio Generator from Forestry. You may be looking for the Bio-Generator from Mekanism. |

| Bio Generator | |

|---|---|

| Name | Bio Generator |

| source mod | Forestry |

| ID Name | |

| type | block |

| Stackable | Yes (64) |

| Blast Resistance | 7.5 |

| hardness | 1.5 |

| Solid | Yes |

| transparent | Yes |

| Affected by Gravity | no |

| Emits Light | no |

| Flammable | no |

| Required Tool |

The Bio Generator is used to convert Biomass or Biofuel into EU. It Produces 8,000 EU at 8 EU/t when running on Biomass or 128,000 EU at 16 EU/t when running on Biofuel (per bucket). It stores 10 buckets worth of fuel and can store up to 30,000 EU of excess energy.

The Bio Generator will only accept Biomass and Biofuel from Pipes, Cans, and Capsules. It does not accept the Biomass Cell or Bio Diesel Cell, meaning that you must send your plant matter through a Fermenter, and cannot simply place it in a cell.

It’s worth noting that while a Biogas Engine takes 10,000 ticks, or 8 minutes and 20 seconds, to use a bucket of Biomass, the Bio Generator will use up the same amount of fuel in just 50 seconds. Similarly, a Combustion Engine takes 40,000 ticks or 33 minutes 20 seconds to use a bucket of Biofuel, while a Bio Generator burns it in 1 minute 40 seconds. Thus, if you have a setup that uses Biomass or Biofuel to power engines, and you connect a Bio Generator to the same fuel pipe, you should expect it to starve your engines.

Specificity of biogas production

Biogas is formed as a result of the fermentation of a biological substrate. It is decomposed by hydrolytic, acid- and methane-forming bacteria. The mixture of gases produced by bacteria turns out to be combustible, because. contains a large percentage of methane.

By its properties, it practically does not differ from natural gas, which is used for industrial and domestic needs.

Biogas is an environmentally friendly fuel, and the technology for its production does not have a particular impact on the environment. Moreover, as a raw material for biogas, waste products are used that need to be disposed of.

They are placed in a bioreactor where processing takes place:

- for some time, the biomass is exposed to bacteria. The fermentation period depends on the volume of raw materials;

- as a result of the activity of anaerobic bacteria, a combustible mixture of gases is released, which includes methane (60%), carbon dioxide (35%) and some other gases (5%). Also, during fermentation, potentially dangerous hydrogen sulfide is released in small quantities. It is poisonous, so it is highly undesirable for people to be exposed to it;

- the mixture of gases from the bioreactor is cleaned and enters the gas holder, where it is stored until it is used for its intended purpose;

- gas from a gas tank can be used in the same way as natural gas. It goes to household appliances - gas stoves, heating boilers, etc.;

- decomposed biomass must be regularly removed from the fermenter. This is an additional effort, but the effort pays off. After fermentation, the raw material turns into high-quality fertilizer, which is used in fields and gardens.

A biogas plant is beneficial for the owner of a private house only if he has constant access to waste from livestock farms. On average, out of 1 cubic meter. substrate can be obtained 70-80 cubic meters. biogas, but gas production is uneven and depends on many factors, incl. biomass temperature. This complicates the calculations.

In order for the gas production process to be stable and continuous, it is best to build several biogas plants, and put the substrate into the fermenters with a time difference. Such installations operate in parallel, and the raw materials are loaded into them sequentially.

This guarantees a constant production of gas, so that it can be continuously supplied to household appliances.

Homemade biogas equipment, assembled from improvised materials, is much cheaper than industrial production plants. Its efficiency is lower, but it fully corresponds to the invested funds. If you have access to manure and the desire to make your own efforts to assemble and maintain the structure, this is very beneficial.

Calculation of plant profitability

Cow dung is commonly used as a feedstock for biogas production. One adult cow can give enough of it to provide 1.5 cubic meters. fuel; pig - 0.2 cubic meters; chicken or rabbit (depending on body weight) - 0.01-0.02 cubic meters. To understand whether this is a lot or a little, you can compare it with more familiar types of resources.

