How to insulate a chicken shed for the winter with your own hands simple ways

If you work in a garden or vegetable garden, then you are at an increased risk of infestation with parasites. They enter the body when working with the earth, multiply rapidly and cause health problems (papillomas, warts, fungus, etc.). Experienced gardeners use to prevent infection with parasites. Read more. »

But not always there is a place on the site for the construction of the necessary premises, and time is running out. In summer, you can even install a plastic shed. or use an existing one, but neither is suitable for winter. Before you insulate a chicken shed for the winter with your own hands, check out our offers - you will surely find the right one. Most often, the inside of the barn is insulated with clay mixed with straw or the same sawdust.

If the walls are wooden, to increase adhesion, stuff small nails into the boards before plastering and stretch wire or thread between them. If there are thin wooden slats, you can fill the crate from them.

The layer of plaster should not be thicker than 5 cm, otherwise it will not hold well. It is desirable to finish the plaster long before the onset of cold weather, so that everything dries out properly.

The method is cheap and the result is quite good, but if your region has severe winters, you will have to spend money on the purchase of thermal insulation materials - mineral wool or polystyrene. To insulate with mineral wool, it will also be necessary to pre-stuff the rails on the walls - they should be located vertically, from ceiling to floor, at a width slightly less than the width of the mineral wool rolls. We spread pieces of insulation between the rails - it does not need to be additionally fixed with anything. Then the thermal insulation layer should be hidden under sheets of plywood or boards.

If you are insulating the barn with foam, it is better to do it from the outside, since the material is quite fragile, and chickens can peck at it. The insulation layer on the walls should be plastered and whitewashed with lime. In order for the plaster to adhere well to the surface of the insulation, it is best to glue a special fiberglass mesh to the foam, and only then apply a layer of cement.

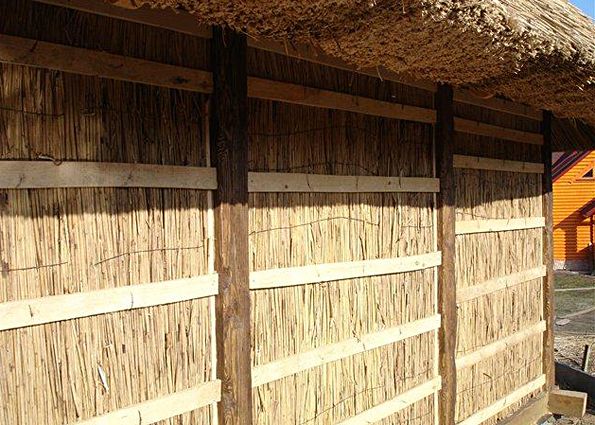

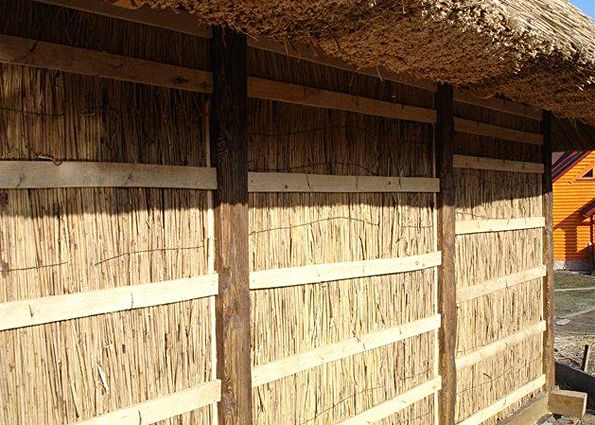

Wall insulation

The best option would be insulation from the outside. This will solve problems with dampness, freezing and blowing

This is especially important with a steel frame. Externally sewn racks will be protected from external influences, maintaining performance for a long time

With external sewing, the structure is not subject to freezing. Temperature fluctuations do not affect strength. To insulate the structure in this way means to rid it of dampness. From the inside, everything will be dried with warm air.

Warming technology can be:

- frame;

- Wet method;

- Well way.

The first option is suitable for insulation for finishing with a board, profiled sheet and other similar elements. A frame in the form of an aluminum profile or wooden slats is stuffed onto the surface of the wall. The step is set taking into account the future finish.

The wet method is named so because of the finishing plastering. Often, the barn is insulated with foam by gluing plates. After complete setting, the foam is fixed with plastic dowels.

