How chimneys are arranged

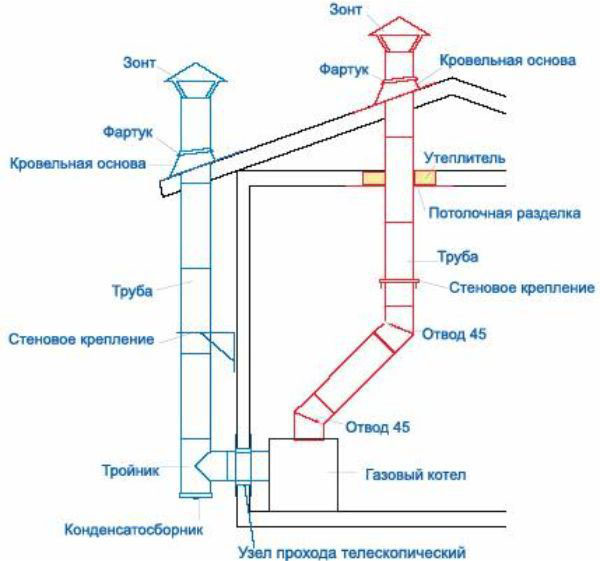

Almost any chimney for a gas boiler consists of the following parts:

- pipe;

- branch pipe with an adapter connecting it to the pipe;

- telescopic tubes,

- clamps to ensure better connection density at the junction of structural elements,

- mounting brackets for fixing the entire structure,

- bends;

- tee;

- cap with condensate drain;

- conical tip.

Currently, chimneys are made from various materials:

- brick,

- asbestos cement,

- ceramics,

- galvanized steel

- stainless steel,

- coaxial flue.

The coaxial chimney deserves special attention - a design consisting of two pipes of different diameters, one of which is inside the other: combustion products are removed through the inner one, air enters through the outer one. The movement of gases is provided by a turbine.

Each of the materials has its pros and cons:

| Chimney option | pros | Minuses |

| Brick | Low cost | hygroscopicity,

roughness of the inner surface, not resistant to corrosion the tightness of the joints is easily broken, foundation is required the construction of which requires special skills. |

| Asbestos-cement | Low cost,

ease of assembly |

hygroscopicity,

the tightness of the joints is easily broken, foundation required |

| Ceramic | Efficiency,

corrosion resistance, smoothness of the inner surface, low hygroscopicity, ease of installation |

High price,

foundation required |

| Steel single layer | Low cost,

ease and speed of installation, smoothness of the inner surface, lack of hygroscopicity, corrosion resistance. |

unaesthetic appearance,

large heat losses the formation of a large amount of condensate |

| Steel from sandwich pipes | ease of installation,

smoothness of the inner surface, lack of hygroscopicity, corrosion resistance, maximum tightness of connections, own thermal insulation. |

high price,

unaesthetic appearance, when used outdoors requires additional thermal insulation |

| Coaxial | small design dimensions

ease of installation, no condensation high efficiency, autonomy, Fire safety. |

high price,

only suitable for combustion boilers |

Types of chimneys

Let's start with a brick chimney. This is a classic option, for which there was simply no alternative for a long time (except perhaps a stone). Its undoubted advantage is strength and stability. But, on the other hand, only experienced craftsmen, who are very difficult to find, can fold such chimneys. Yes, and they charge quite an impressive amount for their services. In addition, a brick chimney does not always meet the requirements of modern heating appliances.

Another disadvantage is that a brick chimney can only be installed during the construction of a building. And if there is a need for its changes, then the chimneys must be disassembled and assembled elsewhere. Yes, and the overlap must be designed for its considerable weight.

An exotic option includes a glass chimney, which has a number of undeniable advantages, including low thermal inertia and the complete absence of corrosion. But at the same time they are very expensive and therefore not widely used.

Another option is asbestos-cement chimneys. But they are put only by people who have not sufficiently studied this issue or are severely limited in funds. The main thing is that asbestos cement is a carcinogenic material.Therefore, think carefully before living near a source of danger to your health.

And the last type is metal chimneys. The best performance was demonstrated by chimneys made of heat-resistant stainless steel. Such chimneys are an order of magnitude lighter than brick ones, which means that no additional foundation is required.

This is a kind of constructor. Therefore, they are much easier to install, and there is no problem in finding specialists to install them. Metal chimneys are durable, have high corrosion resistance and meet the requirements of modern equipment.

Unlike brick chimneys, metal chimneys have an optimal cross section for the passage of combustion products. Due to its round shape, there are no turbulences in it that interfere with the movement of smoke.

It is also important that soot does not settle on smooth walls. And one more very important point

Metal chimneys can be freely installed in built cottages, even in those where additional heating installations are not provided.

