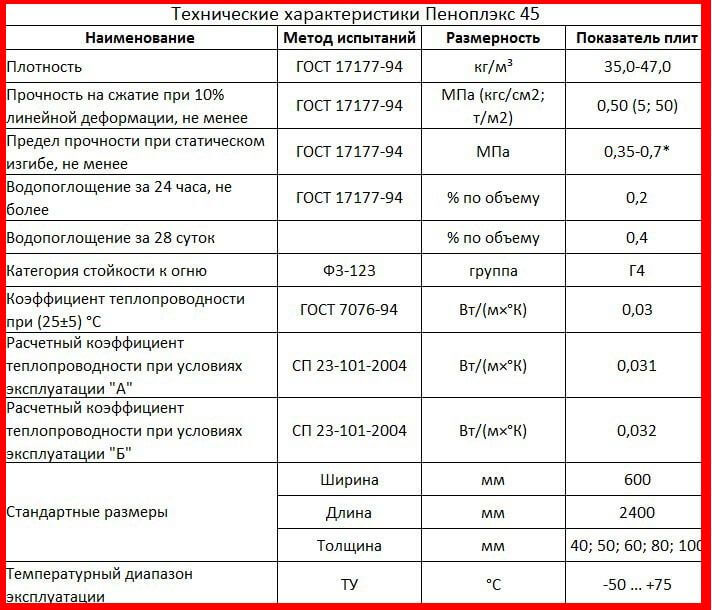

Characteristics Penoplex 45

Thermal insulation "Penoplex 45" - the Russian name for extruded polystyrene foam, which is a modified foam.

The product is produced in the form of orange rectangular slabs with a homogeneous cellular-porous structure. In addition to polystyrene, foaming agents, flame retardants, plasticizers and dyes are included in the foam insulation.

The density of foam with marking 45 is 35.0-47.0 kg / m³. The product is able to withstand heavy loads without surface deformation and damage to the original quality criteria.

Technical characteristics of penoplex 45:

- operating temperature range -50…+75°С;

- water absorption - no more than 0.2% by volume in 24 hours;

- vapor permeability coefficient - 0.05 mg / (m * h * Pa);

- combustibility group (resistance to fire) - G4;

- thermal conductivity - 0.03 W * m * 0K;

- modulus of elasticity - 15 MPa;

- service life - 50-60 years.

The environmental safety of the insulation is achieved through the introduction of freon-free technologies into the production cycle and the use of non-toxic components.

Penoplex products are resistant to negative environmental influences and most chemicals: organic and inorganic acids, alcohols, alkalis, bleach, ammonia, etc.

The main criterion for choosing a heater

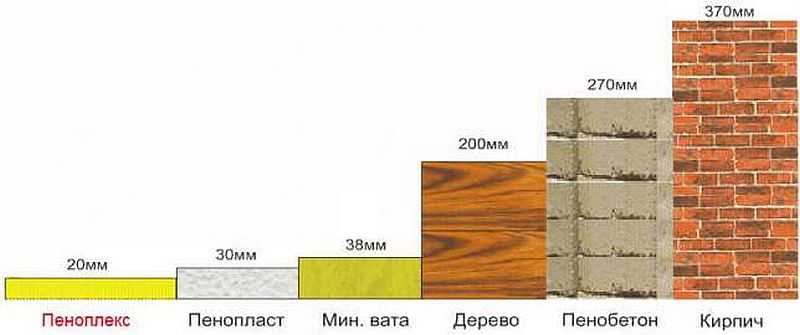

Insulation is selected according to the heat-shielding ability. This property is quantitatively expressed in thermal conductivity, which shows how much thermal energy per second a heater one meter thick will release from the room with a temperature difference of one degree inside and outside. Extruded polystyrene foam, from which PENOPLEX boards of all grades are made, has low thermal conductivity: from 0.029 to 0.034 W / m•K. In this, the material surpasses other widespread heat insulators - mineral wool and foam plastic, in which the thermal conductivity, respectively, fluctuates in the ranges of 0.037–0.055 and 0.041–0.059 W / m•K. Thus, to create the same temperature conditions in the room, a layer of thermal insulation made of mineral wool or polystyrene will need to be 30–70% thicker than PENOPLEX boards. Useful space is saved.