A fiberglass mesh is mounted over the insulation layer. It is necessary to keep the plaster on the surface. The canvas is fixed with glue or a stapler.

A plaster or cement-sand mortar is applied over the mesh. It can be in the form of an even layer or in the form of a “fur coat”.

The well method can be created with masonry or using boards. When laying, two half-brick walls are erected, fastened in height with mortgages.In the space between them fall asleep:

- slag;

- foam balls;

- expanded clay.

Sawdust is poured into the space. Insulation is being rammed. Further, the following sewing and backfilling takes place. Insulation of the barn from the inside is also not uncommon. Often shingles are used for such purposes. This is a mixture of sawdust, water and clay. The material is applied to the frame of their thin rails.

You can make insulation yourself or order a ready-made mixture. Many firms produce such formulations in dry form with different properties.

The advantage of warming will be that it is not a pity. It is difficult even for ungulates to damage such a lining. Even if this happens, you can always repair the defect. The cost of insulation is small, and the effect is quite good.

For a more lived-in barn, sheathing with reflective material is suitable. Its feature is to retain heat indoors. Therefore, when using it, it is necessary to install a heater inside.

The insulation can be attached both with glue and with wooden slats. The second option is more reliable. In addition, according to this design, after you can create a more attractive finish.

First, consider how to insulate a wooden shed.

Board building

Even if the barn is built of boards, it can be well insulated.

- Boards crack even with good care, and even more so in a plank shed. This phenomenon will have to be fought. You can use improvised materials (tow or dry moss) in order to repair cracks, but it can be done much faster with the help of polyurethane foam.

- Now from the inside you need to make a second wall at a distance of 30 cm from the main one. A frame is simply made onto which OSB sheets are screwed, and the space is filled with insulation material. Design features do not matter, the main thing is that the system is reliable. Instead of OSB, you can use an unedged board, nailing it with a herringbone. In this case, the gaps and from the inside will have to be sealed with mounting foam.

- So that the insulation does not draw moisture from the floor into itself, roofing material is laid on the ground, and only after that the insulation is laid.

Board building

Shed from boards

- Boards crack even with good care, and even more so in a plank shed. This phenomenon will have to be fought. You can use improvised materials (tow or dry moss) in order to repair cracks, but it can be done much faster with the help of polyurethane foam.

- Now from the inside you need to make a second wall at a distance of 30 cm from the main one. A frame is simply made onto which OSB sheets are screwed, and the space is filled with heat-insulating material. Design features do not matter, the main thing is that the system is reliable. Instead of OSB, you can use an unedged board, nailing it with a herringbone. In this case, the gaps and from the inside will have to be sealed with mounting foam.

- To prevent the insulation from pulling moisture from the floor, a roofing material is laid on the ground under it.

Internal additional works

In order to maintain a favorable microclimate in the insulated hozblok, you will need to take care of air circulation. Animals in the process of life emit a lot of moisture, and moist air is a breeding ground for the development of mold and fungus. To organize air exchange, one or two exhaust devices with a check valve will have to be cut into the wall at the top of the room, preventing cold air from entering the room. Supply ventilation, as a rule, is provided by the remaining leaks, a gap under the door and its periodic opening.

If possible, a vestibule with an inner door should be equipped in an insulated shed. It is convenient to store food and care items for animals out of their reach. Tambour allows you to save up to 30% of heat.

12.10.2018

The owners usually prefer to cope on their own with the construction of households. buildings. And quite often the question arises, how to insulate the barn.Even before construction begins, you need to know for what purposes you need it: for storing unnecessary trash, tools, or livestock will live in it. Determine the dimensions of the future building. Then mark the planned barn on the site, dig a trench under the foundation. It can be shallow, about half a meter. When pouring the foundation, you can use stones, pieces of old brick, mixing them with cement mortar. If suddenly the foundation settles, you just need to add a new one.

How to insulate a barn outside with your own hands step by step diagram

Step 1: Frame the Walls

The back wall of the frame will be the existing surface of the walls, and we will put together the front wall from the boards. Suitable even not quite smooth. But what about the cracks? There is one tried and tested method - the boards are nailed with an overlap! First, two boards are nailed to the bars, between which there is a distance for the third. The middle one is inserted so that the upper part goes under the first board, and the lower part covers the second board from above. It will turn out a "herringbone" through which no wind will break through. The advantage of this design is that it is protected from drying out, because if we just put together the boards butt-to-butt, sooner or later large gaps formed between them.