1 m3 biogas provides the same amount of thermal energy as:

- firewood - 3.5 kg;

- coal - 1-2 kg;

- electricity - 9-10 kW / h.

If you know the approximate weight of agricultural waste that will be available in the coming years, and the amount of energy needed, you can calculate the profitability of a biogas plant.

For laying in a bioreactor, a substrate is prepared, which includes several components in the following proportions:

- manure (preferably cow or pig) - 1.5 tons;

- organic waste (it can be rotted leaves or other components of plant origin) - 3.5 tons;

- water heated to 35 degrees (the amount of warm water is calculated so that its mass is 65-75% of the total amount of organic matter).

The calculation of the substrate was made for one bookmark for six months, based on moderate gas consumption. After about 10-15 days, the fermentation process will give the first results: the gas will appear in small quantities and begin to fill the storage. After 30 days, you can expect full fuel production.

If the plant is operating correctly, the volume of biogas will gradually increase until the substrate rots. The performance of the structure directly depends on the rate of biomass fermentation, which in turn is related to the temperature and humidity of the substrate.

Interaction with pipes

Receives through the pipe:

- Capsules with biomass and biofuel - any side.

- Buckets of biomass and biofuel - either side.

- Biomass and biofuels in the form of liquids - either side.

Nothing can be extracted.

|

Forestry |

|||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| materials |

|

||||||||||||||||

| Tools |

|

||||||||||||||||

| Backpacks |

|

||||||||||||||||

| Mechanisms |

|

||||||||||||||||

| Automatic farms |

|

||||||||||||||||

| Beekeeping |

|

||||||||||||||||

| Building |

|

||||||||||||||||

| Other |

|

Instructions for self-construction

If there is no experience in assembling complex systems, it makes sense to pick up on the net or develop the simplest drawing of a biogas plant for a private house.

The simpler the design, the more reliable and durable it is. Later, when building and system handling skills become available, it will be possible to modify the equipment or mount an additional installation.

When calculating the volume of the fermenter, it is worth focusing on 5 cubic meters. Such an installation allows you to get the amount of gas needed to heat a private house with an area of 50 square meters, if a gas boiler or stove is used as a heat source.

This is an average indicator, because the calorific value of biogas is usually not higher than 6000 kcal/m3.

The construction of a biogas plant can be divided into several stages.

Stage 1 - preparation of a pit for a bioreactor

Almost the entire biogas plant is located underground, so a lot depends on how the pit was dug and finished. There are several options for strengthening the walls and sealing the pit - plastic, concrete, polymer rings.

The best solution is to buy ready-made polymer rings with a blank bottom. They will cost more than improvised materials, but additional sealing is not required. Polymers are sensitive to mechanical stress, but they are not afraid of moisture and chemically aggressive substances. They are not repairable, but if necessary, they can be easily replaced.

Stage 2 - arrangement of gas drainage

Buying and installing special agitators for biogas plants is expensive. The system can be reduced in cost by equipping gas drainage. It is a vertically installed polymer sewer pipes, in which many holes have been made.

When calculating the length of the drainage pipes, one should be guided by the planned filling depth of the bioreactor. The tops of the pipes must be above this level.

The substrate can be immediately loaded into the finished bioreactor. It is covered with a film so that the gas released during the fermentation process is under slight pressure. When the dome is ready, it will ensure the normal supply of biomethane through the outlet pipe.

Stage 3 - installation of the dome and pipes

The final stage in the assembly of the simplest biogas plant is the installation of the dome top. At the highest point of the dome, a gas outlet pipe is installed and pulled to the gas tank, which is indispensable.

The capacity of the bioreactor is closed with a tight lid. To prevent mixing of biomethane with air, a water seal is equipped. It also serves to purify gas. It is necessary to provide a release valve that will work if the pressure in the fermenter is too high.

