Advantages and disadvantages of cassette fireplaces

Cassette fireplaces for the home have many advantages, namely:

- the closed type of a fire chamber retains heat much better. A smaller amount of warm air goes into the chimney, thereby the rooms are well heated;

- cassette fireplaces differ from other types of stoves in their compact size and light weight;

- most stoves need constant monitoring during combustion, but the cassette type of construction is the safest and allows you to leave a burning fire unattended without fear, only an electric fireplace is safer to operate;

- the firebox can be placed in any "cassette", which allows you to apply the most interesting design solutions for finishing the fireplace;

- thanks to a special control system, you can choose the required intensity of the flame;

- cassette fireplaces are allowed to be installed in apartment buildings.

There are several disadvantages to using a fireplace as a heating device:

- the fireplace heats the room only during its operation. As soon as the logs burn through, the fireplace stops supplying warm air;

- to maintain a comfortable temperature in the room for a long time, the fireplace needs to be stoked every 5 hours.

A cassette fireplace has more pros than cons. It is one of the most successful models for stove home heating.

Installation of a cassette fireplace

Installation of a cassette fireplace can take place both in a country house and in an apartment. Before installation, it is necessary to prepare the area where the future furnace will be located:

- The cassette fireplace cannot be installed on wooden surfaces, and such common coatings as laminate and parquet will not work as a base. They should be removed in the area where the future fireplace will be located. It is best to use a concrete slab as a base. To level the floor surface, a waterproof membrane is used and a screed is poured. The minimum layer thickness is 15 mm.

- On the wall adjacent to the fireplace, the trim should be completely dismantled. After that, it is necessary to install a layer of thermal insulation over the entire surface of the wall. It is best to use mineral wool for these purposes, as it does not burn. Thermal insulation is fixed with a metal profile, which is screwed with screws.

- The air duct that will be connected to the chimney of the fireplace must first be cleared of congestion.

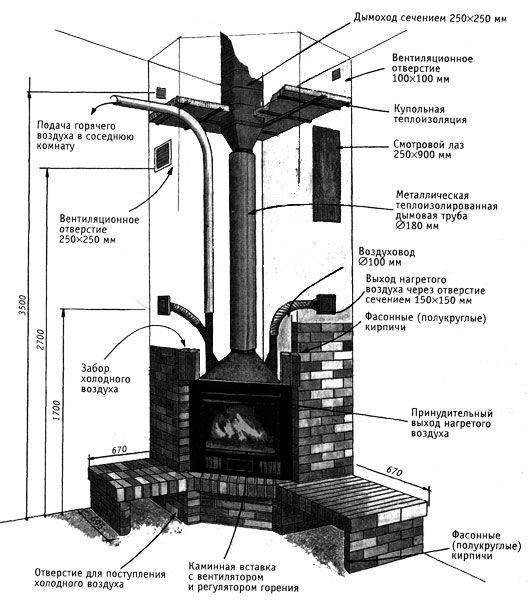

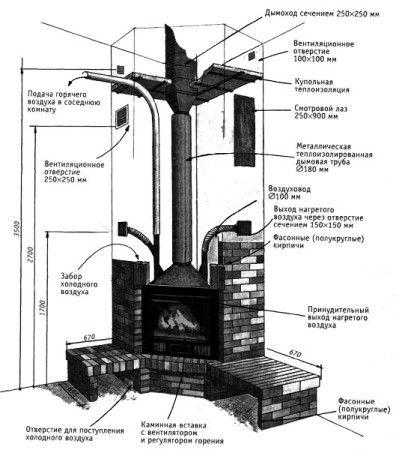

After all dismantling work has been carried out, you can proceed directly to the installation of a cassette fireplace. The installation must be carried out in stages. First of all, a pedestal is installed for the future fireplace. After the firebox is mounted. Next comes the installation of the "cassette". And the last step is the installation of the chimney.