Features of the installation of penoplex

• When choosing penoplex, it is necessary to take into account the density of the material. For insulation of walls, balconies, plinth, it is recommended to use indicators of 25-32 kg / m3. For roofing work, a heater with a density of up to 35 kg / m3 is selected.

• Before fixing the plates, it is necessary to prepare the surface in advance by cleaning it of dirt and repairing the detected cracks. If the structure is dilapidated, it is irrational to produce insulation.

• Start laying penoplex should be with the installation of the L-shaped profile (starting strip). The arrangement of the plates resembles brickwork. The offset of the seams along the rows gives the surface strength.

• First, the insulation is attached with a special adhesive. After it hardens, additional fixation of the insulation is performed using fungal dowels. 5-6 pieces are consumed per square meter.

• Joints between foam sheets should be minimal to prevent the formation of cold bridges.

• Corner parts of the working surface are reinforced with special perforated corners.

• If further finishing involves the use of plaster, a fiberglass reinforcing mesh is attached to the insulation with a mortar. In the case of covering the surface with finishing panels, the joints of the plates are additionally glued with foil tape to make the joints tight.

• The strength of foam plastic is quite high, so almost any plaster can be used for finishing: embossed, structural, etc.

• Plates for thermal insulation of the floor have grooves along the edges, so when connected they form a flat surface. This method of insulation can be used under the topcoat, having previously cleaned and re-primed the concrete base. The main condition is the installation of a log.

Before using penoplex, as well as any other material, you should consult with a specialist about the possibility and rationality of this insulation for a certain type of work. The master will be able to recommend the density of the plates, based on the study and calculations of heat losses.

Is it profitable to use penoplex 45

Affordable price and thermal insulation characteristics provided foam 45 with a wide area of operation and stable demand in the market.

Penoplex was used in the insulation of foundations, basements, basement floors of residential and public buildings, inverted roofs, floors in production shops and workshops.

It is used in the reconstruction of city streets and as a “substrate” for ice arenas, sports grounds, car parks, and pedestrian zones.

Additional thermal insulation of transport highways eliminates the risk of freezing and frost heaving of the soil, which means it prevents the appearance of potholes, cracks and dents on the road surfaces.

The economic feasibility of using insulation is aimed at saving energy resources and is due to a reduction in the cost of heating buildings, restoration of structures, and road maintenance.

Ways to increase fire resistance

There are several ways to increase the fire resistance of building structures. The simplest and most common option is to use plasters and plasters. In this way, you can close structures made of different building materials. That is, there are no restrictions, in principle. At the same time, they close both load-bearing and non-bearing structures.

The most common mixtures are lime plasters, cement, which include perlite, vermiculite, and others. But the ideal solution is based on asbestos. They try not to use it indoors.

The second option is lining. Usually brick, gypsum or clay slabs are used for this.

Here it is important to indicate the fact that each material has its own special requirements for the fire resistance limit. Because it all depends on the time that the lining can withstand

For example, an ordinary brick, laid with a layer of at least 80 mm, will withstand the onslaught of fire for 2 hours. But a clay slab of the same thickness resists fire for 4.8 hours.

The third option is protective screens. In fact, screens for walls and columns are panel structures such as siding. Hanging products are used for the ceiling. Manufacturers today offer two varieties of them that differ from each other in the way of protection: these are reflective materials and absorbing. The latter are screens that oppose the radiant energy of the flame of fire. Such fire protection can be stationary or mobile. Water curtains can be classified as protective screens - not the best option if a fire occurs over a large area.

The fourth is the use of flame retardants. Unfortunately, the advertised method is not a panacea for the harmful effects of fire. It has little to do with fire resistance. Impregnation simply delays the burning of wood for a short time.

And the fifth way of protection is special paints and varnishes. Their action is to swell at high temperatures, creating a fairly thick layer of insulation. But it is still ineffective compared to plasters or cladding. Therefore, most often paints are used to protect metal.

Speaking about the limits of fire resistance of building structures, it must be understood that all of the above methods increase the cost of construction.But today it is a simple necessity, which sometimes guarantees the lives of people who are in a burning building.

Video:

What is Penoplex and its area of \u200b\u200buse

Penoplex (sometimes written "Penoplex") is a heat-insulating material produced by the company of the same name.

