Best Answers

Skorpi:

Buy special literature and do it!

Victor:

.karelin-kamin / Oleg this link has a catalog of ready-made fireplace projects, distance learning of stove-makers, literature Furnace works.

Stanislav:

make a lining of chipped boulders, very beautiful.

the fastest thing is to go as a student to the MASTER….

20090114:

You need to get some theoretical knowledge ... Try to cut through what a fireplace tooth (smoke tooth) is, how it is made, what it is for, and then the rest will begin to appear. And for the area of \u200b\u200bthe room you need 100x40 \u003d 4000 watts, i.e. area of the open part, about 1.3 m2. Keep in mind, a fireplace is a VERY fuel hungry creature!,

Ivan Ivanov:

Buy a fireplace cassette, connect it to a chimney (sandwich or brick) and finish with stone or brick. At least you won't burn out and burn out. The main thing is that it can not be done by a stove-maker.

Andrey Balmashev:

It is best to entrust this matter to a good specialist, in the manufacture of fireplaces there are a lot of nuances that must be observed in order for the fireplace to work normally!

Kurban Adamovich:

This is a very troublesome business, there are things that must be strictly observed - so that the efficiency is good, so that the waste does not come out, So that it is not particularly voracious, etc. I myself did it according to the book “How to build a fireplace”, it seems to work out well

Combined crown bridges

Such crowns are called metal-plastic (Fig. 14-15). They, like cast crowns, are made by one-piece casting from a cobalt-chromium alloy, but the front surface is additionally lined with white plastic. Their merits include acceptable aesthetics. For metal-plastic crowns - the price will be from 5,000 rubles per 1 unit, which by the way is already comparable to the cost of economy-class cermets.

Disadvantages of metal-plastic crowns -

- Plastic in the oral cavity quickly loses its aesthetic properties, and over time, the white color of the plastic changes to gray. In addition, plastic tends to absorb liquid and swell a little. This leads to the fact that over time the plastic begins to exude the smell of unbrushed teeth.

- Metal-plastic crowns are also not very reliable: with strong compression of the teeth or during chewing, the plastic lining can simply fall out.

- Plastic is not very healthy (especially for allergy sufferers), because. in plastic there is always some amount of chemically active monomer, which is released for a very long time.

Combined bridge prostheses -

Because the metal frame of metal-ceramic, as well as solid bridges, are made on the same cast metal frame - different types of crowns can be combined in one bridge prosthesis. For example, you need to make a bridge of 3 units supported by 5-7 teeth. In this case, the closest 1-2 crowns that fall into the smile line can be made with metal-ceramic, and the far crowns can be cast (Fig. 16).

Dentists and dental technicians are not very fond of such designs, because. this reduces their cost. And if you are told that this cannot be done, then this will only speak of the unwillingness of the doctor.

Features of pricing in dentistry

How much it costs to put a crown (even of the same type) can vary significantly in different clinics, and depends on:

Pricing policy - each dental clinic can be focused on a specific segment of consumers (taking into account their income). That is why the cost of crowns of the same type, for example, zirconium, in different clinics can range from 16,000 to 25,000 rubles per unit.

-

From the qualifications of the staff - → an orthopedist, whose task is to grind teeth for crowns, take casts, select the color of future crowns, fix the finished crowns on the teeth.On average, the salary of an orthopedist will be about 20% of the cost of a crown (max 25%, if a very highly qualified doctor).

→ a dental technician whose task is to make crowns on the basis of dental impressions. On average, the cost of manufacturing a crown in a dental laboratory is about 25% of the final cost of the crown. Those. the clinic keeps about 50%, from which you need to deduct administrative expenses, rent of premises, depreciation of equipment, the cost of some consumables, utility bills, salaries of nurses, nurses, chief doctor ... taxes.

- From the cost of the materials used - for example, you can use high-quality German ceramic mass in the manufacture of cermets, or you can use our Russian or Belarusian. The price of the latter is an order of magnitude lower, which allows you to slightly reduce the final cost of the work. The same applies to metal alloys required for the manufacture of both solid cast crowns and a metal frame - for metal-ceramic ones.

From having our own dental laboratory, the technical stage of crown manufacturing takes place in the dental laboratory. Dental technicians sit there and make crowns. Not all dental clinics have their own laboratories. If there is no laboratory of its own, then in this case the clinic must have an agreement with one of the third-party dental laboratories. Accordingly, the cost that will be included in the services of a third-party dental laboratory will include not only the cost, but also the profit margin, like any commercial enterprises. The presence of its own laboratory allows the clinic to be more flexible in setting the final price for the consumer.