Step 2: Fill the frame with insulation

The space between parallel walls can be insulated with your own hands in different ways. If funds allow, buy mineral wool or blow out the voids with polyurethane foam. However, initially we agreed to save money, which means it's time to remember the ways of warming for the winter, which were used by our grandparents. What could be easier than sawdust! The material is almost free - at the nearest sawmill this stuff is at least heaps, for a bottle of something stronger you bargain with the watchman.

It is desirable to take sawdust dry and small. To prevent rodents from getting into them, it is enough to mix wood with fluffy lime - 1 part of lime is enough for 25 parts of sawdust. When insulating with sawdust, the space between parallel walls should be at least 25 cm. The prepared material is covered in layers, constantly ramming. Over the next two weeks, the insulation will still shrink - do not forget to add more sawdust after a while.

Step 3: Insulate the ceiling

In the case of the ceiling, the same frame is created. But unlike walls, a layer of high-quality waterproofing is also laid on top of the thermal insulation. Just covering it with slate or tiles is not enough; there must be a layer of roofing material or plastic film between them. The most important thing at all stages is to prevent the penetration of moisture into the sawdust. To prevent this from happening, many pack sawdust in plastic bags, and only then carefully place it in the space between the walls.

Step 4: Insulate the floor

To insulate the floor with your own hands, it is important to make a mound of soil at least 10 cm high above the main level. Then clay is poured and compacted

The disadvantage of this method is in the dirt, which will always be inside the barn. If you want to make a clean and durable warm floor, it is recommended to make an expanded clay embankment instead of a mound of soil and pour a cement-sand screed over it. Only this should be done in advance, in the warm season.

The first way is boarding.

The barn outside can be sheathed with boards according to the principle of brickwork, closing the gap between the two boards of the third. The walls are upholstered with slate in the same way that is used when covering the roof. In addition, the barn can be sheathed with boards from below. Slate sheets are placed higher, and then timber is stuffed.

In the process of work, insulation is poured between the walls, which needs to be tamped with something. As a heater, you can use pine needles, fallen leaves, sawdust. These materials are mixed with lime in a combination of one to twenty-five. This avoids problems such as rodents between walls.The ceiling also needs to be hemmed, and the same composition is poured on top. Boards are stuffed over the rafters and covered with roofing material in several layers, which must be nailed with wooden slats at a distance of half a meter. The lower part of the barn on both sides can be furnished with slate, which will protect the room from rodents and predatory animals.

From below, the barn is insulated by sprinkling the floor with soil, 10 cm below the main floor, and then laying and compacting the clay mortar.

The door is made of boards knocked down diagonally, putting a layer of roofing material between them so as not to release heat.

The second way is sheathing with shingles.

How to insulate a barn if money is tight? The walls need to be sheathed with shingles, it needs to be nailed obliquely, starting work from the corner. Do the work in one direction, then in the other, having achieved the crossing of the shingles. It can be replaced with goat willow branches, then the clay can be applied thicker.

Engage in the preparation of a clay solution by adding sawdust to it. The clay must be soaked and diluted with water to the consistency of liquid sour cream. Sawdust should be added a little at a time, achieving the required density of the solution. For cooking, it is better to take larger dishes so as not to knead several times. The finished solution should stand for a while.

Apply the mortar to the bottom of the wall in large quantities and smooth it with a spatula. Its layer should be at least 3-5 centimeters

Apply the solution evenly, paying special attention to the corners of the room. They can even be rounded and made even warmer.

After finishing plastering, let the walls dry for several days. During this time, cracks form, which must be rubbed with a solution of clay and sand in a ratio of 1 to 2. The walls must be whitewashed with lime. Take lime in granules, dilute in half a bucket of water. Within a minute, the reaction with water will begin, the solution will become very hot. When the reaction is over, fill the bucket with water to the top, add a spoonful of table salt.

Insulate the barn ceiling. At the level of 15 cm from the roof around the perimeter, fix the bars. The length of the boards should allow them to lie on the bars and fit snugly against the walls. On top, fill the boards with a solution of clay with sawdust, 10 cm thick, after opening the roof

And again, special attention should be paid to the corners.

The process of warming the barn in this way is quite laborious, but the cheapest and very reliable. Now your animals will definitely not freeze!