The PENOPLEX company produces extruded polystyrene foam (EPS or XPS). This material is used as a heater. From a cheaper analogue - expanded polystyrene (polystyrene, PPS or PPS) - it differs in greater density, due to which it better tolerates mechanical loads. Another distinguishing feature is lower vapor permeability. Rather, he almost does not conduct steam. And the main trump card is the best thermal performance. Penoplex 20 mm thick in terms of heat preservation is equivalent to almost double the thickness of mineral wool and 37 cm brickwork.

Penoplex is one of the most effective heat-insulating materials

These characteristics determine the area of use of Penoplex. It is recommended for warming those areas where resistance to stress is important, and low vapor permeability is one of the requirements. Specifically, Penoplex is recommended to use:

- For floor insulation:

- under the screed, on it, as an intermediate layer;

- when arranging the floor on logs (with some reservations);

- heat-insulating layer under a heat-insulated floor (water or electric).

- When arranging a blind area around the house.

- Insulation of the basement of the house (if it is non-residential).

- On rooftops (ideal for flat roofs, green roofs, the rest you have to be careful because it does not emit much steam).

- Paths, platforms for gazebos.

- Warming of septic tanks, wells, etc.

Another area of use is the thermal insulation of facades or internal walls. But here it must be understood that due to the fact that Penoplex practically does not conduct moisture, additional measures will be needed to ensure that vapors do not get inside the wall. Plus, a well-thought-out ventilation system is needed to normalize the humidity in the house. And, in addition, you need to choose the thickness of the insulation so that the dew point is inside the insulation, but not in the wall.

Optimal - insulation of a recessed basement

If you prefer "breathing" walls, natural regulation of humidity - for this case, Penoplex is unsuitable for wall insulation. It does not go under ventilated facades either. There, just the task is to remove moisture from the insulation due to the movement of air in the ventilation gap. This material is not able to provide, since moisture simply does not get inside the Penoplex.

Fire resistance class v1 which means alekstroy.ru

/ Fire protection / Resistance and hazard classes /

An important parameter of materials, especially in the field of construction, is their fire hazard. It is such a priority that the flammability groups are determined by the Federal Law. There are four of them: G1-G4. Non-combustible materials are allocated in a separate category.

It is important to understand what this classification means, this will allow specialists to correctly select and use building materials to ensure the fire safety of facilities. It is possible to determine the degree of fire resistance only in a special laboratory that has official specialized accreditation

Methods are regulated by GOST30244-94

It is possible to determine the degree of fire resistance only in a special laboratory that has official specialized accreditation. Methods are regulated by GOST30244-94.

Fire resistance of premises

The fire resistance of building structures must be approached taking into account their presence in the premises. The latter in terms of fire resistance are determined by their content. That is, those things, materials, furniture and other accessories that fill the space of the room. There are five positions here:

- Category "A".Explosive and flammable materials and products that ignite and explode at temperatures below +30C are stored in the premises.

- "B". The same only at temperatures above + 30C.

- "V". The same only without the formation of an explosion. That is, the filling only burns, but does not explode.

- "G". In the premises there are materials of non-combustible type, which, according to technological processes, are in a heated state. They give off heat, sparks, and so on.

- "D". Non-combustible materials (liquids, gases, solids) are stored or processed in a cold or frozen state.

The use of comfort foam

The use of this type of insulation is possible in almost any climatic zone. It can be used not only for thermal insulation of floors, but also for warming pools, saunas, baths and other rooms with a high level of humidity. Installation work on laying sheet material does not present any difficulty, it has clear geometric shapes, for ease of connection, the edges are made in the form of the letter G. Penoplex "Comfort" is successfully used for insulation:

- balconies and floors;

- ground floor;

- building roofs;

- wall structures;

- foundation bases.

Variants of using foam "Comfort" for roof insulation

In thickness, this type of expanded polystyrene can reach 15 centimeters, which determines the mechanical strength of the coating and significantly increases the operational life of the building structure. In direct contact with moisture or soil, Comfort foam, due to its antifungal properties, is not subject to rotting and decomposition processes.

Floor insulation on logs

Insulation of the floor on the logs begins with the inspection and replacement of damaged areas and the treatment of the boards with a special compound that prevents them from rotting. Then all cavities are leveled with putty, the surface is dried and covered with soil. Insulation sheets pre-cut to the required dimensions are laid on dry boards with a minimum gap. The joints are sealed with tape.