Installation of a pedestal for a cassette fireplace

At the beginning of work, a pedestal is installed. Any durable material will work for it. If you make a cassette fireplace with your own hands, then brickwork or concrete blocks are used as a material. The height of the pedestal should be approximately three rows of bricks.

When installing the pedestal, you need to make the camera in the center of the building

When installing the pedestal, you need to make the camera in the center of the building

The size of the chamber should reach the wall. In the place where the chamber is in contact with the wall, a hole is made through which cold air will be taken from the room. Further movement of air currents will occur between the fireplace and the wall.

Installation of a cassette fireplace insert

It is necessary to install the firebox of a cassette fireplace strictly according to the instructions that are indicated in the selected model. The gaps between the wall and the fireplace, as well as between the firebox and the “cassette”, are specified in the instruction manual.

Before you install the combustion chamber on the fireplace, you need to put a sheet of metal and some wooden blocks. With their help, the design of the firebox is aligned. After installation, the bars are carefully removed.

Installing the "cassette"

It is necessary to carry out the installation of the fireplace body in such a way that gaps are formed between the firebox and the walls of the fireplace for proper air circulation. The size of the gaps varies depending on the furnace model used.

Close to the wall, but at the required distance from the combustion chamber, brick walls are laid out. Other refractory material can be taken for the construction of walls. A cornice is installed on top of the walls. It must be located above the glass-ceramic door.

If a wooden cornice is used in the work, it is necessary to lay a layer of thermal insulation before installation, since wood is a combustible material.

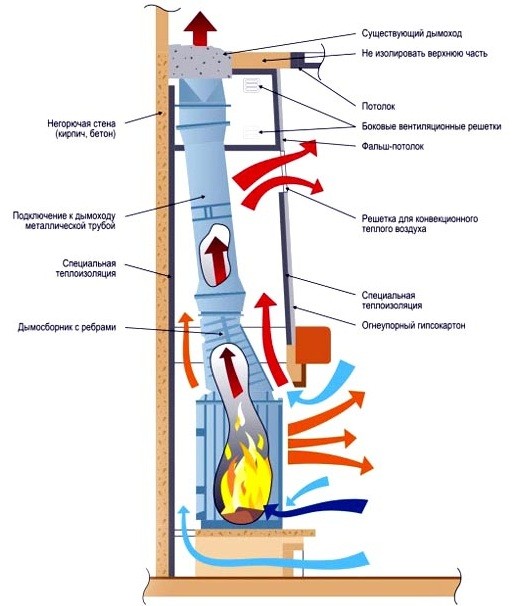

Installing the chimney of a cassette fireplace

The installation of a chimney depends on whether a ready-made duct will be used or a new one will be installed. If the chimney is already in the room, there are several installation methods:

A metal pipe for ventilation is installed in an existing chimney. This method is suitable if the duct is a wide structure. For example, a rectangular brick chimney from an old dismantled stove.

A steel pipe is connected to an existing chimney. This method should be chosen if the ventilation hole is rather narrow

It is necessary to pay increased attention to the tightness of the pipe joints, since at the slightest gap the draft can be broken.

The chimney can be made independently. For this, a metal pipe is used. It is installed on the smoke hole of the fireplace and is led out through the ceiling to the roof. It should be noted that according to fire regulations, the pipe must necessarily be with additional thermal insulation.

The cassette fireplace is easy to install indoors. This is an excellent option not only for an interesting piece of furniture, but also for a heater with a high level of efficiency.

https://youtube.com/watch?v=MBP60RvaGHw

What is a cassette fireplace

Cassette fireplace is a prefabricated structure of several elements. It most often uses a closed type firebox. It is usually made of cast iron or steel.

