Expert answers

Special opinion:

plasticizers increase workability without increasing the water-cement ratio. the more water, the worse for the solution

from Igor

smears like butter on a bun, the solution loses its properties !!!

wanderer:

for greater plasticity of the solution .... but the proportions must be very precise. if you poke around…. the screed will lose its declared properties .... from the appearance of cracks to loss of strength.

Trahenskauskas:

for floor screed, I think only the owner's money is spent

Scarifier:

A plasticizer with 3 gives a plasticizer.

Kirill Smolnikov:

C3 has such properties as: plasticization of the mixture (fluidity), crack resistance, less shrinkage after drying. It is described in more detail here Koekak. rf

Tatyana:

The store has a variety of...

KIPYATKOFF:

superplasticizer that increases the water resistance of concrete, with low consumption: Superplast - 1 liter per 1 cu. meter of concrete or 0.20 ... 0.25% by weight of cement.

just a plumber

dishwasher "myth" you know? do not overflow current. But it doesn't get any cheaper or easier.

husky:

take any washing powder. The action of both powder and superplasticizers (basic) is similar - surfactants (surfactants). dosage 0.2 - 0.3 percent of the weight of the cement. Only after all, on polystyrene concrete, it would be necessary to lay a 2-3 cm screed from cement mortar. otherwise the polystyrene balls will *dust*. Still, it’s interesting - how are you going to mix polystyrene foam and mortar at home ....

Igor Lutsenko:

Don't reinvent the wheel! :-))) Buy a special dry mortar based on cement with the addition of expanded polystyrene granules, called Knauf UBO! True, as was noted, then you still need to do a coupler on top! Good luck!!!

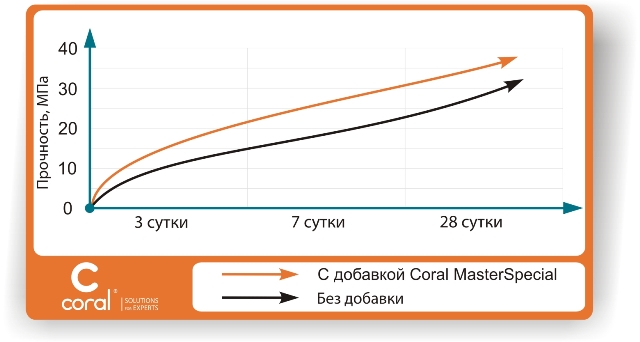

Effect of plasticizers on concrete strength

In the manufacture of a concrete solution, a dilemma arises: concrete will be more durable, in which there is less water, but it is difficult to work with it, it can form voids, and as a result, the strength of the finished product will decrease; if you increase the plasticity of the solution by adding water, the mixture will delaminate, give a strong shrinkage, crack, and the strength of the concrete will also decrease.

Plasticizers increase the plasticity and fluidity of concrete without increasing the water in the solution, which means that the mixture is easier to fit, compacted, and does not form voids. As a result, the strength characteristics of concrete increase.

Types of plasticizers:

- for concrete;

- for cement mortar;

- for the manufacture of paving slabs;

- for warm floors;

- for screeds.

What is a plasticizer and where is it used

The higher the density index of the screed, which is located above the level of the laid underfloor heating device, the more evenly the surface will be heated and, accordingly, the overall efficiency index will be higher. For this, a plasticizer is used for underfloor heating screed. At the same time, it is recommended to use concrete of the highest quality, which is almost impossible to achieve without using a component such as a plasticizer.

Used for screed

Masters say that the usual cement mortar is not the best solution when installing underfloor heating. Such a mixture does not have the necessary characteristics, such as mobility and plasticity.

For warm floors, based on the existing concept, the formation of microcracks in the thickness of the cement screed over time is characteristic. This will cause small temperature differences, which will become more noticeable over time. Along with the deformation of the screed, there will be a violation of the integrity of the floor covering. In rare cases, pipes that are components of the underfloor heating device are damaged. Breakthroughs will occur, after which the device must be completely replaced.When working with a cement-sand mortar, achieving maximum uniformity is very problematic.

During installation, voids and bubbles appear, which will affect the level of density of the screed. This will lead to a decrease in the efficiency of the heating device.

A plasticizer for underfloor heating makes the concrete mortar more uniform and of high quality, which affects the process of pouring this layer. After adding the auxiliary component, the mixture will become more plastic and acquire the necessary waterproofing indicators. Resistance to mechanical damage will also improve, as will adhesion and resistance to aggressive detergents. The compositions of the element are different, in most cases the complete list of components is kept secret by the manufacturer.