05/26/2013 at 16:05

How to insulate a poultry shed so that chickens rush?

Construction and insulation work outside the barn

Rural residents hardly need to be explained what pets are and how to care for them. But yesterday's "urban", who decided to move closer to nature, everything is new! As a rule, the first in the list of pets, not counting dogs and cats, are chickens. In spring and summer, it is not at all difficult to take care of them, the main thing is to provide high-quality food and a canopy where they can hide from the sun. But in winter, the question is different - you can’t invite a chicken “mob” led by a pugnacious rooster into the house for the whole winter, and in the tool shed the animals will simply freeze.

The issue should be resolved quickly and efficiently. And, as everyone thought at that moment, preferably - inexpensively. Even a leaky tool shed can be turned into a warm room for the winter with your own hands. The easiest option is to knock down a wooden frame from the boards, hollow inside.

Heating is a radical way to keep the barn warm.

If winter has caught you suddenly, and the barns with animals turned out to be poorly insulated, a radical way to increase the temperature inside the premises is to provide heating for the winter. Heating can be electric or wood burning. In the first case, heaters are used, in the second, a stove is built. Heaters are a temporary solution to the problem, but the stove should be installed even in insulated rooms.

The fact is that thermal insulation does not warm, but only prevents heat from leaving the barn. The stove will allow you to quickly and cost-effectively heat the air for a comfortable life for your pets. What to make a stove from, you decide. Just keep in mind that brick structures heat up for a long time, but then cool down for a long time. Metal stoves heat up almost instantly, but then also cool down quickly.

Insulated doors will help keep the heat inside the barn. It is best if the door leaf consists of two independent halves. To release the animals into the yard or into the aviary for walking, it will be enough to open the bottom door. Warm air accumulated from above will not be able to leave the room. And in the summer, the top half will make it easier for you to clean the barn - through it you can throw fresh manure out.

If you live in a private house, then you have some opportunities that residents of state-owned apartments do not have. You can grow your own vegetables, fruits, get your own livestock and treat yourself to a fresh, environmentally friendly product. True, the cattle still need to be kept somewhere. And here already someone is into something much - they drive the poor cattle wherever they get, even into rooms that are completely unsuitable for that.

In this article, we will try to give recommendations on how to insulate the barn on your own.

A cheap way to insulate a barn

To insulate a farm building for poultry, pigs and other livestock, it is not necessary to be a professional builder.

All work can be easily done by hand.

Installation of a wall structure

First you need to build a second wall around the entire perimeter of the building. To do this, two boards are nailed parallel to each other, and on top of the seam is the third board.

Insulation bookmark

Insulating material must be placed in the resulting space between the wall surfaces. It can be autumn leaves, pine needles or sawdust. To prevent small rodents from starting in the shed, the heat insulator must be mixed with slaked lime in a ratio of 25: 1.

The insulation layer must be at least 20 cm. At the same time, it must be placed everywhere - on the walls, ceiling and floor. It is well tamped, and then allowed to stand for another 2-3 weeks. If necessary, the material is added and "seal" the space.

Floor insulation

How can you insulate the floor in the barn? Even ordinary clay will do. To do this, first pour the soil around the entire perimeter of the building 10-15 cm above the main one, and then lay the compacted clay.

At the same time, it is very important to prevent the penetration of moisture from it to the sawdust, otherwise they will begin to rot quickly.

Thermal protection of doors

The door in the outbuilding can be insulated with ordinary boards and roofing material. To do this, the boards are nailed diagonally, and a sheet of roofing material is inserted between them.

By isolating the barn in this way with your own hands, you can provide warmth all year round for chickens, pigs and any other living creatures.

3 How to insulate a poultry shed, stove and improvised materials

What else to insulate a poultry shed, if not with straw. It is enough just to throw it on the floor, you can also throw in an old rag. Of course, this is an additional method of insulation that needs to be combined with the main ones. If the frosts are very strong, and the poultry can hardly tolerate them, the most effective way of warming is the construction of a small brick stove. It is not recommended to make it from metal - although it heats up quickly, it cools down just as quickly, but the brick will keep heat for a long time.

The stove does not have to be large and made of refractory bricks - ordinary materials are quite suitable. If you make a stove with a stove, then in addition to heating, you can cook tubers on it or heat water for steaming feed. Usually such stoves are heated with wood. Do not forget about lighting - in good lighting, and in a warm room, your chickens will rush with triple their strength!

