About insulation and vapor barrier

The most important and basic thing for a steam room is that it must retain heat very well.

At any time of the year, there should be the required temperature inside the steam room. If the vapor barrier is not completed, then the steam leaves the room through the walls, after which condensation forms between the walls and the finish. As a result, the tree begins to rot and mold forms on it.

A professional installation of insulation and vapor barrier will keep the structure of the bath in its original form and protect it from destruction.

Also, in a comfortable bath with the thickest walls, it is necessary to provide ventilation.

When the human body lacks air, a feeling of dizziness, nausea and weakness appears, this is especially dangerous for people with the initial stage of diseases of the cardiovascular system.

Ventilation is intended for the following purposes.

- Redistribution of air masses in the steam room; Formation of fresh air and its inflow. This is especially necessary when using an electric heater as a heating element, since it burns out oxygen.

Wall construction

Unprepared developers often think that it will take them a lot of time and effort to build a bath from foam blocks. In reality, everything is much simpler. Foam block masonry is performed similarly to brickwork, and the large size of the blocks makes this event as convenient as possible.

Tools for building a bath from foam blocks

Walling

Armed with a building level, find the highest corner of the foundation. From it you will begin masonry.

Walling

Lay out the walls for the first time. M25 foam blocks are optimally suited for the construction of steam room walls. To fasten the elements, use an ordinary cement-sand mortar. Lay the blocks on edge. Try to keep the seams between the individual elements as thin as possible.

Do-it-yourself foam block wall laying technology

Align the first row of building blocks strictly in level. A rubber mallet will help you with this. Be as careful as possible at this stage, since the main operational properties of the finished structure directly depend on the correct laying of the starting row.

Start laying the second row. Lay it out with a shift. To fasten the elements, use not a solution of sand and cement, but a special glue designed for mounting specifically porous materials. Apply glue with a 0.5 cm layer. You can not wait until it dries - it does not matter.

window openings

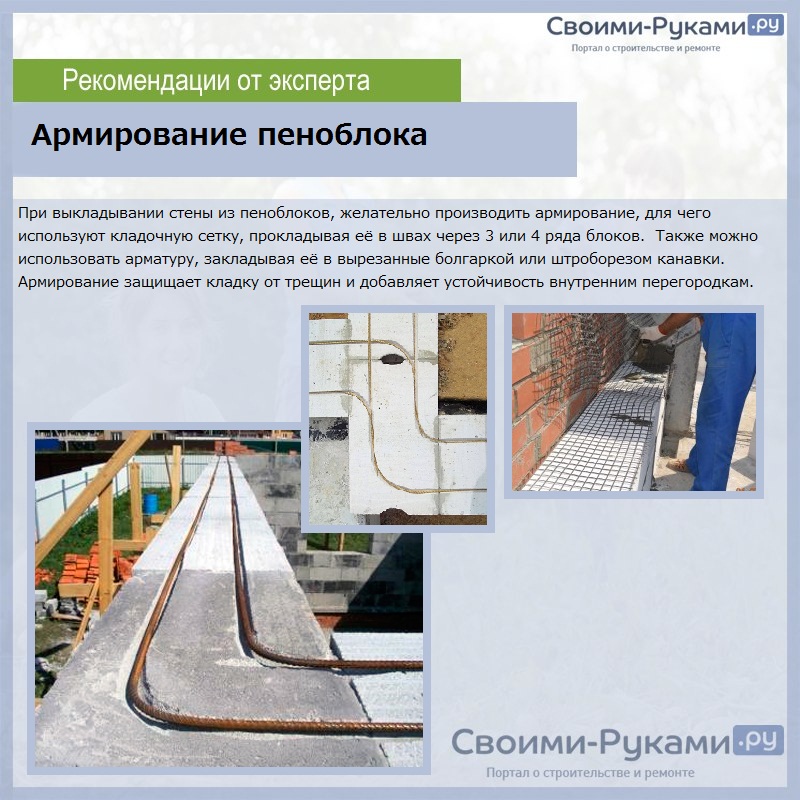

Lay out the walls of the required height. After every third row, be sure to lay a fine-mesh metal mesh for additional reinforcement.

Reinforcement of the foam block

In the process of laying out the walls, leave openings for future doors and double-glazed windows. At this point, be guided by your personal preferences.

After laying out the walls, if possible, leave them for 3-4 days, and then proceed to the arrangement of the roof structure.

