Do-it-yourself technology for laying ecowool on the floor

Ecowool in bags is strongly compressed in order to make it easier to transport. So, a 15-kilogram bag is only about a meter high. The density of ecowool in the package depends on the manufacturer.

According to the standard for floor insulation, the density of ecowool should be in the range of 40-45 kg / m3. That is why, if you plan to lay your own hands without using a blow molding machine, it is better to choose a heater with a density of up to 90 kg / m3. Then, by simple calculations, it is easy to calculate that for the correct insulation of horizontal surfaces, ecowool must be fluffed up to a twofold increase in volume.

So, the process of laying ecowool on the floor is as follows:

- In a container, for example, a plastic trough, ecowool is whipped with a construction mixer. Pour it to about half the capacity and beat until the trough is full.

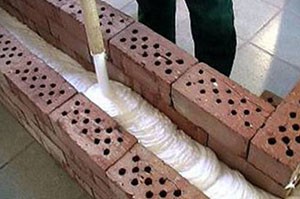

The finished insulation is poured onto the subfloor between the lags. The advantage of cellulose material is that, due to the unique properties of moisture absorption and evaporation, no vapor barrier is required. This ensures that the natural humidity in the house is maintained, which makes the frame house "breathable".

After filling the space between the lags, the ecowool is leveled with a wide mop. It is very important to start the floor insulation from the far end, gradually moving towards the exit - you cannot step on the insulation, it loses its properties when pressed.

Waterproofing also does not spread over the insulation, but the floor boards are immediately stuffed. According to technology, ecowool must be laid with the expectation of further shrinkage by 4-5 cm. Therefore, it must be poured “with a gorge” so that the insulation layer is above the lag level.

Some builders loosen the insulation directly in the floor cells.

But this is rather inconvenient, as it requires more accuracy and precision of work. In addition, a much larger volume of insulation can be loosened in a high trough with the same labor costs.

Do-it-yourself types of equipment for penoizol basic equipment

The production of insulation can be established in any room, but it is recommended to do it directly at the work site in order to save on transportation.

To make the unit you will need:

- Foam pump.

- Foam generator.

- Solution pump.

- Electricity.

- Compressor.

Equipment for the production of insulation today on the construction market is presented from different manufacturers. Models differ in their characteristics and cost. The average price of the device is 35,000 rubles. Experts recommend giving preference to installations that are made in Russia or Ukraine.

Insulation production technology

The first stage in the production of insulation, called mineral wool, consists of preparing a charge, which may include several ingredients. The composition of mineral wool largely depends on the number of components and their technical characteristics. The dried and crushed mixture is melted in special furnaces, the temperature in which reaches one and a half thousand degrees. The stone, molten to a liquid state, is sent to special rolls, where, under the influence of air or gas flow, the finest fibers of insulation are obtained.

The further process of production of all types of mineral wool is the formation of the most insulating material. Depending on the size of the fiber diameter and the functionality of the product, the structure of its carpet can be created by a vertical or chaotic arrangement of fibers, have a corrugated appearance. After that, the cotton wool is sent to a cooling chamber, where, simultaneously with cooling, the fibers are impregnated with a certain type of binder.In the production of some types of mineral wool, the process can be supplemented by stitching mats with fiberglass, steel wire or linen cord.

Mineral wool based on a synthetic binder (phenol or formaldehyde) and organic, that is, bitumen, is fundamentally different in production technology. However, any material undergoes the process of polymerization of the binder, during which excess moisture evaporates from the mineral wool.

Installation of ecowool

Cellulose insulation is used for thermal insulation of walls, interior partitions, attic and attic rooms, as well as roof structures and floors on logs. But it cannot be laid under the screed: it is a loose material that needs free space. Ecowool is delivered to the object compacted (3-5 times of the nominal density), so it must first be brought to its original state. During manual laying, the material is loosened with improvised tools in any large container and laid out on insulated surfaces (floors, ceilings) or fall asleep in the cavity of frame walls and ceilings

It is very important to observe the application density: for horizontal structures it is 35-40 kg / m3, for vertical structures - 60-70 kg / m3. This method requires a lot of time and effort, and therefore is used extremely rarely, only with small amounts of insulation.