The open part of the furnace hole is hidden behind a layer of glass-ceramic. The material can withstand heat up to 800 degrees. The door can be either horizontal or vertical. Models with a vertical glass door are much more expensive, as they are an element of an open type combustion chamber. Most often, classic rectangular doors are installed. But the form can be absolutely any. There are models with an angular type of door. Some cassette fireplaces are equipped with a glass-ceramic door in the form of a prism or a semicircle.

Various devices can be used as a "cassette". You can make the base yourself or use an old oven.

"Cassette" can be made of any finishing material. Brick, drywall, natural or artificial stone is used.

The cassette fireplace chimney is a shortened version of the classic stove duct. This is done in order to conserve energy and save heat. The air duct is built only from refractory materials.

We make a decision

Before making your choice and deciding in favor of such fireplaces, you will need to study not only the device of a cassette fireplace, but also its distinctive features, which include not only advantages, but also disadvantages:

- Manufacturers offer ready-made lines, the models presented in which differ not only in their size and placement, but also in style (from baroque to minimalism);

- Such furnaces cool down quickly enough and are not able to continue heating when not in use. In order to keep the heat after the end of the furnace as long as possible, it is recommended to make a portal from a material such as brick;

- Some types of cassettes can be connected to special pumps and tanks that provide heating of water and its distribution through the general heating system of the house. Such fireplaces are also classified as having a water circuit;

- Also, the adjustable mechanism can be not only water, but also air. In this case, the heating of the structure must be carried out after a short period of time, for example, every 4-6 hours;

- Due to the need for a chimney, such heating units can be placed exclusively in private houses or on the last floors of multi-apartment high-rise buildings;

- The smoke channel in such models is always equipped with a glass damper. Due to this, the efficiency and speed of heating by such methods is significantly increased.

Can be used to decorate frames

The closed combustion chamber has a higher heat capacity…

Model equipped with support legs without portal

Built-in cassette hearth

The video in this article will help you learn more about the advantages and disadvantages of such combustion chambers.

Features of closed cassette foci

Cassette fireplaces, the installation of which does not require significant time costs and serious physical effort, has the following distinctive features:

|

Design features |

Descriptions and explanations |

|

Efficiency |

Installing a cassette fireplace with a closed hearth is the most efficient and powerful. Such devices have a high efficiency and can serve as both the main and additional source of heating at home. Open models are not distinguished by high efficiency and sufficient heat capacity. In this case, all the heating does not go into the walls of the structure, but into the air, and thus does not allow high-quality heating. Such fireplaces perform a decorative role. |

|

Compact chimney |

The device of cassette fireplaces includes a chimney. This element has a small cross section and a shortened size. This makes the use and placement of such a heating unit as convenient as possible. Due to the shortened chimney, the products of combustion and decay are quickly brought out into the street and do not linger in the inner part of the hearth. |

|

Availability of cassettes |

The fireplace cassette is the main distinguishing feature of this design. This element is responsible for the uniformity and speed of heating and allows you to perform the fastest possible heating of the premises. For uniform distribution of air masses, special fans can be used that distribute hot air masses. Some models with fireplace cassettes are equipped with built-in air ducts that supply air arbitrarily. If necessary, such air ducts can be blocked in the upper part with valves. |

|

Affordable cost |

The price of such models is affordable compared to electric and wood-burning installations. The cost is due to the simple principle of operation and the minimum set of functions. The most budget option would be a cassette fireplace device which is represented by a steel case and a simple door equipped with a horizontal mechanism. |

In order to get acquainted with such heating installations in more detail and find out what a cassette-type fireplace is, we also recommend viewing the photos collected in this article.

Formation of cost and choice of interior solution

A cassette-type fireplace can also have doors with a vertical folding mechanism. Such ovens have a higher cost due to their unique design, various shapes and finishes.

The best choice would be a heating unit with doors equipped with refractory glass. It can be either completely smooth and transparent, or matte, refrained and colored, as well as lined with mosaics. Many manufacturers equip their products with useful and important features. For example, due to the constant circulation of air inside the structure, the glass can be cleaned independently and is less prone to the occurrence of various contaminants.

