We lay the substrate mounting technology

In principle, for laying linoleum, you do not need to have any special knowledge, but you should still follow some rules. First you need to carefully clean the floor of dirt and dust, vacuum, and if necessary, then wash it.

Now the layer of the insulator itself is laid. If the substrate material is rolled, then you just need to cut off the strips of the desired length and lay them on the floor, and glue the joints with adhesive tape. If the substrate is sheet, then it is necessary to lay out the sheets in a checkerboard pattern and carefully glue the joints.

The next layer is linoleum itself, however, before final laying, it is recommended to spread it freely on the floor and leave it in this position for a couple of days.

About the need for vapor barrier

Many do not know why a vapor barrier is needed in a floor covering with insulation. The fact is that the water vapor that is released during wet cleaning or cooking tries to seep through the walls and floors of the rooms, while it negatively affects various wooden structures, such as logs. Through the temperature difference in adjacent rooms or inside and outside the building, the steam turns into condensate. Subsequently, water seeps into the structure of the wood and causes its destruction.

The walls of a wooden house, as well as the roof, are protected from moisture by an antiseptic or waterproofing impregnation, which cannot be said about the elements of the floor. To protect the lag, a vapor barrier film is used, which protects not only wood, but also insulation, such as mineral wool, from destruction. In this case, the vapor barrier allows the building to breathe. That is, air saturated with water will freely pass through thermal insulation and wood products.

Linoleum on felt base

Felt-based linoleum is a heat-insulating two-layer finishing material, the lower layer of which is made of an antiseptic gasket, and the upper layer is made of a polyvinyl chloride film. For the flooring of such linoleum, the base is thoroughly cleaned of dust and debris, it must be strong, even. To prevent the absorption of moisture by the fibrous part of the linoleum, the moisture content of the base should not exceed 5%. For these purposes, a small piece of glass is used, which is placed on the base. After two days, there should be no traces of moisture on the glass. If this condition is not observed, the felt base of the laid linoleum may rot after some time. This will entail additional costs, including surface treatment with special solutions that prevent the spread of mold.

Linoleum on a felt basis is laid with panels of different sizes. In specialized workshops, several elements are pre-welded together into panels, which are carefully protected from moisture during transportation. If necessary (subject to compliance with all conditions), such welding can be done directly in the room. But it must be remembered that the possibility of penetration of moisture under the linoleum in the future depends on how well the seams are welded.

Having rolled out the finished panels onto the base without gluing, they are left in this position for at least 48 hours.At the same time, the panels should be matched by shade, color and pattern, should not contain waves and swellings, they should not have spots, scratches and tears, and butt welds should be located in the direction of light.

After some time, the panels are cut around the perimeter of the room, leaving a small gap between the wall and the edge of the linoleum of about 0.5 cm, then a threshold cut to the size of the opening is laid at the junction and glued to the mastic. The cut edges of the linoleum are bent, and, well smearing the base of the linoleum with glue, they are pressed tightly to the base. After that, the cargo is left in these places for some time.

The price of felt-based linoleum

For example, here are the prices for some types of felt-based linoleum:

| A type | Price m2 |

| Domestic | 200-300 rub. |

| semi-commercial | 300-500 rub. |

| Commercial | 400-2000 rub. |

| antistatic | 400-500 rubles. |

| anti-slip | 900-1200 rub. |

| Natural | 700-1500 rub. |

Warm linoleum

Such a variety as warm-based linoleum also deserves special attention. We are talking about the following type of coating: the film is glued to a base made of felt or jute. The result is a fairly elastic and at the same time soft linoleum, which is pleasant to walk on.

Laying linoleum on a warm base is very simple, it does not take much time, because gluing to the floor surface is not unnecessarily laborious.

True, this kind of coating is characterized by certain disadvantages. So, linoleum with a warm base does not have enough strength. Consequently, it is very easy to damage it, which requires the utmost care in handling this flooring.

For this reason, linoleum with a warm base, being installed in places with very high traffic, very quickly begins to lose its external properties.

In addition, it will not be possible to lay a warm linoleum coating in those rooms where there is a sufficiently high level of humidity: the effect of water negatively affects the base, causing its destruction. This is especially true for those coatings in the manufacture of which natural materials are used.

Therefore, the most relevant warm linoleum is for children's rooms and bedrooms. And if the basis is also felt, then such linoleum can be laid very quickly and easily.