Metal chimneys are easy to maintain, multifunctional (suitable for almost any type of fuel), have low thermal inertia. Thanks to all these advantages, they come to the fore, occupying a significant segment of the market.

The following articles:

- Construction of sewer networks

- How to choose the right architect

- Experiments in the design of the exterior

- Membership in SRO

- Balcony glazing in a cottage

Previous articles:

- Construction of a wooden house

- House renovation plan

- The choice of materials for the construction of the bath

- Choosing a construction company

- Start building a house

Next >>

Ventilated Chimney Craft

By ASDasdasdaAS454354861 In Uncategorized

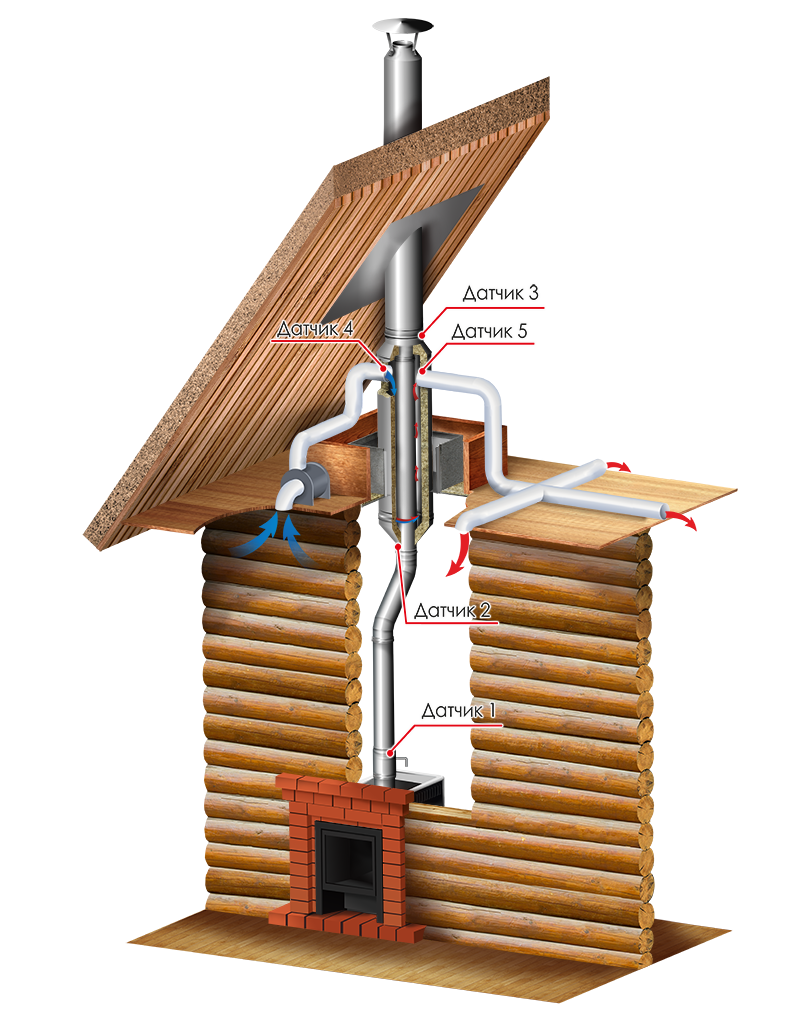

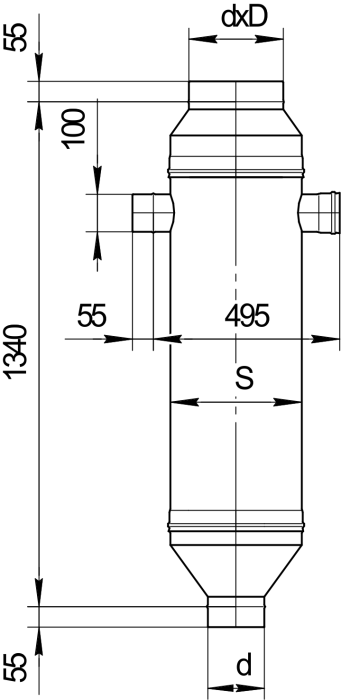

A ventilated or three-walled chimney is a structure that combines a single-walled and insulated chimney. It consists of a main pipe of a smaller diameter, through which combustion products move directly, and an outer sandwich of a larger diameter. Between the inner pipe and the sandwich (consisting of two pipes and thermal insulation between them) there is a hollow part filled with air coming from the air intake.