Much more productive is the application by means of a blowing machine, which loosens the insulation in the bunker and delivers it in the air stream to a distance of up to 200 m horizontally and up to 40 m vertically. In this case, the material penetrates into the most inaccessible cavities and gaps, forming a continuous and seamless heat and sound insulating layer. The technique allows you to adjust the density of the blown insulation, which means that it becomes much easier to observe the quality of installation

It is important that ecowool is blown out with a margin of 10%, since even with the most competent application, it will settle a little over time

Well, wet laying is considered the most reliable, when ecowool is applied to structures with water or diluted glue, which significantly increases its adhesion to the base. The wet-glue method, used primarily for inclined surfaces (pitched roofs, vaults, arches), allows you to achieve a perfectly uniform and even layer of insulation.

Reference by topic: How to properly insulate a house. Insulation schemes

Advantages and disadvantages of liquid insulation

The obvious advantages of this material can be evidenced by a technological comparison of its parameters with similar thermal insulators. For example, only 1.0 mm of thermal paint is identical in efficiency and heat capacity indicators of 50-70 mm of common roll materials (basalt wool, mineral wool) or foam.

- With its use, the occurrence of condensate is excluded, which prolongs the life of the surfaces

- Material provides corrosion resistance

- Reduced heat loss

- Liquid heat insulator does not take up space - its maximum layer does not exceed three millimeters

- The content in the structure of the material latex insulation perfectly resists a humid environment

To insulate a house built from other materials, any type of insulation is suitable. Thermal insulation of walls requires high-quality and effective materials. Such is the insulation Polynor (POLYNOR), the characteristics of which are located here, and the advantages are also listed.

The composition of ecowool

As mentioned above, ecowool is made from paper raw materials with the addition of antiseptics and fire inhibitors. Let's consider these components in more detail and start with the main thing - waste paper. Overseas manufacturers tend to use ink-free paper, which is known to contain unsafe lead. Domestic companies, unfortunately, sometimes do not disdain newspapers and other waste materials that are not suitable for the manufacture of thermal insulation.

Therefore, when buying ecowool, it is important to at least visually check it for scraps of cardboard, coated paper (which forms the smallest dust), rags and other debris.

Boric acid - an antiseptic, time-tested, does not raise questions. Its concentration is too low to create any health problems for residents. But with flame retardants, everything is more complicated. The fact is that ammonium sulfates and phosphates, used by some manufacturers, can be a source of an unpleasant ammonia smell.

In addition, over time, these substances lose their fire-fighting properties, as evidenced by studies conducted at the California Bureau of Home Furnishings and Insulation.

Borax (borax) does not have the above disadvantages. So when choosing a material, it would be wise to give preference to the one in which the drill was used. By the way, the borax is an additional guarantee that rodents will not start up in the wall structure - they cannot tolerate this substance.

Ecowool scopes: 1. Mansards. 2. Walls. 3. Floors and floors. 4. Attics

What is ecowool made of?

Related link: Ecowool - advantages and disadvantages of the material. Do-it-yourself ecowool laying

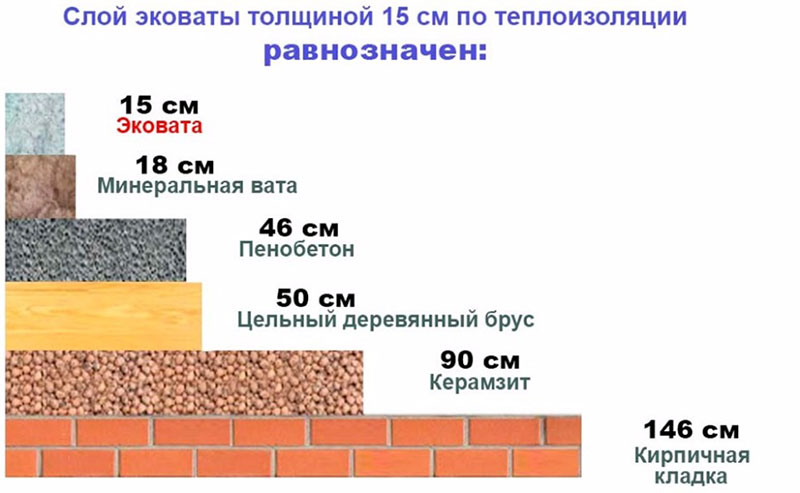

First of all, these are high thermal insulation properties. With a thermal conductivity coefficient of 0.037-0.042 W / (m-K), a layer of sprayed ecowool of 150 mm corresponds in terms of energy saving to a brick wall 4.5 bricks thick. The technology of applying the material (filling or spraying) provides a uniform heat-insulating layer without voids, seams and gaps.