How clinics save on patients:

Low qualification of the staff - this means lower costs for salaries, because good doctors require a higher percentage of wages when hiring, which affects the cost of services. Therefore, clinics often hire bad and inexperienced doctors who are willing to work for a small percentage of the proceeds (this is somewhere around 12-15%). Therefore, when you are offered cermet for 4500 rubles, you need to think carefully.

The use of cheaper materials - the use of low-quality materials of Russian and Belarusian production has its consequences. For example, the use of cheap ceramic mass can lead to inaccurate fit of crowns to the teeth, because. such a mass can give uncontrolled shrinkage during firing

In cheap ceramics, the transparency indicators can differ significantly from natural tooth enamel, which will lead to poor aesthetics of the finished crown. Also, cheap ceramic mass may have poor adhesion to metals (which is important in the manufacture of metal ceramics), which will lead to a high risk of ceramic chipping. The use of cheap metal alloys can lead to cracks in the metal frame of crowns and the need to replace them.

We hope that our article on the topic: Types of crowns for teeth and which ones are better - turned out to be useful to you!

1. Personal experience as a dentist, 2. “Orthopedic dentistry. Textbook "(Trezubov V.N.), 3. National Library of Medicine (USA), 4. "Zirconium crowns" (Gevorgyan Kh.M., Zhidkih E.D.), 5. "Metal-ceramic prostheses" (Zhulev E. N.).

Implant-supported crowns

The cost of crowns on implants depends on the choice of options for crowns and abutments. As a rule, the choice here is quite simple - it is metal-ceramic with a metal abutment made of titanium, or a zirconium crown with an abutment also made of zirconium dioxide. Moreover, their cost will differ significantly from similar types of crowns, which are fixed on turned teeth (this is due to their more complex manufacture).

- Ceramic-metal for an implant - from 15,000 rubles.

- Zirconia crown - about 25,000 rubles.(the cost is indicated together with the cost of the ceramic abutment).

Prosthetics of the 5-6-7 tooth on implants - photos before and after

→ The cost of installing different implants → Calculation of the cost of prosthetics on implants

How to make a fireplace

The main thing in the fireplace is not its design performance, although, of course, there is no place without it, but its reliability and durability. It will not work to build a fireplace without preliminary design, consultations with specialists and the choice of high-quality material.

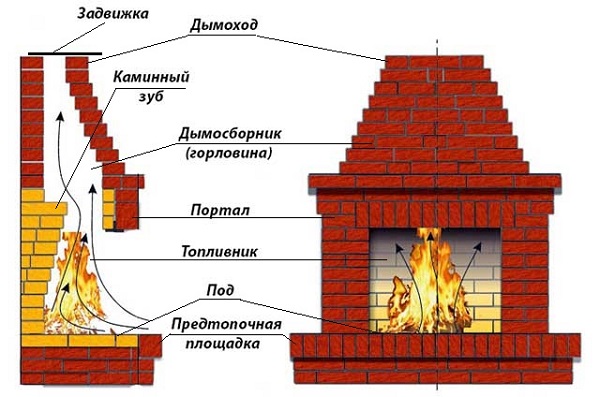

a. Cross section of a fireplace.

v. Fireplace facade.

With. The interior of the fireplace.

1 - pipe; 2 - smoke box; 3 - firebox (firebox); 4 - floor; 5 - inclined wall, "tooth"; 6 - side walls of the furnace; 7 - mantelpiece (table); 8 - firewood basket.

When wondering how to make a fireplace correctly, first of all, you need to decide on its type. It can be classic or created on the basis of a finished factory firebox made of cast iron and other materials.

In addition, the fireplace can be located against the wall, in the middle of the room or in the corner. The way the bricks are laid depends on the type of fireplace and its location. Note that it is best to build this hearth according to ready-made arrangements and drawings developed by professionals. You can, of course, and order a fireplace project from specialists.

When planning to build a fireplace, pay special attention to its location. This hearth, unlike the stove, is of an open type, and therefore it is not recommended to put it in places where drafts are possible.

It is desirable to build a fireplace at a distance from all doors and windows.