| d | 110 | 115 | 150 |

| D | 200 | 200 | 250 |

| S | 300 | 300 | 350 |

| Weight 0.8x0.5x0.5 | 20,13 | 20,58 | 25,20 |

Temperature sensor readings

It should be taken into account that when using a lower power fan, the temperature at sensors 3 and 5 will be higher. For example, when using a fan with a capacity of 100 cubic meters per hour, the temperature at sensor 5 may rise to 180°C. During the tests, the ambient temperature (outside the window and in the room where the heat generating apparatus is installed) was 25-27°C. In the table below, the sensor values are valid when using a fan with an impeller diameter of 100 mm and a capacity of 250 cubic meters per hour

| max | 789,2 | 637,9 | 167 | 21,3 | 62,1 |

| medium | 509,3 | 369,9 | 106 | 20,8 | 40,8 |

| min | 346,5 | 203,7 | 88,4 | 21 | 33,5 |

The principle of operation of a three-wall chimney

The three-circuit smoke exhaust system is a chimney with independent sealed channels for smoke removal and air supply / exhaust. The system operates under slight overpressure (regular air circulation by means of a fan). An extractor hood is installed in the attic or in the dressing room, which takes cold air from the room. The air enters the heat exchanger between the inner channel, through which the smoke is directly removed, and the outer sandwich. In the process of contact with the wall of the inner pipe, the air is heated and discharged through the ventilation duct to other rooms. Continuous air circulation is possible only when the fan is switched on. The operation of the chimney without forced air intake is possible, but it is necessary to observe fire safety measures when passing through the ceilings, since in this case the outer contour of the chimney will also heat up to high temperatures.

Appointment of a ventilated chimney.

The use of a ventilated chimney in individual residential projects has two main purposes: cooling the outer contour of the chimney for fire safety measures and heating the premises with warm air. Let's look at each goal in more detail.

Ensuring fire safety measures for the facility.

Most often, a heat generating apparatus (fireplace, stove, boiler) and a smoke exhaust system are adjacent to flammable and combustible materials - wood, clapboard, chipboard

During installation, it is important to follow the rules for installing the stove and chimney with respect to the walls, floor and ceilings of the room. But during operation, the chimney may experience an increased load, and therefore an increase in operating temperature.

In this case, it is important that the outer contour of the chimney is cooled in time and evenly. This is especially important when passing through ceilings. The device of a three-circuit chimney fully meets the listed requirements. Due to its design, the outer contour of the chimney, even at the highest operating conditions, remains within acceptable temperatures and provides protection from heating and ignition of adjacent ceilings.

Room heating.

The second function of a ventilated chimney is to heat rooms with the help of circulating air. The design of the system, in addition to the smoke channel itself, also consists of air ducts for cold air intake and warm air distribution. Air intake is carried out from any room, for example, from a dressing room. Most often, such a room is the location of the heat generating apparatus. In the process of passing through the chimney channel, the air is heated and discharged through the air ducts to other adjacent rooms. Due to the high technological effectiveness and tightness of the system, warm air enters the premises without admixture of combustion products and provides good continuous ventilation.

Why do you need a chimney

Air intake is a necessary condition for the correct operation of the boiler and for cleaning the room from side impurities released during the combustion process.

Equipping a chimney for gas equipment in a residential building is regulated by a number of requirements. They cannot be ignored not only for fear of a fine, but also because they did not appear out of nowhere. Compliance with these requirements is the key not only to the correct operation of the entire heating system, but also to safety.

Chimney Requirements

The device of chimneys for gas boilers is regulated by legislative acts, compliance with which is mandatory for all owners of residential buildings where gas heaters are used. Deviations from the requirements are considered not only a violation of the law, but can also be life threatening for residents of a building that uses equipment that does not meet the standards.

- Each heating appliance needs a separate chimney, i.e. if the boiler is installed in one room and the gas stove in another, then there should be two chimneys.

- The cross-section of the chimney pipe must correspond to the outlet pipe of the gas boiler: the ratio of the sides of the rectangle (if the pipe has a rectangular shape) cannot be more than 2:1. The pipe must not exceed 0.10.

- At the base of the smoke channel, pockets 25 cm deep are installed to clean the combustion products.

- The inner walls of the chimney must be smooth, resistant to corrosion and temperature loads up to 2000. The wall thickness is from 0.5 mm.

- Smoke channels can have turns, but not more than three, and at the same time, the radius of curvature on each of them must be the same as that of the pipe itself or more. The turn is equipped with an inspection hatch, which serves to clean and drain condensate.

- The total length of the chimney and ventilation ducts located next to it is at least 5 m.Moreover, if the roof is flat, then the chimney should rise above it by 2 m, and if it is pitched, then the height depends on the distance between the roof ridge and the chimney.

- The presence of deflections, even those that seem insignificant, is not allowed.

- The chimney must be equipped with a deflector (a cone-shaped tip that prevents clogging of the chimney and the ingress of precipitation into it).

- From below, the pipe is equipped with a revision and a dripper so that condensate does not accumulate.

- All joints must be sealed without gaps.

- The distance from the chimney pipe to surfaces made of non-combustible materials must be at least 5 cm, from flammable materials - 25 cm.