Despite its "paper" nature, cellulose insulation does not ignite upon contact with fire, but only smolders and, having lost a heat source, fades itself. Due to the capillary structure of cellulose fibers, it is able to retain up to 20% moisture in the upper layers without losing heat-insulating properties.

Vapor barrier is not required for it. Antiseptic additives make ecowool immune to attacks by harmful microorganisms, insects and small rodents. It is also worth noting that cellulose insulation has high soundproofing characteristics, significantly surpassing mineral wool in this indicator. A layer of material 100 mm thick reduces the noise level by approximately 60 dB. If you use it not only in the outer walls, but also in the partitions, the house will become much quieter.

Laying ecowool with a garden vacuum cleaner

The advantage of this method is that it is cheap and easy to implement. There is only one drawback - you will need an assistant, since you cannot cope here on your own. With a garden vacuum cleaner, you can insulate both the floor and walls, but only with dry ecowool. The wet method requires special equipment.

So, first you need to make a blow molding machine:

- Any garden vacuum cleaner is taken. It is better to choose reliable brands, but without a built-in chopper. The cheapest models break down quickly - they are enough for 12-15 cubes of insulation. The built-in grinder greatly reduces the density of ecowool.

- A flexible corrugated hose with a diameter of about 60-70 mm and a length of 7-10 meters is bought. The diameter must be selected under the outlet pipe on the vacuum cleaner itself - the hose must fit tightly.

- The bag for collecting waste is removed and a corrugation is put on the pipe. To make it more convenient, you can bite out the teeth that fix the bag with wire cutters. The corrugation is fixed with ordinary tape or electrical tape so that there are no air leaks at the junction. A working vacuum cleaner creates a strong air pressure, so you need to fix the corrugation as securely as possible.

Everything, the blow molding machine is ready. The process of floor insulation is practically no different from the manual method:

- ecowool is broken in a high barrel with a construction mixer - there is no need to greatly increase the volume;

- the nozzle of the vacuum cleaner is lowered into the heater;

- the second assistant holds the end of the corrugated hose as close to the floor as possible - this reduces the amount of dust that inevitably forms when blowing ecowool;

- the vacuum cleaner turns on and the filling of the floor cells with insulation begins.

If you first sew up the floor with boards, leaving only one loose board for each cell, and insert the corrugation into the resulting hole, you can minimize the amount of dust.

You can also first pour a “mountain” of insulation, trying not to stir it up, and only then level it.

Wall insulation with a vacuum cleaner also requires two workers:

- the walls are completely sewn up with OSB;

- at a distance of 10 cm from the ceiling, holes are made for the diameter of the corrugated pipe - two holes per OSB sheet;

- the corrugated hose is inserted into the hole and goes down so that there are 30 centimeters to the floor;

- the filling of the wall begins, as soon as the suction sound changes, it means that the layer of ecowool has reached the outlet and you need to raise the hose another 30 cm;

- you can make several holes and more accurately control the filling of the pier.

Holes in the walls are closed with OSB circles remaining after cutting. This is easy to do by nailing the circles first to the pieces of oilcloth, and after the edge of the oilcloth to the walls.

The attic roof is insulated in the same way. To simplify the process, it can be “blown out” in layers, starting from the bottom and ending at the crown. A description of a home-made machine and the process of attic insulation are presented in detail in the video:

Methods for applying ecowool

Ecowool can be applied in just a few ways: manual and mechanical.

The manual method is quite labor-intensive, as it requires a lot of physical effort and time. Also, when filling voids with insulating wool, there will be no guarantee that “cold bridges” will not form in the wall, so to speak. However, this method has its positive aspects: it does not require special equipment.

A roll of ecowool is fluffed up before starting work and manually compacted into pre-prepared voids in the floor, roof or walls. It is best to fluff ecowool in a special barrel using a construction mixer.

The mechanical method is of two types: wet and dry. From the name it is clear that the dry method consists in the fact that the voids are filled with dry cotton wool using special machines. To do this, a small hole is made in the floor, roof or wall, into which a special sleeve is inserted to supply the material. Then all the work will be done by the technician.

The wet or damp method of insulation is preferred for insulating exposed areas such as external walls. A special device wets the ecowool with the required amount of water, after which it becomes like glue. Through the supply sleeve, the finished composition is applied to the walls, after which the excess protruding sections can be cut off and then reused. In order to increase the adhesion of the material to the surface, specialized additives are added to it, which increase its adhesion.