Sheets of material intended for arranging a vapor barrier layer are laid on top with an overlap. Chipboards, plywood or other similar material are attached to the most leveled surface, parquet, laminate or linoleum is laid on top. It turns out several layers:

- beam ceilings;

- wooden lumber;

- foam sheets;

- vapor barrier layer;

- shield cover;

- material used as a floor.

Floor insulation with laying on the ground

Penoplex "Comfort" fits on the ground for floor insulation in building structures supported by a strip or pile foundation. A layer of crushed stone or gravel is poured onto the leveled soil, on top of it is sifted sand, which is tightly compacted.

Insulation sheets are laid on the resulting surface with minimal gaps, the joints of which are carried out using spikes and grooves cut into them. A film is placed on top of the insulation to form a waterproofing layer, a reinforcing mesh is laid, and the surface is covered with cement mortar. After it dries, the floor covering is laid. The following layers are obtained:

- soil surface;

- crushed stone backfill;

- sand cushion;

- insulation;

- film waterproofing;

- mesh reinforcement;

- a layer of cement mortar;

- material used as a floor.

Wall insulation from the inside

Insulation of walls from the inside begins with their thorough cleaning and applying a layer of soil to their surface. Insulation sheets are reinforced with glue and plastic fasteners. Joint gaps are filled with construction foam. If their width exceeds 100 mm, cut insulation boards must be inserted into the cavities.

Insulation of walls, floor and ceiling of the loggia with penoplex

A reinforcing mesh is strengthened on the resulting surface, on top of which a layer of mounting plaster is applied. After it dries, a finishing plaster is applied to the surface and the final wall covering with wallpaper or painting is performed. Thus, the following layers are formed:

- primed surface;

- adhesive layer;

- insulation sheets;

- fiberglass mesh;

- plaster layer;

- putty;

- wall finishing material.

Stability class feature

PENOPLEX boards of all brands are durable. The service life of extruded polystyrene foam, according to the results of tests at the Research Institute of Building Physics, is at least 50 years. During all this time, the material stably retains heat-shielding properties due to zero water absorption. Water has a higher thermal conductivity than insulation and degrades the heat-shielding properties of non-moisture resistant materials, including fibrous mineral wool and granular foam.

Zero water absorption of PENOPLEX also deprives the source of life of bacteria, fungus, mold and other harmful microorganisms, for which this material, moreover, is not of interest as a food product. Thus, PENOPLEX is distinguished by absolute biostability, which is confirmed by tests in mycological centers.

Where is used

The performance qualities of Comfort foam allow it to be used not only in a city apartment, but also in a private house. If you compare the insulation with other building materials, you can notice significant differences. Similar insulating products have a narrower specialization of application: thermal insulation of walls or roofs.

Penoplex "Comfort" is a universal insulation that is used for thermal insulation of balconies, foundations, roofs, ceiling structures, walls and floors. Also, the insulation is perfect for thermal insulation of baths, pools, saunas. Insulation "Penoplex Comfort" is used both for internal construction work and for external.

Safety first

PENOPLEX boards contain no toxic components. In their production, the same grades of polystyrene are used as for the manufacture of children's toys, food packaging and medical devices. Materials for the food and medical industry are subject to strict sanitary standards. Therefore, PENOPLEX does not pose a danger to human health. We also note that plastic processing waste is not used in its manufacture, only primary polystyrene is used.

PENOPLEX has a certificate with a high degree of environmental safety. The plates are painted orange, which symbolizes warmth and environmental friendliness.

Where penoplex 45 is justified

First of all, the use of this material is justified for the thermal insulation of bases that are regularly subjected to dynamic loads. Here, foam plex plates are assigned the role of stabilizers and vibration dampers, which are able to withstand up to 50 tons of excess weight per 1 sq.m. and evenly distribute gravity.

Penoplex type 45 also performs the function of an auxiliary supporting structure - for example, in the construction of agricultural hangars and private low-rise buildings.

Different types of Penoplex have their own characteristics, they can be divided into several main groups.

The main properties of the material include a fairly low coefficient of thermal conductivity. Another important advantage of this material is soundproofing.

