Styrofoam qualities

These qualities are used for thermal insulation of premises from the inside and outside. Foam plastics are moisture and vapor-tight, so water does not affect the thermal insulation properties.

The use of these materials to insulate a room from the inside poses the challenge for builders to protect against condensation. Warm air, coming into contact with the cold surface of the walls, leads to the formation of dew drops on them. Once under the foam, the liquid cannot evaporate. This leads to the destruction of concrete, brick and wood.

Foamed polymers are flammable, so additional fire safety measures must be taken.

When ignited, the foam releases toxic substances. There are also flame retardant foams on the market that are more difficult to ignite. In terms of ease of ignition, they are comparable to wood and cost half as much.

Foam plastics are easy to cut and saw, easy to use, attached to any surface and strong enough not to break under their own weight. This allows for simple installation procedures. Such qualities distinguish polystyrene from mineral wool and other heaters.

Thermal conductivity, which is 15 times lower than that of concrete, attracts mice that nest in foam insulation in families and colonies. Styrofoam insulation requires regular treatment of the premises in order to prevent the appearance of rodents.

If the mice are already wound up, then it will be difficult and expensive to drive them out.

Styrofoams differ in density and hardness. From soft, easily crumbling, which are used to cushion household appliances during transportation, to hard, which you can safely walk on. The denser and stronger the foam, the higher the price and weight. The thermal insulation properties of the density depend slightly. Doubling the density results in a ten percent improvement.

Good heaters are obtained from expanded polystyrene - their thermal insulation properties are 10-15 percent higher than those of analogues with the same density and thickness.

Ground floor preparation

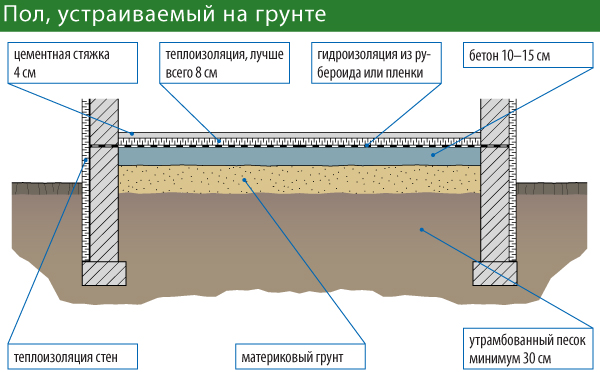

Scheme of the device floor on the ground.

The future warm floor begins with the choice of the base of the floor on the ground. The base on the ground can be several options. The first is coarse river sand, poured with a layer of at least 30 cm, instead of the removed layer of soil. Such a thickness of sand is quite justified, the fact is that it is precisely 30 cm that moisture rises during capillary seepage upwards, therefore a thickness of 300 mm is the minimum possible, it is simply pointless to do less. The only difficulty with such sand is that it is quite difficult to purchase coarse-grained river sand for soil foundation, it is not available everywhere, and besides, exporting the same amount of soil from your site for the future floor is also a dubious pleasure.

Therefore, the second option for preparing the base of the floor on the ground is to leave the same soil as it was. But only if this soil does not consist of black soil or peat, the last two options are categorically not suitable as a base for floor insulation on the ground. A layer of bulk soil having a loose structure with a thickness of less than 200 mm must simply be compacted. And if a thickness of more than 200 mm is provided, then it is necessary to add crushed stone to the soil, about 20-40 mm in size and carefully tamp this base under the floor. To ensure proper looseness, it is necessary to add a little wet sand to the soil.

The third option for preparing the floor base on the ground is expanded clay insulation. Expanded clay can significantly improve the insulating properties of the base, and this will contribute to maximum insulation. After all, the insulating properties of expanded clay are 2.5 times higher than those of wood and 10 times higher than those of brickwork. So, as a heater, expanded clay is a very good choice when building your home. Expanded clay is covered with a layer about 10-15 cm thick, and in the future the whole technology is similar to the previous varieties above.