In fact, ecowool insulation does not cause any particular difficulties. With its help, you can efficiently and quickly insulate almost any building in any way that suits you best. In addition, the use of this insulation will not hit your wallet as hard as other heat insulators. Its production is already well established at many enterprises, so you can buy ecowool at any construction store or, in extreme cases, make a reservation.

conclusions

As you can see, the best way to isolate heat in four walls is to use Ecowool as a material. Then the standard "+18C" will not run away. But not only will they not run away, they will also grow to “+30C”. After all, thermal insulation is excellent, and most importantly, it will keep you healthy. Harmless cellulose will not cause any harm. And boric acid also disinfects.

In addition, the material will save you from unwanted "neighbors". With Ecowool, no rodents, mold, fungi are afraid.

Yes, and will allow its owners the luxury of not listening to the music of neighbors from above. All the seams are filled, the music will not fit in them.

Advantages and disadvantages of insulating material

Despite the assurances of manufacturers that ecowool is the standard among thermal insulation materials, these statements should not be fully trusted. This is a common marketing ploy designed to increase sales.

The material has a lot of undeniable advantages, but, like analogues, it is not without serious drawbacks. Let's start with the merits.

The advantages of ecowool are the following characteristics:

Low moisture permeability.

The capillary structure of the material allows you to absorb water without losing useful qualities. For example, if a mineral insulation is moistened in total by 1%

, heat loss will increase by almost 10 times

. If ecowool is moistened by 25%

, decrease in thermal conductivity will not exceed 5%

. This is a very good indicator.

Seamless isolation.

The loose mass of the filler fills all the voids, completely excluding cold bridges. To achieve a similar result with roll or sheet insulation, the material must be laid in 2-3 layers

which increases the overall cost of the work.

High level of sound absorption

. Ecowool is a great way to insulate buildings that are located on busy streets, near federal highways, railway lines and airports.

In addition, an undeniable advantage is the affordable price, which elevates ecowool to the rank of the most popular heaters for private construction.

Let's move on to problems. Serious disadvantages of thermal insulation include the following points:

Gradual decrease in thermal insulation properties

, increased heat loss. This is due to the fact that the material is reduced in volume or supersaturated with moisture. You can avoid problems by laying insulation with a margin in 20-30%

from the calculated volume and making the layer ventilated so that moisture can evaporate into the atmosphere.

Difficulties in installation.

In order for the insulation to fully meet the technical specifications, special installation equipment will be required. This means that you will have to hire a team of professionals, and these are additional costs.

Loss of time.

Ecowool can be laid in two ways: dry and wet installation. The first option creates a lot of dust during the work and does not guarantee high-quality compaction. The second - creates a high-quality layer of thermal insulation, but the material will dry about 3 days

, which is not always possible with the pace of modern construction.

Relatively low stiffness

. If we compare ecowool with other types of insulation, for example, foam boards, its rigidity will be noticeably lower, which makes it impossible to use the material for frameless insulation.

Material shrinkage.

Occurs with vertical insulation already in the second year. This problem cannot be avoided.

Burning speed up to 30 seconds.

This means that the material does not burn, but slowly smolders. As a result, there is a risk of ignition of adjacent materials and high smoke.

As you can see, ecowool is not a perfect thermal insulation. This is a rather specific material with a limited scope and a peculiar installation technology. In addition, assurances of environmental safety also raise doubts: boric acid and borax can hardly be called fillers that are safe for humans.

Advantages and disadvantages

The active use of kraft paper is due to a number of its undoubted advantages, including:

- Environmental Safety. It is an environmentally friendly material that does not emit harmful substances. As a result, it is safe for human health and the environment.

- Affordable price. The low cost of this insulation allows you to perform thermal insulation at the lowest cost.

- Ease of installation. The insulation can be easily placed even in hard-to-reach places: it is easily attached to various structures using a construction stapler, self-tapping screws, etc.

Along with the positive properties, cardboard is not without drawbacks, among which the main ones are a high level of fire hazard and the possibility of rodent penetration (if it is not treated with special means). In addition, the material is not recommended for use in conditions of constant high humidity (a single wetting will not affect the properties of the insulation).

The use of kraft paper allows you to create a reliable barrier, so often internal vapor barrier work involves the use of this method. Vapor barrier is especially in demand in the construction of energy-efficient houses. In addition, the choice of this method for vapor barrier is able to provide a high-quality result in combination with other options, in particular, with ecowool (the basis of this insulation is also cellulose).