For fire safety purposes, all structural elements

For storing firewood and briquettes, a small firewood rack is often used, provided for by the design of the portal

Floor surface within

Advantages and disadvantages

Any model of a fireplace in different conditions shows its advantages and disadvantages.

The undoubted advantage will be the versatility of the design, which perfectly complements any interior. A rich assortment of models allows you to decorate the interior in your favorite style - from classic to baroque.

Another option is to use the cassette as a boiler. It is necessary to bring a tank to it, which plays the role of a heat accumulator for batteries. This system is only applicable to certain types of cassettes. An alternative option is air distribution through the rooms, however, in this case, it is necessary to heat the cassette after 5 hours.

If desired, the cassette can be lined with any materials ─ from wood to artificial stone. According to the norms of SNIP, a cassette fireplace can be installed even for residents of apartments on the last floors of high-rise buildings.

A short chimney can be considered an advantage, since combustion products are not emitted so intensively. The chimney must be installed in any case, in accordance with the safety regulations.

Varieties of cassette models

The cassette for the fireplace may have a certain variety. The choice of a suitable model is made based on such parameters as power, size and footage of heating:

- Cassettes for fireplace stoves can be installed in an open hearth. Such models are characterized by low efficiency and are designed for heating rooms with a small area;

- Heat cassettes for fireplaces are often installed in a closed-type combustion chamber. Such stoves are more efficient, and the cassettes themselves have a higher power and are intended for heating houses with a sufficiently large footage.

The most expensive are multifunctional models ...

Classic fireplace set…

Corner cassette hearths take up little space ...

Principle of operation

Combustion of fuel takes place in a closed space surrounded by walls made of steel or cast iron. From the front side, the fireplace cassette is supplied with heat-resistant glass. It performs a protective role, preventing embers from falling out, provides access to the firebox and does not let heat through. The latter property is not a drawback, since the entire amount of heat is given to air heating, because the cassette fireplace heats the room with the help of convection currents.

The cassette is equipped with channels necessary for the supply of air, which provides an influx of oxygen, and air, which plays the role of a heat carrier. In addition to natural circulation, injection is provided by special turbines built into the cassette.

The body consists of a double layer separated by a channel for air circulation. During the operation of the fireplace, the inner wall heats up and gives off its heat to the air. Passing through the entire channel, the air enters the air ducts. They provide heating for different rooms and are subject to adjustment.

The glass door opens horizontally or vertically. The vertically open door turns the cassette fireplace into an open hearth.

Features of work

The name of the cassette fireplace is associated with its design features, it has a special cassette - a steel firebox, which is covered with glass. The closed type firebox makes it possible to use the fireplace even in a room with the presence of people, as it is considered fireproof. High functionality and a short chimney can also be noted as advantages.

Regardless of the type of fuel chosen, very little smoke will be emitted. A cassette-type fireplace is an option that can be considered for equipping a home with warmth. Cassettes contribute to the distribution of warm air masses through the air ducts and heat the home. By equipping the structure with special valves, air distribution can be stopped at any time.

Cassette fireplaces with air ducts for a country house can have a vertical or horizontal door. This affects the price and, of course, the external design. The cheapest option is a modification with a horizontal door. The vertical door makes the price of the structure higher, but its main advantage is to turn the fireplace into equipment with an open combustion chamber.

The door is made, according to the standard, of heat-resistant glass. The more glass used to produce the door, the higher the cost per element. Its shape may differ and be angular, bilateral, in the form of a prism, semicircle, rectangle. Due to the special cleaning mechanism, the door is constantly clean.

The cassette model perfectly heats the room. The efficiency is quite high and reaches 90% (when compared with a fireplace with an open combustion chamber, whose heat transfer is a maximum of 25%). Heating occurs with the help of air masses warming up inside the fireplace. Heated air is distributed throughout the room, using air ducts. It is possible to control air masses by blocking the air ducts.