Insulated linoleum varieties and main characteristics of the coating

Linoleum has long been considered one of the most comfortable and popular floor coverings. This is due to many reasons: the hygiene of linoleum, its good performance, relatively low cost, simple installation.

Among the existing variety of types of linoleum, insulated linoleum should be specially mentioned. Such a coating may have different properties. So, taking into account the binder, natural linoleum, PVC (i.e. polyvinyl chloride), alkyd, colloxylin and the so-called relin (rubber linoleum) stand out. Insulated linoleum can also have a foam base or warm.

Photo: insulated linoleum

Photo: insulated linoleum Insulated linoleum is used in cases where there is a need to insulate the floors of the room, while avoiding high costs. Most often, this type of coating is used for laying a concrete base, which, in principle, is quite cold. However, laying is carried out on wooden surfaces. Since the insulated linoleum has a significant indicator of thickness, its use is also justified in those rooms where the coating is not perfect enough, there are cracks, relatively small height differences. This approach saves time.

Insulated linoleum

Details : 04 January 2014

To create a floor that would keep a comfortable temperature even in the cold season, it is not necessary to spend money on expensive insulation systems and materials. Now there is a wide choice of floor coverings that will perfectly cope with this task, at a more affordable cost.

Insulated linoleum is worth noting especially in the category of available materials for floor insulation.

Its popularity can be explained by its high wear resistance and ease of installation. Often, the decision to use such linoleum as the final floor covering is made when there is an urgent need to insulate the floors, but with high quality and budget.

Insulated linoleum is laid both on a concrete base, which, as you know, is quite cold in itself, and on a wooden floor. There are two types of warm linoleum - linoleum on a warm substrate and on a foam base.

In fact, there are not many differences between these two types, but they lie in different compositions and wear resistance.

Linoleum on a warm substrate. This type is the simplest and most inexpensive. This coating consists of two layers - the base and the top layer. The bottom layer is usually made of jute or felt, and the top layer is PVC film. This linoleum is soft and resilient.

Since the top layer of PVC film is not too strong, it is very easy to damage it, so you need to be extremely careful with it during operation.

In addition, this type of insulated linoleum is not advised to be laid in places with a high operational load, because its base may lose its thermal insulation properties.

You should also not forget that since the base is made of natural materials, such a coating should not be laid on a base with low waterproofing and in rooms with high humidity. Otherwise, there is a high probability of mold. Now linoleum on such a basis almost does not appear on sale, it has been replaced by linoleum on a foam basis. Its average cost is 130 rubles/sq.m.

Foam-based linoleum. This type of linoleum is characterized by its multi-layer, it consists of 5-6 layers, each of them performs its function.

A bottom layer of foam rubber or foamed polyester/vinyl blend provides flexibility and high load capacity. It stretches well, does not tear and has increased moisture resistance.

The next layer is the carrier, it is made of fiberglass and is responsible for the strength of the entire coating. On top of it is a layer of foamed PVC, followed by a layer on which the pattern is applied. On top of the linoleum is covered with a protective film, which ensures the wear resistance of the coating.

Such a multilayer structure gives the coating high heat and sound insulation, moisture resistance and strength. The average price of such coverage is about 200 rubles/sq.m.

When choosing a warm linoleum, it is worth remembering that linoleum on a warm base of jute or felt should not be laid in rooms with high humidity, and it is also not advised to glue it, in order to avoid a decrease in thermal insulation properties. But for the "Warm floor" system, such linoleum is more preferable than on a foam basis, due to its greater naturalness.

Carpet: types and advantages of coverage

Modern excavators perform many functions…

Cargo platform trucks are one of the best…

Currently, conveyor suppliers http://ko…

KamAZ dump truck http://autospecmash.ru/ can be purchased…

In today's world, there are a huge number of…

It is sometimes quite difficult to pick up tulle, because modern ...

Making repairs in the hall is a serious matter, especially if…

The decorative design of the premises is made by many…

3D photo wallpaper is a unique finishing material for…

The Seven Best Building Books 1. How to Build…

Do you have a good imagination? Wonderful. However, often...

Small walk-through rooms, shared bathroom,…

The ancient Chinese technique of Feng Shui claims that...

Photo printing on stretch ceilings gives a wide…

The modern restaurant is a…

Remember the cute Carlson who lives on the cr…

Floor insulation in the apartment on the first floor

In the case when the apartment on the first floor of a residential building is located above the basement, the best option for floor insulation will be laying thermal insulation from the side of the cellar

In this case, one important advantage can be achieved - the floor in the apartment does not need to be torn off and redone. In this case, the level of the floor covering will remain at the same level as before.