You can make a heater with your own hands. For more effective thermal insulation, it is recommended to make cellulose boards. For this you need:

- finely cut the paper;

- make a solution of engine oil;

- mix the solution and paper, mix the resulting composition thoroughly;

- place the composition in the forms intended for drying.

After the mixture has dried, the resulting cellulose boards can be used to insulate various surfaces. Unlike cardboard, they have good water-repellent properties and provide protection against rodents. But there is also a negative point: this method is among the unsafe, because it increases the likelihood of a fire.

General advantages and disadvantages of the material

Such an active widespread use can be easily explained by a whole list of undoubted advantages of the material. Among which are:

- Absolute environmental friendliness. The composition of the paper is really exclusively eco-materials, which eliminates any danger, both for people and for the environment.

- Affordable price range. The prices for such insulation can significantly save.

- Easy installation. Kraft insulation can be easily placed even in the most inaccessible places. Easily mount on various structures using self-tapping screws, a stapler and other parts.

But in any barrel of honey there is a fly in the ointment. In addition to all its undoubted advantages, kraft material also has certain disadvantages. For example, this:

- Fire resistance;

- Weakness to rodents;

- High humidity level.

But even here there is a small “beam of light”. If nothing can be done about the lack of fire resistance, because it is still paper, then the other two points can be argued with. You can protect such a heater from rats and mice by treating the craft with a special tool. A one-time wetting will not have a detrimental effect on the material.

The use of kraft material provides an excellent opportunity to create a very impressive thermal barrier, which is why it is so often used in internal heat and vapor barrier work.

It is worth noting that it is quite possible to make such a heater with your own hands. You can even make cellulose boards to improve efficiency. To make this material:

- Finely cut the paper;

- Make a solution of machine oil;

- mix;

- Stir thoroughly until the composition becomes homogeneous;

- Pour the mixture into drying molds.

When the mixture dries, the finished tiles can be used to insulate a wide variety of surfaces. They differ from kraft cardboard in that they have very good water-repellent qualities. They are also immune to rodent attacks. However, even they have a drawback - they still remain fire hazardous.

Characteristics and features of ecowool

Ecowool is a non-combustible material, but at high temperatures it can smolder without creating an open flame. The material does not rot and does not get sick with mold, perfectly delays external noise, does not let heat through.

- Thermal conductivity coefficient - 0.037-0.042 W / (m K);

- After wetting and drying, the properties of the insulation are completely restored;

- Material density - 30-65 kg / m 3;

- According to GOST 30244, GOST 30402, DIN 4102, GOST 12.1.044, DSTU B V.2.7-38-95, the flammability group is G2 V2, D2, RP-1, which means: moderately combustible, moderately flammable, moderately smoke-producing, with zero flame spread over the surface;

- Air permeability 80-120 10-6 m 3 /ms Pa;

- Vapor permeability of ecowool - 0.3 mg / (mh Pa);

- Adsorption in 72 hours - 16%;

- pH - 7.8-8.3.

Cellulose insulation methods

Such cellulose mats can be made by hand.

Eco paper insulation is suitable for insulating vertical and horizontal structures:

- walls inside and outside;

- ceilings;

- pitched and straight roofs;

- attic;

- attics.

Unlike insulating a house with cardboard, this method has been put on stream and an installation technology has been developed, moreover, not one. You can work with ecowool both with the help of special equipment and without any tools. There are two methods for applying cellulose to insulated surfaces:

- dry;

- wet - using a water-adhesive solution.

The dry method of warming a house with cellulose is that ecowool is simply poured into niches prepared for it.

This is either a draft floor or an inter-wall space in frame houses. It should be remembered that the material is fine-grained and dusty, besides, it contains chemicals that cause redness and itching of the skin. Accordingly, you need to protect yourself from these negative factors. It is necessary to work with gloves and a respirator, and protect the ecowool with kraft paper.

You can fill up the insulation manually or with the help of special equipment. The water-glue mounting method is only possible with a blow molding machine. It consists of a tank in which cotton wool is loosened, a compressor and a system of pipes of different diameters. At the outlet of the supply pipe, the material is abundantly moistened. Thanks to this, it adheres better to the wall, and after hardening it becomes more dense. This is due to PVA glue, which, when cured, forms an elastic film.