Site preparation

For the construction of a bath, any flat area is suitable. It is desirable that the soil is dense.

Get rid of all sorts of garbage and start excavation work.

Get rid of all kinds of garbage and start excavation

As a rule, foam concrete baths are built on strip foundations. Dig a hole around the perimeter of the future foundation with a depth of 50-100 cm (depending on the characteristics of the soil on the site) and a width of about 30 cm.

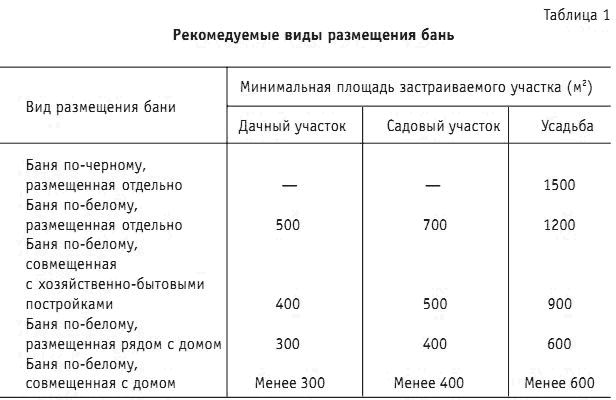

Bath accommodation options

Hammer in the corners and along the perimeter of the trench (in increments of about 100 cm) metal bars and pull the rope between them.This markup will make it easier for you to navigate when performing further work. Be sure to check the horizontality of the prepared structure.

Interior decoration difference

For cinder block baths and their interior decoration, high temperatures and high humidity are typical, so it is necessary to provide and install a vapor barrier on site. It is very often performed with the following materials:

- Foil (has 100% vapor resistance); Tiles and ceramics; Roll materials.

The first step is to glue the walls with paper without any impregnation.

This is followed by a layer of thermal insulation (mineral insulation can be used as it). The next layer is the vapor barrier itself, which is paper with a layer of foil, which does not let moisture into our insulation. Sheets of foil are interconnected with a special adhesive tape.

Due to all of the above, condensation will not form in our bath, leading the foam blocks to resolution and loss of properties.

External insulation also helps to get rid of condensation.

This is due to the fact that inside the bath and outside the temperature equalizes.

Next, we move on to the next stage, which is responsible for the aesthetics and attractiveness of the interior decoration of the aerated concrete bath as a whole.

It is advisable to finish a bathhouse made of a log house with wooden materials that are environmentally friendly and do not emit substances hazardous to human health when heated.

This interior decoration baths made of foam block and wood differ little.

The most popular and economical are finishing materials made of cedar, larch and linden. The formation of condensate and the loss of properties of a log cabin bath, in contrast to a foam block bath, is minimized.

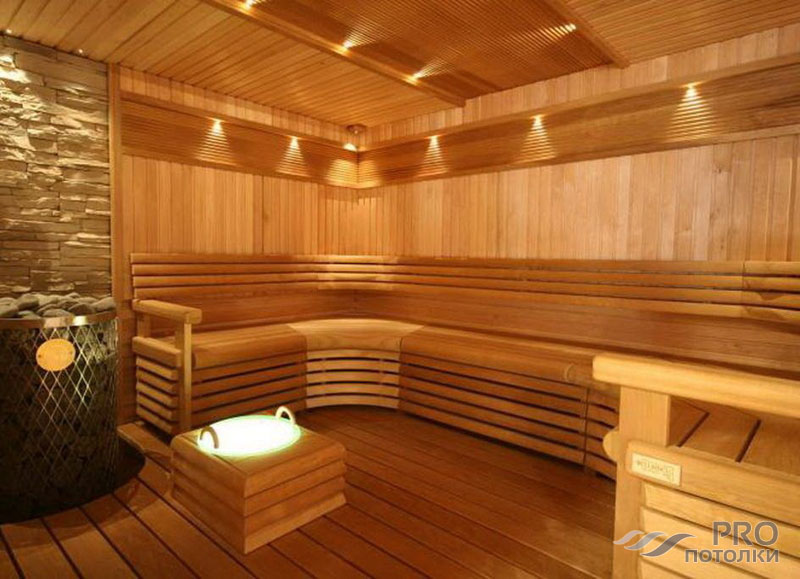

What is required for bath ceilings

To figure out how to properly make the ceiling in the bath, let's dwell on the requirements for surface coating.