Such work can be carried out even by inexperienced builders, since the base surface does not need a fine finish.

As a heater, many choose affordable mineral wool, but laying such material requires special knowledge and the availability of construction tools. That is why most property owners use foam floor insulation.

The whole process of work consists of several stages:

- They find the plan of the first floor of the house and mark the basement in such a way that the boundaries of the insulation slightly exceed the dimensions of the apartment;

- We determine the defective places on the basement ceiling. We close up cracks, holes or chips on the surface with mounting foam or cement-sand mortar;

- We lay vapor barrier, plastic film. This material is overlapped, the sections are glued together using ordinary adhesive tape;

- We build a frame from a metal profile or wooden bars of the desired thickness;

- We lay mineral wool slabs, fix plywood sheets.

Installation of foam sheets is carried out somewhat differently. The fact is that the insulation in question does not allow moisture to pass through, so it can be fixed on the surface of the basement walls using a special adhesive solution. For the final fixing of the products, plastic dowels are used.

The second option, the insulation of the floor covering in the apartment, is characterized by increased labor intensity. Before carrying out repair work, it is necessary to calculate the possibilities for the maximum rise of the floor. The higher this indicator, the thicker the insulation layer can be laid. In the case when insulation work will take place after the repair of the premises, the first step will be to remove the floor covering.

https://youtube.com/watch?v=6eSa8gPCLsM

After dismantling the floor structure to the base, the master checks the surface for bumps, cracks and chips. All defective places are sealed with a cement-sand mortar. Subsequently, the dried and hardened base is treated with a fixing impregnation, a substance called silling. At the next stage, a waterproofing polyethylene film is fixed on the surface, the panels of which are fastened with adhesive tape.

Next, a layer of roofing material is laid on the base, a wooden beam is installed, and logs are fixed. These elements must be securely fixed in concrete. Next, expanded clay granules are poured to the thickness of the log. The upper part of the insulation is leveled with a cement screed. The logs do not fall asleep to the top, but in such a way that insulation can be laid between the rough and finishing floors.

As an additional heat-insulating material, mineral wool slabs of the required thickness, foam plastic or foam plastic can be used. In addition, liquid insulation - penoizol - is often laid in the gap formed. Next, fix the plastic film along the logs with a stapler. At the final stage of work, a subfloor is made from plywood sheets or boards. The insulation is completed by laying the selected floor covering.

Do you need

The expediency of using a substrate for linoleum on a concrete floor follows from its main functions listed above.Therefore, it is necessary to use an intermediate layer when laying a floor covering in the following cases:

- a cold floor is one of the most common reasons for choosing underlayment linoleum flooring. This simple detail will not allow the penetration of cold from the lower unheated rooms. With such a problem, flooring experts advise using underlays made from a combination of natural ingredients such as wool, jute and linen, which are best able to keep the floor warm;

- Another popular reason for using underlay is an uneven floor. Today, hardly anyone can find a perfectly flat concrete floor. Therefore, with the help of an intermediate layer, you can hide small irregularities and cracks in the concrete floor screed, which will also protect against premature damage to linoleum;

- the use of underlay material becomes a must when choosing linoleum without a base. Thin linoleum does not hide the flaws of the concrete floor and is not able to provide thermal insulation, therefore, it needs an additional intermediate layer.

Other situations allow you to start laying the flooring without the use of an underlay.

Why you need to insulate the floor

Insulation of the floor structure is necessary to create a favorable microclimate in the house. Carrying out such work is especially important in an apartment on the ground floor, because the premises of such a dwelling are not heated from below. Many property owners believe that wood flooring retains heat well, but in fact, even such products need additional insulation.

So why insulate the floor, many are perplexed? The answer to this question can be quite simple. The fact is that the flooring of a country house or apartment occupies a significant area. Cracks and chips may be present on its surface, which contribute to the release of heat and the ingress of cold air into the middle of the room.

If we take into account the concrete base, then such a material is characterized by high performance (durability and strength). Despite this, a reinforced concrete floor slab or leveling mortar screed has one significant drawback - this is a high coefficient of thermal conductivity.

Due to this characteristic, concrete is considered a cold building material. Insulation of the flooring structure increases the efficiency of the heating system, helps to reduce energy costs.