Is it possible to insulate walls with cardboard together with cellulose? Theoretically, of course, it is possible, only cardboard in this case will act only as a fence. This is necessary when working with dry ecowool. But as we said earlier, kraft paper is better suited for these purposes. It is lighter and thinner, besides, the degree of filling of voids with cellulose can be seen through it. Working with such material is more convenient and faster.

No processing

kraft paper

Let's start with an acquaintance with one fairly popular type of pulp products.

Kraft paper is a very durable material that is made from long fibers of sulfate pulp. Raw material - wood; wood chips are boiled in an aqueous solution of sodium sulfide and some other substances.

In this capacity, kraft paper is familiar to everyone.

What is the use of thin and dense kraft paper in terms of insulation?

Of course, not as a heat-insulating material.

The classic design of a frame house is a frame made of timber, sheathed outside and inside with clapboard, OSB or plywood. The space between the outer and inner skins is filled with insulation. Mineral wool, polystyrene foam and other modern materials for insulation are often used as it; the heat-insulating material is protected from blowing and saturation with moisture by special polymer films. This scheme has two drawbacks:

- The materials used are of artificial origin and often continue to saturate the air in the house for many years with phenolic resins, styrene or fine mineral fibers that irritate the eyes and respiratory organs.

- They are by no means cheap.

Meanwhile, many decades ago, a very simple and incredibly cheap scheme was used for insulation: the space between the inner and outer wall cladding was simply covered with sawdust - free waste from sawmills.Kraft paper served as a vapor barrier and windproof membrane: it kept the sawdust damp and protected the wall from wind blowing.

The cheapest way to insulate a ceiling or interfloor ceiling is the same sawdust, expanded clay or slag. Bulk insulation. Kraft paper is the cheapest material for laying under insulation, which will prevent it from falling on the head of the owners of the house.

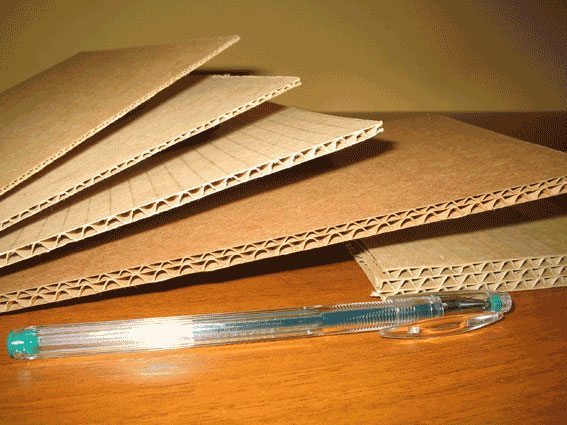

Cardboard

Corrugated cardboard, however, can also be used as an independent heat-insulating material. Of course, cardboard insulation will be obtained only when laid in a thick layer - at least 5 - 10 centimeters.

The cellular structure of the corrugated cardboard should protect the packaged goods, but it will also have to be in the yard in the insulation.

However, the time spent on laying is compensated by the fact that the material will cost exactly the cost of its transportation: any large base will be only too happy to get rid of the packaging material, the removal of which it usually has to pay.

How to use cardboard insulation? The instruction is very simple: it fits tightly inside the wall frame and is sewn up from the inside. It is clear that the outer wall covering should reliably protect the cardboard from precipitation.

There is one nuance associated with styling. To prevent the walls from being blown through, sheets of packaging material are laid layer by layer with offset joints between them. Can be fixed with a stapler.

Advantages and disadvantages

They are common to both kraft paper and its derivatives.

- Cheap, cheap and more cheap. Heating costs will be minimal.

- Environmental friendliness. Paper does not emit harmful substances into the atmosphere.

- Ease of use. As a windscreen, the paper is attached with an ordinary stapler; wall insulation with corrugated cardboard will also not make you rack your brains and look for a complex tool.

- The material is flammable. However, in a wooden house, its fire hazard will not change the overall picture.

- Rodents without any problems make moves in paper and cardboard; moreover, mice also appreciate the thermal insulation properties of cellulose and willingly use it to insulate their nests.

Mice will react to the new insulation without much trepidation.

Paper is hygroscopic. With a one-time wetness, this will not create problems, but constant dampness will worsen thermal insulation many times over.

Frame insulation technology

Thermal insulation of a frame house is carried out in a dry or wet way. For application on walls, it is better to choose a “wet” technology; for floor insulation, a “dry” technique is suitable.