The difference between a bath and living and working premises is constant temperature changes with high humidity. To create a comfortable microclimate, the temperature can rise to 80 degrees, and in the steam room up to 100. The air humidity is also too high and reaches 98%. Therefore, when choosing a coating for facing such a room, all the nuances should be taken into account.

The correct ceiling in the bath must meet certain requirements and perform the following tasks:

- eliminate heat loss inside the washing and steam compartments;

- retain wet vapors, preventing them from reaching wooden floors;

- no harmful substances should be emitted and accumulated inside the premises;

- material must be flammable;

- long service life under conditions of high humidity, and sharp temperature fluctuations.

These requirements must be considered if you are going to make a ceiling in the bath with your own hands.

When choosing a material for interior cladding of a space, special attention should be paid to fire safety, reliability and environmental friendliness.

Steam room ceiling cladding

The ceiling in the bath is best made of wood. It is better to stay on deciduous trees, such as linden, alder or aspen.

Conifers are not recommended for use in a steam room. Under the influence of high temperatures, the coniferous surface can release resin. Resin dripping onto the skin causes severe burns.

The wood for the ceiling in the bath with your own hands must be clean, dry and not infected with fungus and other microorganisms. If you ignore these requirements, then during operation, the coating will begin to break down and release harmful substances.

Advantages of foam blocks for the construction of a bath

Foam block bath

Foam blocks are large-sized blocks (compared to the dimensions brick) made of cellular concrete (foaming + cement mortar). To date, there are many manufacturers of foam blocks, and the material itself is available on any construction market.

Foam block compared to brick

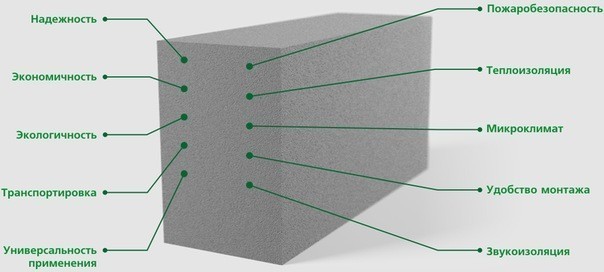

The advantages of the foam block are as follows:

- Foam blocks have large dimensions with low weight, which positively affects the labor intensity of work during the transportation of material and the construction of a bath from foam blocks.

- The material has excellent heat capacity (it holds heat several times better than brick)

- The foam block has a relatively low cost

- Cellular concrete has high strength and durability

- Even an inexperienced summer resident can build a foam block bath (which cannot be said about construction of a bath from a profiled beam)

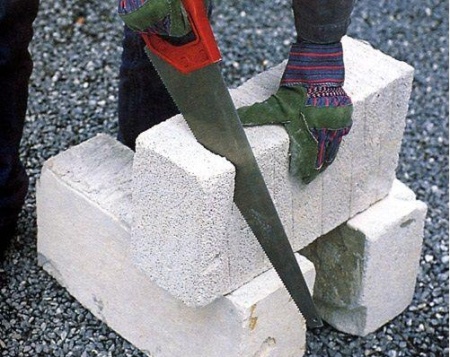

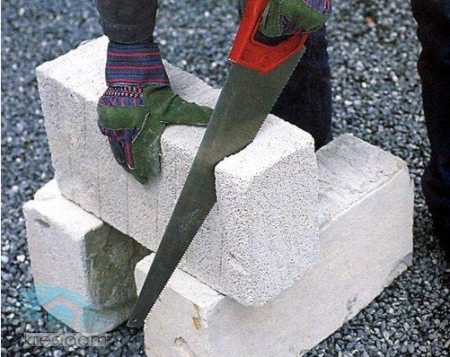

- In order to cut off part of the foam block, you can use a hacksaw (or even a sharp knife)

- The material is flame retardant

It should also be noted that the foam block has several significant drawbacks that spoil the popularity of the material:

- The foam block is not able to withstand heavy loads, therefore it is recommended to build a maximum of 2-3 storey buildings from this material

- Aerated concrete absorbs moisture well, which is why the foam block is a sponge and requires additional waterproofing measures for the bath

Despite the fact that a foam block bath has two significant drawbacks, they can be easily refuted. Firstly, a bathhouse in a country house can be a maximum of a 2-story building, so the foam block can easily withstand the weight of such a structure. Secondly, any bath requires additional waterproofing measures, besides, all that is needed is to treat the foam block with special hydrophobic impregnations from the outside and cover it with foil material from the inside of the building.