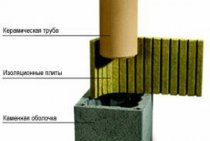

Also, do not forget that wall and corner fireplaces should not be placed close to the walls of the room. Firstly, they should be thermally insulated with special materials, especially if the walls are wooden, and secondly, you need to build a fireplace at a small distance so that there is an air gap between the walls of the building and the hearth.

The construction of the fireplace begins with the base - it can be brick or metal. Its task is to protect the floor from a possible fire. The base must be larger than the fireplace. Some experts advise making protrusions of 30-50 centimeters in front and on the sides, others - at least five.

And about materials. For a fireplace that will be used for its intended purpose, and not just for decorative purposes, you need to use extremely durable and fire-resistant bricks, such as fireclay. You can also lay out the facade of the fireplace with standard ceramic bricks. It is strictly forbidden to use silicate brick.

The firebox is one of the most important parts of a fireplace. It can be laid out of fireclay bricks (classic) or use ready-made cast iron. In both cases, it is necessary to provide a hole for it. Its depth directly depends on the area and volume of the room, and can be from 20 to 60 centimeters.

The height and width of the firebox are also determined depending on the size of the room. So, for example, for a room with an area of 20 square meters and 60 cubic meters in volume, a firebox with a height of 50-55 centimeters and a width of 60-65 cm is suitable. In this case, the depth of the hearth will be about 34 centimeters. For rooms with a larger area, these values will naturally be higher.

We note right away that an incorrect ratio of the sizes of different sections of the fireplace can lead to smoke (if they are smaller than necessary) or poor heat transfer (if they are larger). In any case, when designing a fireplace, we advise you to consult with specialists who will help you make accurate calculations.

And one more nuance that should be taken into account when building a firebox - special smoke collectors should come from it, which are equipped with special valves in the upper part. The chimney should also pass right there, the cross section of which is calculated from the ratio of 1 to 10 to the cross section of the furnace.

Concluding the conversation about the features of the construction of the fireplace, we want to draw your attention to the fact that for the reliable operation of the hearth, it is necessary not only to comply with all the technology, but also to let the fireplace dry well. Experts recommend making test kindling with paper immediately after construction work is completed, and then leaving the fireplace for several weeks (preferably a month). After that, you should somewhat limit the temperature: that is, start a fire of low intensity and gradually increase it day by day.

Features of the construction of small country fireplaces

When choosing the optimal size of the structure, it is necessary to take into account the area of \u200b\u200bthe room, the wishes of the owner himself and, of course, be guided by the general requirements of fire safety. There is an established standard to ensure proper use and maximum efficiency.

Let us dwell in more detail on each of the elements of the device and their technical characteristics.

Firebox

The standard size of the opening in the firebox of a brick mini-fireplace is 50x40 cm. Of course, you can choose the parameters as you wish, but still you should not go beyond the indicated limits.

fireman

The depth of the firebox must reach 30 cm or more, which is necessary for the safe operation of the chamber. In this case, some experienced craftsmen use a little trick: they make a protrusion of the upper beam jumper in the firebox by about 5-6 cm in relation to the vertical axis. In this case, the depth of the combustion chamber will be less than 30 cm.

Walls and heat transfer

In a small fireplace, there are two calorific channels located on the side walls. They provide increased heat transfer. When wood is burned in the fireplace, cold air from the room enters the 2-3 level channels, heats up there and returns to the room through the holes in the 13-14th row.

Expert answers

apparently the cross section of the gas flue does not correspond to the cross section of the new furnace ... the fireplace tooth is incorrectly executed. . requires careful examination. . as a temporary measure or permanently install a deflector…. the door in this case will not help .. and put it again correctly ... you need to be able to

Albert Anisimov:

The section of the chimney is very important for the draft of the fireplace. You didn't change it

Of course, it is very bad that in the recommendations of experts there are no possible reasons for the poor performance of the fireplace that they recommend to create. The size of the firebox depends on the size of the area of the room in which it is planned to be placed. In your situation, a reasonable way out is a glass door, it is only tedious to leave a small gap under the door to suck in air. It will be very good if this gap can be adjusted. The fireplace is serious business.

Alexandra Poleshchuk:

It was necessary to make at least one knee .... be sure to put a spark arrester on the pipe, with such a pipe sparks fly out and can get on the roof ....