Floor vapor barrier on the ground

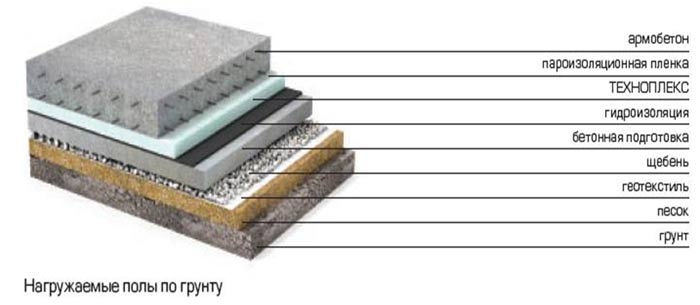

Scheme of loaded floors on the ground.

Normal floor insulation on the ground is impossible without work on hydro and vapor barrier. After all, a warm floor cannot be in cases where its warping allows moisture to pass through. One of the best, based on the combination of price and quality, floor waterproofing on the ground is polymer-bitumen membranes. These membranes are one of the best materials for floor waterproofing, they have good strength, durability and elasticity, resistance to chemical and biological attack, are easy to install and can provide proper home insulation. The best varieties of such membranes for floor insulation on the ground based on fiberglass. PVC-based membranes are more durable, but at the same time their price is higher.

It is also possible to carry out vapor barrier of floors on the ground with the help of a polyethylene film, only it is extremely vulnerable to mechanical damage and it is rather unsuccessful to step on it so that the film begins to let moisture through. For a greater guarantee, the film is often laid in two layers, but still the risk of damage will still be present. After all, it is almost impossible to somehow check the integrity of the laid film.

The use of foam for floor insulation

In the modern market of thermal insulation materials, polyurethane foam heaters, in particular, foam plastic, are very popular. The material meets all the requirements for floor insulation, at the same time it has high sound insulation and much greater strength and environmental friendliness compared to other popular polymer insulation - foam.

Penoplex can be used both to insulate the floor along the logs, and to equip the heat-insulating layer, followed by the application of a leveling screed.

Penoplex can be used both to insulate the floor along the logs, and to equip the heat-insulating layer, followed by the application of a leveling screed. The thermal conductivity coefficient of foam plastic is significantly lower than that of foam plastic, therefore, using this heat-insulating material, it is possible to create a heat-insulating layer of much smaller thickness.

Penoplex is easy to install and process. During the installation of the material, it is possible to minimize the cost of insulation, which will make it possible to significantly save on consumables.

Penoplex is suitable for insulating floors located on the ground or above unheated basements, and for insulating interfloor ceilings, for which the heat-insulating layer acts as a sound insulator.

Penoplex is resistant to temperature extremes, the material can work in permanent conditions, where the stage of freezing of the heat-insulating layer is replaced by the stage of its thawing.

It is possible to mount sheets of material directly on the base with a preliminary waterproofing layer, since with constant contact with moisture, the insulation can significantly lose its thermal insulation properties.

Penoplex is resistant to temperature extremes, the material can work in permanent conditions, where the stage of freezing the heat-insulating layer is replaced by the stage of its thawing.

The material can be used to insulate wooden floors, since penoplex prevents the development of microorganisms, therefore, you can not be afraid of the appearance of mold and fungi in the sub-floor space. The fire resistance of the material also makes it suitable for insulating wooden structures.

The disadvantages of penoplex include the need to follow a certain technology for laying plates and carefully close up the joints of the sheets of material. Foam foam is laid in a checkerboard pattern, and the seams between the sheets of material are foamed with mounting foam or other sealing compounds. If the seams between the foam sheets are not sealed, then cold bridges will form, and the likelihood of condensation under the heat-insulating layer also increases.

When applying a leveling screed to the foam plastic heat-insulating layer, the structure must be additionally reinforced.