If desired, you can organize a long burning mode. It makes it possible to make a bookmark of logs and leave them for burning at night. Because of this, the fireplace is considered suitable for heating housing outside the city.

The fireplace cassette is a variant of the combustion chamber for the fireplace. Its design includes a convection hood, so it can work without ventilation grilles.

Fireplace insert EdilKamin Ecostar N

Warm air is circulated by convection through the upper layers of the combustion chamber, so heat enters the room. Cassettes can be equipped with from one to six turbines. This plays a role in the intensity of circulation of warm air. A thermostat is placed in the fireplace cassette. He analyzes the heating in the combustion chamber.

Cassettes can be different according to the material of manufacture of the combustion chamber. The cheapest of them are made of steel, those that are more expensive are made of steel with fireclay lining. An acceptable price solution is cast iron cassettes.

The operation of a cassette-type fireplace also varies. There are options for temporary action, and there are options for continuous burning. All combustion chambers have an adjustable air supply system. As a result, the draft becomes better, and the temperature of the non-functioning cassette does not decrease.

How to properly clean a fireplace?

Mounting Features

Compared to brick, the cassette type is lighter and does not require additional reinforcement. It can be mounted even on the floor of a high-rise building

If there is any doubt about the strength of the house, you need to pay attention to the mass of the fireplace indicated in the documentation

Chimney

A fireplace with a cassette has its own installation subtleties, which must also be taken into account when choosing a device. Chimneys of such devices are always under vigilant control. Limiting temperature with the threat of overheating is the main reason for close attention.

When operating a cassette fireplace, you can use a pipe with a smaller cross section than usual. It is also allowed to use more bends when installing the chimney, since in a cassette fireplace, even with prolonged and intense burning, soot does not settle.

Installation rules:

- A cassette fireplace is safer than a traditional one, but only if all the rules for its installation are observed.

- The plane for fixing must be absolutely flat. With wooden floors, the layer of wood must be removed and a concrete base installed, lifting it to the level of the floor.

- The area around the fireplace must also be laid out with heat-resistant tiles. The walls next to the heater should be freed from finishing and treated with protective materials.

- When choosing a place for the stove in the house, you should protect it from contact with electrical wiring.

- If the house has an existing chimney of a suitable section, it must be cleaned and used to install pipes in the finished channel, saving on costs.

- Cuffs and couplings will fix the pipes rigidly and firmly.

- The new chimney must have an exit to the street, fixed from the outside.

- For proper installation, it is necessary to make gaps between the firebox, floor and walls. You can specify the distances in the data sheet of the device.

- The hood is lined with stone, brick, drywall. From the inside, reflective thermal insulation is attached to the walls and finishing material.

- Basalt or aluminum foil is used to reflect heat and protect equipment from overheating. To cut plaster of suitable size, use a regular hacksaw. Plasterboard structures are fixed with heat-resistant glue. For the fasteners of the box for mounting exhaust grilles, holes are made in the plasterboard.

Before the first firebox of the fireplace, it is necessary to allow the structure to dry completely. This usually takes up to two weeks.

Final finishing

The joints of gypsum joints are treated with a lime-type putty. The surface can be coated with acrylic paint. In order for wooden parts to serve for a long time, they are impregnated with wax. This prevents drying with cracking when the oven is in operation. For a rich color and gloss of a brick, it is coated with a solution of white spirit.

It is quite possible to assemble a fireplace in this way with your own hands. If there is no leakage, the cassette is inserted correctly. The fire can be set to the minimum level in the form of a smoldering flame or make a powerful flame that provides heat for a long time. Modern fireplaces with a cassette have a high efficiency - up to 85%.

On the video - a cassette fireplace combined with a cooking stove.