Equipment for blowing ecowool

High-quality insulation of vertical surfaces is impossible without the use of specialized blowing machines for installing ecowool. There are many different models on the market, differing in power, completeness and scope. Equipment for ecowool can be designed for both dry and wet methods.

Some craftsmen make the unit with their own hands. To make a do-it-yourself blowing installation, you should understand the principle of building technology. Mandatory work units:

- Platform. Skeleton for fixing the loading funnel with an engine, a blower, a sluice and a gearbox.

- Engine. Use a two- or three-stage motor.

- Gateway. Provides capture of cotton wool, dosage of air. Inside the chamber, the material is turned over and under pressure is fed into the hose.

- Reducer. Increases power output by reducing the speed of the opener and motor.

- Baking powder. Knife system as in a blender for fluffing, mass preparation.

- Loading funnel for laying insulation.

- Control Panel.

The described completeness corresponds to the dry spraying unit. To implement the wet-glue method, you will need a block for moistening the cellulose briquette.

Home insulation: wet method

The technology is excellent for application to open areas.The method allows to control the uniformity of laying and provides a high density of the heat-insulating layer. Cellulose wool is pushed under pressure and adheres to the surface. Lignin provides high adhesion - it is released when water is added to ecowool.

Work progress:

- Perform wall framing.

- Fill the bunker with fluff.

- Start spraying. At the exit, dry cotton wool from the nozzle is moistened and supplied under pressure.

- Evenly distribute ecowool over the surface of the walls.

- Wait until it dries completely and cut off the excess - the waste can be reused.

"Dry" filling of the wall space

Waterless technique is implemented on horizontal, inclined coatings. Spraying is used for insulation of closed cavities, non-separable structures, interfloor ceilings.

The essence of the method:

- At the top of the wall, make a hole commensurate with the dimensions of the insulation supply hose.

- Insert the sleeve and turn on the equipment.

- Fill voids by periodically tamping the dry mass.

- Close and close the hole.

Blowing into the cavity is carried out regardless of weather conditions and avoids the dismantling of structures. However, the technique has several significant shortcomings - it is difficult to ensure uniform distribution and the required density of thermal insulation.

Manual backfilling of floors

The easiest way is to insulate the ceiling or floor. The technology does not require specialized equipment, but takes more time. The method is only suitable for thermal insulation of horizontal surfaces.

Do-it-yourself backfilling sequence:

- Level the surface, mount the logs - the height of the boards is 8 cm, the approximate size of the cells is 40 * 80 cm.

- It is good to fluff the pressed briquette. Put the mass into a bulk container and mix intensively with a drill with a mixer nozzle.

- Fill the space between the lags with insulation. Ecowool should be in abundance - a slight slide of dry material will subsequently be covered by floorboards.

Experts advise to let the cellulose wadding “settle”. The lignin included in its composition will react with moist air vapor and a dense crust will form on the surface of the insulation. The layer will improve the preservation of heat.

Where is kraft paper used

If you look closely, it is quite difficult to find a material, especially in the paper industry, that would have an equally extensive scale of use. Paper has gained immense popularity due to environmental friendliness and a high degree of strength.

It can be said that, by tradition, such paper is used mainly as packaging, it is used everywhere, for any kind of goods - from metal parts to books and flower bouquets. There are really no boundaries. Application area:

- for the production of ecological bags for the food industry,

- as a protective paper in the paint industry,

- in the furniture industry for furniture packaging,

- for making decorative bags and envelopes,

- in the production of ribbons and threads,

- for packing fresh food, flowers, books,

- to protect the edges of pallets and goods from damage during transportation (cardboard corners),

- airbags - dunnage,

- for fixing the surface of the premises in painting and repair work.

In a short period of time, it has become a very fashionable design solution. Kraft paper is used not only by ordinary needlewomen, but also by professional designers with a worldwide reputation. As already mentioned, printing and drawings can be applied to it. Many artists use it as a favorite material for "drafts" of their masterpieces.

Due to the aforementioned quality, it is often used in printing. Menus, advertisements, posters, business cards - kraft paper is used everywhere.

It is also used to produce well-known products of everyday life:

- Sketchbooks for drawing;

- Paper bags;

- boxes;

- Postal envelopes;

- Commodity tags.

Any gardener knows how effective kraft paper is for sheltering plants for the winter. Surely this is far from all the possibilities for the material.