Penoplex allows you to create sound absorption in the room, this is especially important in the use of private housing construction. The service life is also important, Penoplex sheets will effectively serve for more than a dozen years, and the waterproofing properties of foam are manifested in low moisture absorption.

The safety characteristics of penoplex are expressed in environmental friendliness and moderate fire resistance (Fire resistance category: G3 or G4).

The resistance of Penoplex is due to the low rates of compression of the material. Penoplex will also not decompose under the influence of certain solvents and soil salts.

All the main characteristics of Penoplex are given in the table:

Thermal insulation of external and internal enclosing structures

Not for use in loaded structures!

Select sheet thickness:

| 20 mm | 30 mm | 40 mm | 50 mm | 60 mm | 80 mm | 100 mm | 120 mm |

Description

PENOPLEX OSNOVA is a high-performance heat-insulating material of the latest generation, manufactured by extrusion from general purpose polystyrene. Zero water absorption, high strength, low thermal conductivity and environmental friendliness are the main advantages of PENOPLEX insulation compared to other materials.

Application of PENOPLEX BASIS

Designed for use in industrial and civil construction, it is a universal material for use in any structures (walls, roofs) where there are no special requirements for structural loads.

Characteristics of PENOPLEX BASIS

- consistently low thermal conductivity;

- zero water absorption (homogeneous structure of sealed cells);

- high compressive and bending strength;

- absolute biostability;

- durability;

- environmental friendliness.

Technical details

Name

Test method

Dimension

Slab index

Compressive strength at 10% linear deformation, MPa (kgf/cm2; t/m2) 50 mm

GOST EN 826-2011

Water absorption in 24 hours, no more

Water absorption for 28 days, no more

fire resistance category

Estimated coefficient of thermal conductivity under operating conditions "B"

Partition soundproofing (GKL-PENOPLEKS 50 mm-GKL), Rw

Structural noise insulation improvement index in floor construction

Standard sizes penoplex 45

Penoplex 45 plate dimensions: standard length - 2400 mm, width - 600 mm, thickness varies between 40-100 mm. Products of a different format with individual dimensions and thickness are made to order.

If necessary, during the installation process, the Penoplex panels are cut into separate segments, adjusting to the desired dimensions.

After laying, to maintain the integrity of the outer surface, the insulation is covered with finishing materials, a reinforcing mesh. And during storage, in order to protect the penoplex from exposure to ultraviolet radiation, they control the safety of the factory packaging. Penoplex insulation is a convenient and reliable thermal insulation that will last a long time if you follow the technology of storing and laying the material.

Penoplex OSNOVA

Universal lightweight insulation based on extruded polystyrene foam. Designed for insulation of ceilings, floors, walls and roofs, as well as any other structures that do not carry increased loads. Plates Penoplex Basis can also serve as effective sound insulation and wind protection. Thanks to the L-shaped edge, made on all four sides, a continuous insulating layer with tight windproof joints is obtained. This is an environmentally friendly thermal insulation and it is allowed to install it in residential premises. The material is safe, so you can work with it without protective equipment. The manufacturer produces another similar insulation - Penoplex Comfort. Its physical and mechanical characteristics are almost identical to the Base, except for one parameter - compressive strength. The material can withstand 0.18 MPa/sq. M, which corresponds to 18 t/sq. m. This indicator indicates a lower bearing capacity.

Application in the insulation of building structures

The versatility of the application is facilitated by the low prices for heat-insulating boards Penoplex Osnova, as well as its excellent technical characteristics. The material is popular and widely used both in St. Petersburg and in all other climatic zones of Russia for thermal insulation of ceilings, floors, walls, roofs and any parts of the building that are not designed for high loads.However, most often the insulation is placed in the construction of floors, plinths, blind areas.

| Aerated concrete wall insulation, well masonry system | Brick wall insulation, well masonry system | Insulation of a monolithic reinforced concrete wall, well masonry system |

You can appreciate the advantages of these extruded polystyrene foam boards when installing the thermal insulation of the floors of the first floors above the ventilated underground. Overlapping works in the conditions of sharp temperature difference and high humidity. Nevertheless, the efficiency of the insulation is at a high level. The material will be useful when laying under the screed, for soundproofing floors between heated floors, as well as in the construction of "warm floors".