Installation rules

The cassette type model is absolutely safe, but during its installation it is necessary to follow some rules. The plane for fasteners must be flat, without flaws and distortions. Do not install the fireplace on a wooden floor. If the flooring of the house is made of wood, then it must be removed to the concrete, and the concrete itself must be raised to the floor level.

It is advisable to lay out the fireplace area with heat-resistant tiles. Adjacent walls should also be freed from finishing and overlaid with heat-resistant material.

Pay attention to the wiring. She shouldn't walk next to the fireplace.

Completely clean the existing chimney before installation. Pipes for better reliability are fixed with couplings and cuffs.

Chimney installation options

The new pipe should go outside and be fixed on the outer surface. If the installation is done correctly, then there will be gaps between the walls, the firebox and the floor covering. A frame is mounted on the side parts of the product, which serves as protection against overheating. After installation, the structure should be stable for two weeks.

A cassette fireplace is a model that can be used not only for decoration, but also for heating the whole house. The design can be of different types, with different variations of the cassette and door.In order for it to serve for a long period, follow the installation rules. As a rule, the model is low-budget, so everyone can easily afford it.

We carry out installation

At the first stage, it is necessary to take care of the chimney. The hearth is mounted on almost any ceiling, and additional reinforcement is not required. If the mass of the fireplace plays an important role, you can find it out from the attached documentation.

Assembly and installation instructions:

- The casing and the main part of the fireplace should have a small gap. To separate the outer box from the pipe itself, the surface must be insulated with refractory materials (mineral or basalt wool is used);

- The diameter of such a chimney has a smaller pipe section than in standard classic furnace units. The number of rotary, horizontal elements and wiring in this case can also be increased;

- To install the hearth in the first stage, you will need to make the flooring even. This is necessary to give the structure stability. If the floor covering is made of wood, it should be partially reinforced with concrete;

- The floor and wall surfaces located near the combustion chamber must also have an appropriate finish with heat-resistant materials. As an additional protection, it is recommended to cover the floor and walls with a special varnish or refractory impregnation;

- With the initial presence of a chimney pipe having a suitable cross-sectional diameter, it can be used to connect it. Before use, a complete cleaning of the inside and a leak test of both the entire structure as a whole and each individual joint and section are carried out;

- Each element is fixed by means of cuffs and couplings;

- For fire safety purposes, heating elements should not come into close contact with walls, portals and other elements;

- The walls are additionally insulated, and the frame is made of drywall or any other heat-resistant materials.

Only refractory materials are used for finishing and assembling structures.

Installing the hearth and portal on a pre-prepared pedestal

Construction finish

Finishing the outer part of the structure can be done as follows:

- Each joint and connection must be treated with putty, which contains lime;

- The easiest to perform and budget option will be the use of a simple acrylic composition. Such paint tolerates exposure to high temperatures and their sudden changes;

- Separate details and decor can be treated with wax, which forms a special protective layer, and the main part of the surfaces is impregnated with white spirit.

Ready-made fireplace set in a classic style

The combination of marble countertops with decorative plaster cladding

Facing the portal with decorative plaster

A cassette fireplace, assembled, lined and installed in accordance with all the rules, will be guaranteed to be effective and safe to use. Due to the absence of leaks, proper insulation and sealing, the efficiency of such installations can be up to 90 percent.

| (Votes: 2, Rating: 2.5) |

07/07/2017956Pechnik (Moscow)

How to start building a cassette fireplace

If the house already has a major chimney, there is no doubt about where to place the fireplace. At the chimney, preparation of all surfaces to which the fireplace will adjoin is carried out.

Even a cassette fireplace requires a project. It is best to plan the location of the heat source at the stage of building a house

And if the construction is in the finished space, you need to pay attention to the safety of the structure, drawing up a general scheme for installing the fireplace.