Do you still find it difficult to restore your vision?

- Your eyesight is failing you

- Presses head and eyes

- You squint a lot and wrinkles appear from this

- Do you have elevated intraocular pressure?

Stop tolerating it, you can't wait any longer, delaying treatment.

Read what Elena Malysheva advises and find out what drops she uses.

How to insulate a cellar with minimal labor and cost

As you know, building a cellar does not mean getting a good place to store your crops. Poor waterproofing can be the cause of the penetration of groundwater into the room, and poor-quality thermal insulation can lead to unfavorable temperature conditions and the formation of condensate. That is why we will consider how to insulate the cellar in the garage or under the house, this will create an optimal microclimate in which all products will be kept fresh for a very long time.

It is worth remembering that only an integrated approach: good waterproofing, high-quality insulation and competent ventilation guarantee that the cellar will not be damp.

Styrofoam is a very popular option for cellar insulation among developers.

Insulation serves two main tasks:

- In winter, freezing of the structure is prevented.

- In the summer, high-quality thermal insulation allows you to keep a low temperature in the cellar even on the hottest days.

Options and materials for thermal insulation

How to insulate a barn with your own hands? First of all, you need to choose the technology and material. The following materials have traditionally been used for thermal insulation of outbuildings:

- Chopped straw. This insulation has been used by people for thousands of years. It is highly environmentally friendly, but short-lived. Straw is flammable, prone to wetting and rot, insects and rodents readily start in it. In order to protect the material, it is impregnated with lime at the rate of 1 part lime to 25 parts straw. The resulting mixture fills the space between two plank walls. Straw is also used to insulate the ceiling. The thermal insulation coefficient of straw is low.

- Sawdust. Sawdust, like straw, is also flammable and subject to biological hazards. They are mixed with lime in a ratio of 1:15. To strengthen the composition and increase its moisture resistance, up to 10% cement is added. Sawdust is prone to caking; in case of wall insulation, they will have to be added annually.

- Expanded clay. These are light pellets with a diameter of 1-2 cm, sintered from ceramic raw materials. The material is not hygroscopic, durable, non-flammable, little caking. It is also immune to biological threats. The only drawback is the low thermal insulation performance, forcing the use of thick layers of material. When backfilling expanded clay between walls, it is often mixed with cement mortar. It turns out a very durable material. This should be done in layers of 20 cm, each time giving the solution time to set. Otherwise, the lower part of the wall may open.

Expanded clay - material for warming the barn

Expanded clay - material for warming the barn

Nowadays, more modern materials are increasingly being used to insulate sheds. They are more expensive, but have several times higher performance. Among them are:

Foam glass. Small pellets of foamed glass. Does not burn, does not get wet, does not allow the development of mold, microorganisms or rodents.

Mineral wool. The product is made from rocks (basalt wool) or from waste glass production. The material does not burn, is not subject to biohazards. It has high thermal insulation performance, so a layer of 50 mm mineral wool is equivalent to a 25 cm layer of sawdust. Mineral wool is mounted in a guide system. It is suitable for insulation of both walls and ceilings.

When wet, the material loses its heat-insulating properties, therefore, during installation, special attention should be paid to waterproofing and steam removal.During installation, mineral wool emits dust harmful to health, it should be worked with protective gloves, tight clothing and shoes, and a respirator.

Styrofoam

The household name of the material is polystyrene. It is produced in sheets of 100*100cm in size and can be easily mounted on vertical and horizontal surfaces. It has good thermal insulation, does not absorb moisture. One of the main disadvantages is fragility.

When pressed hard, the sheets crumble, so care must be taken when handling them. Another significant disadvantage: the material is combustible, when heated, it emits toxic gases and aerosols

This limits the use of foam for insulation of residential premises.

Extruded polystyrene foam. It is obtained by extrusion, has a significantly smaller granule size than conventional foam. The material is durable, does not crumble, does not need additional vapor and waterproofing. Great for floor insulation.

Polyethylene foam. Common name - penofol. This flexible and resilient roll material is covered on one side with a layer of foil that reflects heat back into the protected room. It is used as a waterproofing and additional insulation, or as the main heat insulator. Easily mounted on wooden surfaces with a construction stapler. The material also releases harmful substances when heated. The widespread use of penofol is limited by its high price.