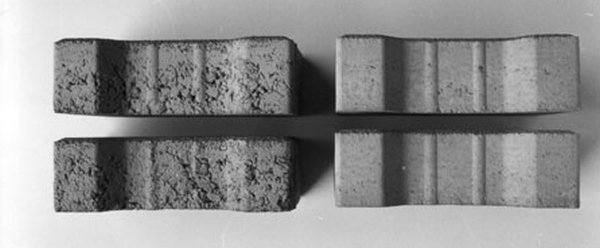

Example of concrete with and without plasticizer

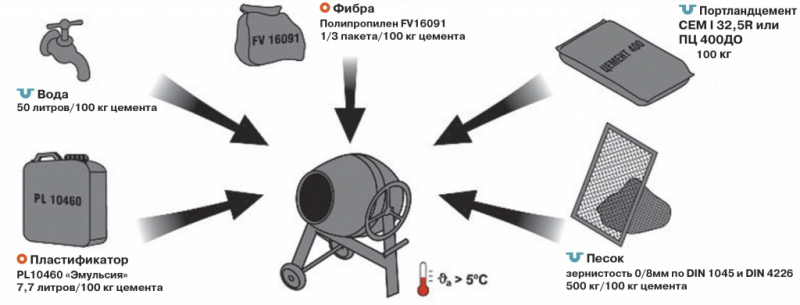

The following components are used:

- water;

- sulfuric acid (concentrated);

- defoamer;

- phenolic elements;

- sodium solution;

- formalin.

Plastic fibers are also part of effective plasticizers, as they are able to give the solution improved reinforcement performance, which helps to avoid the formation of cracks in the future. Which plasticizer to use will depend only on the master.

The effective chemical composition of such an auxiliary element as a plasticizer will help to achieve the optimal technical result. Reduces the number of bubbles during mixing and the rapidity of foam shrinkage, thereby increasing the homogeneity of the mass.

The use of additional components has both certain advantages and some disadvantages. You should familiarize yourself with them before starting work with the material.

Advantages and disadvantages

If the task is to create a uniform layer of concrete or cement screed, then the use of one of the plasticizers is mandatory.

Before buying, special attention should be paid to both compositions (plasticizer and cement), because their compatibility is one of the fundamental aspects that will lead to an excellent result. The consumption of plasticizer for underfloor heating is based on the quadrature of the room and the mass of the cement mixture used

The advantages include the formation of a homogeneous mixture, which is perfect for such a design as a warm floor.

The advantages include:

- After the mortar layer is completely dry, it will be perfectly smooth. In this case, there are obvious savings, since there is no need to purchase additional leveling compounds that are used for modern coatings.

- Improving the elasticity of the composition. The pressure will decrease when exposed to temperature (uniform heating).

- Due to the increase in density, the layer thickness will decrease by 15%.

- The density of the composition will increase (the better this indicator, the greater the degree of protection of the heating elements). This will evenly distribute heat over the entire surface.

However, the element can be used only if there is a lot of time, since the time for the solution to solidify with the addition of this component increases significantly. Additives that will speed up the hardening process will help solve this problem.

To create your own hands you will need:

- the most common shampoo;

- powder that is used for washing things (diluted);

- liquid soap.

Sequence of actions and applicable proportions:

- To create a warm floor with your own hands, you also need a plasticizer, which can also be created at home. You will need a bag of cement and soap. It is better to use in combination with expanded clay. This will help extend the setting time by a few hours. Liquid soap can be added during the kneading process.

- For the same purposes, it is possible to use slaked lime. It will take no more than 65 gr. per 10 kg of cement.Used for finishing uneven surfaces by professional builders and masons.

Best Answers

Aa kk:

Tip car. Choose..

Vladislav!!!:

Plasticizers are certainly good, the more expensive, tes is usually better. I would recommend pouring the screed, pouring it with water, and then go through the deep penetration primer cereait ct 17 like

Denis Garan:

any brand of building chemistry has additives for both a simple screed and under a warm floor (water). I don't know which ones are available in your area

Alexei:

Dishwashing liquid, try it. The solution will not set quickly and slow down the setting process

Spitz Pomeranian:

The most accessible we have is C-3. Improves workability with the least amount of water, hence higher strength.

costiann:

fairies, yeah...