The technical potential of Penoplex Osnova boards is ideal for thermal protection of the basement and first floors. In these structures, there is an increase in air infiltration due to a large pressure drop between the outer and inner sides of the wall. In addition, direct contact with the soil makes such qualities of the material as biostability and low water absorption indispensable. That is why the zone of the first floors requires increased protection, which is provided by the insulation.

| Basement insulation, for finishing with natural stone or clinker tiles | Basement insulation, for finishing with plaster with a metal mesh | Insulation of the basement from the inside |

Benefit from the acquisition of material

The purchase of these plates is beneficial for several reasons. Firstly, the convenient size and the presence of a connecting edge allow you to perform a perfect installation on your own and save on labor costs. Secondly, zero moisture absorption makes it possible to avoid the installation of a separate layer of waterproofing, i.e., saving both on material and on work. Thirdly, reliable thermal protection and the absence of "cold bridges" significantly reduce heating costs. However, these are far from all the benefits of acquiring Penoplex Osnova. A strong argument in favor of this brand is the low price both per m3 and per sheet. The plant for the production of the material is located in the Leningrad region, so for residents of the city of St. Petersburg, the cost of delivery and the trade margin are minimal.

Universal insulation Penoplex Basis has excellent technical characteristics. The low density provides light weight, due to which the boards do not weigh down the supporting structures. Despite the lightness, the material is quite durable - the compressive strength is 0.12-0.22 MPa. Low thermal conductivity guarantees high energy efficiency of the house and significant energy savings. The clear geometry of the plates and the presence of an L-shaped edge help protect the house from drafts. Thanks to them, you can get a continuous heat-insulating contour, impervious to cold.

It should also be noted such valuable qualities of the material as low vapor permeability and zero water absorption, excellent biostability and environmental safety. Thermal insulation is not subject to biodegradation, is not affected by mold and microorganisms, and is completely safe for the natural environment and humans. In addition, the plates are very durable and will last more than 50 years.

Rough nuance

This is useful where a rough surface is indispensable. PENOPLEXSTENA boards are used for thermal insulation of walls with finishing without mechanical fastening. In other words, where the finishing material cannot be attached with nails or dowels with self-tapping screws, but one has to rely only on adhesion forces (adhesion). We are talking about finishing with plaster and tiles.

Recall that the plaster system is built as follows. A layer of basic plaster-adhesive composition is applied to the heat-insulating layer of PENOPLEX boards with a rough surface, a reinforcing mesh is embedded into it, then, after drying, a facade primer is applied and, finally, a finishing layer of decorative and protective plaster.Therefore, for the reliability of such a plaster system, high adhesion (adhesion strength) of the insulation surface with basic plaster and adhesive compositions is required. For the rough side of the PENOPLEXSTEN board, this indicator is, of course, significantly higher than for the smooth surface of the PENOPLEXSTEN board and the surfaces of other heat-insulating materials. In particular, it exceeds the adhesion of foam plastic by more than 1.5 times, mineral wool - by more than 2.5 times.

It is important to note that the adhesion strength of the rough surface of PENOPLEXSTEN is 3 times higher than the standard value specified in the technical specifications for the use of adhesive compositions

Thus, PENOPLEXSTENA boards are designed for wall insulation with subsequent finishing with various types of plaster: cement, lime, lime-gypsum, cement-lime, polymer-cement, acrylic, etc. At the same time, PENOPLEXSTENA can be used both for external insulation with a plastered wall, as well as and internal with wall decoration with interior decorative plaster.

An example of a wall construction with PENOPLEXSTEN thermal insulation and external finishing with plaster on a polymer mesh.

PENOPLEXSTEN is a highly specialized insulation, in contrast to PENOPLEX COMFORT, which can be called a wide profile insulation.

Finishing the story about the differences between the brands PENOPLEX COMFORT and PENOPLEXSTEN, we note one more important possibility of using thermal insulation. PENOPLEXSTEN boards go on sale with a rough surface of factory quality. However, you can prepare a plate for applying the plaster composition with your own hands. To do this, immediately before installation, notches are applied to the PENOPLEX COMFORT boards to improve adhesion. But it is more expedient to purchase specialized PENOPLEXSTEN boards, which are prepared for plastering work in the factory.