Andrey Gorbatenko:

Take everything apart to start with. And then lay down the fireplace. But in fact, as Igor Ya. wrote, the entire system of chimneys-heat pipes will have to be drowned out. To be honest, a fireplace is a waste of fuel with show-offs, if it is not intended for heating, imitation is enough, and if it is intended, then get ready to freeze

Andrew:

Dynamite! around the head))

Igor Yarukhin:

in the stove there is a cranked chimney for heat transfer, and in the fireplace it is necessary to be as straight as possible - for draft, from here and dance

Alira:

Ravshan take a brick .... put on the stove... yellow tulip...

Yuri Klyuchnikov:

if the stove has 2 chimneys - summer and winter, there is such a thing, you can’t see it, then you can do it, but don’t listen to what the firewood says to the wind, you can adjust the draft with a damper, but comfort, aesthetics will appear in the house, and it’s better to warm up by the fireplace than by the stove.

20090114:

The photo, I suppose, should be viewed with the head bent to the left by 90 degrees! ? At a fireplace removal of flue gases from a fire chamber differs from chimney.The almost direct exit of flue gases into the chimney at the fireplace has some features, in particular the tooth of the fireplace. Therefore, before a cardinal destruction, I recommend talking with a stove-maker, on whose side there are at least five stars for successfully operating fireplaces. And I recommend thinking about the fact that a fireplace is a rather voracious source of heat and maintenance that requires no less serious than a stove.

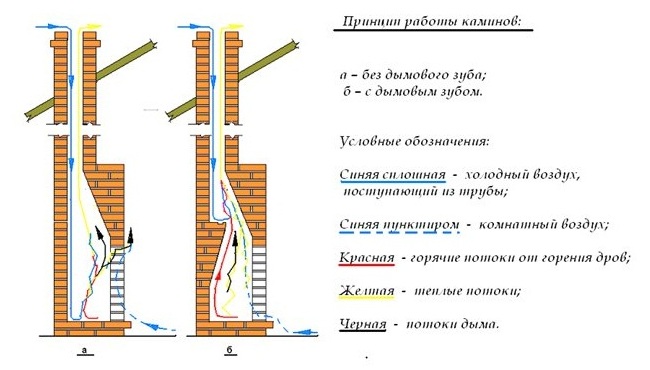

The main purpose of the tooth

The opinion found in native literature and common among some experts that the tooth serves to trap gases descending along the rear wall of the smoke box, without letting them into the furnace space, is not very significant. Cold gases descend not only along the back, but also along the side and along the front wall, where there are no ledges at all. Moreover, the area of the front and side walls is larger than that of the rear wall. Another statement that the purpose of the tooth lies in the collection of soot deposits that have fallen out can most likely finally convince the novice stove-maker of the uselessness of such a tooth, but nevertheless, the diagrams built by Professor Rozin are a convincing argument in favor of the actual purpose of the tooth in the fireplace.

A ledge is needed, it fully contributes to the normal productive functioning of the fireplace. Even in domed fireplaces, open on all sides, a part is installed inside the dome that performs the functions of a tooth - an overturned cone made of sheet iron, located at its base 15-18 cm above the domed edge.

The main dimensions of the fireplace, during the construction of the furnace fireplace tooth, which determine the mode of its operation, include: the dimensions of the portal, the location of the smoke eaves (ledge) along the height of the firebox, the dimensions of the opening in the upper section of the firebox, the smoke box chamber and the dimensions of the diameter of the chimney pipe. All these dimensions are tightly connected with each other, and a change in at least one of them must, without fail, entail a change in others.

The resulting gap between the dome and the cone, 12-14 centimeters wide, can provide the same as the construction of a fireplace tooth in a standard fireplace - an increase in the speed of air movement at the entrance to the smoke box.

When developing each fireplace, it is imperative to provide for a narrowing of the firebox in the upper part, after which there should be a sharp expansion with a subsequent transition to the smoke chamber.

There are no unnecessary trifles in the project of a brick wood-burning fireplace. Each element performs its function. For hundreds of years, the skill of building fireplaces has been gradually honed, and the device has been modernized in order to increase efficiency. There were closed hearths, sloping walls of the furnace, shielding heat, a ledge in the upper part of the furnace, which is called a smoke tooth.

Tooth in a closed fireplace insert

If there were no tooth on the wall, and the combustion would not be too strong, then the gas obtained in the combustion process, when in contact with the walls of the smoke box, cooled sharply and increased its density. By increasing the density, the gas would begin to descend back to the source, creating turbulization of gas flows along the way. That is, if the fire in such a fireplace is not intense enough, 2 physical phenomena can occur:

- Hanging smoke in the furnace.