Read more about how to make biogas from manure in this material.

Advantages and disadvantages of the system

Biogas plants have many advantages, but there are also enough disadvantages, so before starting design and construction, you should weigh everything:

- Recycling. Thanks to a biogas plant, you can get the most out of the garbage that you would have to get rid of anyway. This disposal is less hazardous to the environment than landfill.

- Renewability of raw materials. Biomass is not coal or natural gas, the extraction of which depletes resources. In agriculture, raw materials appear constantly.

- Relative small amount of CO2. When gas is produced, the environment is not polluted, but when it is used, a small amount of carbon dioxide is released into the atmosphere. It is not dangerous and is not capable of critically changing the environment, because.it is absorbed by plants during growth.

- Moderate sulfur emission. When biogas is burned, a small amount of sulfur is released into the atmosphere. This is a negative phenomenon, but its scale is known in comparison: when natural gas is burned, environmental pollution with sulfur oxides is much greater.

- Stable work. Biogas production is more stable than solar panels or windmills. If solar and wind power cannot be controlled, then biogas plants depend on human activity.

- You can use multiple settings. Gas is always a risk. To reduce potential damage in the event of an accident, several biogas plants can be dispersed around the site. If correctly designed and assembled, a system of several fermenters will work more stable than one large bioreactor.

- Benefits for agriculture. Some types of plants are planted to obtain biomass. You can choose those that improve the condition of the soil. For example, sorghum reduces soil erosion and improves its quality.

Biogas also has disadvantages. Although it is a relatively clean fuel, it still pollutes the atmosphere. There may also be problems with the supply of plant biomass.

Irresponsible plant owners often harvest it in ways that deplete the land and upset the ecological balance.

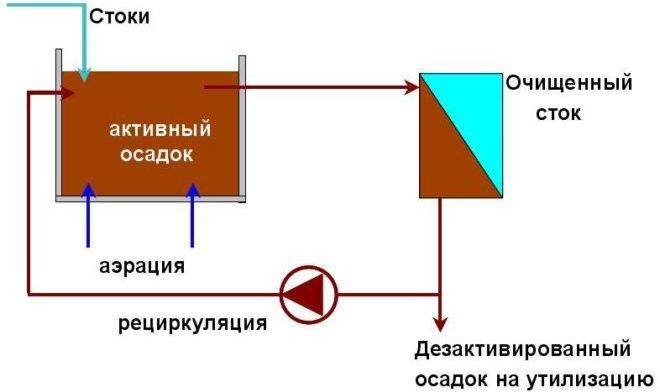

Features of the operation of membrane bioreactors

To restore the initial important indicator of the bioreactor membrane permeability level, treatment with solutions of various reagents is carried out. Most often, such chemical washing involves the use of oxidizing agents.

In most cases, regardless of the specific model of equipment, the following substances are used for this process:

- Citric acid with a percentage of 0.2 to 0.3.

- Sodium hypochlorite, having concentration values ranging from 0.2 to 1%.

As an addition to the above reagents, to achieve a better result, hydrochloric acid, caustic soda and other substances from the category of detergents or complexing agents can be used.

It is reasonable to carry out the cleaning procedure using an expanded composition no more than 1 time in 2-3 months. And when using hypochlorite, the procedure can be repeated up to 2 times in 1 month.

To flush the pressure module, the solution circulation technology is used, supplied by a connected pump from a special container, in which the entire submersible version of the equipment is placed. That in the first and second case, the time for washing is from 2 to 3 hours.

In case of severe pollution and the inefficiency of the above methods, membranes are selected, and washing occurs mechanically by supplying a jet of water, which rids the surface of deposits.

Difficulties in the operation of the bioreactor

There are several problematic issues associated with the practical application of a membrane bioreactor.

Pretty fast contamination of the main cleaning elements, namely membranes and filters. Associated with the need to control the pre-treatment process, and the complete removal of elements such as hair, scraps of fibrous materials, etc.