In addition, progressive spray materials such as polyurethane foam and ecowool are becoming more widespread. The high cost of the equipment makes it unlikely to purchase them specifically for the barn. However, if they carry out thermal insulation of the main house, and the equipment has already been delivered to the site, then it is quite possible to use the remaining materials for outbuildings. The sprayed materials have no seams and create a perfectly even continuous layer of thermal insulation. They do not cake, do not crumble and are characterized by consistently high thermal insulation properties and durability.

How to insulate a barn working from the inside

Shingles, although a budget option, will take you a lot of time. If you value time, then instead of budget options, you can use more costly, but also more efficient in terms of speed of work. These include the option of insulation with mineral wool and foam. It makes no sense to talk about the merits of materials - we have already talked about this more than once in articles devoted to these heat insulators. Recall the shortcomings - mineral wool is easily saturated with moisture, as a result of which it loses its thermal insulation qualities, and also cakes over time.

When insulating with mineral wool in a checkerboard pattern, nails are stuffed onto the walls to create a reinforcing mesh. Rolls of mineral insulation are unwound and laid on the walls, while a reinforcing mesh is created with the help of a rope that will hold the wool in position. Mesh is not necessary if you use rigid or semi-rigid slabs instead of soft rolls. But in this case, you will need to make a crate of boards with your own hands.

The distance between the boards should correspond to the width of the plates, and even be a couple of millimeters less so that the plates fit snugly into the space. How to insulate a barn with mineral wool for the winter? The secret is to prevent the material from getting wet due to moisture condensation. And therefore, a layer of vapor barrier is stuffed over the insulation - glassine or more modern versions of membranes.

Styrofoam insulation inside the barn is even easier. If the base is strong, you can glue the insulation boards with your own hands on any available glue, even on ordinary PVA. Suitable and mounting foam, and liquid nails. For greater strength, it is possible to fix the plates together with the adhesive base using special dowels.In any case, after this, it is imperative to protect the material from mechanical damage. Any sheet material will do. In a chicken coop, this can be flat slate, and in a barn for small horned thinness, sheets of plywood.

Shingles environmentally friendly way

Clay and straw is another budget option for do-it-yourself insulation, which, moreover, is absolutely safe from an environmental point of view. To this day, clay and straw are used to make adobe (lampach, valek, clay block) - clay bricks, which combine both insulation and the basis for the walls of the shed. Straw mixed with clay acts as a reinforcing material, so that the clay does not crack or crumble.

Under a layer of plaster, adobe is able to serve for many decades. So if you intend to build a barn for the winter from scratch, consider this budget option. Clay bricks in the villages used to be made by all relatives - there will be a reason to get together. If the barn has already been built, the clay and straw option is still relevant. Do-it-yourself warming of the barn should be carried out from the inside - a mixture of materials is applied to a pre-prepared shingle.

Shingles - wooden planks stuffed from the inside of the room. First, one layer of planks is stuffed diagonally, and then the second in the opposite direction. To prepare the solution, first soak the clay (sour cream consistency) and add straw in portions. The resulting solution should be thick enough so that it does not slip from the surface. Let the mixture cool for a bit before you start working.

The clay mixture is applied to the walls with their own hands from the bottom up. The layer thickness is at least 3 cm. Use a spatula to make it easier to level. At the corners, the layer thickness can be increased up to 5 cm by rounding them. When drying, cracks may appear - this is not a problem. They should be covered with a solution of clay and sand (1: 2). The final stage is whitewashing the walls with lime.

Shed insulation materials

As an insulating material for a barn, you can literally use what lies under your feet. This:

- straw with clay;

The use of improvised means eliminates the significant costs of creating thermal insulation. If there is a desire to build a more capital structure, then polystyrene foam is more suitable. It is affordable and easy to install. But it should be remembered that it is more efficient to fix the plates from the outside of the barn. Then the living creatures inhabited in the room will not damage the fragile material.

In the case of choosing a heater at the construction stage, preference is given to foam blocks or wood concrete. Such structures are not afraid of frost, and the requirements for the foundation are low.

It is irrational to use other materials to isolate the room from frost. Their cost is high for a utility room. But at the request of the owner, polyurethane foam, basalt wool, foam glass, etc. can be used. When choosing an insulator, the purpose of the utility room should be taken into account. If the premises are intended for keeping animals, it is recommended to use environmentally friendly materials.