- Overturning thrust into the room.

The device of the tooth inside the fireplace creates a place for squeezing the gas masses in the upper part of the furnace. A smaller area of the pipe increases the speed of the flow, while discharging the gas and eliminating its ejection back into the room.

A smoke tooth in a closed-type furnace is also called a flame diffuser or deflector. Its main task is to prevent direct fire from entering the chimney, to scatter flames onto the surface of the smoke box for its rapid and uniform heating.

To increase the heat transfer efficiency of fireplace inserts, manufacturers extend the smoke path in the upper part of the furnace by arranging additional smoke circulations. In particular, the Czech company Romotop, in order to obtain a greater trajectory for the removal of combustion products, has developed the Double Spin system for stoves and fireplace inserts. This made it possible to achieve maximum heat transfer from flue gases, better and more environmentally friendly combustion of wood fuel.

Crowns made of metal-free ceramics

Unlike metal-ceramic ones, these crowns are already made entirely of ceramic mass and do not have a metal frame inside. The absence of metal can significantly improve the aesthetics of artificial crowns. The fact is that only an opaque ceramic mass can be used to mask the metal, which does not allow the metal-ceramic crown to become translucent to the enamel of a real tooth.

For the manufacture of ceramic crowns in dental clinics, 2 types of ceramics are most often used - zirconium dioxide and E.max glass ceramics. These materials have certain transparency coefficients, i.e. similar in optical properties to tooth enamel (this property makes it possible to make crowns from these materials as similar as possible to real teeth).

Purpose

Many people try to answer the question of what a tooth is for in a fireplace, but not everyone can confidently say that they know the answer. From the hottest part of the furnace, the smoke enters the smoke box, where it begins to cool due to contact with colder walls. According to all the laws of physics, it should go down. The result is a picture in which ascending flows are placed in the center of the furnace, and the cooled smoke along the walls goes down, forming a swirl.

Theoretically, you can get rid of the accumulation of smoke by increasing the speed of the combustion products in the specified area. Then circulation will take place, and cold air will come from below to replace the heated gas that has left the furnace.

This idea is implemented by narrowing the upper part of the firebox in the form of a ledge. With a decrease in the cross-sectional area of the channel, the speed increases, and a higher speed leads to a decrease in pressure. This theory of the flow of liquids and gases, described by Bernoulli, allows you to create a lifting force acting on the wing of an aircraft.

The vacuum formed by reducing the pressure leads to the fact that a stream of air rushes from below, supporting and displacing the smoke into the chimney channel. Thus, the smoke tooth of the fireplace prevents the draft from tipping over, which has been proven theoretically and in practice. Now everyone will know for sure why the protrusion in the firebox is considered an important element.

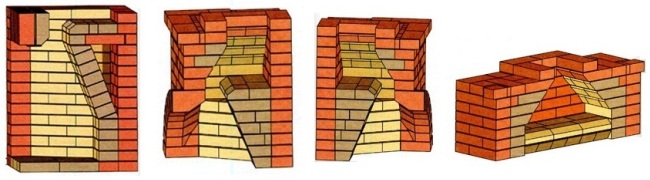

Self-construction of a mini-fireplace for a summer residence

The construction of this heating device for a country house is notable for its simplicity. The only difficult process is the overlap of the firebox. When laying a fireplace tooth, some irregularities are allowed, since it is lined with a sheet of metal, respectively, all inaccuracies will be hidden.

One of the most suitable materials for building a fireplace is high-quality red brick. Work begins with the laying of ten rows of the back wall. In the next two levels, it is necessary to make an overlap of 1/4 brick in size. When laying the side walls, it is necessary to provide for a turn at an angle of 25 degrees, while leaving vertical channels. In the third row, you need to make holes that provide passage for cold air.This contributes to the additional heating of the room.

On the back wall of the firebox in the 11-12th row, protrusions are provided for the formation of a smoke tooth. Four metal pins are also mounted here, which will hold the inclined stainless steel screen. The back wall can be made of treated brick.

The dimensions of the fireplace at the base, excluding the pipe, are 1020x510 mm, height - 1120 mm. The cleaning door is installed on the rear wall, which allows you to clean the chimney tooth from ash and soot.