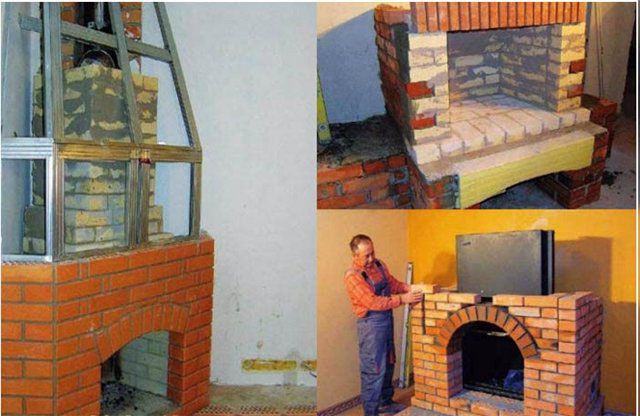

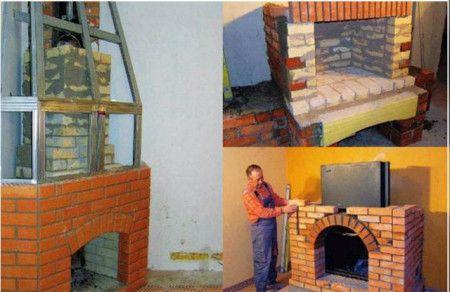

After determining the installation site, you need to make a base for the fireplace.To do this, a layer of insulation (or thermal insulation) is laid directly on the floor.

A reinforced concrete screed is made on it under the pedestal of the fireplace. Screed thickness up to 15 mm. The light weight of the future structure allows you not to break the finished floor in order to strengthen the base of the fireplace.

For the construction of the pedestal, it is convenient to use aerated concrete blocks. Give them the shape and the necessary dimensional parameters with a rasp or a hacksaw. Subsequently, this durable material can be plastered or revetted.

For laying aerated concrete blocks, you will need a mortar or glue. Laying is done in the usual way. But keep in mind that the portal threshold will need to be issued immediately. Let's say natural stone. The stone plinth is glued to the pedestal using heat-resistant glue or fixing the material with dowels and screws. When creating a base for the "stuffing" of the fireplace, we must not forget about the technical holes for the subsequent maintenance of the fireplace. The ventilation and viewing manholes of the fireplace after finishing work are closed with decorative grilles.

After completing the masonry, you need to level the top wall of the pedestal. To do this, it is plastered with cement mortar, 10-15 mm layer. Be sure to use a layer of asbestos cardboard and iron for thermal insulation. It is placed under the cassette slot.

Accurately calculate the place of installation of the fireplace cassette in the finished pedestal: it is necessary to plan a sufficient amount of space for the heating system, calculate it so that the metal hose-chimney can be conveniently connected to the part of this system in the cassette. If the cassette-firebox is mounted in an existing fireplace, the main thing is to tightly connect it to the chimney. The mobile fireplace cassette is installed on a finished pedestal. It is better to first place it on the bars and then remove them one by one, making sure that the cassette fits securely and clearly into the prepared niche.

Cassette fireplace frame and cladding

We proceed to facing the base and the shelf of the hearth. When using aerated concrete blocks, steel corners are needed along the perimeter of the structure, which will be the frame of the structure. They are welded on the outer corner.

- To decorate the mantelpiece, you can use marble, which is laid on heat-resistant glue. Allow the glue to dry properly. To prevent the plates from shifting during drying, they are pulled together with clamps to the fireplace base.

- The duralumin or profile frame will easily hold the plasterboard sheathing, which is fixed with metal screws (19-25 mm).

- In addition to the skin, you will need to attach a protective glass for the cassette to the frame.

- After the glass, heat-insulating mats are also attached to the frame, one side of which should be foil-coated.

- If you want to arrange a place for storing firewood, you need to attach brackets to the frame, on which a shelf for storing fuel will be installed. She also gets off with heat-insulating mats.

- The frame is lined with any decorative material: tiles, tiles, natural or artificial stone. Be sure to use hot glue so that the fireplace serves you for many years.