Damage to the permeable membranes during operation or cleaning.

Frequent failures in the operation of the communication line located in the automation system, and failure of the system responsible for the blowing process.

Contamination of gratings, nets, requiring additional time and financial costs for cleaning.

Possible failure of the operation of aerators and blowers, which means expensive and lengthy repairs to the device. The worse the aeration conditions, the faster the process of reducing the level of membrane permeability and the higher the rate of sediment formation.At the same time, such a problem does not have a significant impact on the quality of the degree of purification until a certain time.

Failure of the system responsible for recycling, automatically stopping the operation of the bioreactor, etc.

It should be remembered that the greater the productivity of the bioreactor and, accordingly, the amount of wastewater treated per day, the higher the financial costs for the acquisition and subsequent maintenance.

Video: Membrane wastewater treatment

A selection of questions

- Mikhail, Lipetsk — What discs for metal cutting should be used?

- Ivan, Moscow — What is the GOST of metal-rolled sheet steel?

- Maksim, Tver — What are the best racks for storing rolled metal products?

- Vladimir, Novosibirsk — What does ultrasonic processing of metals mean without the use of abrasive substances?

- Valery, Moscow — How to forge a knife from a bearing with your own hands?

- Stanislav, Voronezh — What equipment is used for the production of galvanized steel air ducts?

Biogas technology

The principle of operation of a biogas plant is based on the fermentation of the biosubstrate. It decomposes under the influence of hydrolytic, methane- and acid-forming microorganisms. Combustible gas is produced containing a high volume of methane.

Gas is actually not inferior to natural, used in everyday life and industry. There are ready-made installations. But, their cost is quite high, the payback period reaches 10 years.

For the operation of a biogas plant, it is possible to use available raw materials - recyclable waste. They are processed as follows:

- Raw materials ferment under the influence of microorganisms.

- Combustible gases are emitted - methane, carbon dioxide and others. The main volume is represented by methane

- The gases are purified and enter the gas tank, where they are stored until they are used directly.

Gas can be used in the same way as natural gas. It can be used as fuel for boilers, furnaces, gas stoves, etc. Waste raw materials must be removed from the installation in a timely manner. Waste can be used as fertilizer.

A prudent owner dreams of cheap energy resources, efficient waste disposal and obtaining fertilizers. A DIY home biogas plant is an inexpensive way to make dreams come true.

Self-assembly of such equipment will cost reasonable money, and the gas produced will be a good help in the household: it can be used for cooking, heating the house and other needs.

Let's try to understand the specifics of this equipment, its advantages and disadvantages. And also whether it is possible to independently build a biogas plant and whether it will be effective.

fermenter

The fermenter is a ready-made complex for cultivating microorganisms with automatic dosing of nutrients.

In the process of growing microbiological cultures, the basic requirements must be observed: climatic factors of the external environment, pressure parameters, speed and intensity of mixing, removal of by-products (carbon dioxide / sulfur dioxide) must be organized.

Classification of microbiological processes in terms of technological design

Any microbiological process can be classified in terms of:

- aerobic and anaerobic cultivation;

- surface/deep cultivation;

- periodic (phase) and continuous cultivation.

The process of deep cultivation of microorganisms in a liquid nutrient medium has become widespread in the industrial sphere. Such a process has a number of distinctive features: it proceeds in several stages and is reduced to the transformation “gas - liquid - solid composition (cells)”.

An insoluble carbon source (for example, n-paraffin) can also act as such a solid-state substance.

The cultivation of microorganisms is inevitably associated with the release of heat. This also applies to cases where cultivation is carried out in a laboratory. With small volumes of cultivation and with the use of special chemical glassware, the thermal effect is small, however, in large installations with a significant amount of substance, abundant heat is released.

It is extremely important during the growing process to maintain the same temperature phase throughout the entire volume for a long period of time.