The design of this mini-fireplace for giving is slightly different from the original, which was offered in the original source. In our case, the arch that covers the fuel chamber is made of 9 bricks, not 7, as originally indicated. In the presented project, the gaps between the bricks of the arch are reduced. The central brick has non-standard dimensions and is rather narrow.

Heat-intensive fireplaces

Heating and heat storage fireplaces, i.e. the so-called fireplace stoves, are stove designs that combine the advantages of both fireplaces and stoves. When the fire is lit, the chimney damper is in the upper position, the passage to the chimney is open, and the stove works like a fireplace. At the same time, the fireplace insert door is also kept open. When they want to use the stove for heating, when the firewood is actively burning, the fireplace dampers and the upper connecting damper are closed, and the flue gases are discharged through the side channels down and from there into the chimney - the design works like a stove.

Design

Until now, in some sources, a fireplace diagram may slip in which the described protrusion is completely absent. This is due to the fact that some even experienced craftsmen do not quite understand why it is needed.

Explanations suggesting that with the help of a chimney tooth an obstacle is provided for the fall of smoke, they can hardly convince a sane person, because the speed is not so great and there is a lot of free space through which the smoke is destined to enter the room. Therefore, this design feature was often ignored.

When laying a fireplace, in no case should you deviate from the parameters shown in the diagram, because in order to correctly make a tooth, providing a slope of 20 ° degrees, it is necessary to maintain the length and width of the protrusion in size. Approximately at a height equal to 1/3 of the vertical size of the firebox, the first steps in tooth formation are taken. To properly complete this stage, you must constantly check the order. There are several types of teeth:

- Each subsequent row of the protrusion hangs over the previous one, forming a slope of the rear wall in the form of a stepped surface. Not forgetting that our task is to remove smoke without hindrance, they try to get away from such a tooth model.

- The protrusions in the form of sills are removed, after cutting off the corners of the brick. The result is a flat plane, but you need to manage to process all the bricks at one strictly defined angle. The disadvantage is the fact that the brick faces the fire with a cut, which is not recommended.

- The brick itself rotates to the desired angle. This picture resembles the formation of an arch in the fireplace portal. The disadvantage of this method is that such a design is weakened.

- Another option is represented by the processing of three faces of a brick standing on an edge. A whole, untouched face forms a slope and is directed towards the flame.

It is impossible to single out the dominance of one of the methods. It can be seen that each of them has its own advantages and disadvantages. The choice of method for forming a smoke tooth depends on the skill of the stove-maker.

Often in disputes you can hear such a statement that a fireplace without a tooth works normally, but no one claims otherwise. It is possible that other external conditions have such a favorable effect on traction that the buoyancy force independently copes with the removal of combustion products or the height of the portal is excessively high. This allows the smoke at the top to acquire enough kinetic energy to leave the smoke box.

But one cannot hope for such accidents and gifts from nature. Therefore, to ensure reliable traction in all weather conditions, experienced craftsmen must perform a ledge.In some cases, professional repairmen, seeing the presence of a tooth, state that the fireplace was built by a competent and experienced master.

Metal crowns

Modern metal crowns in dentistry are made by one-piece casting and are called "solid". There are also stamped and gold crowns, which at this stage in the development of dentistry may be of interest only from a historical point of view.

Stamped crowns - stamping - an outdated method of manufacturing metal crowns, which, however, can still be found in remote corners of Russia and the CIS. Such crowns are stamped from special blanks (steel sleeves of different sizes). It is possible to make a “gold-like” coating at the crown. The only advantages of such crowns were minimal tooth processing and low cost. Disadvantages of stamped crowns - → complete lack of aesthetics, → thin wall of crowns often leads to “eating through” of the crown, → low work accuracy - the crown does not fit well around the neck of the tooth, which causes leakage under the crown of saliva, microorganisms, food residues. This leads to decay of the tooth under the crown.

Golden crowns (Fig. 13) - today, golden crowns are made mainly only in state dental clinics, because. working with precious metals requires a license, and it is very difficult to obtain one. In addition, their cost will be comparable to the cost of metal-free ceramic crowns, which deprives them of any economic sense. Gold crowns: the price of gold dental crowns will be the cost of gold (about 65 Euro per gram) + the cost of work. It must be borne in mind that it is impossible to immediately say a specific price per tooth. The required mass of gold will depend on the size of the tooth, and the larger it is, the more gold is needed for it (from 2 to 5 g), and the more expensive it will be.