Laying thermal insulation is especially necessary for an apartment, which is located on the ground floor of the house. Living rooms are usually located above a damp and damp basement, which can lead to mold on the walls. To prevent this from happening, laying insulation and waterproofing is necessary. With a minimum of experience and the necessary construction tools, any property owner can handle such work. Next, we describe how to make floor insulation with your own hands.

What you need to know to choose the right one

The choice of linoleum.

When choosing this floor covering, the purpose of the room is taken into account.

So, consider the types of linoleum:

- domestic;

- commercial;

- semi-commercial.

The household type of this material is used for residential premises, that is, where the surface will experience a slight wear load.

Commercial and semi-commercial types withstand a large flow of people, they are used for public buildings.

From what kind of insulation base is used for this coating, its operational properties depend.

foam base

This basis is used for multilayer linoleum.

Foamed vinyl layers are applied to the carrier layer of fiberglass on both sides.

Such a structure gives it elasticity and softness, increases sound and heat insulation properties.

On the front side of the product, the printed pattern is protected by a transparent PVC layer.

It retains a beautiful appearance for a long time, this is facilitated by the use of technology for drawing a pattern over the entire thickness of the layer.

This flooring is durable, easy to clean, practical, not afraid of moisture.

Can be used in high traffic areas.

How to lay laminate on the floor, you can find on our website.

What is osb plate? How to use it to level a wooden floor? If you do not know all this, this article will help you.

What can be put under the laminate, read here: http://floordigest.ru/iskusstvennie-pokritija/laminat/kak-pravilno-klast-laminat.html.

naturalness

Felt or jute is used as a natural base.

This coating is pleasant to the touch, it is soft and elastic.

Good for nursery and bedroom.

Do not use this type of floor product where moisture may appear, because the natural substrate is afraid of decay.

The top layer is not ready for increased abrasion loads, this fact is also taken into account when choosing a floor covering.

Polyester products

The floor covering has proven itself well, where polyester is used as a heater - a white base made of synthetic fiber.

Such material has good strength, heat and sound insulation characteristics.

Double base: foamed vinyl and polyester

The modern look of this flooring, which combines two types of insulation - foamed vinyl, which gives the material additional strength, moisture resistance and polyester, which enhances the thermal insulation properties of the coating.

The product is not afraid of temperature differences, it can be used in periodically heated buildings.

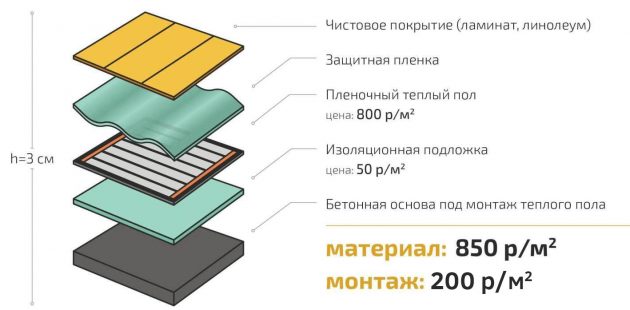

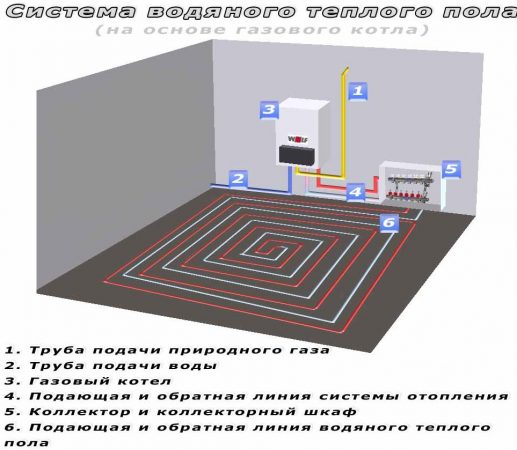

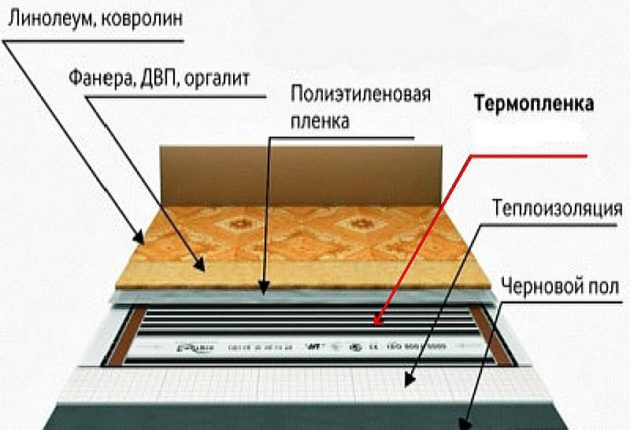

Types of warm floors

Among the technologies used, you can find the following options for underfloor heating:

- Water.