Classification of fermenters depending on the volume of the substance

Depending on the total volume of the cultivated substance, bioreactors are classified into laboratory fermenters and industrial fermenters:

1. The main field of practical application of the laboratory fermenter is the reproduction and cultivation of microbiological samples on a laboratory scale, as well as for breeding innovative cultures, fungi, enzymes and microorganisms.

One or more reactor tanks and a supply unit are the main components of a laboratory fermenter.

The main function of the support unit is to support the life and reproduction of microorganisms. This module may include

- pumps for pumping air and removing carbon dioxide;

- temperature control sensors that support and regulate the life cycle of microbiological samples.

A fermenter, including a laboratory one, from BioRus has a number of advantages:

- ergonomics

- compactness

- the possibility of independent functioning of several vessels under one control;

- accuracy and ease of setting cell culture parameters, the ability to export the results of work, set up alerts, visualize data, etc. due to the SCADA-based software that comes with the purchase of a bioreactor, regardless of its configuration and version

- availability of removable vessels for the same fermenter

- the possibility of equipping with additional equipment (for example, a rotor filter for growing cells in perfusion mode)

- integration of up to four bioreactors (both different and identical sizes) into a single system with a single connection of power supply, gas and water and under the control of one computer with the possibility of an individual control system (modular system).

2. An industrial fermenter is used in the food, pharmaceutical and microbiological industries for the production of fungi, bacteria and yeast, as well as for the production of proteins, bioactive substances, antibiotics and other drugs necessary for a person in various fields of life and medicine.

Integrated system modules or laboratory bioreactors connected to a personal computer and operating on the basis of special software act as control devices.

The cost of equipment of this class directly depends on the volume of the cultivated substance and the multi-functionality of the system unit.

How to make a biogenerator

Its craft is very simple. It is enough to have 6 gold bars, 2 glasses and a solid car. With this set of resources, you can easily craft a biogenerator.

It is also necessary to say a few words about how to work with it. Bioregenerator, as you already remember, is a very wasteful means of obtaining energy. You better think a few times before deciding to use it in terms of energy production.

Why would you need electricity at all? We know that for a lot. Well, I can give the most extreme and coolest example. For example, you need to supply energy to the entire city. If you have a city that you have built, this is a very interesting point in using a biogenerator. If you do not want to build a city with your own hands, you can find minecraft mods for a ready-made city.If so, then you will need a lot of biogenerators and, accordingly, a lot of fields.

Ligravity is in effect

foldable

Conclusions and useful video on the topic

Although there is nothing complicated in assembling and arranging biogas equipment, you need to be extremely attentive to details. Errors are not allowed, because can lead to explosions and destruction. We offer video instructions that will help you understand how the plants are arranged, assemble them correctly and supplement them with useful devices for more convenient use of biogas.

The video shows how a standard biogas plant works:

An example of a homemade biogas plant. Video tutorial on arranging the system with your own hands:

Video instruction for assembling a biogas plant from a barrel:

Description of the manufacturing process of substrate agitators:

A detailed description of the work of a makeshift gas storage:

No matter how simple the biogas plant chosen for a private house is, it is not worth saving on it. If possible, it is better to buy a collapsible bioreactor of industrial production.

If not, make it from high-quality and sustainable materials: polymers, concrete or stainless steel. This will create a truly reliable and safe gas supply system at home.

Have questions about the topic of the article, found flaws or have valuable information that you can share with our readers? Please leave your comments, ask questions, share your experience.

The article on biogas production presented the theoretical foundations for the production of methane gas from biomass by anaerobic digestion.

The role of bacteria in the gradual transformation of organic substances was explained, with a description of the necessary conditions for the most intensive production of biogas. In this article, practical implementations of biogas plants will be given, with a description of some improvised designs.

As energy prices rise and many livestock and small farm owners have problems with waste disposal, biogas industrial complexes and small biogas plants for a private home have come on the market. Using search engines, the Internet user can easily find an affordable turnkey solution to match the biogas plant and its price, get in touch with equipment suppliers and agree on the construction of a biogas generator at home or on the farm.