The foam block can be cut with a saw

Before proceeding directly to the construction of a bath from foam blocks with our own hands, we will provide you with a technology for calculating the required number of foam blocks.

Advantages and disadvantages of foam blocks

The mother in question has a number of strengths and some weaknesses.

The advantages of the foam block

Advantages

- Light weight.

- Ease of use.

- No shrinkage.

- The shortest construction time.

- High fire-fighting properties.

- Ease of transportation and storage.

- Relatively low cost.

With all its advantages, foam blocks, like any other existing material, have some disadvantages.

Foam block cutting

Flaws

- More modest environmental performance compared to natural wood.

- Formation of condensate in internal pores. Condensation can cause blocks to collapse in cold weather. This moment imposes a number of additional requirements regarding the arrangement of insulating layers.

-

Relatively low durability.

However, even with these shortcomings, this material is very popular. A bathhouse made of building blocks is a very profitable solution, especially in the absence of a serious budget and the absence of the possibility of attracting special equipment and third-party labor to carry out construction.

The main thing is to do everything in accordance with the instructions, and the finished foam block bath will in no way be inferior to buildings made from other common materials.

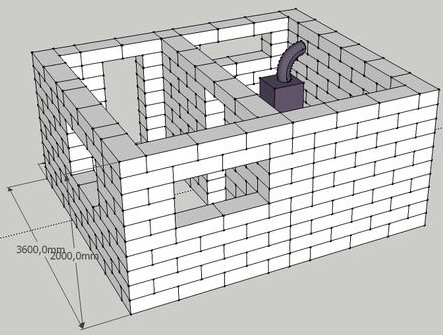

Foam block bath project

Do-it-yourself foam block bath project

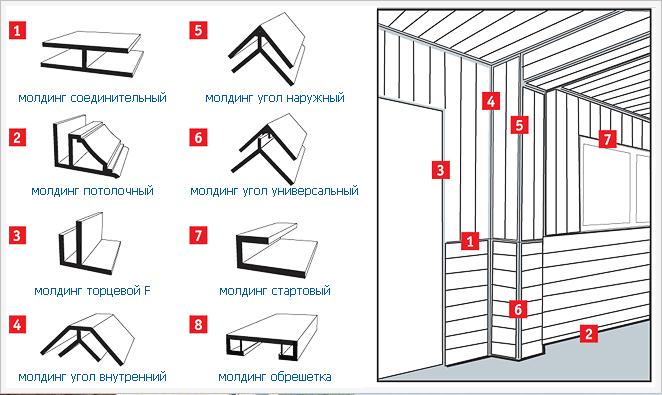

Sheathing material

This process can be done by hand without the involvement of specialists.

In order to calculate the required amount of lining, you need:

We calculate a bath with dimensions of 4x4 meters, in which the ceiling height is 3 meters. We will finish and sheathe all the walls with the ceiling; Suppose that there are two compartments in the bath - a steam room 3x4 and a dressing room 1x4 meters; Next, you need to calculate the area of \u200b\u200bsheathing the steam room.

Calculation of the ceiling area: 3x4 = 12 m2. Calculation of wall area No. 1: 4x4 \u003d 16 m2. Calculation of the area of a short wall: 3х3=9 m2; We consider the total area of all compartments: 12 (ceiling) +16 (wall No. 1) +9 (wall No. 2) +3 (wall No. 3) +3 (wall No. 4) = 42 m2; Next, we perform calculations for the dressing room.

Ceiling area: 1x4=4 m2. The area of two walls No. 1: 4x3 \u003d 12 m2. 12x2=24 m2.

Wall area No. 2: 1x3 = 3 m2. 3x2=6 m2. Total area: 4 + 24 + 6 \u003d 34 m2; The total finishing area is 42 + 34 \u003d 76 square meters; Then we consider window and door openings, their area, then add about 15-20 percent to trim the material.

Installation of beacons

After all of the above, you should measure the parameters of the walls and start manufacturing a wooden frame or beacons according to the measurements taken. The guide beacons must be fixed at a distance of about 0.6 - 0.9 meters from each other, vertically. This is usually done with screws.

Beacons must be level. To do this, they install trimmings of plywood and timber under them.

And whether the guides in the sashes are correctly installed, check with twine or rope. First, a rope is stretched above the floor level, then the same is done in the middle of the wall and under the ceiling. The lace should not deviate beacons in the other direction and no gaps should form between the crate and the lace.