- Electric.

- Infrared.

The water heated floor system is based on heating water in pipes laid inside a concrete screed or over a wooden base. In apartment buildings, such a floor is practically not used, since its laying requires a mandatory screed between the coating and the heating system. For rooms with low ceilings, this option is inconvenient. Water floors are heated to the desired temperature rather slowly.

Electric underfloor heating consists of heating elements, which are placed in a concrete screed, and a regulator. The advantage of this technology is uniform and fast heating. But if the process is not tracked in time, the surface will begin to deform due to overheating.

The infrared floor, one of the varieties of the electric floor, is a system of graphite strips, which are the heating elements. The technical characteristics of this electric floor provide gradual and uniform heating. Of the minuses - the infrared floor is afraid of moisture, so it is not recommended to mount it in bathrooms and showers.

Floor insulation in a wooden house

Before the process of thermal insulation of the floor covering in a private house, it is necessary to select a heater. There are a huge number of similar products on the construction market, but the best materials for floor insulation are:

- mineral wool;

- penofol;

- extruded polystyrene foam;

- isolon;

- ecowool;

- expanded clay;

- sawdust.

It is not difficult to understand that sawdust is considered the cheapest type of thermal insulation. Such material is obtained after wood processing on special equipment. This is a secondary product that is environmentally friendly and has a minimal cost. In addition, sawdust can be poured into any cracks. The floor insulated with their help will be absolutely safe for human health.

The second most accessible and popular heat-insulating materials, mineral wool, are distinguished by good heat-insulating and sound-proofing performance.Such products are available in the form of mats or rolls. They do not burn under the influence of high temperatures, in addition, fungus and mold do not appear on their surface. The main disadvantage of the material is the loss of its original properties when it penetrates into the water structure. In this regard, mats must be protected from moisture with high-quality thermal insulation.

Such heat-insulating material as isolon is made on the basis of mineral fibers. Such products are characterized by low thermal conductivity, resistance to chemicals and biological factors of influence. The insulation has an average cost, is resistant to mechanical stress.

And the last material, expanded polystyrene, has high strength and resistance to moisture. Such products come to hardware stores in the form of plates, they are distinguished by excellent heat-insulating ability. This material is quite durable, rodents and insects do not take it.

To insulate the floor in a wooden house, many choose mineral wool. To carry out insulating work, you will need the following tool:

- hacksaw or parquet floor;

- electric drill;

- building level;

- plane;

- drills of different diameters;

- hammer;

- sharp knife;

- roulette.

The entire list of works is as follows:

- Creating a subfloor from chipboard or boards, laying waterproofing.

- Installation of wooden bars (lag).

- Laying the selected insulation, in our case, mineral wool.

- Floor covering installation.

At the initial stage of work, it is necessary to remove the old coating and correct irregularities on the base. After leveling the surface, a rough floor is created from waste boards of coniferous wood. The slabs are tightly fitted and then treated with an antiseptic. If you do not use the specified impregnation, then the logs and the wooden board will rot after 5-7 years of operation. All elements are fastened together with screws or nails.

At the next stage of work, a metal mesh with a small cell size is laid on the rough coating. Next, this structural element is sprinkled with a thin layer of expanded clay (about 4 centimeters). This material will not only press down the mesh, but also create the necessary ventilation gap between the insulation and the subfloor. Waterproofing, roofing felt or plastic film are also laid from below.

Bars or logs are laid on the waterproofing of a rough wooden floor. They are attached to the surface every 80-100 centimeters with nails or self-tapping screws. One or more rows of mineral wool are placed in the space formed between these elements. The insulation is mounted with overlapping joints, so that there are no gaps between the plate and the lags. Next, the installation of waterproofing is carried out, which is attached to the base using stapler brackets.

As a finishing floor covering, milled boards are used, which are interconnected using a groove-comb system. These elements should have the same thickness within 4 ... 5 centimeters, while their width is in the range from 10 to 13 centimeters. At the bottom of the boards, a special longitudinal recess is made for air circulation under the floor covering. In places where the boards adjoin the walls, a structural gap of 1-1.5 centimeters is left. In the future, this gap will be covered with a plinth.